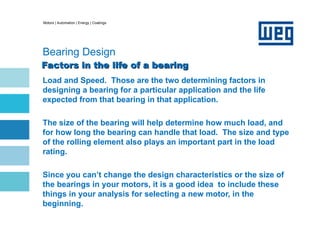

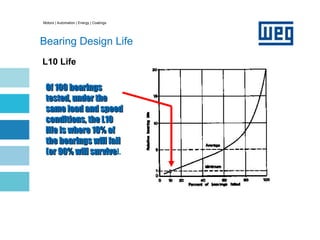

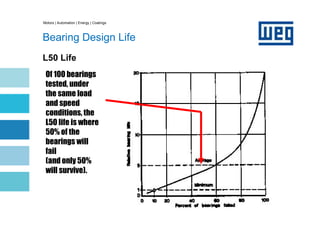

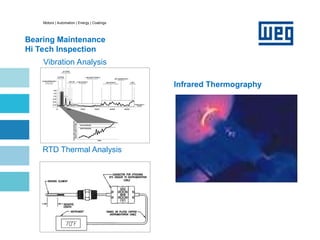

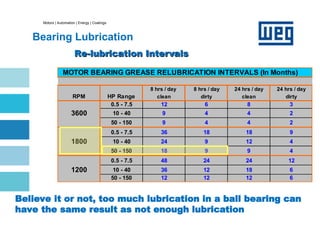

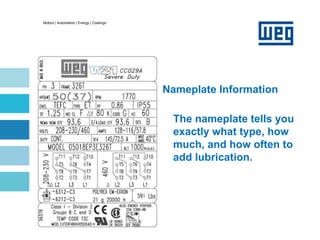

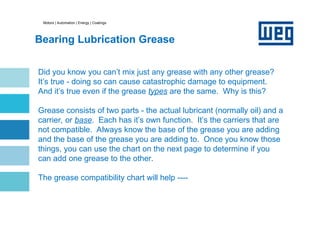

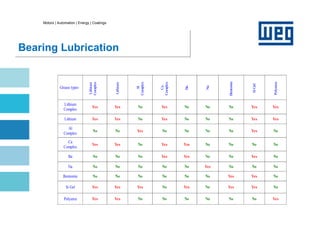

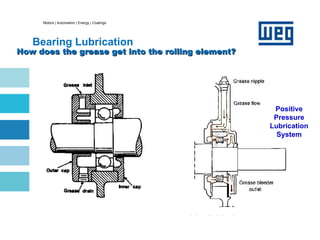

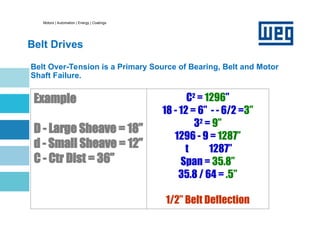

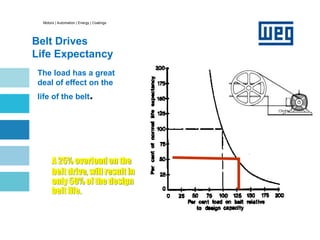

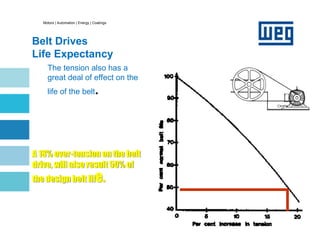

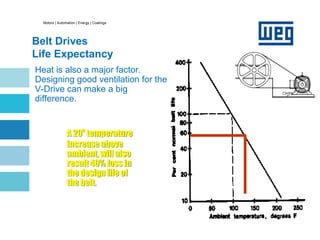

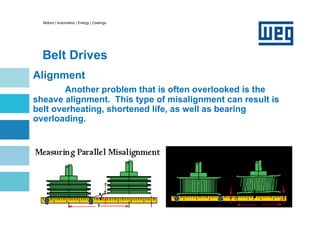

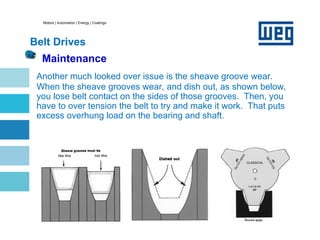

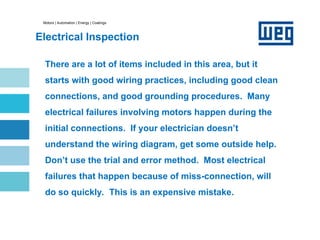

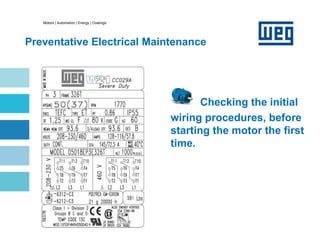

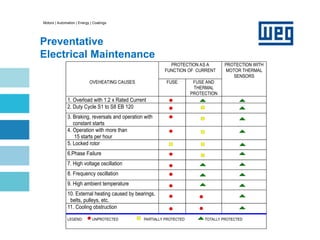

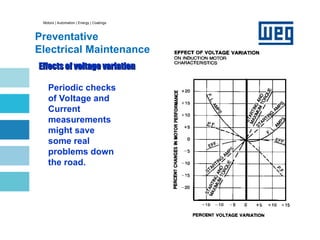

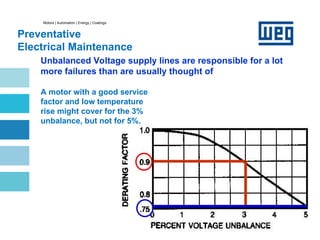

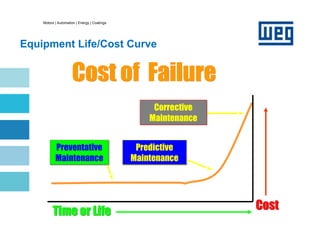

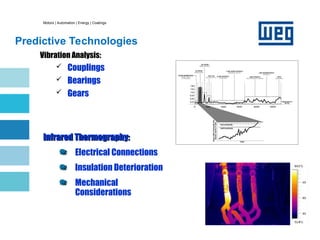

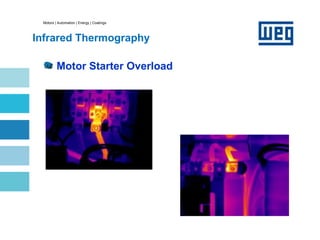

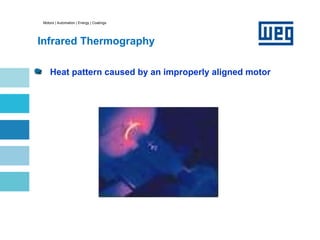

The document outlines essential maintenance and operational practices for electric motors, emphasizing the significance of bearing failures as the leading cause of motor issues. It details factors influencing bearing life, lubrication practices, and the impact of misalignment in belt drives on motor longevity. Additionally, preventive and predictive maintenance strategies are highlighted as critical for reducing downtimes and improving motor efficiency.