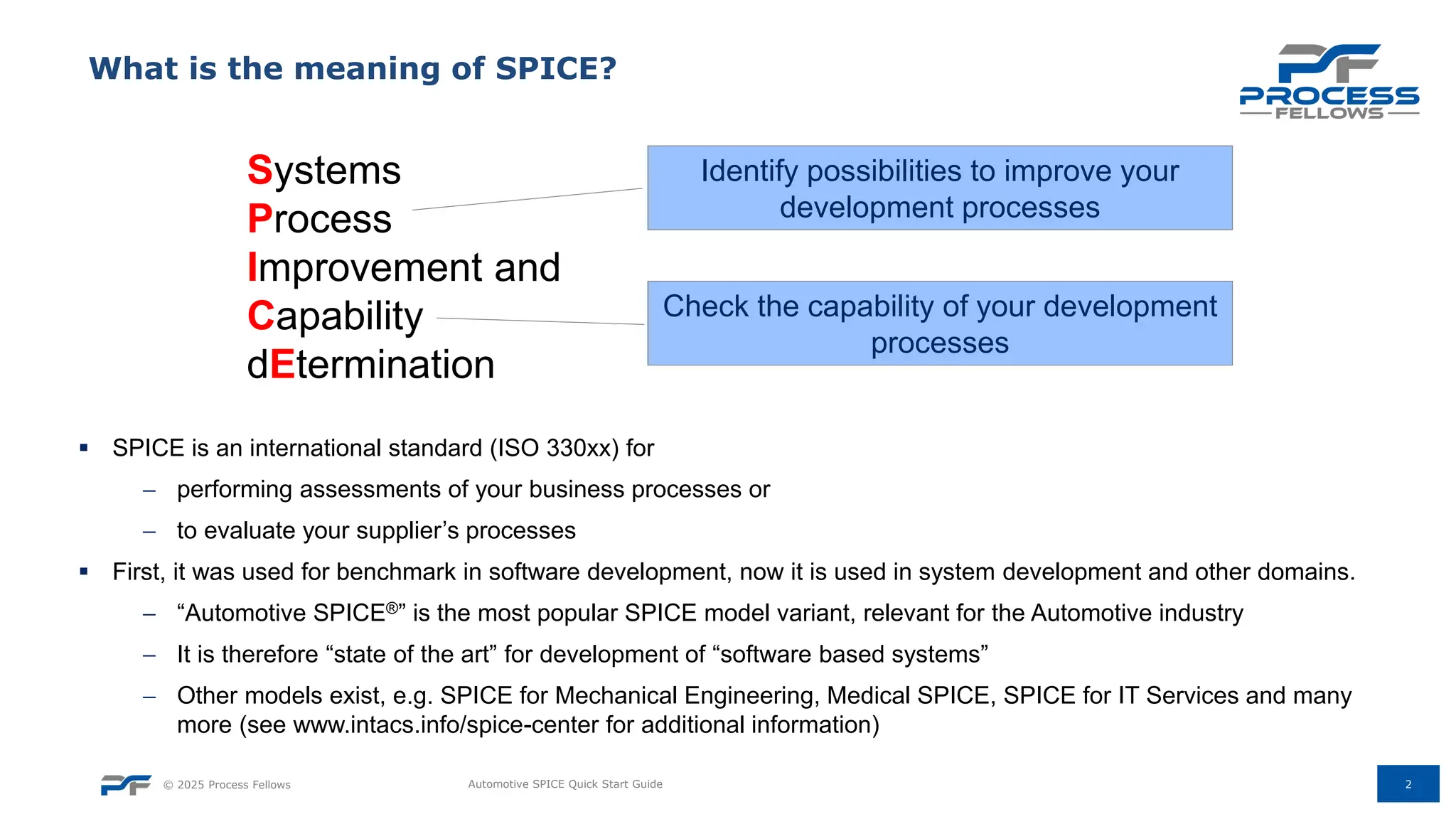

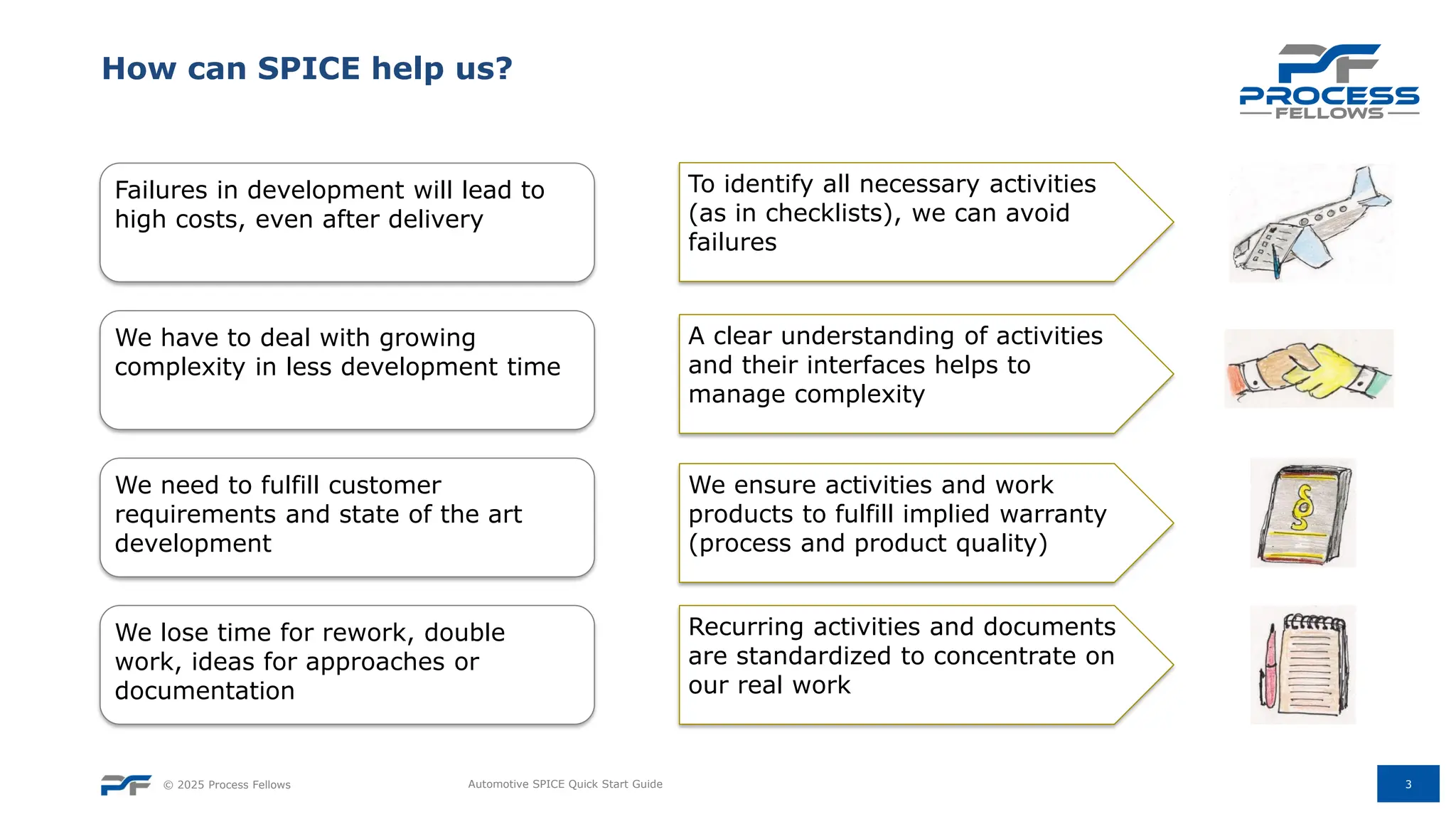

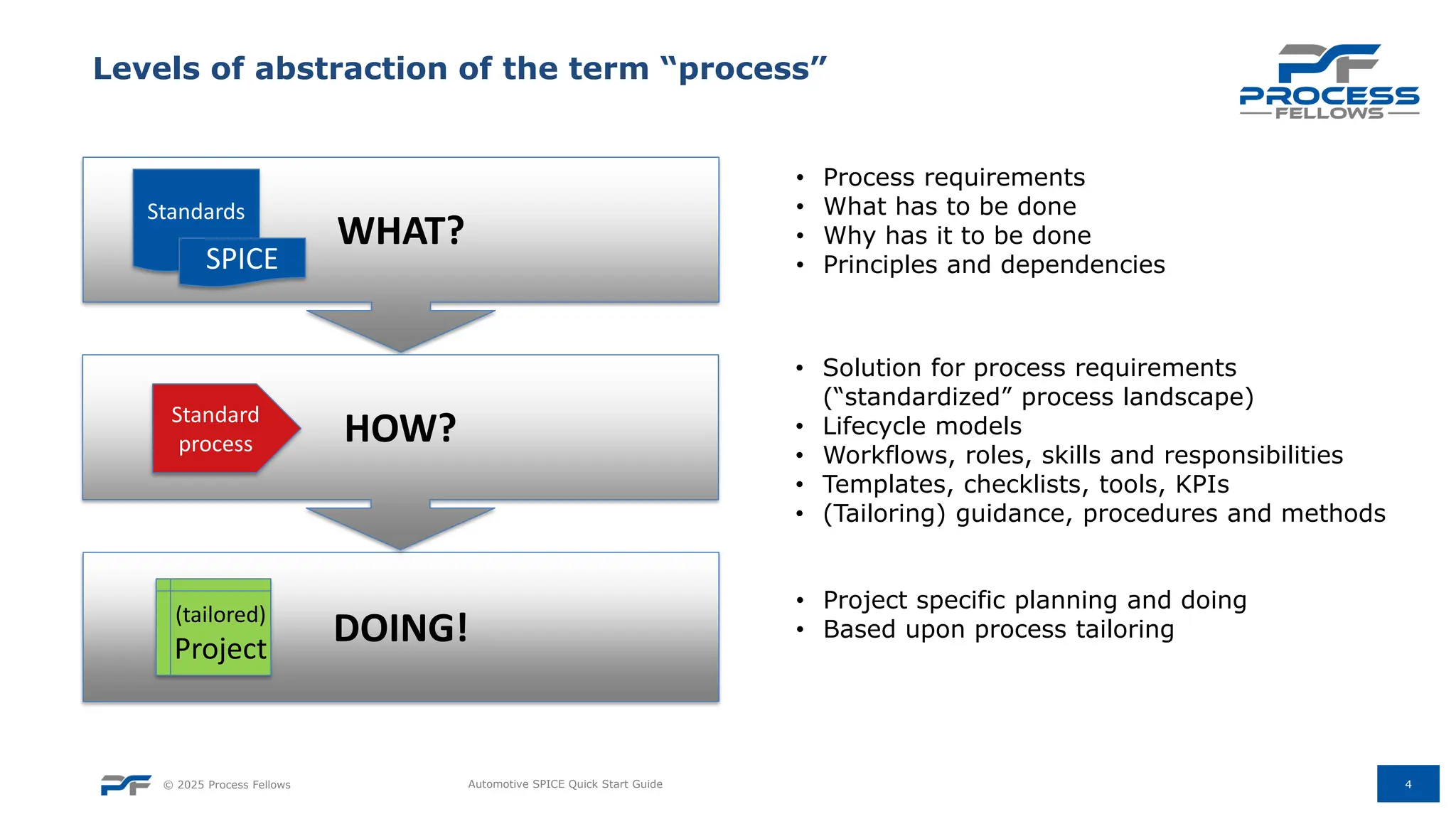

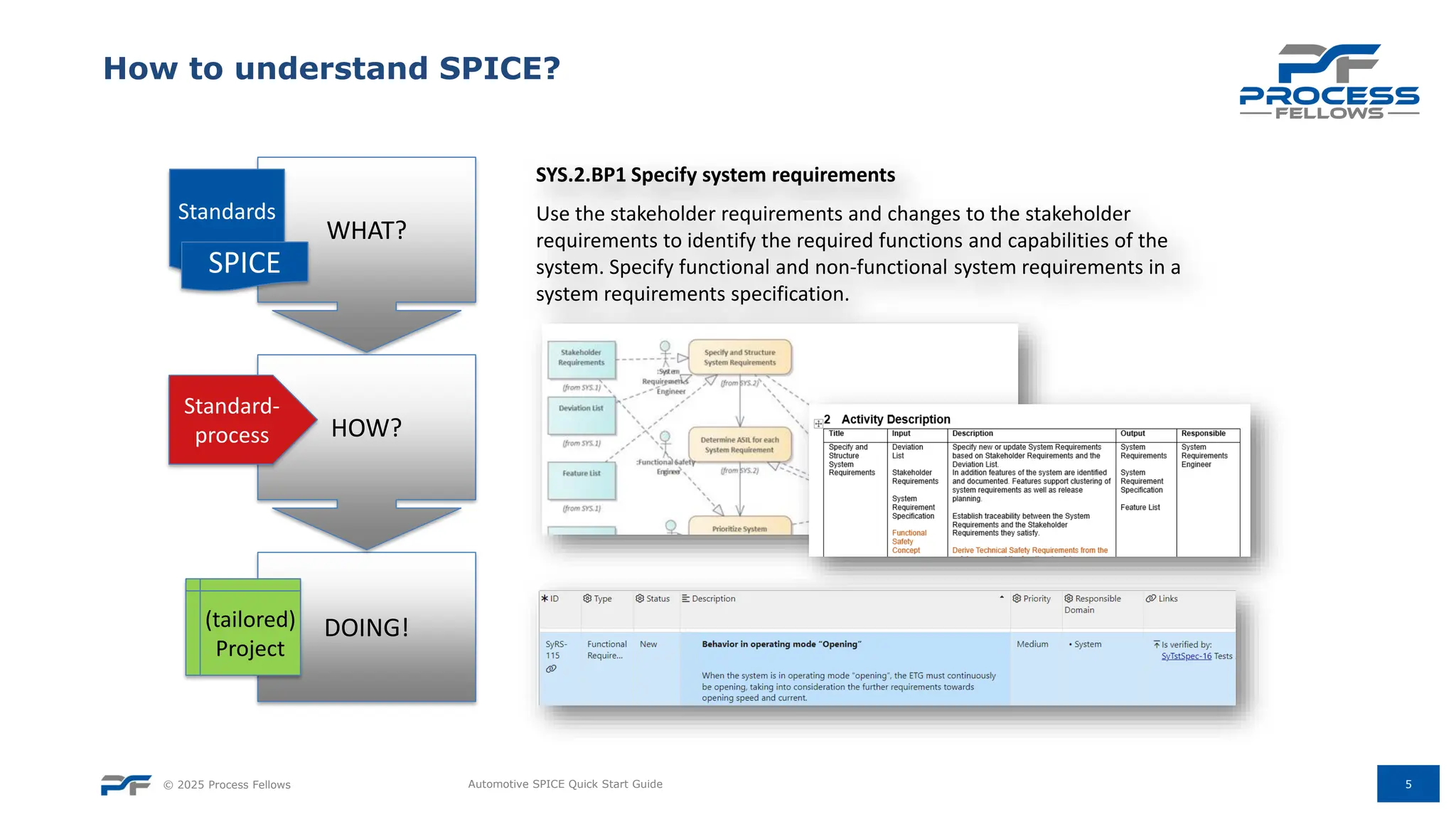

Welcome to this short introduction of SPICE, and in particular to Automotive SPICE®. The goal of this presentation is to give you a quick start guide for understanding what is it about, what is the motivation for using it and how is it typically used in industry. Whether you're an engineer, a designer, a quality assurance engineer, or just someone who's really into cars, we wanna help you understand the core ideas. We're gonna pull out the essential insights so you can get the big picture without getting lost in the details.

This presentation is available as a video on youtube. Just follow the link: https://youtu.be/zGaPpMH5NLs?si=rNsX8zBYpNUjW6HD

Hint: https://www.SPICE4CARS.com is a comprehensive, web-based knowledge platform covering Automotive SPICE® and even more.