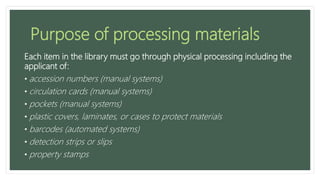

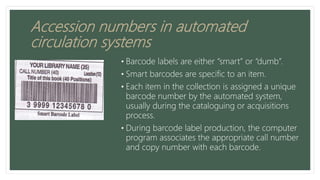

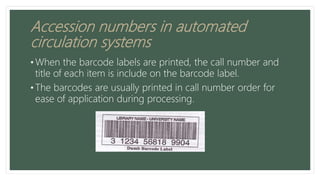

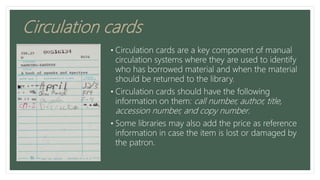

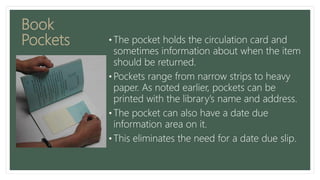

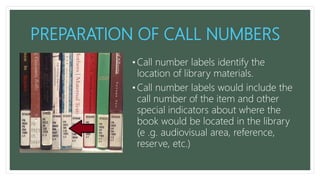

The document outlines the essential procedures for processing library materials, including physical preparation steps like inspection, identification, and the assignment of accession numbers. It discusses the differences between in-house and contracted processing services, emphasizing the labor-intensive nature of the task and the necessity for unique identification of items. Various methods for labeling, covering, and cataloguing materials are detailed, including the use of barcodes and circulation cards.