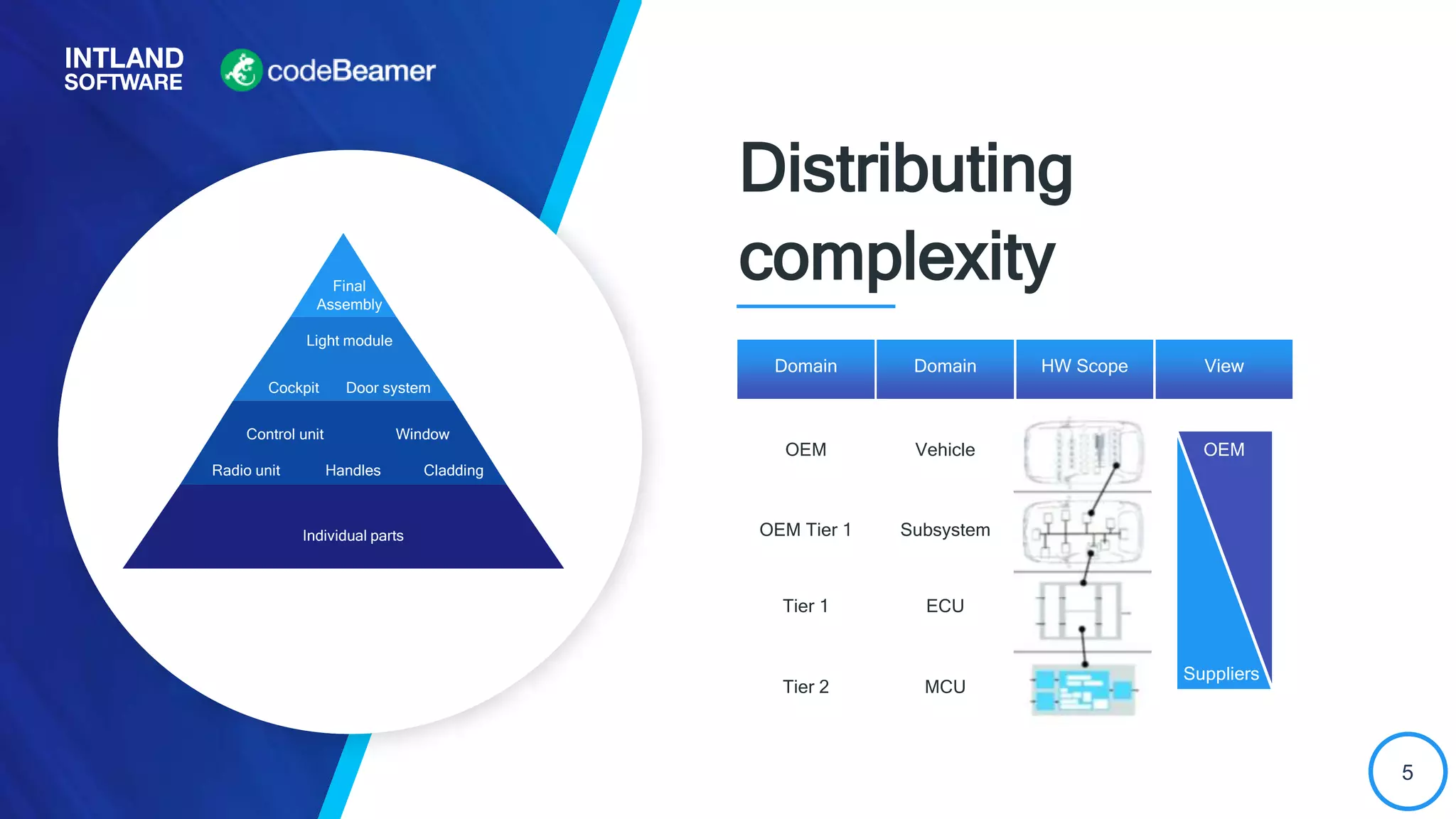

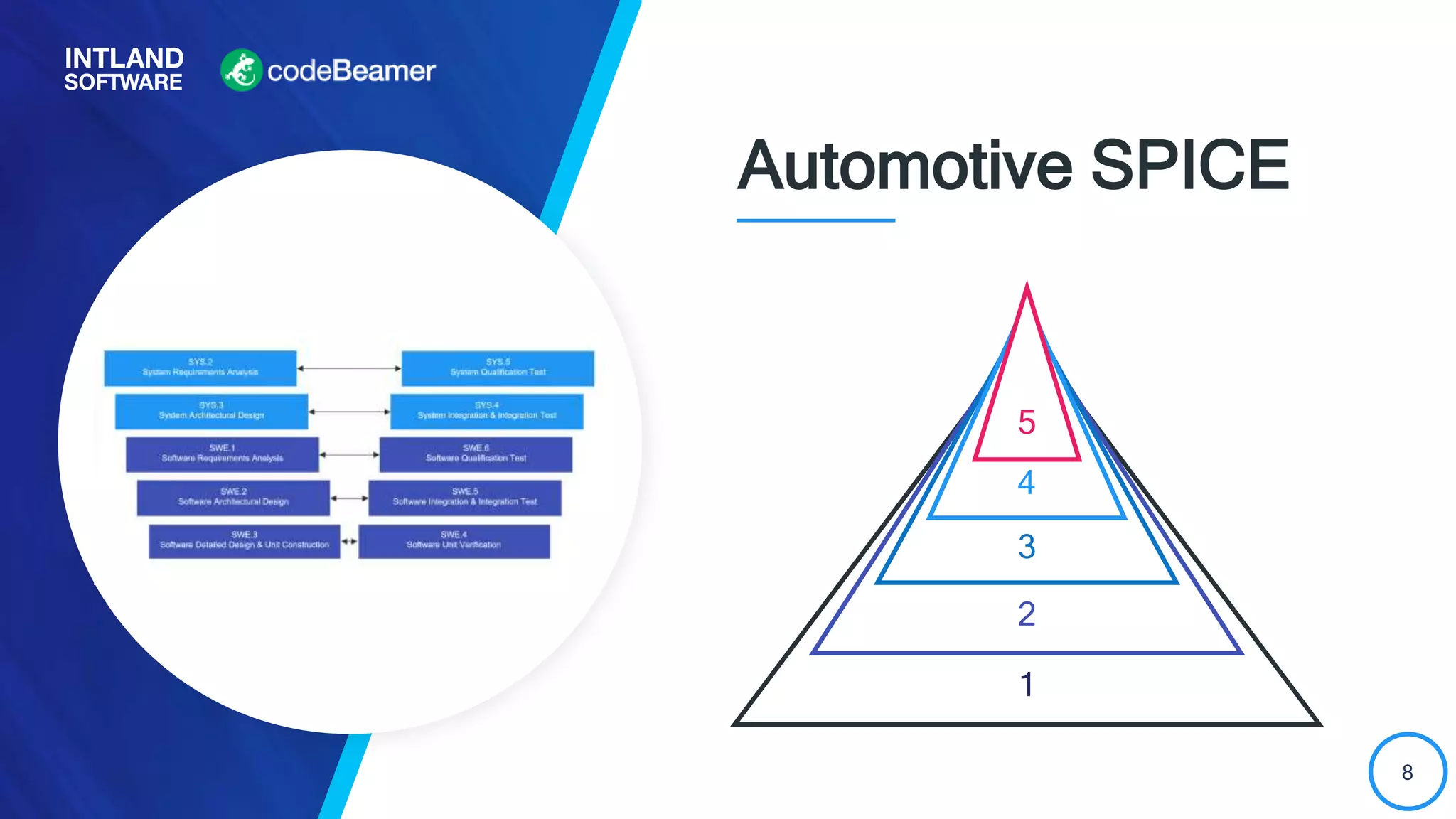

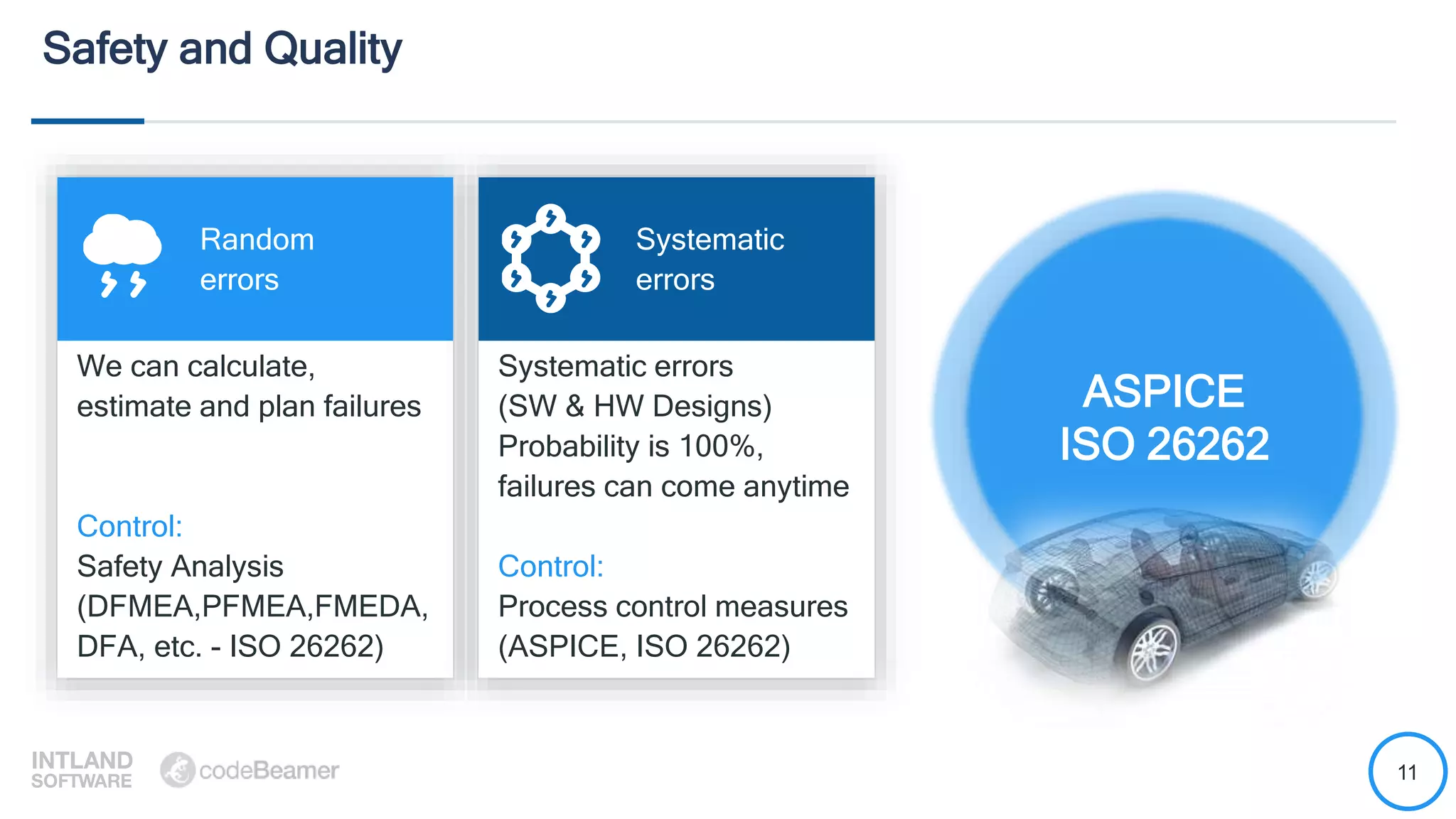

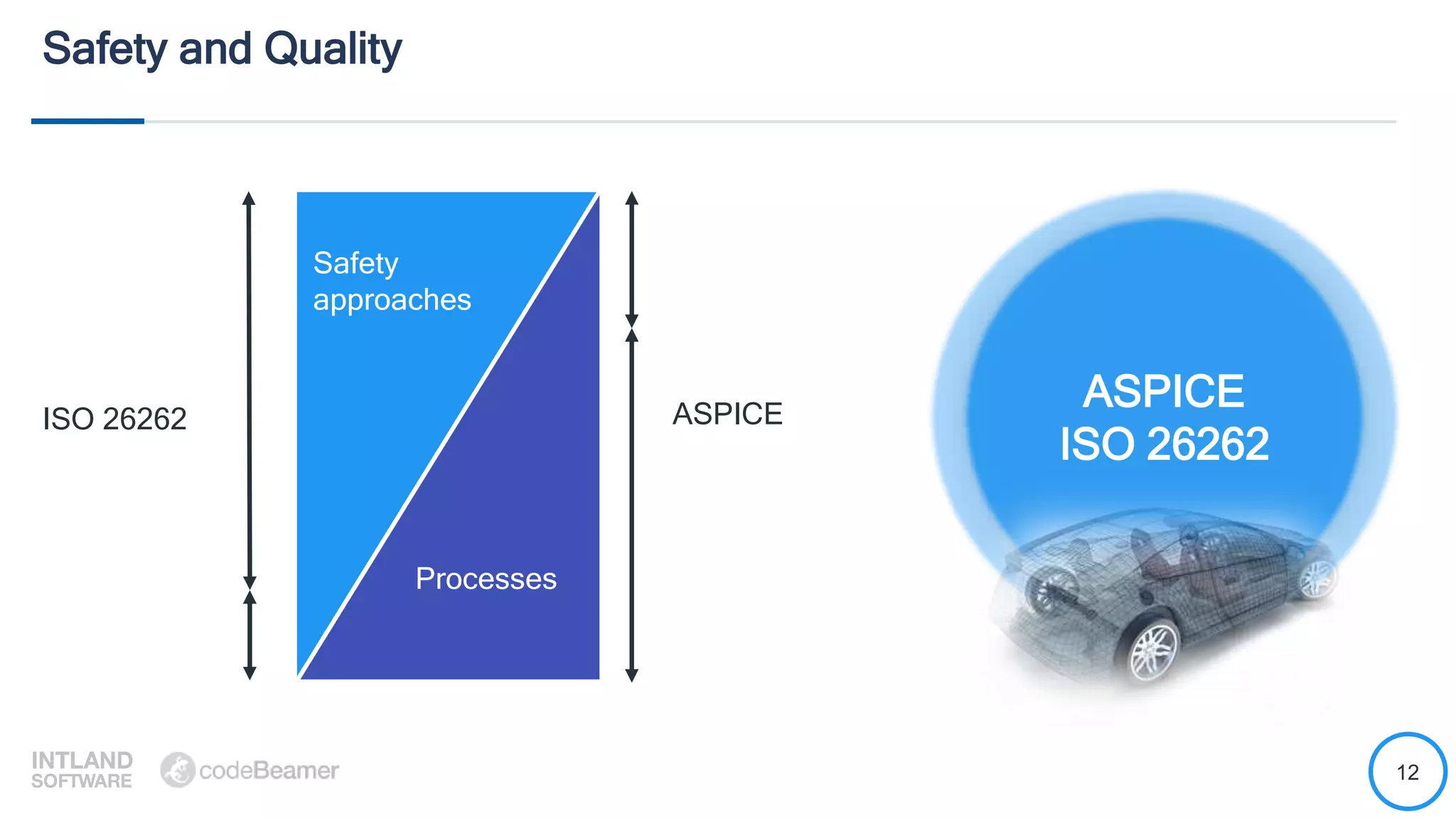

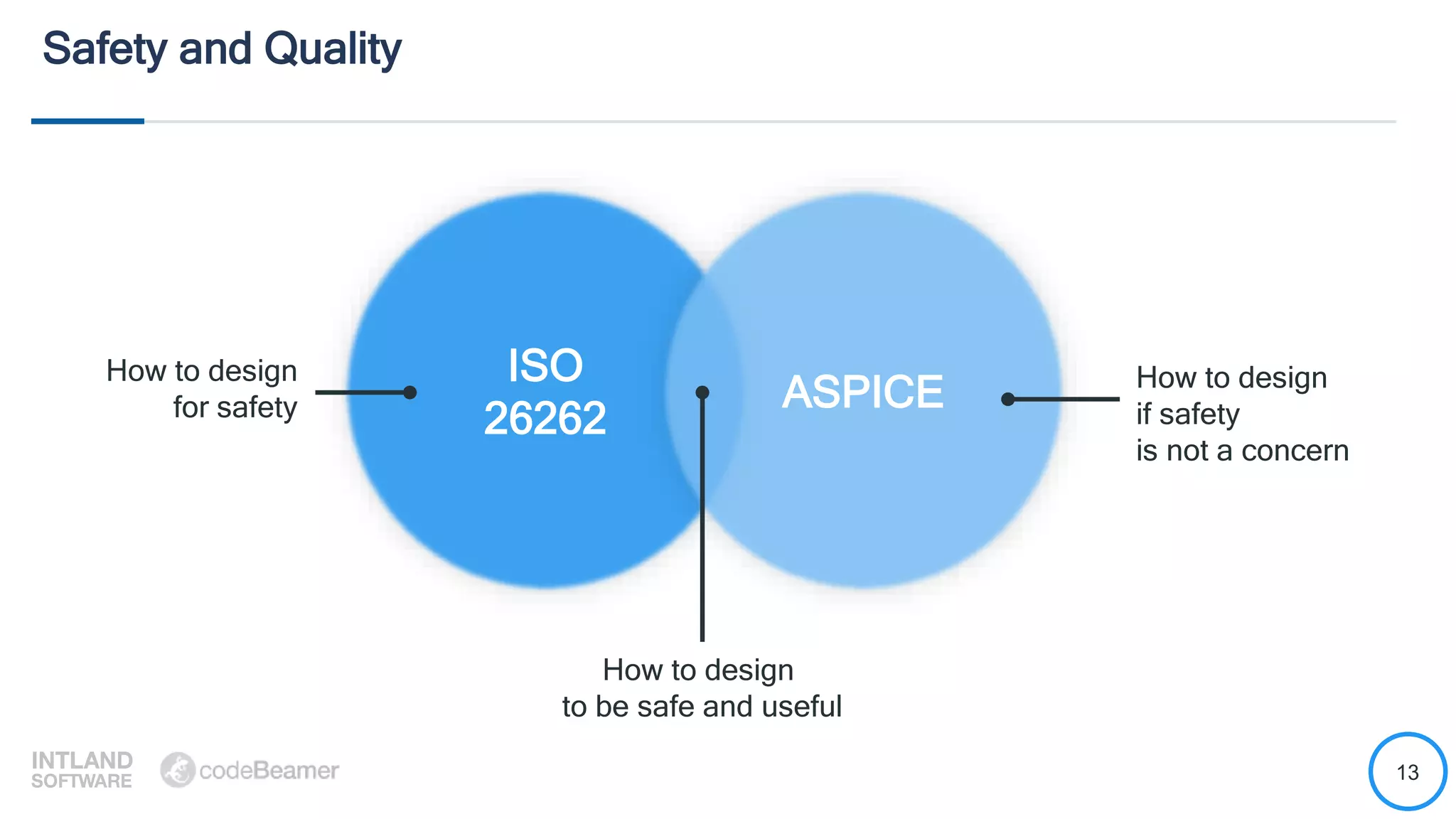

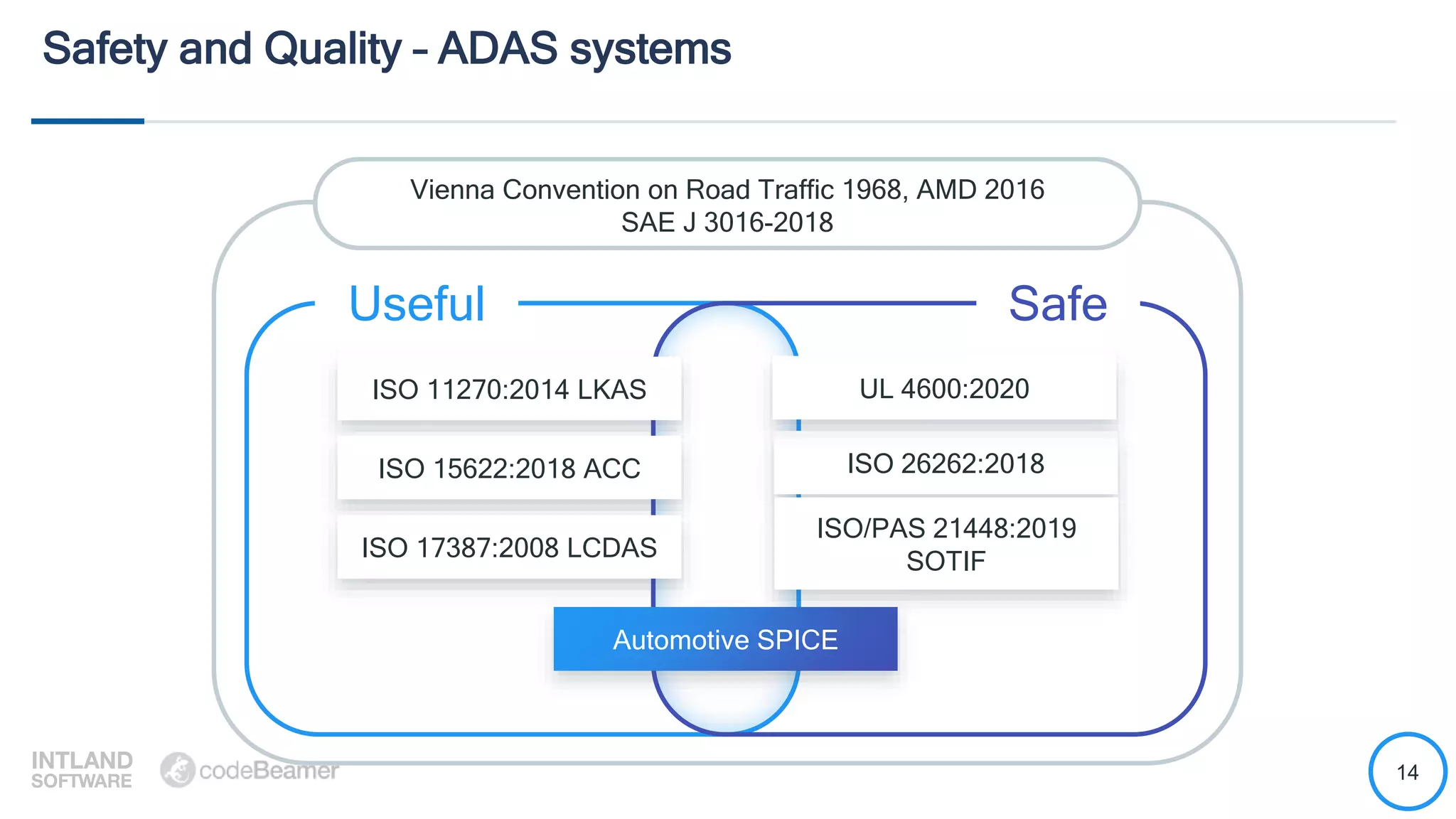

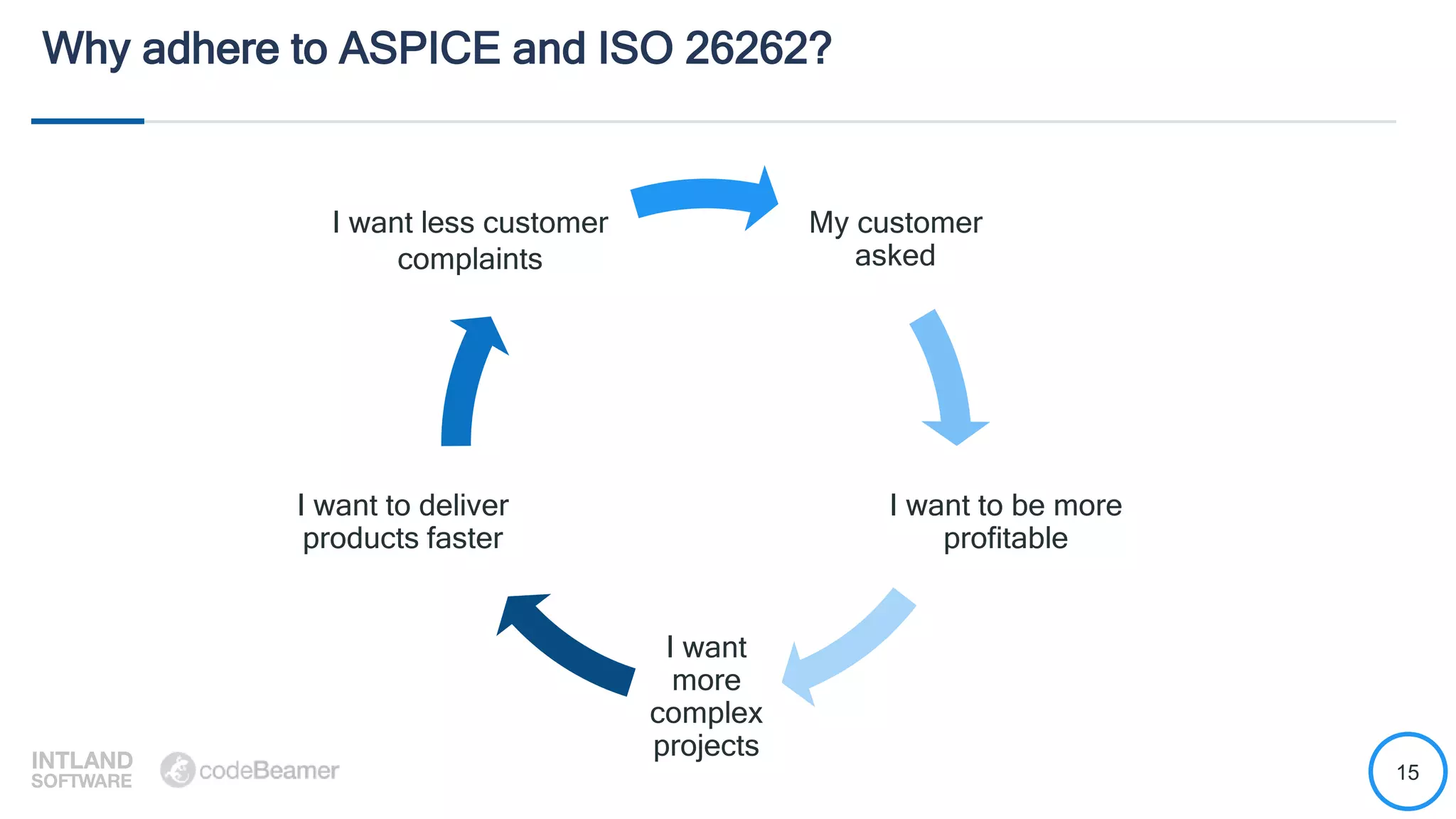

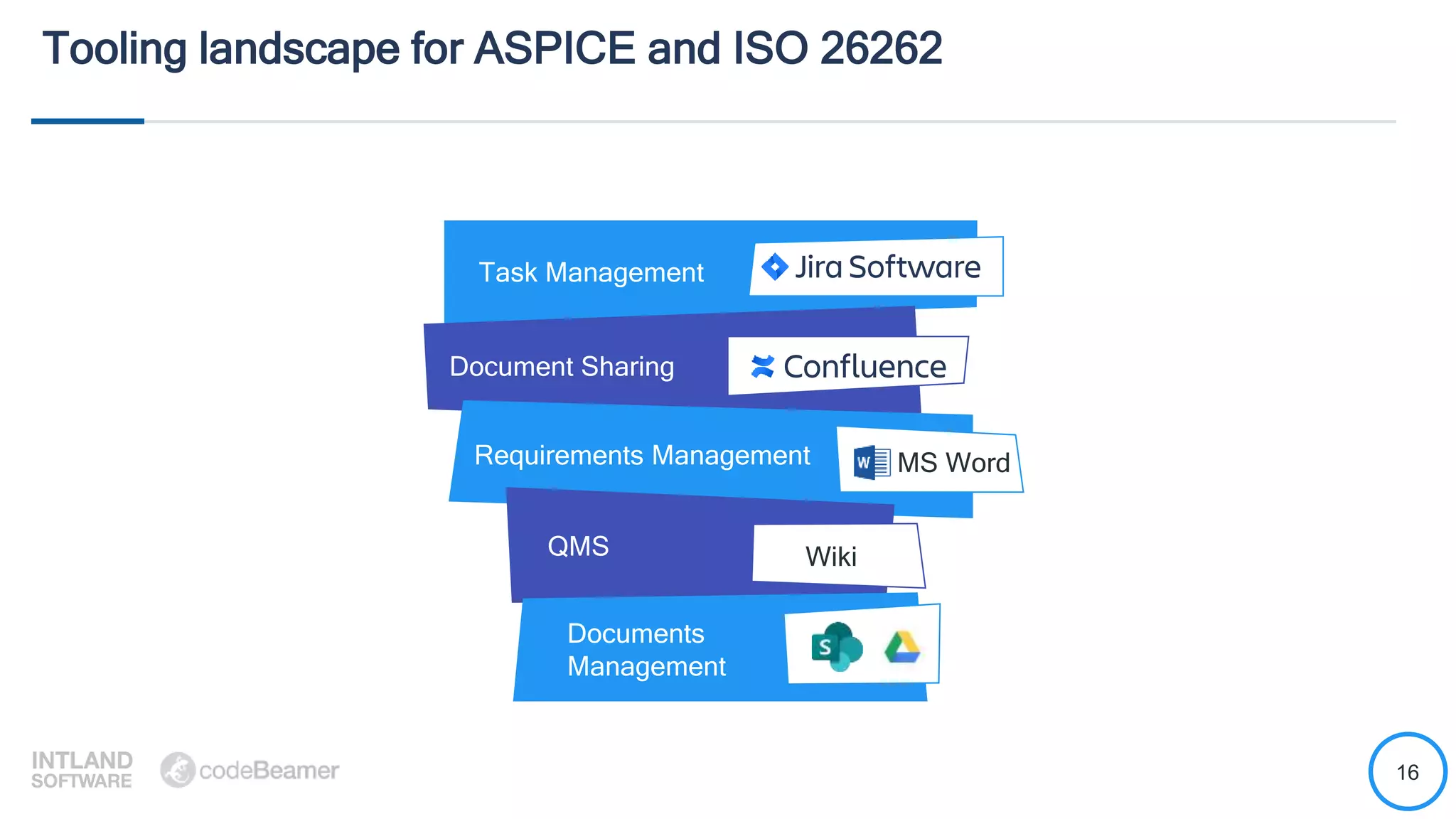

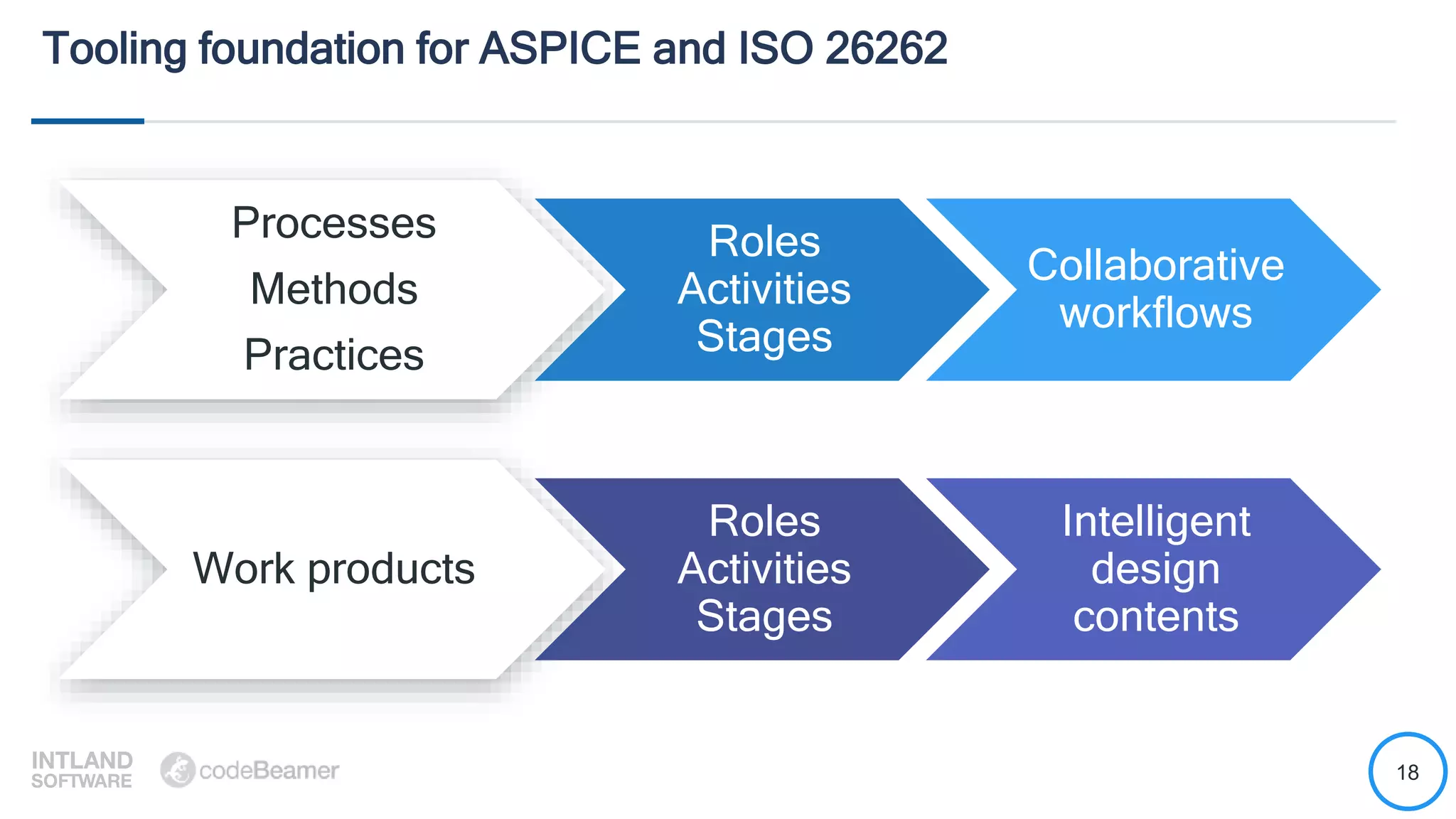

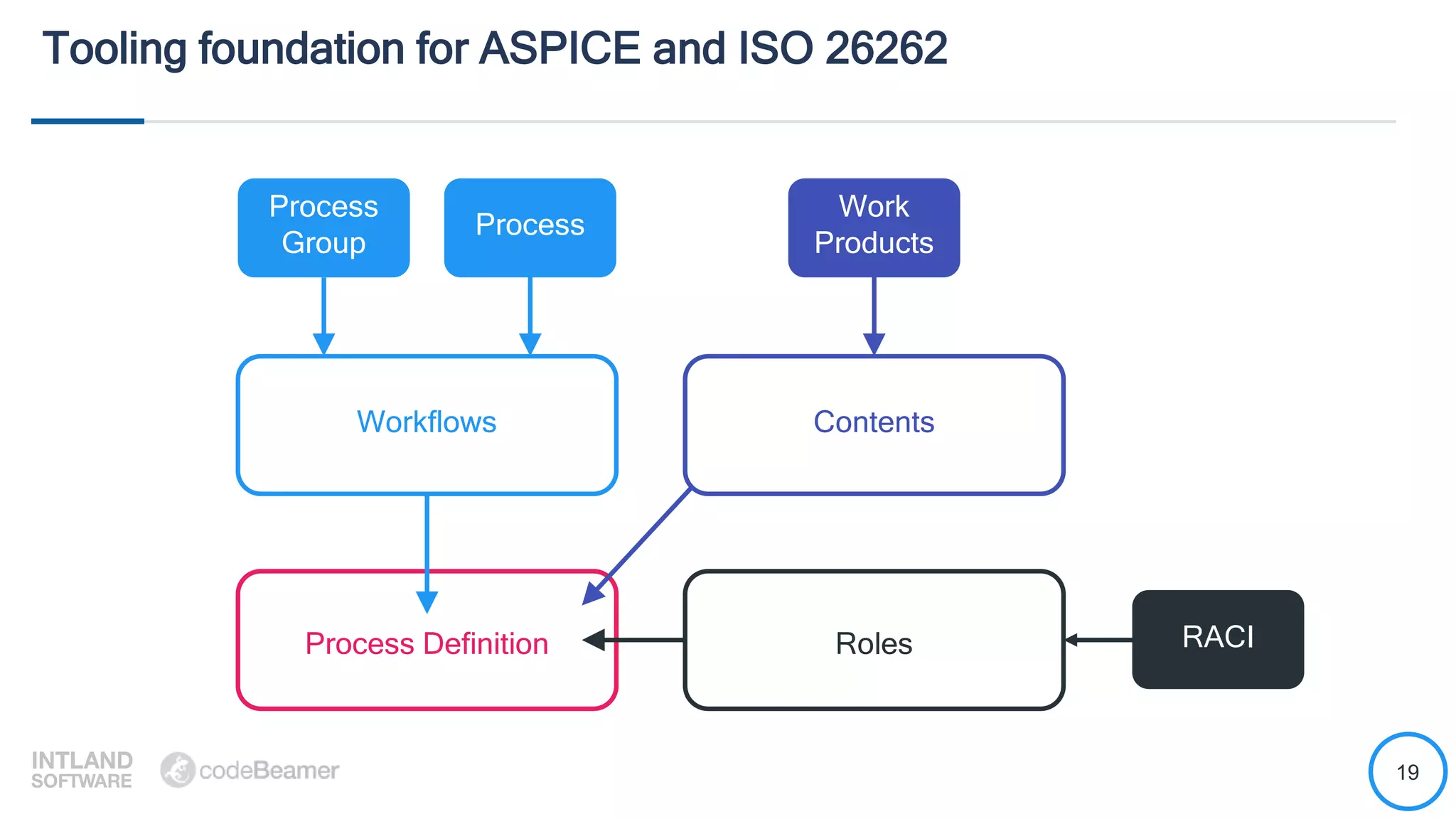

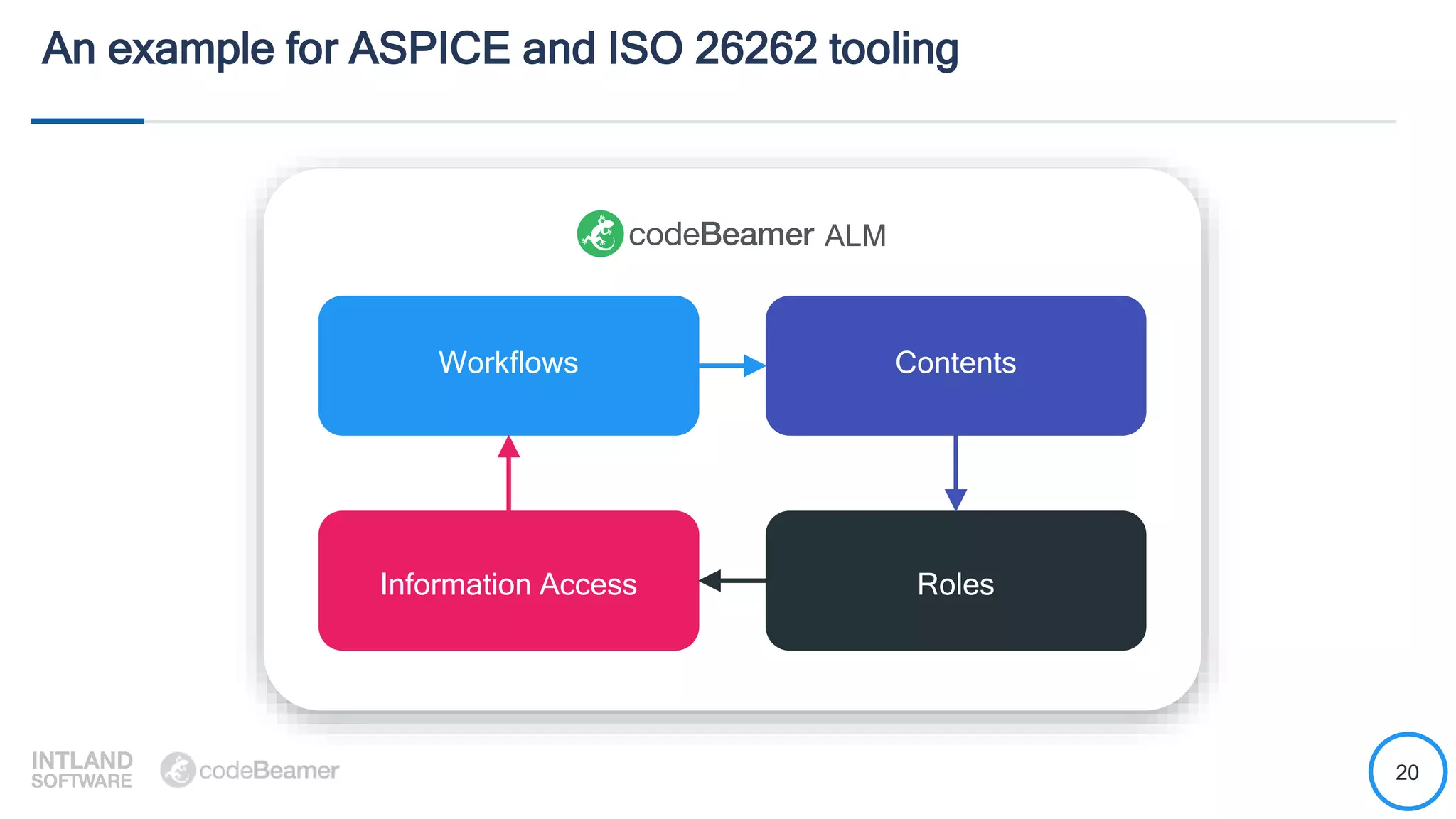

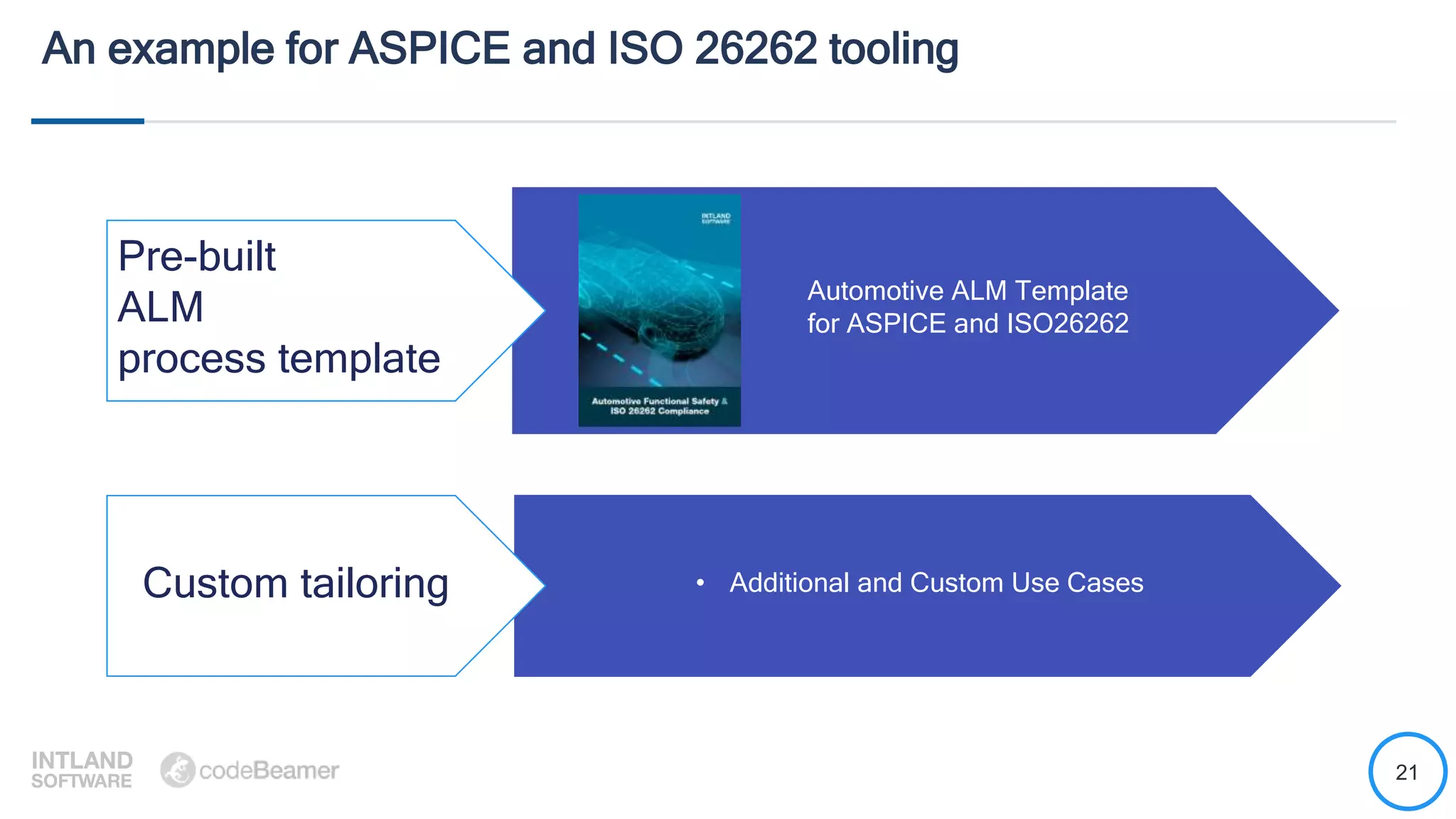

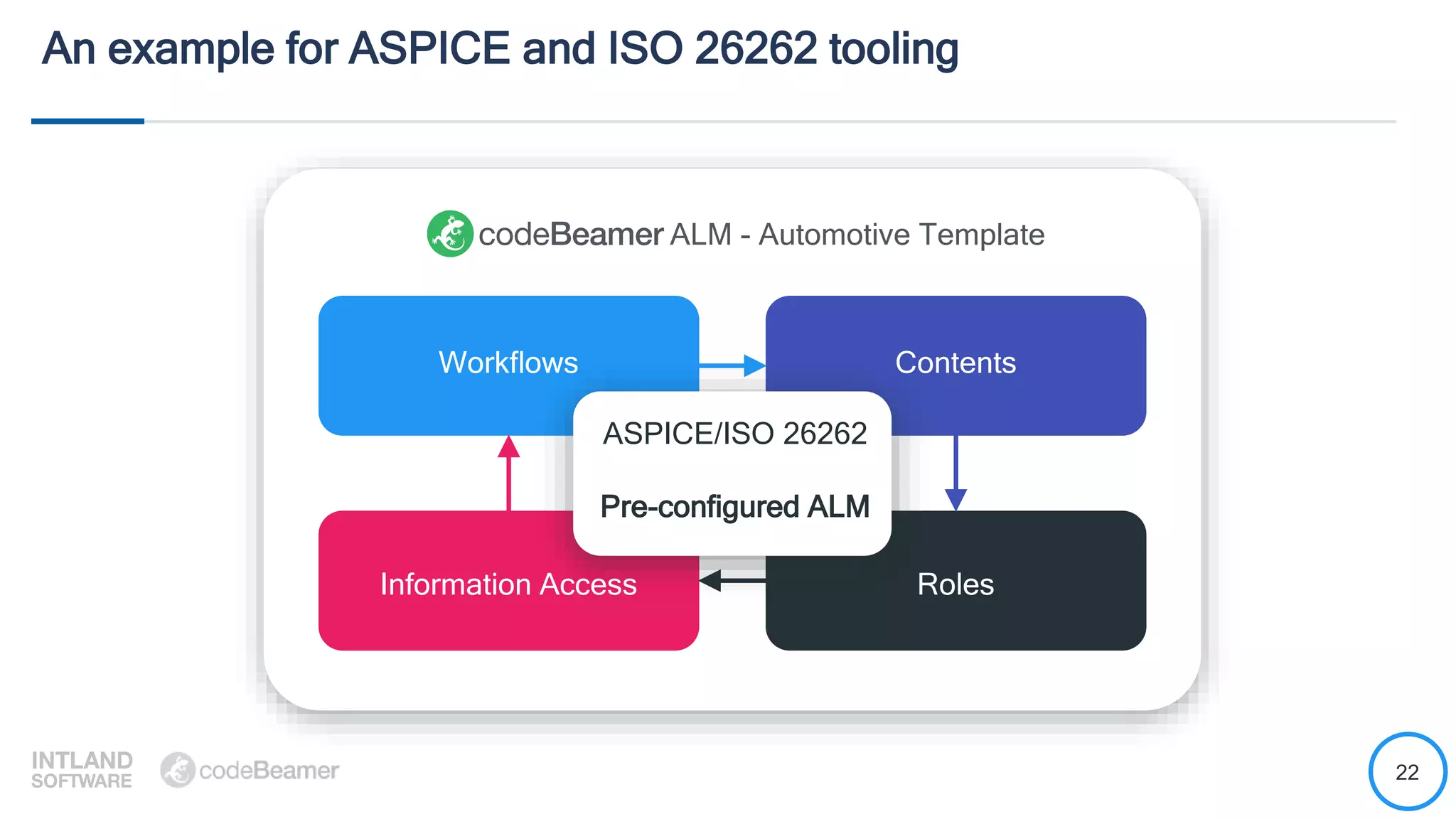

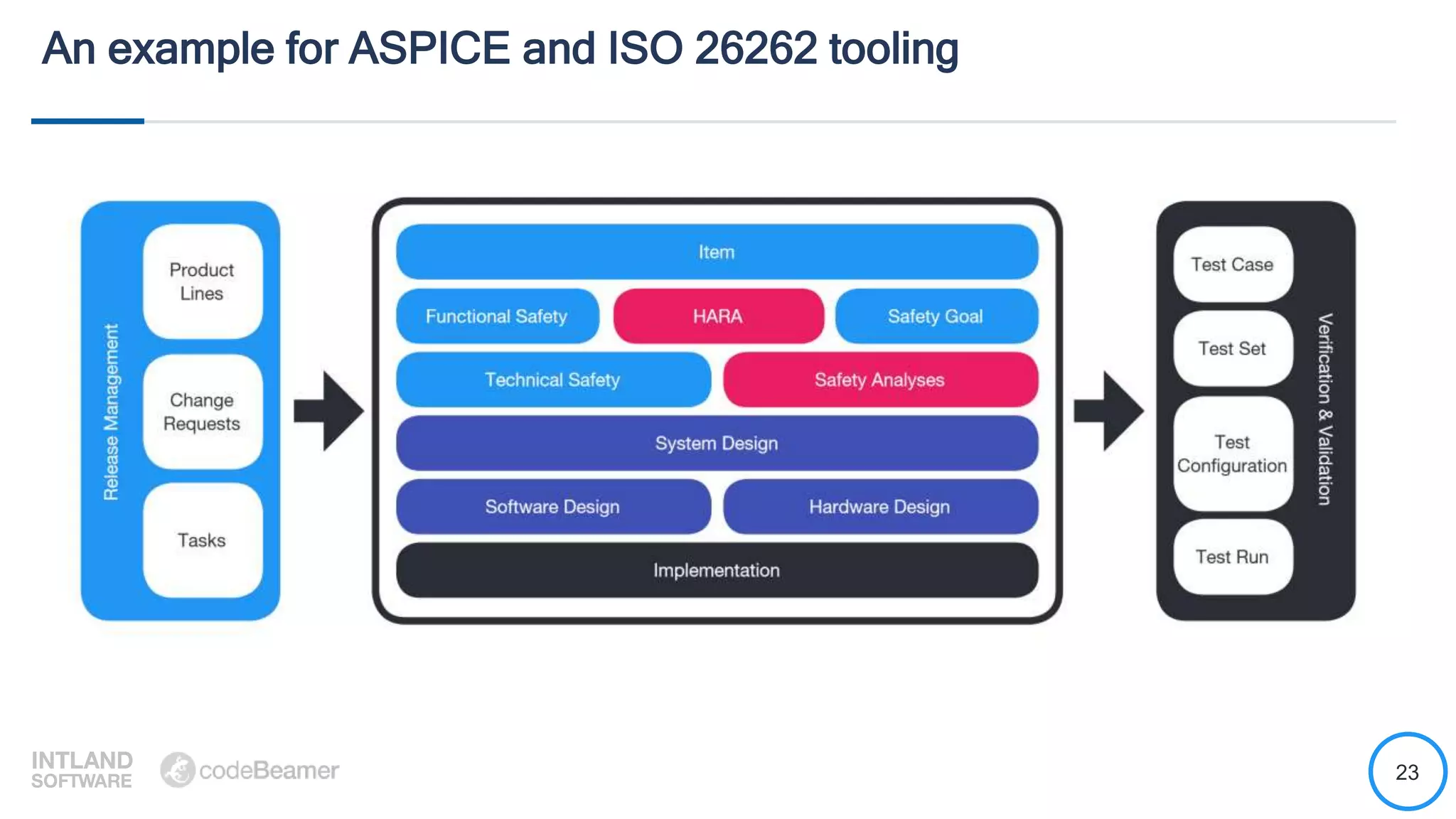

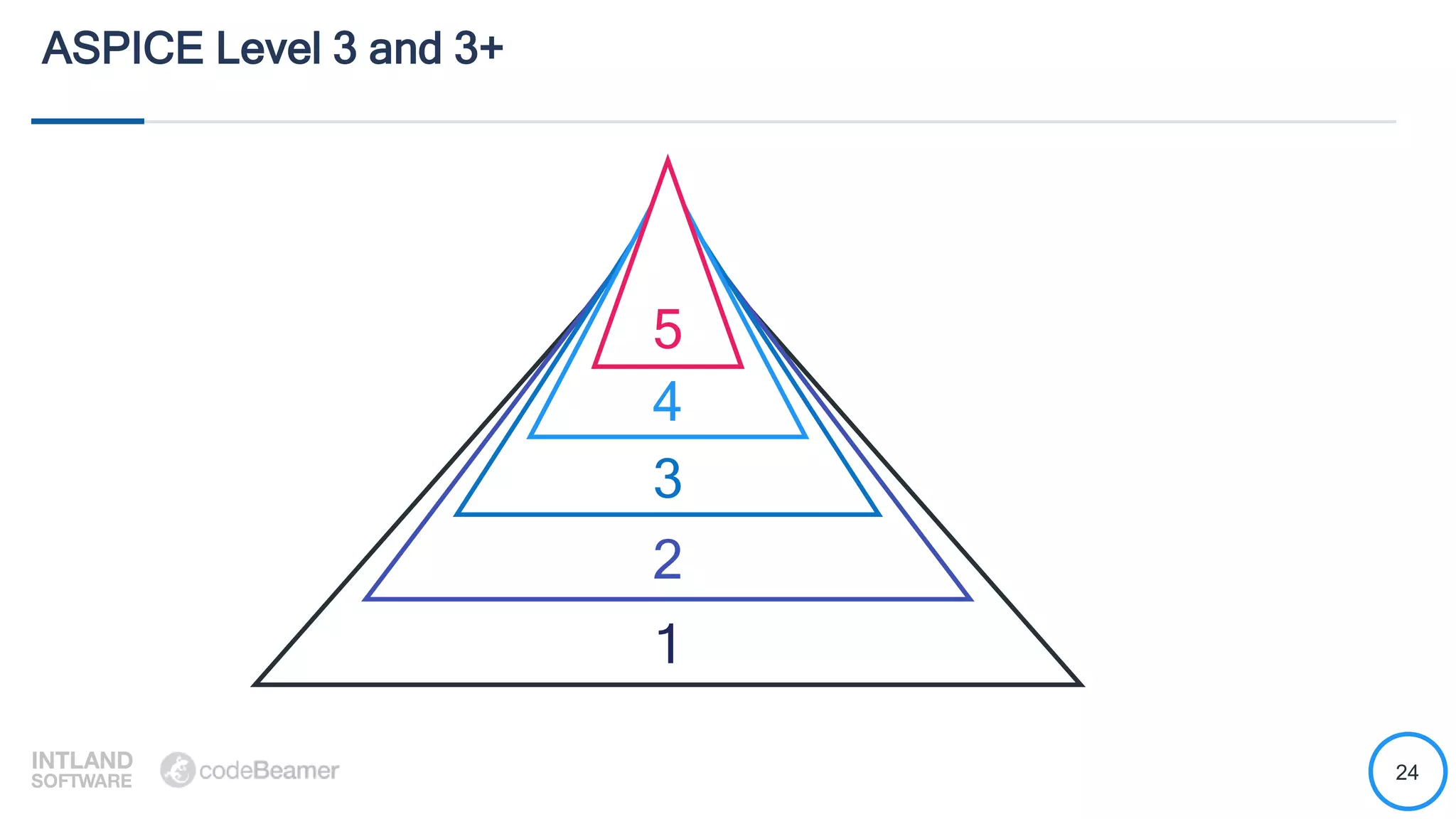

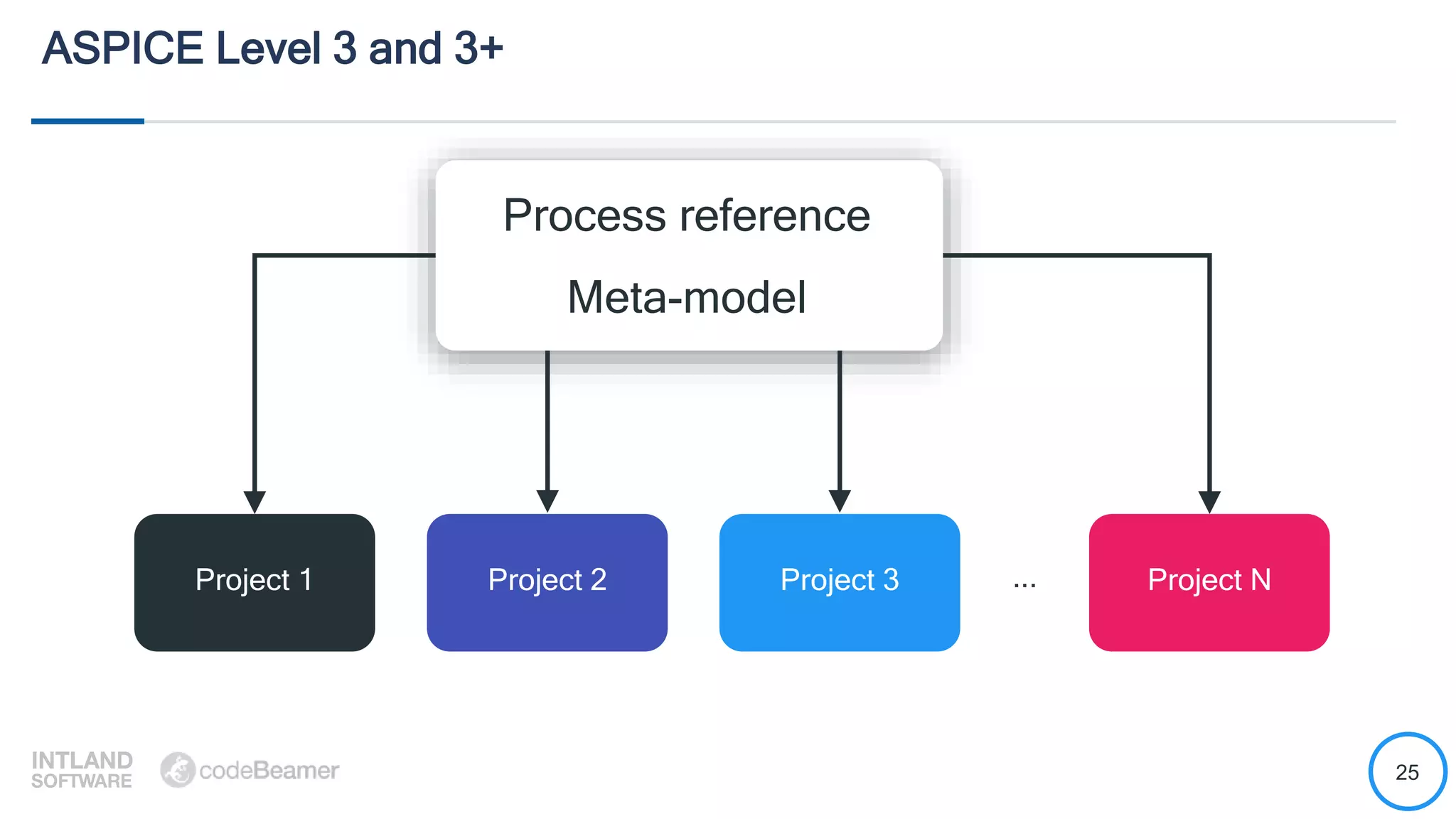

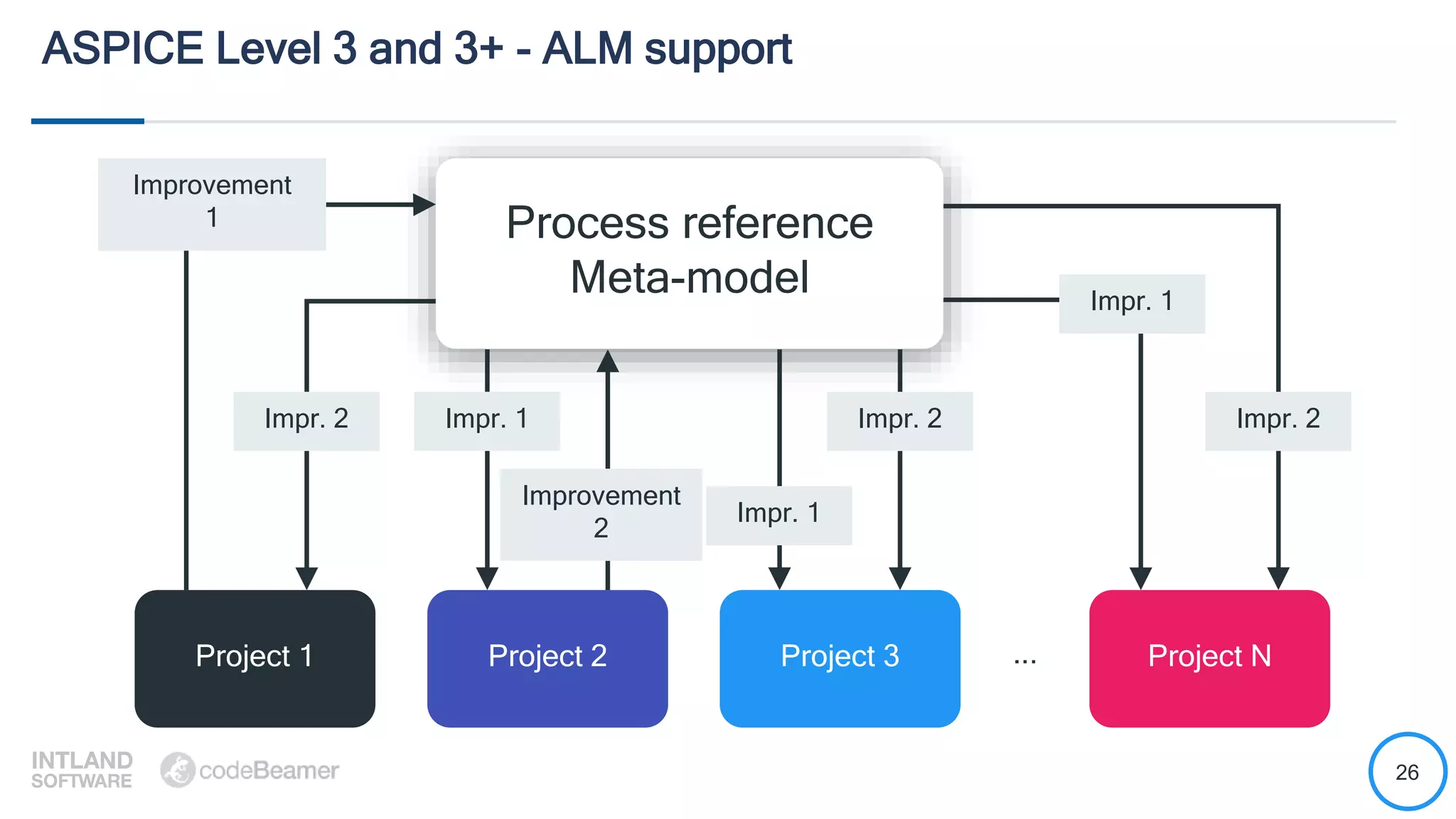

The document discusses the significance of automotive SPICE (ASPICE) and ISO 26262 standards in the automotive industry, emphasizing their role in ensuring safety and quality in electronic designs. It highlights challenges posed by increasing complexity in vehicles and advocates for structured processes and tooling to enhance design efficiency and compliance. The document also outlines potential benefits of adopting ASPICE and ISO 26262, including improved product quality and customer satisfaction.