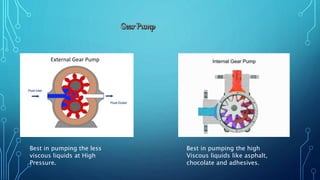

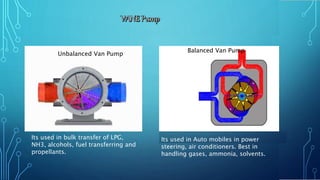

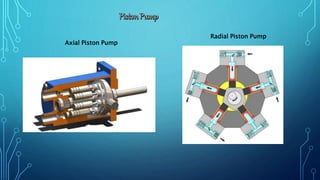

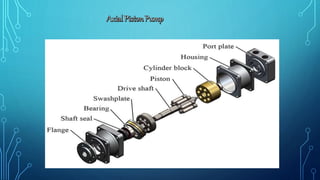

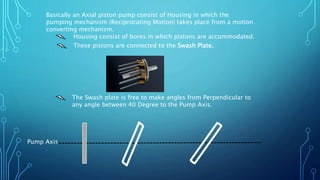

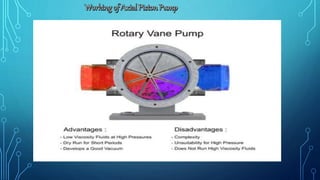

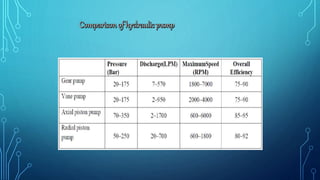

The document discusses various types of pumps, focusing on axial piston pumps and their operation. It explains the mechanisms involved, including the conversion of rotating motion into reciprocating motion and the role of the swash plate in controlling fluid discharge. Additionally, it covers comparisons with other hydraulic and gear pumps, highlighting their applications in different industries.