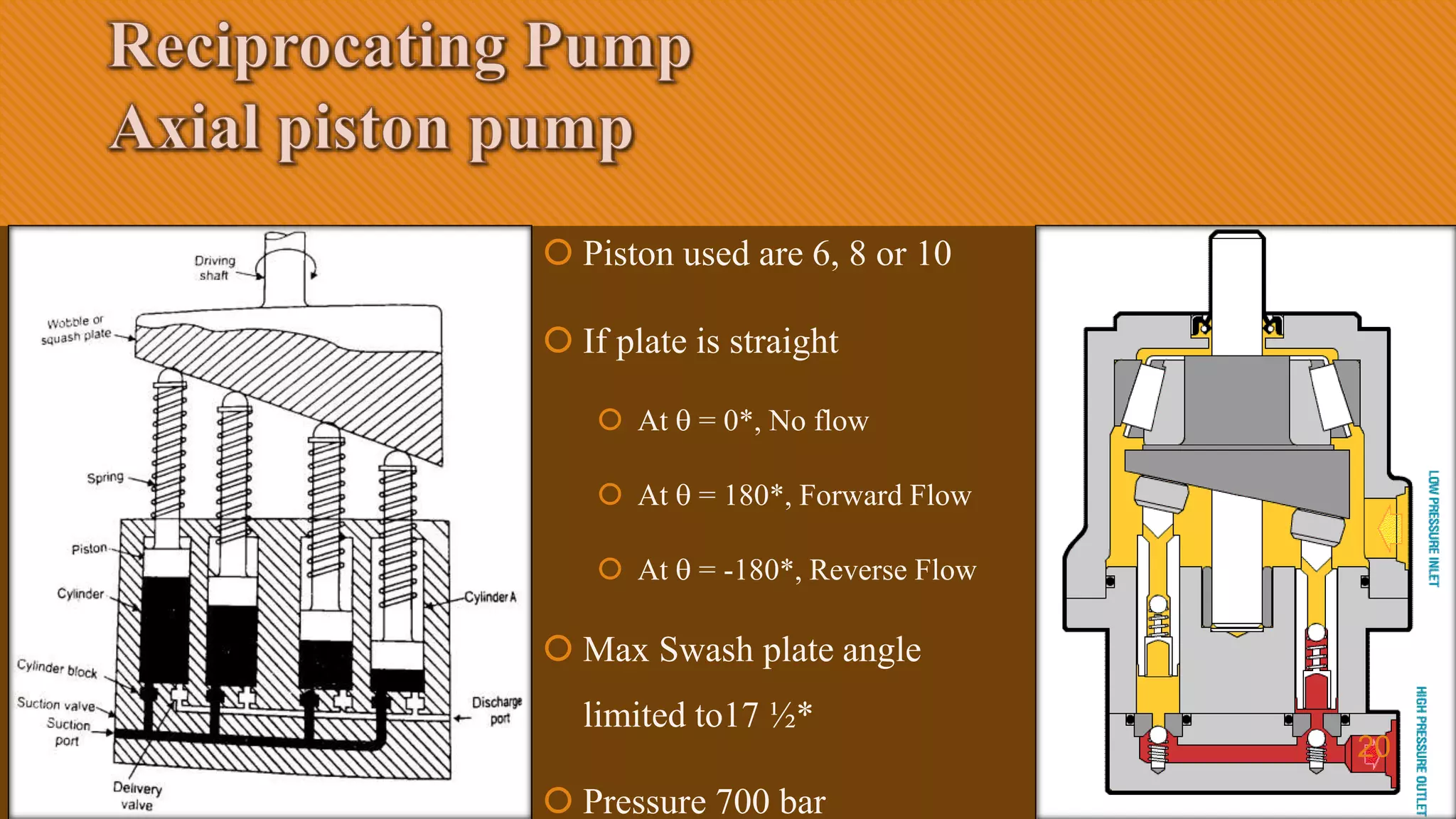

This document discusses different types of pumps, their construction, working principles, applications, and pressure ranges. It covers positive displacement pumps like gear pumps, vane pumps, screw pumps, and piston pumps. It also discusses non-positive displacement centrifugal pumps. For each type of pump, the document explains key aspects like how displacement is achieved, typical applications, and operating pressure ranges. It concludes by summarizing the topics covered and providing pressure and efficiency data for some common pump types.