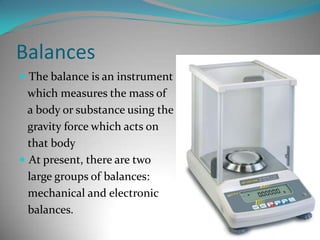

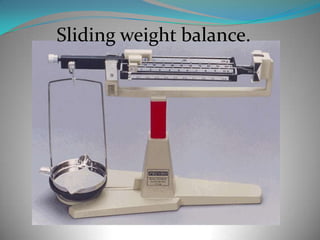

1. Balances are instruments that measure mass using gravity to act on an object. There are two main types: mechanical balances using springs or sliding weights, and electronic balances using load cells or electromagnetic force.

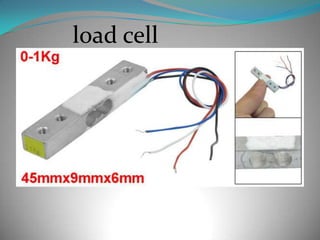

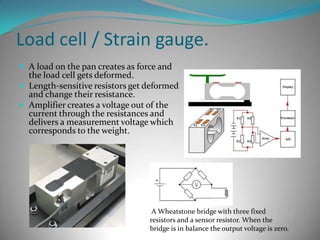

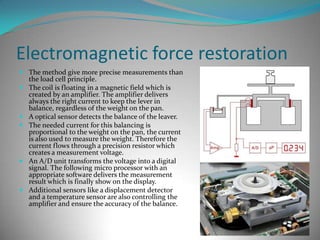

2. Electronic balances operate using either a load cell that detects strain to measure weight, or an electromagnetic force restoration method that precisely measures current needed to balance a lever.

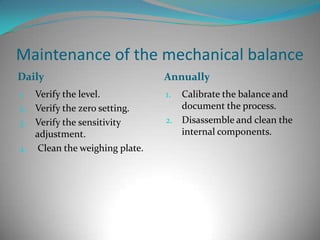

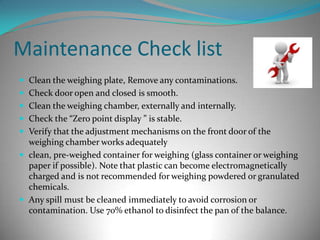

3. Routine maintenance of balances includes verifying level and zero settings, cleaning weighing surfaces, and annual calibration. Faults like unstable readings may result from the balance not being leveled or calibrated correctly.