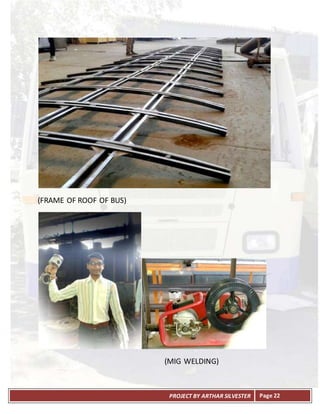

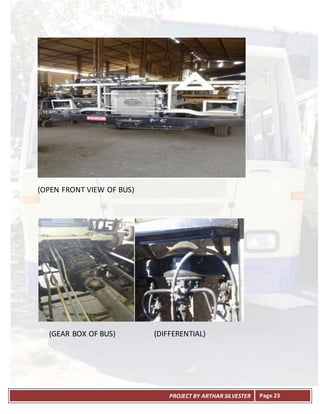

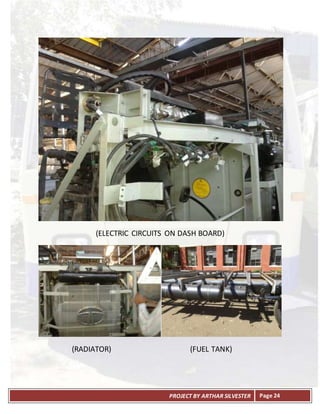

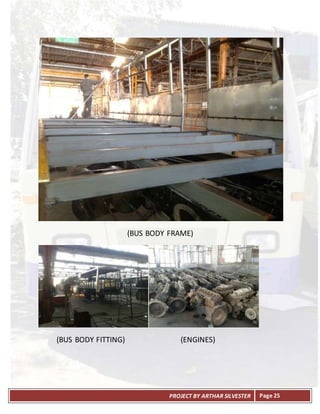

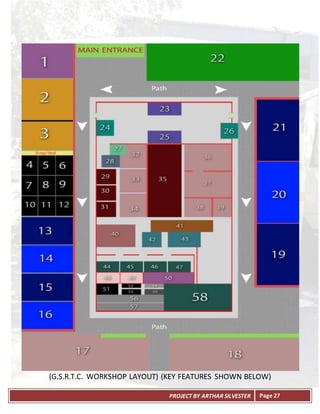

The document discusses the Gujarat State Road Transport Corporation (GSRTC) workshop in Naroda, which is recognized as Asia’s largest bus manufacturing workshop, founded on May 1, 1960. It outlines various departments such as engine testing, body fitting, and painting, detailing their specific functions in the bus production and maintenance process. The workshop emphasizes both manufacturing and training, ensuring efficiency and quality in bus service operations.