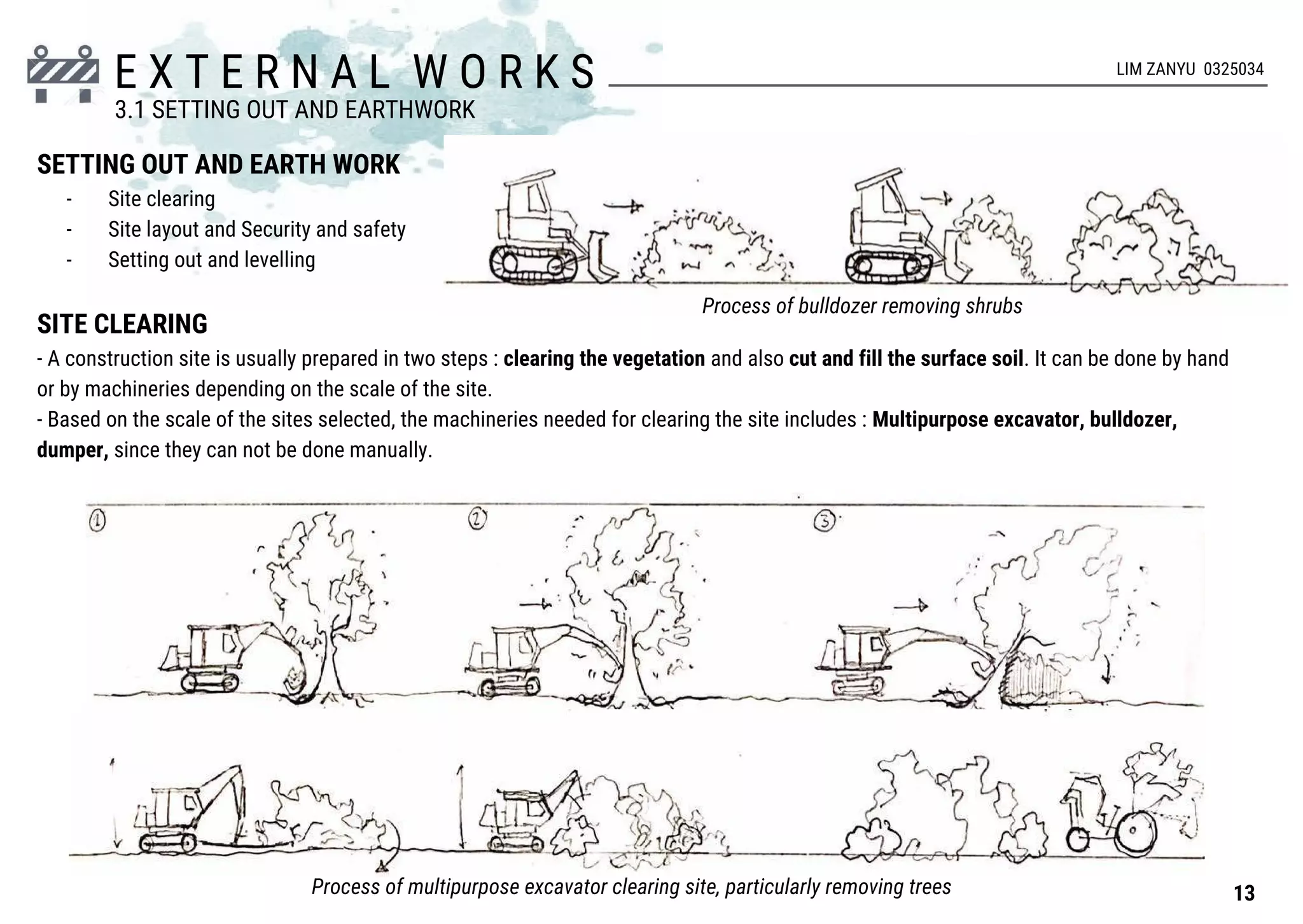

1. Site clearing involves removing vegetation from the construction site using machinery like excavators and bulldozers. Soil filling then levels the ground by cutting and filling soil.

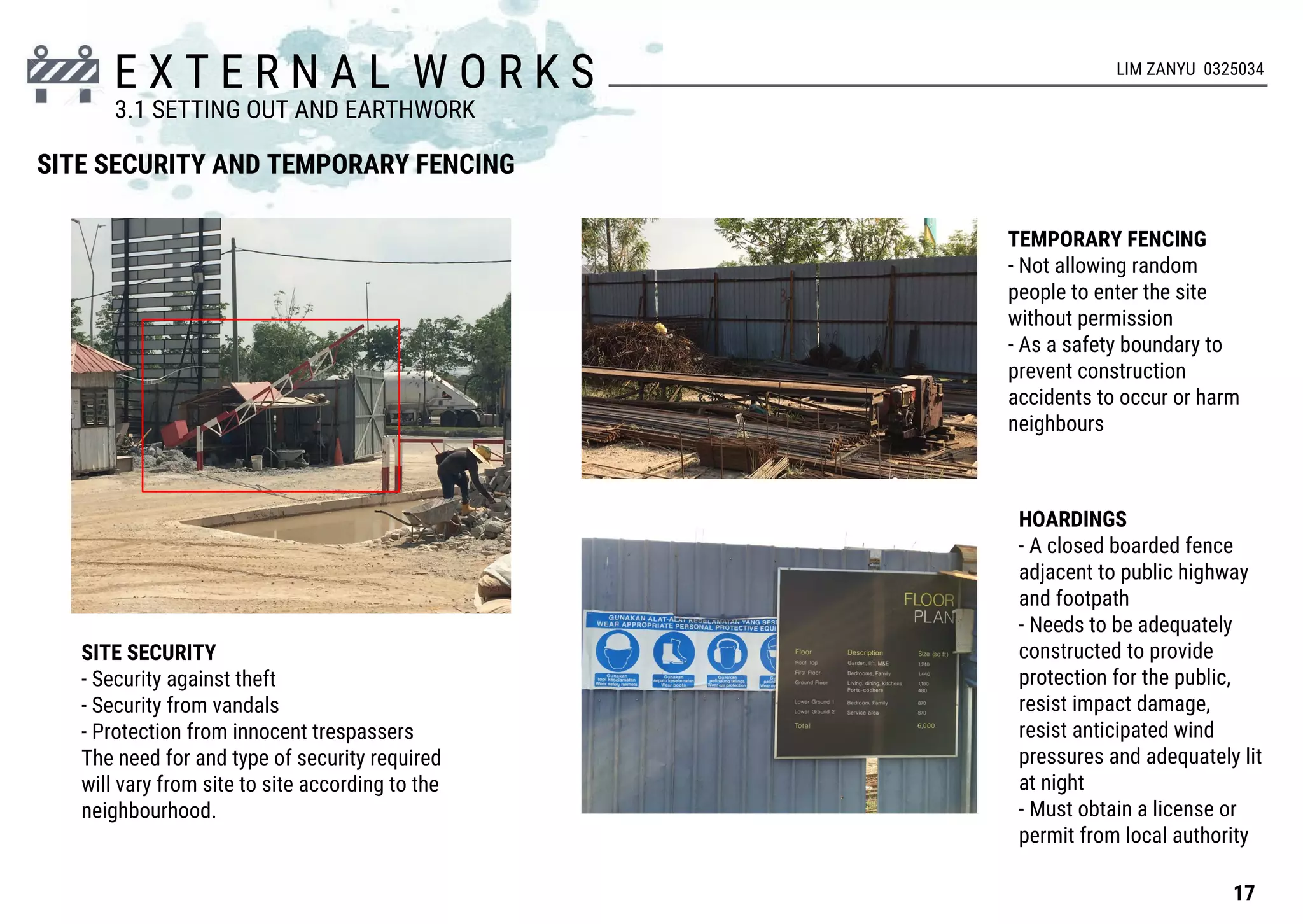

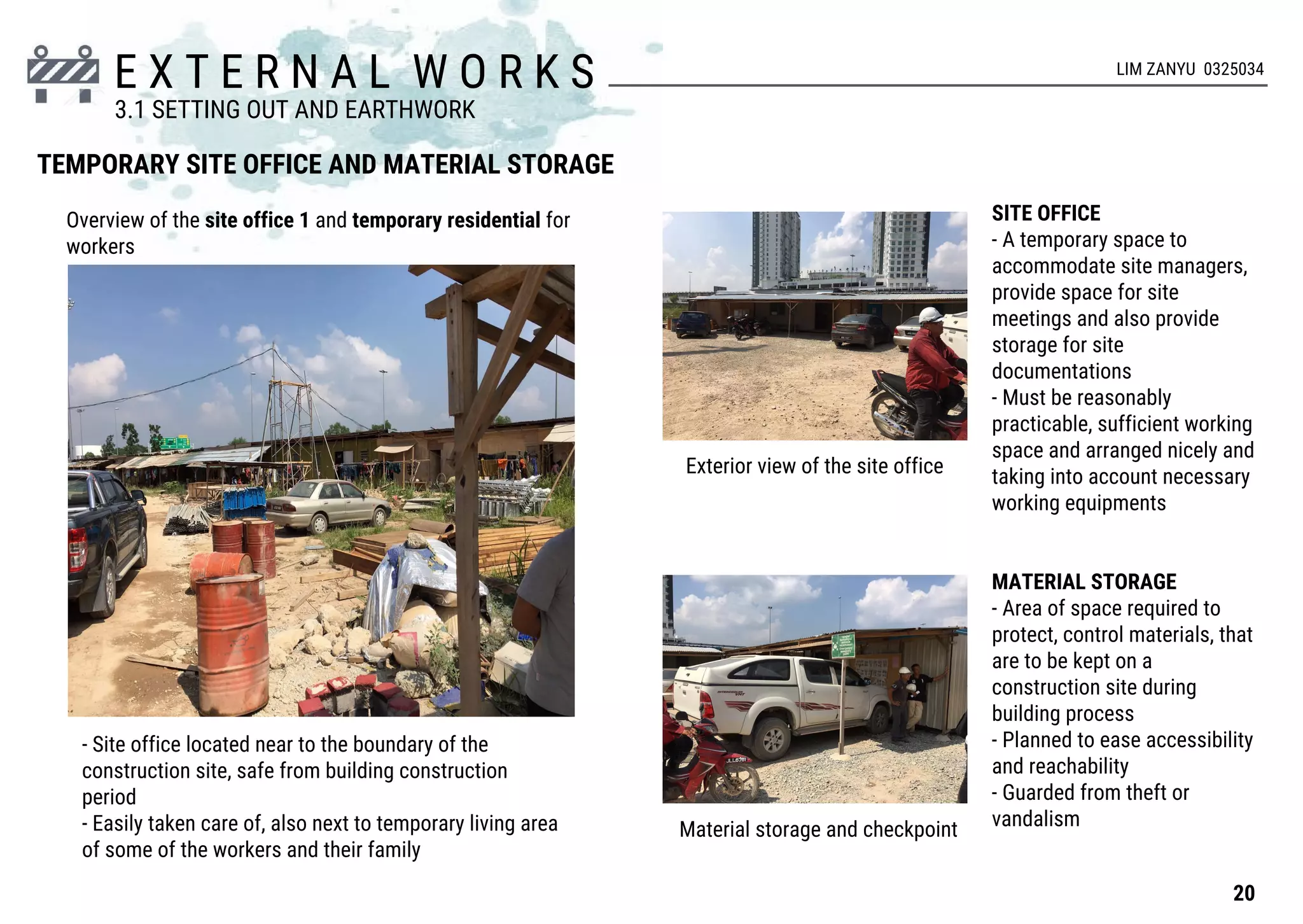

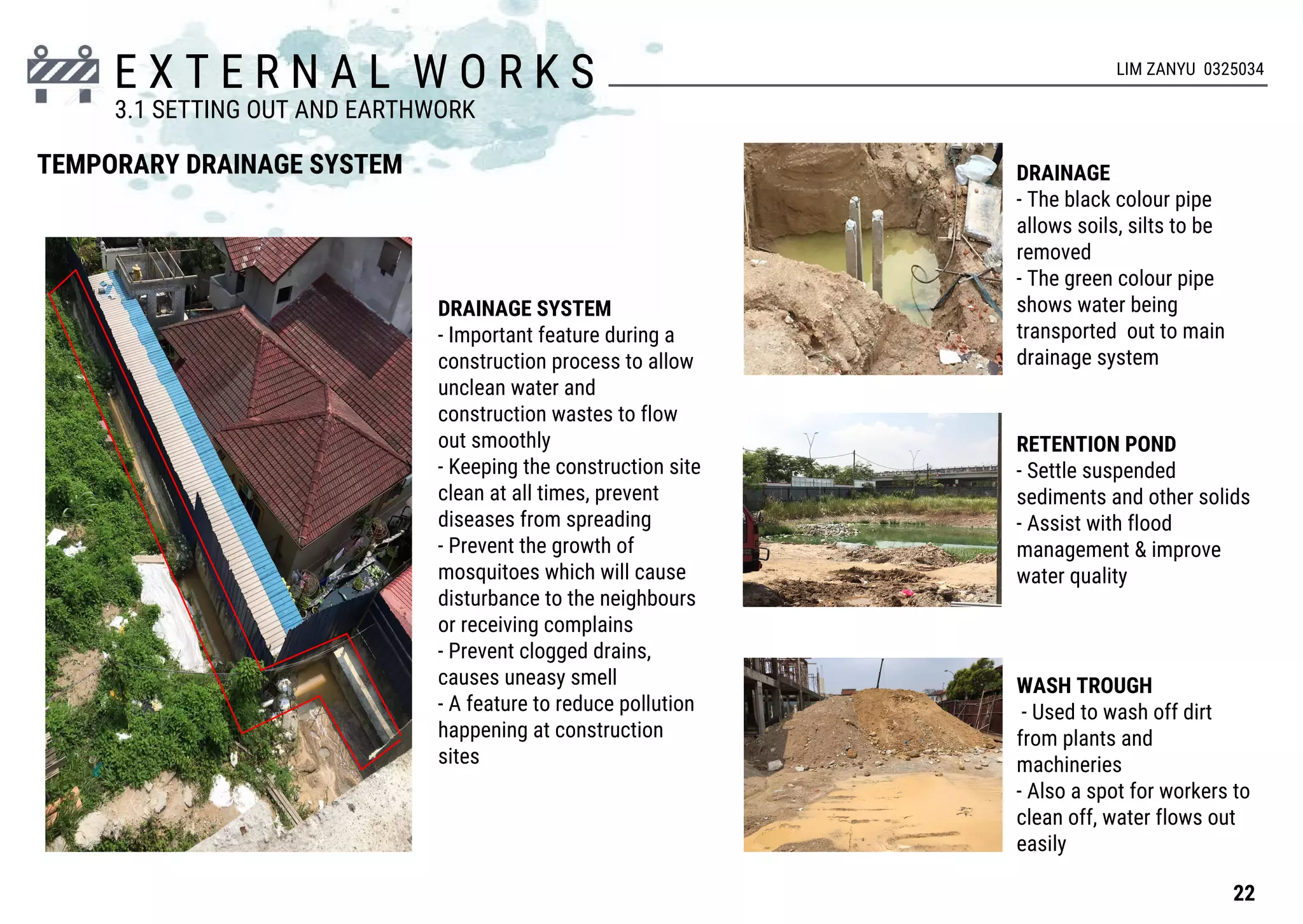

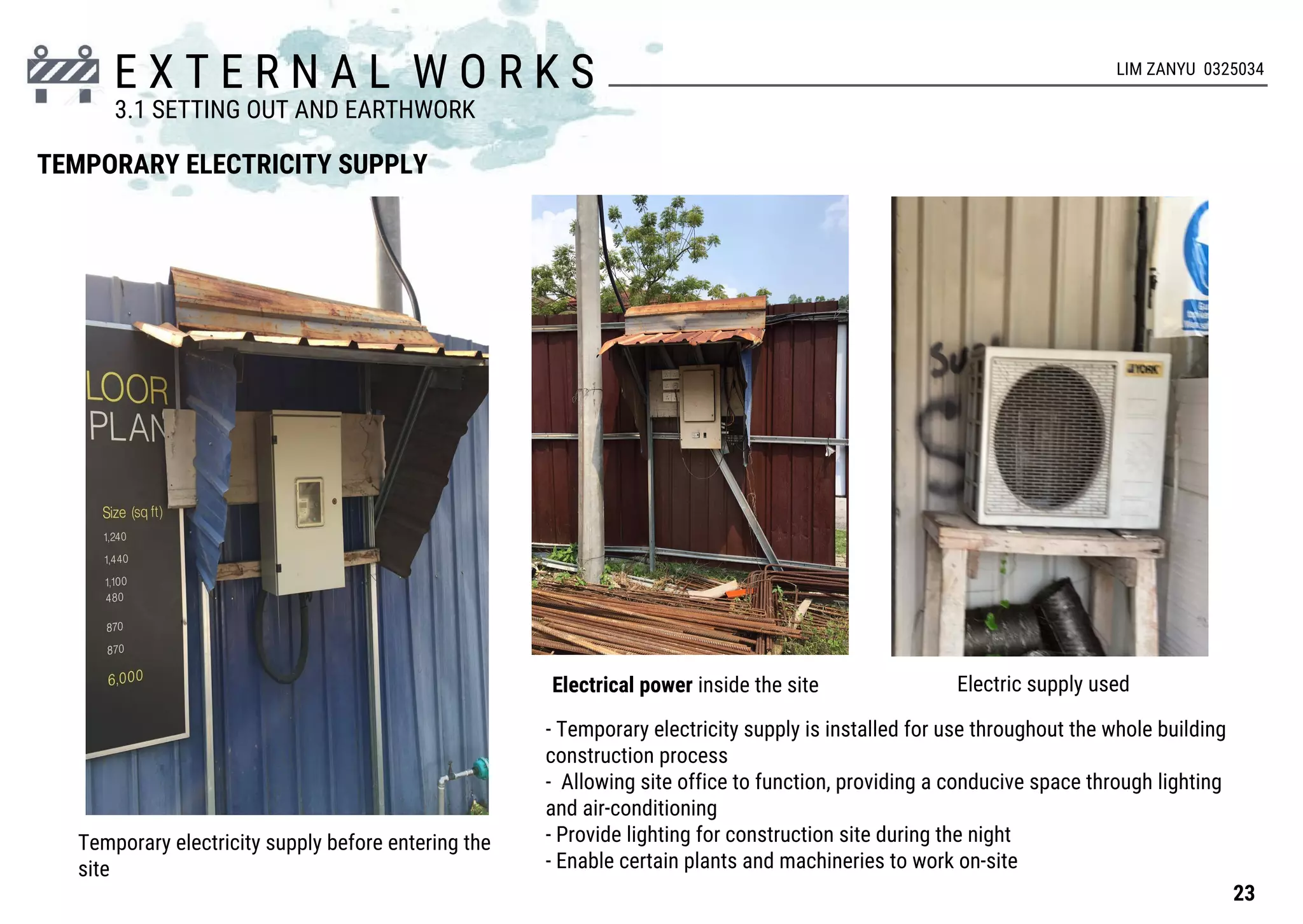

2. Site layout includes temporary site facilities like offices, storage, and toilets. Retaining walls are built for sloped sites to prevent erosion. Fencing secures the boundary.

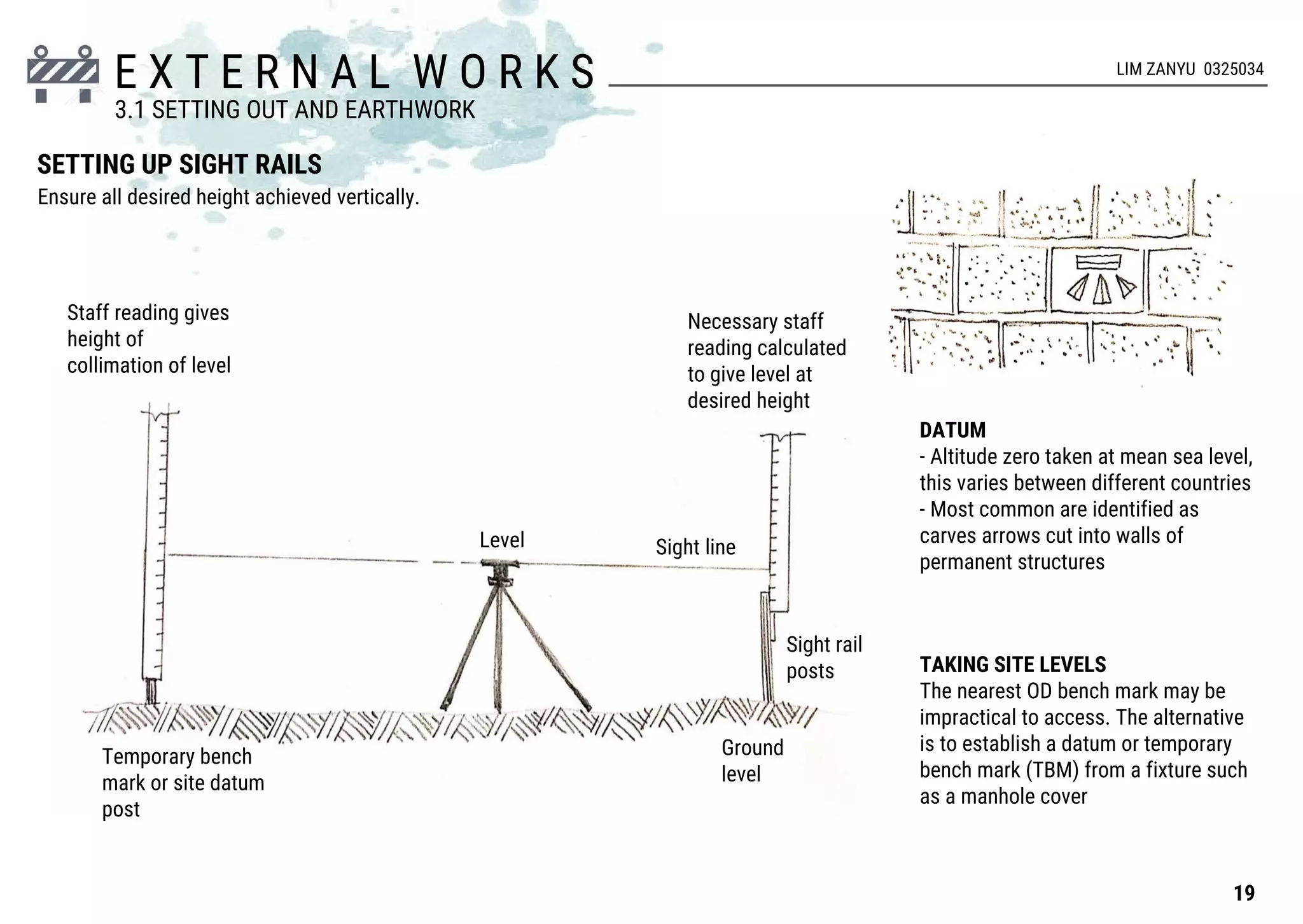

3. Setting out establishes horizontal and vertical control points to lay the foundations and guide subsequent construction stages according to the building plans.