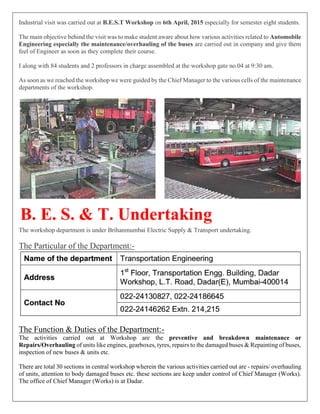

The document details an industrial visit to the B.E.S.T workshop by the final year mechanical engineering students from M.H. Saboo Siddik College of Engineering on April 6, 2015, aimed at familiarizing them with automobile engineering practices, particularly bus maintenance and overhauling. The visit included a comprehensive tour of various workshop sections responsible for different maintenance activities, led by the chief manager, showcasing various engineering operations. Students expressed gratitude for the opportunity, highlighting its impact on their practical understanding and future careers in engineering.