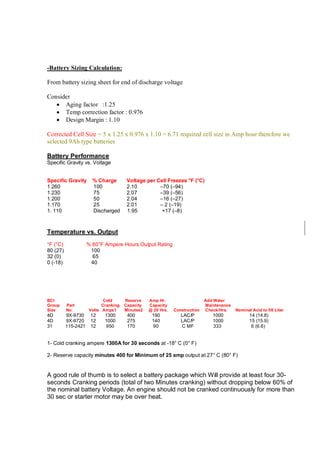

The document discusses battery sizing considerations for diesel engine starting applications. It provides information on factors that affect engine starting like ambient temperature and lubricating oil viscosity. It describes how lead-acid or nickel-cadmium batteries can be used to power the electric starting motor. The document also provides guidance on battery sizing methodology, factors like temperature and aging that impact battery capacity, and considerations for sizing battery chargers.