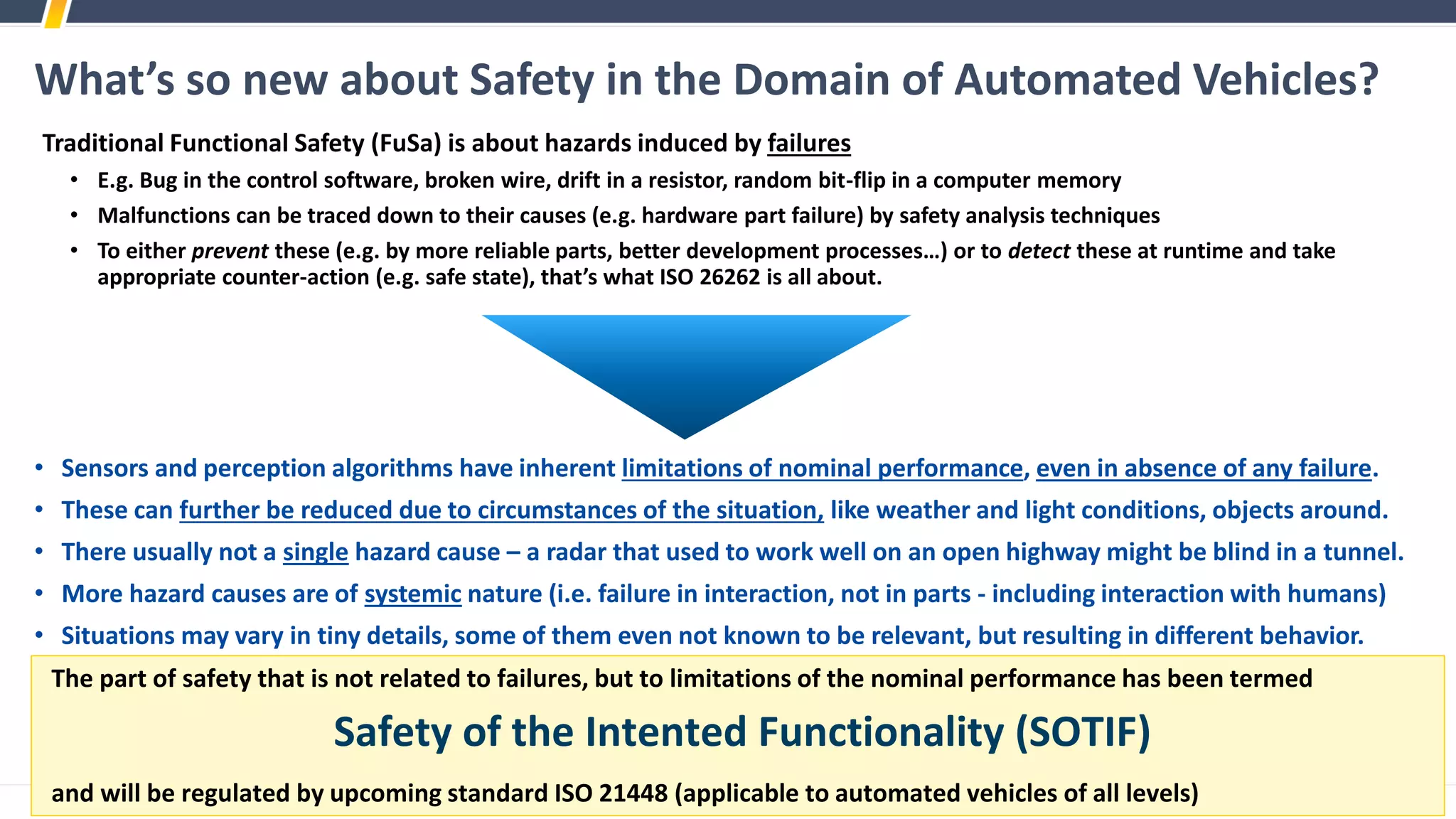

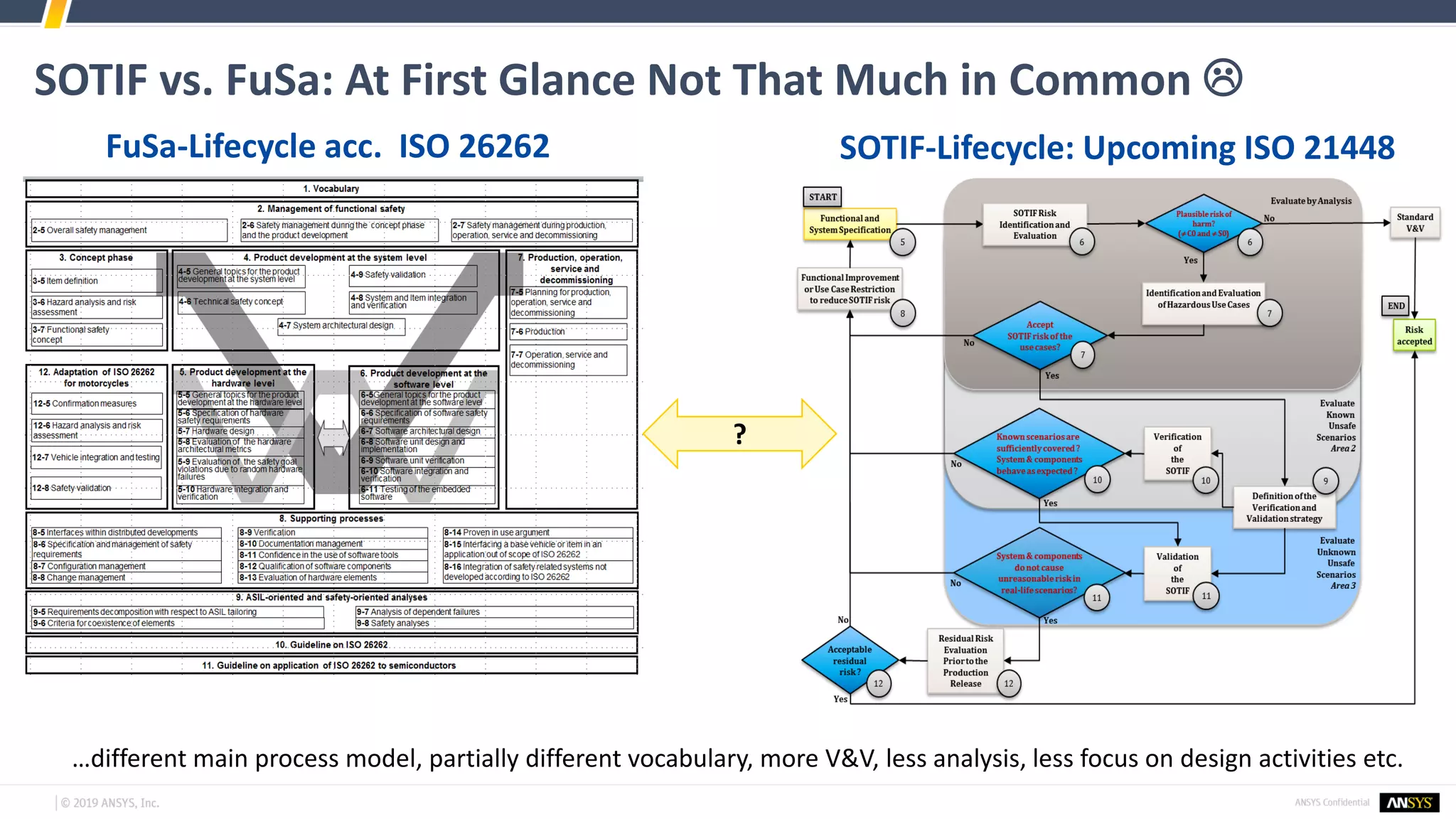

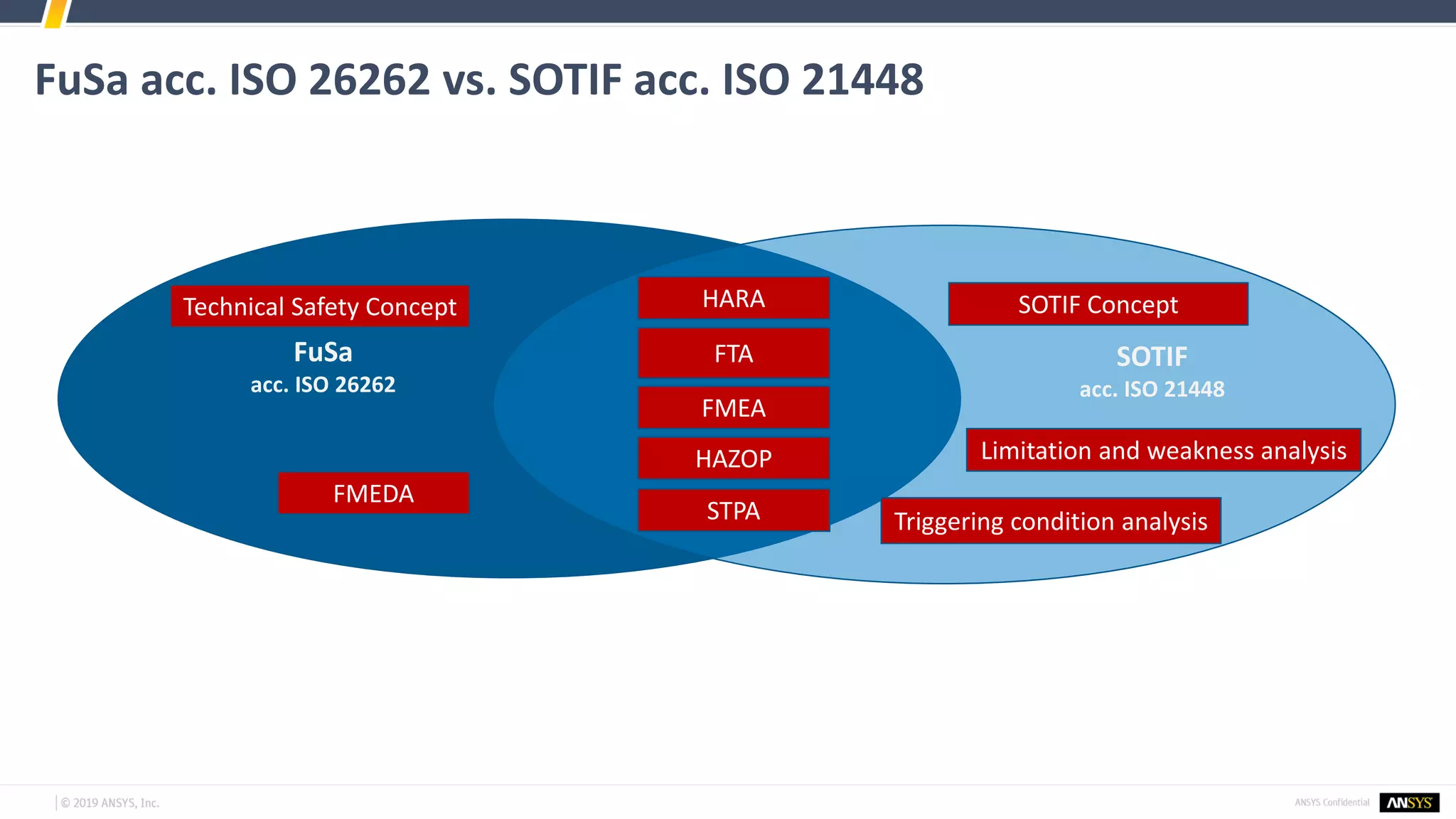

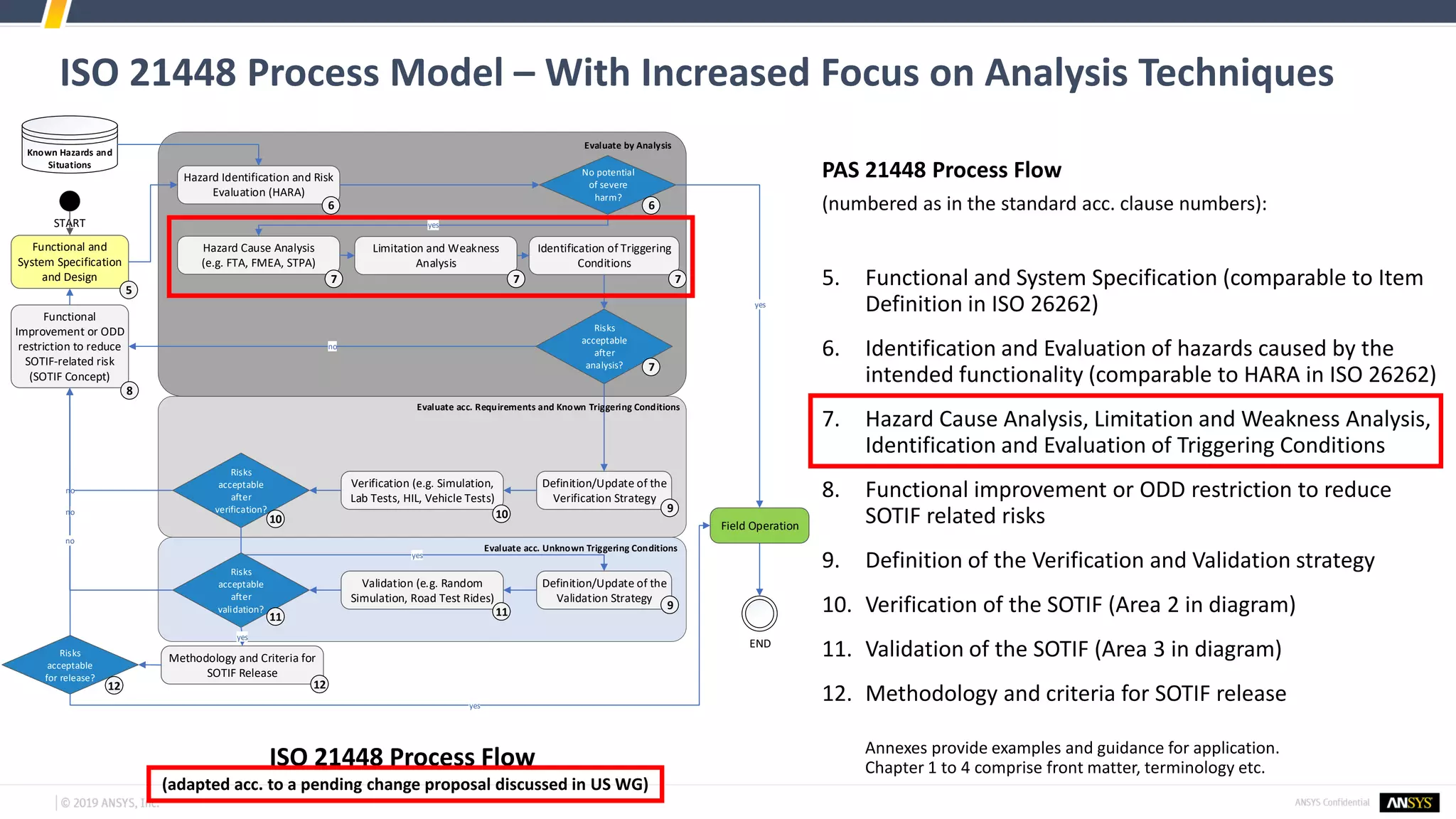

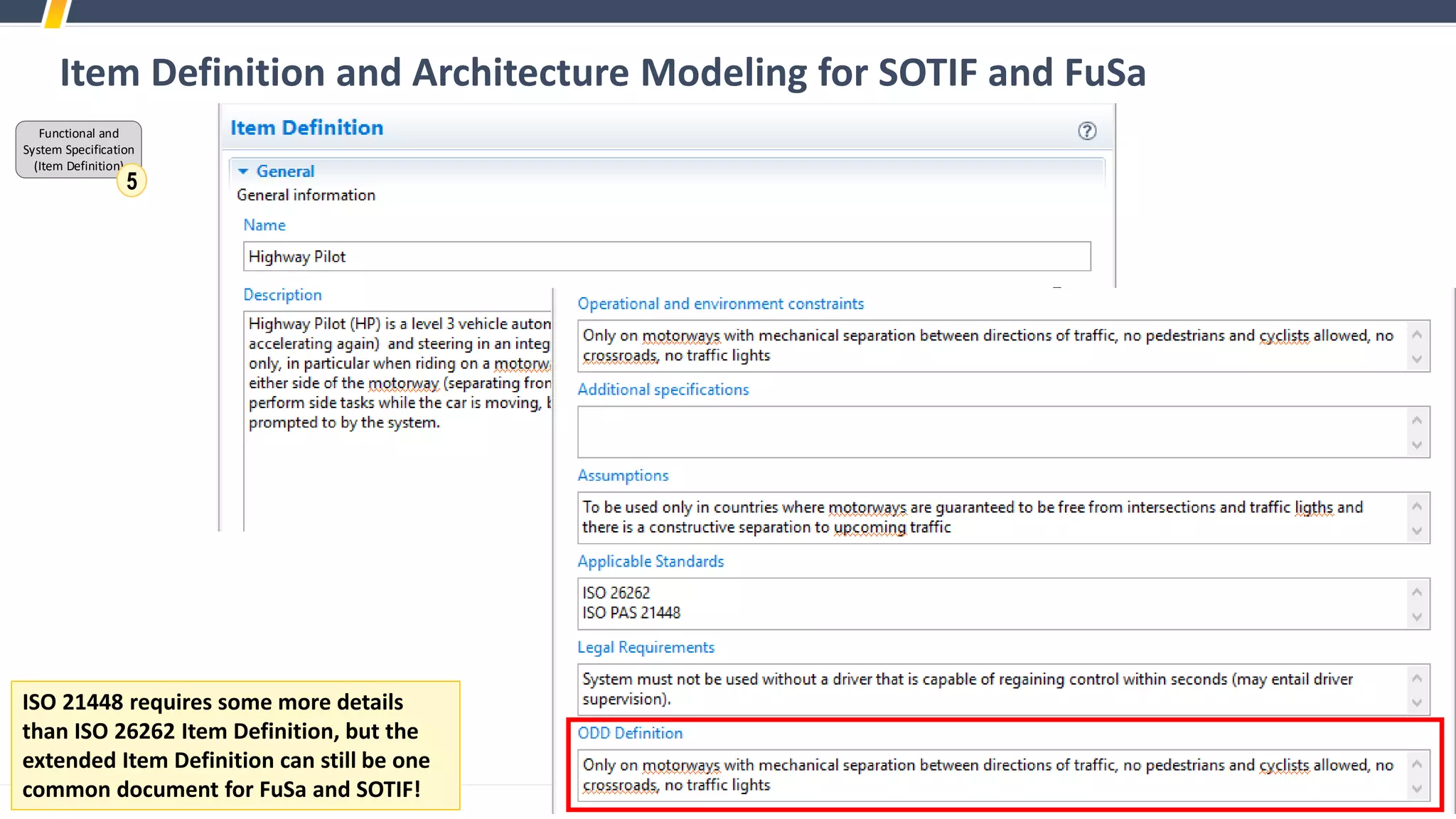

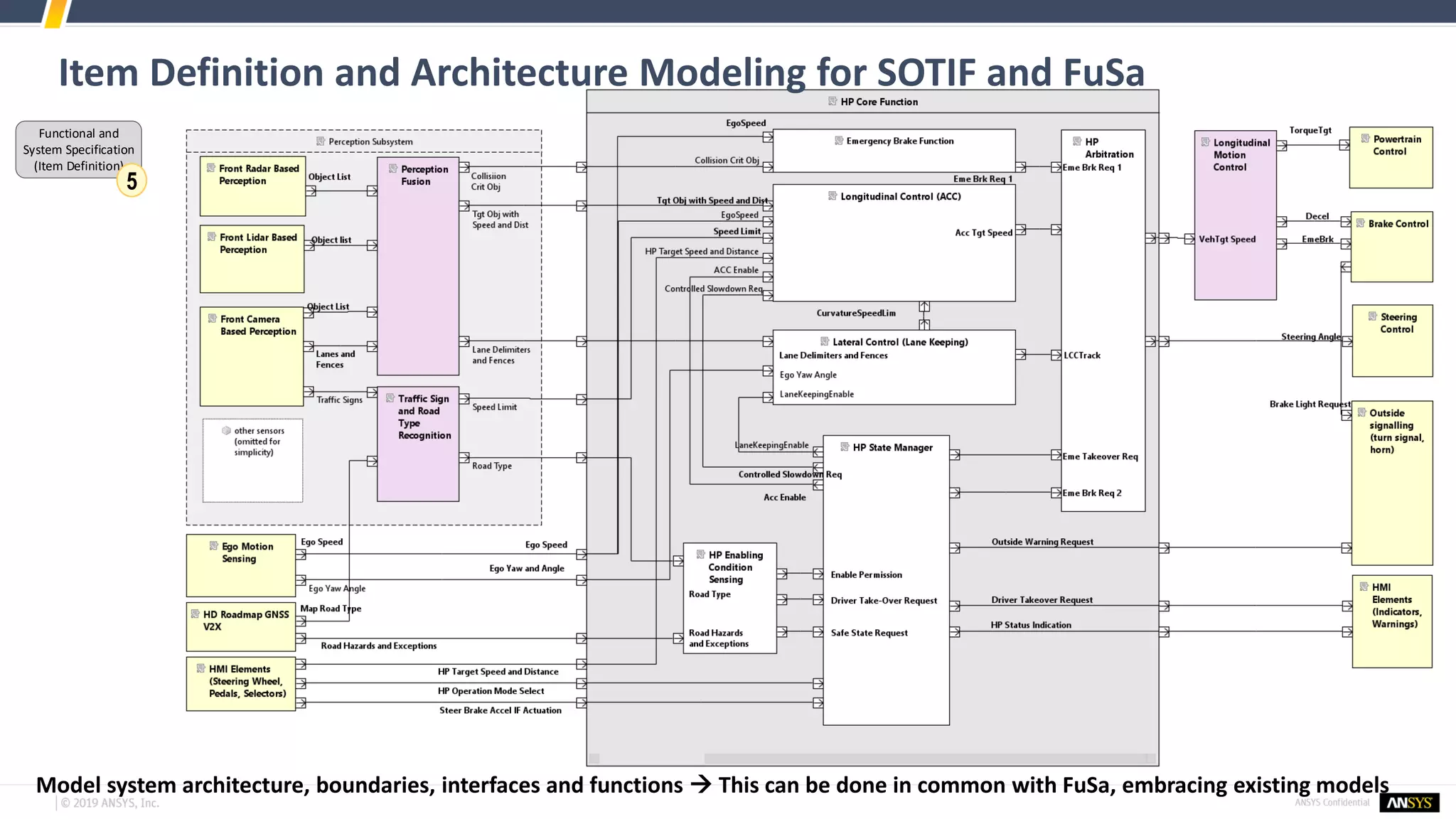

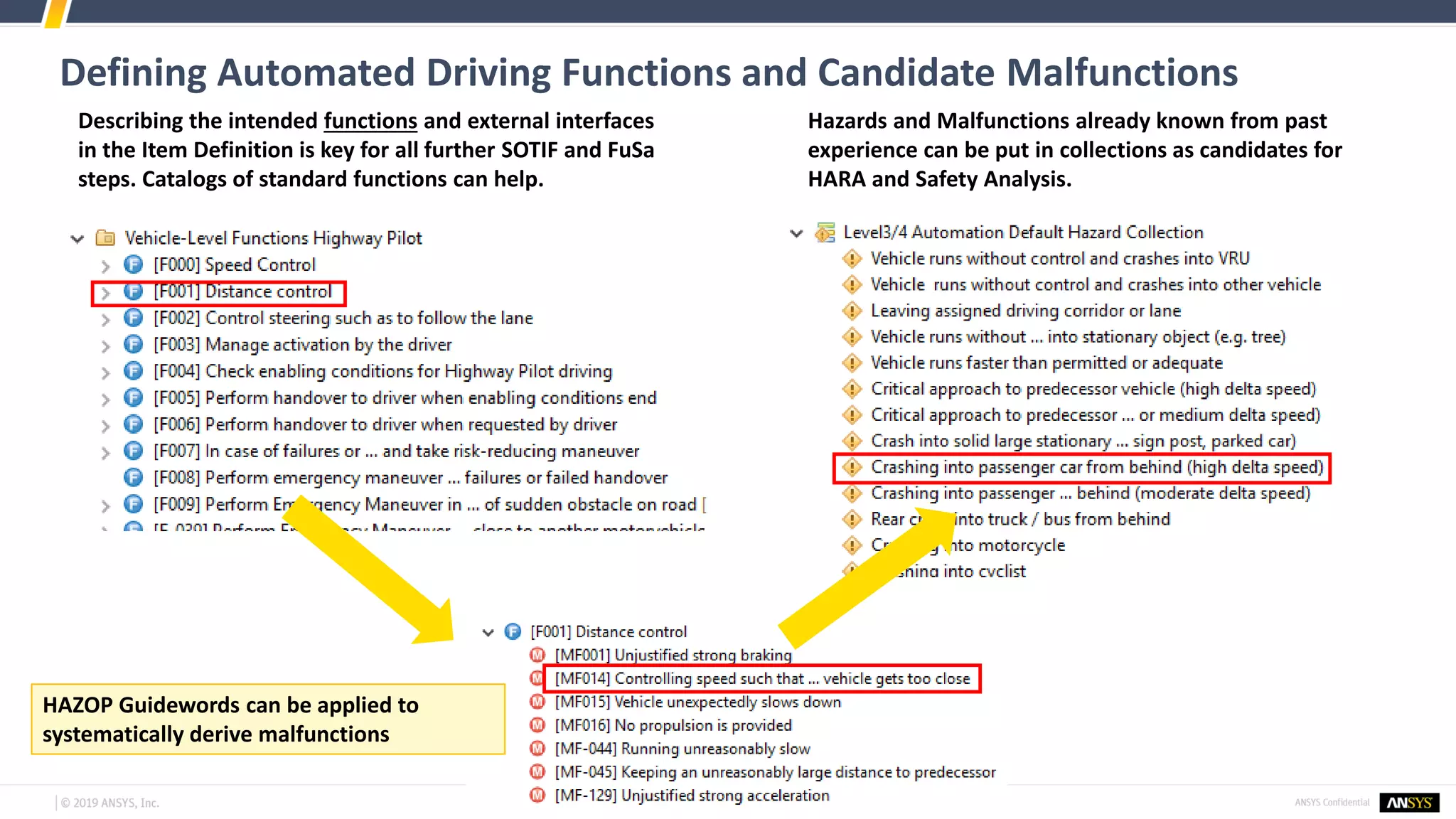

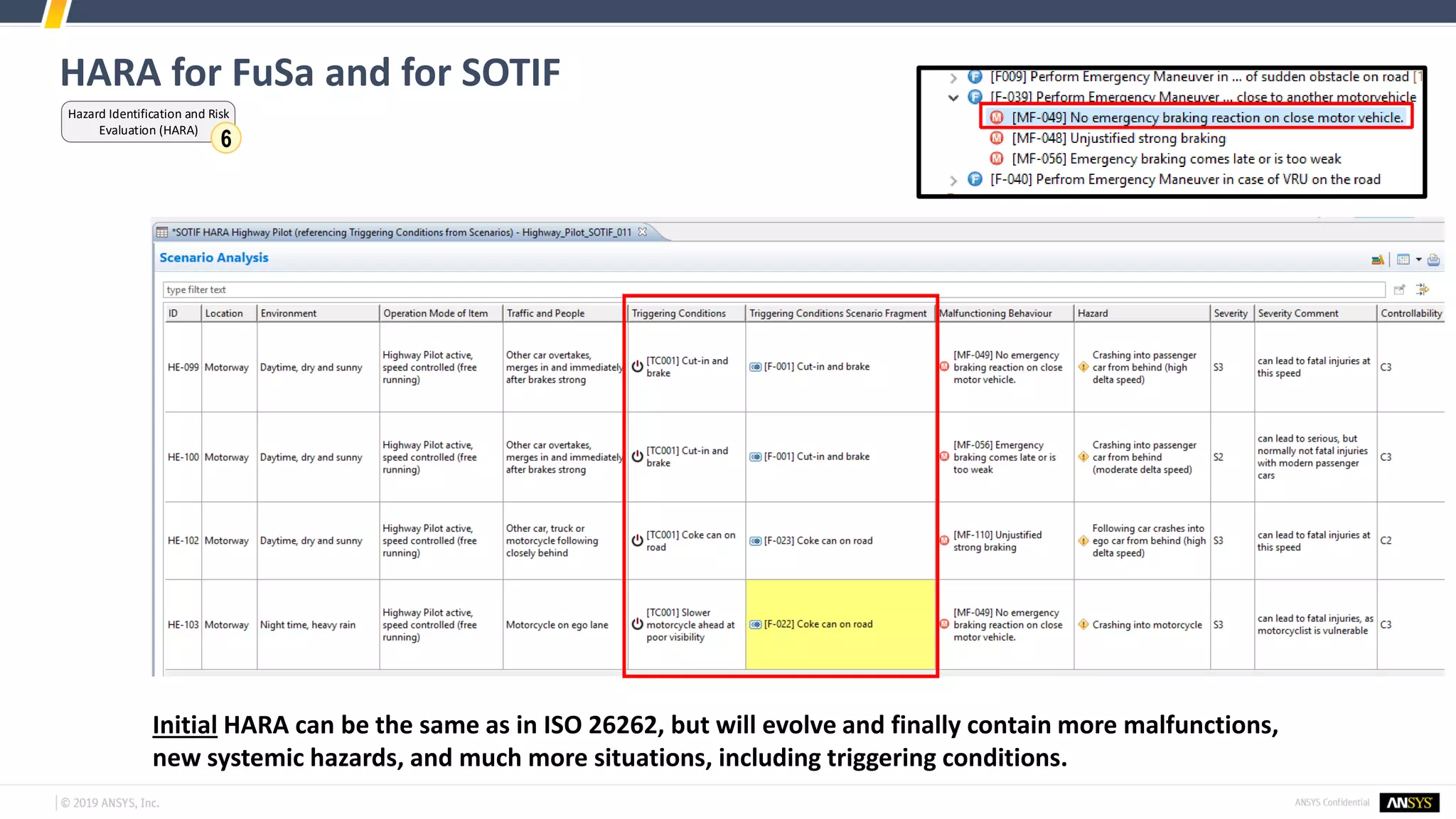

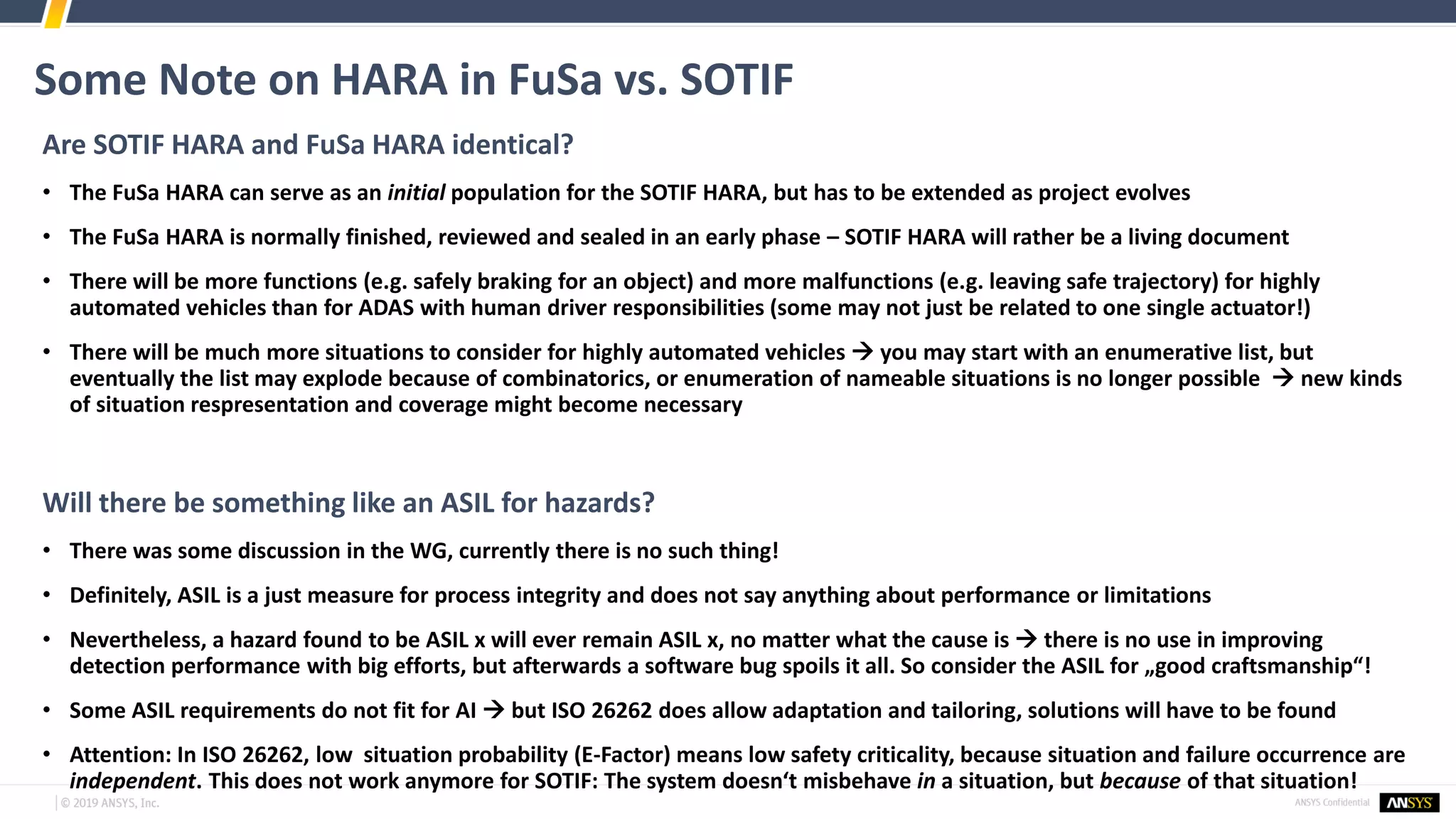

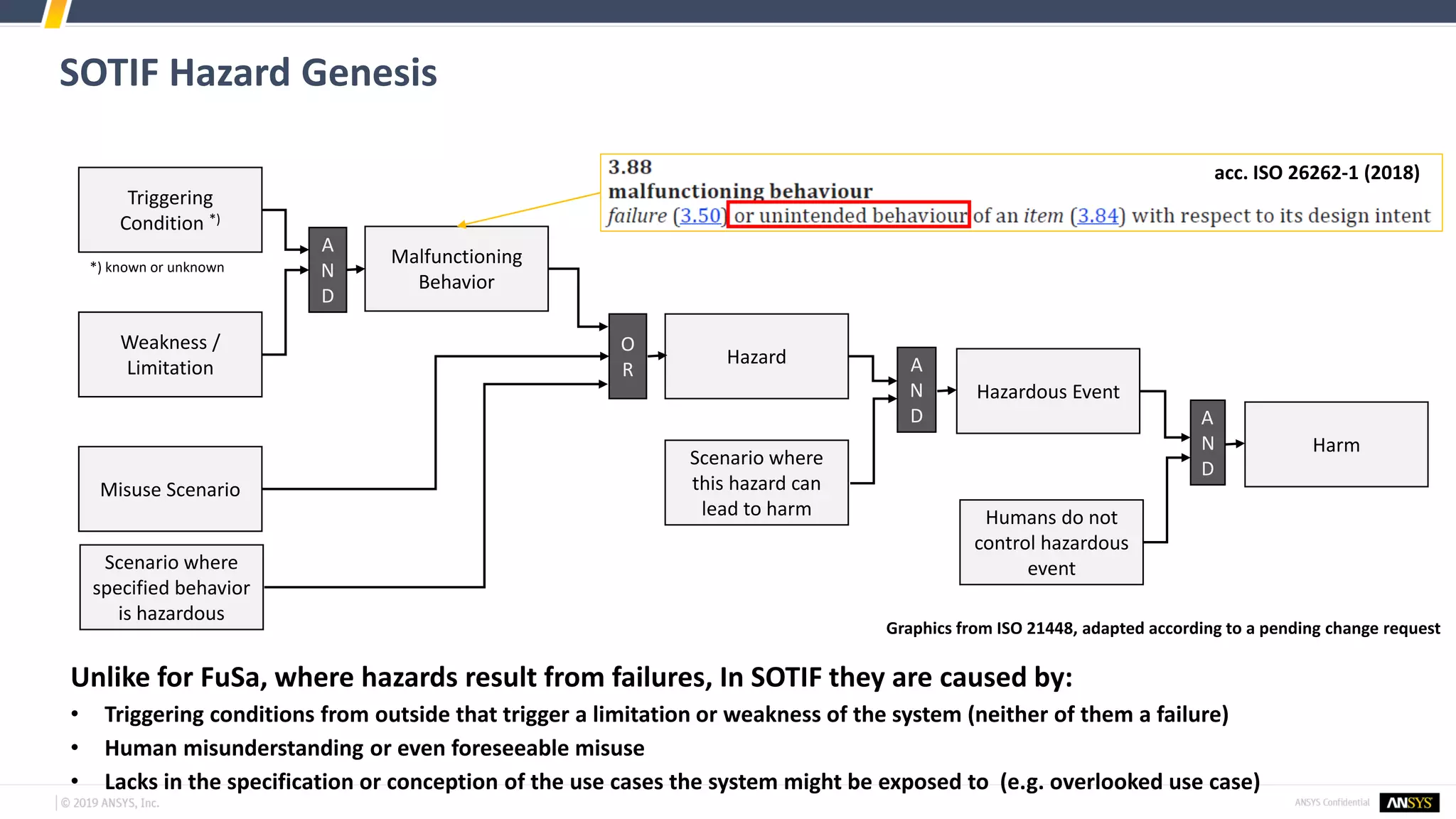

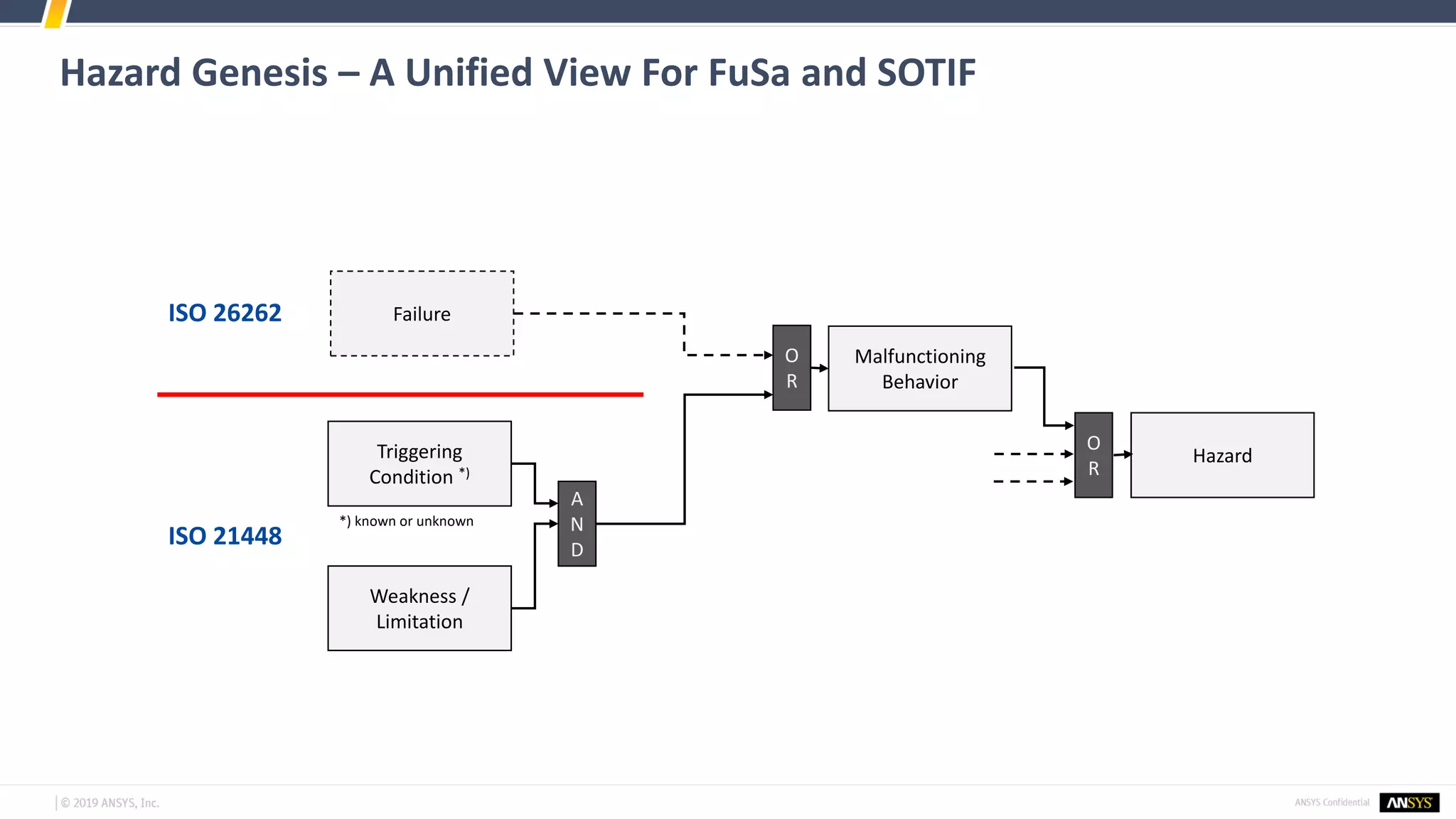

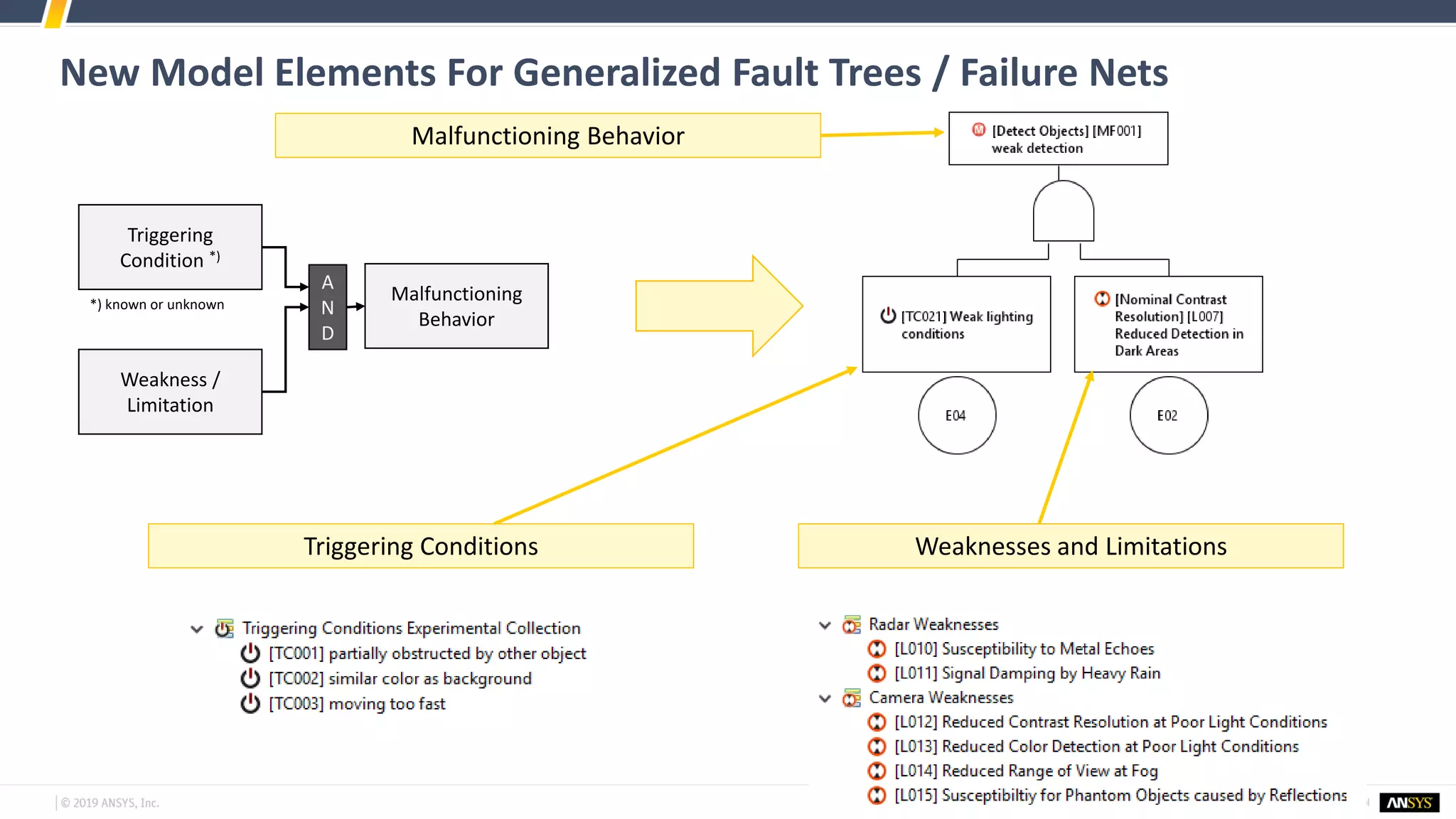

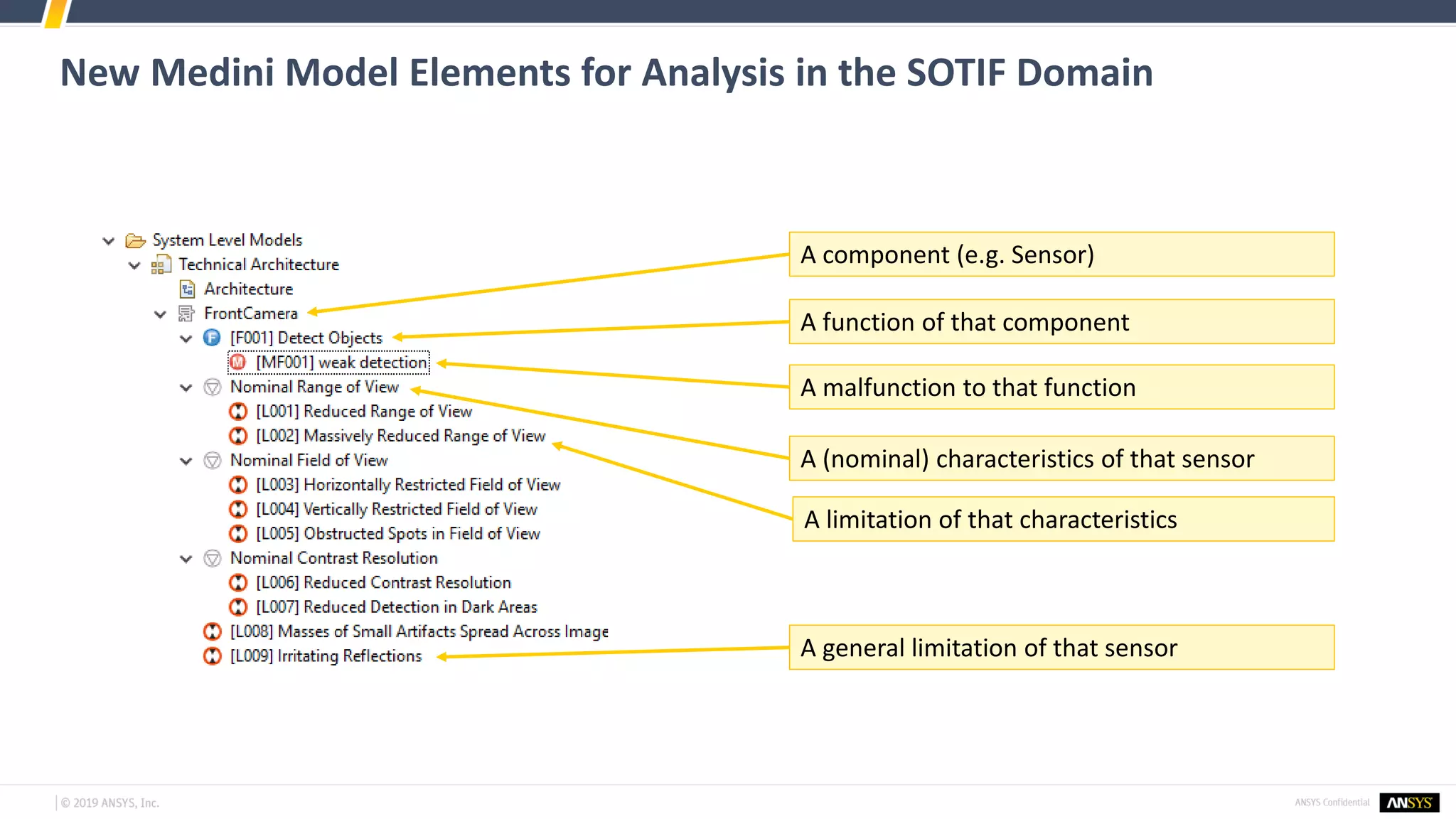

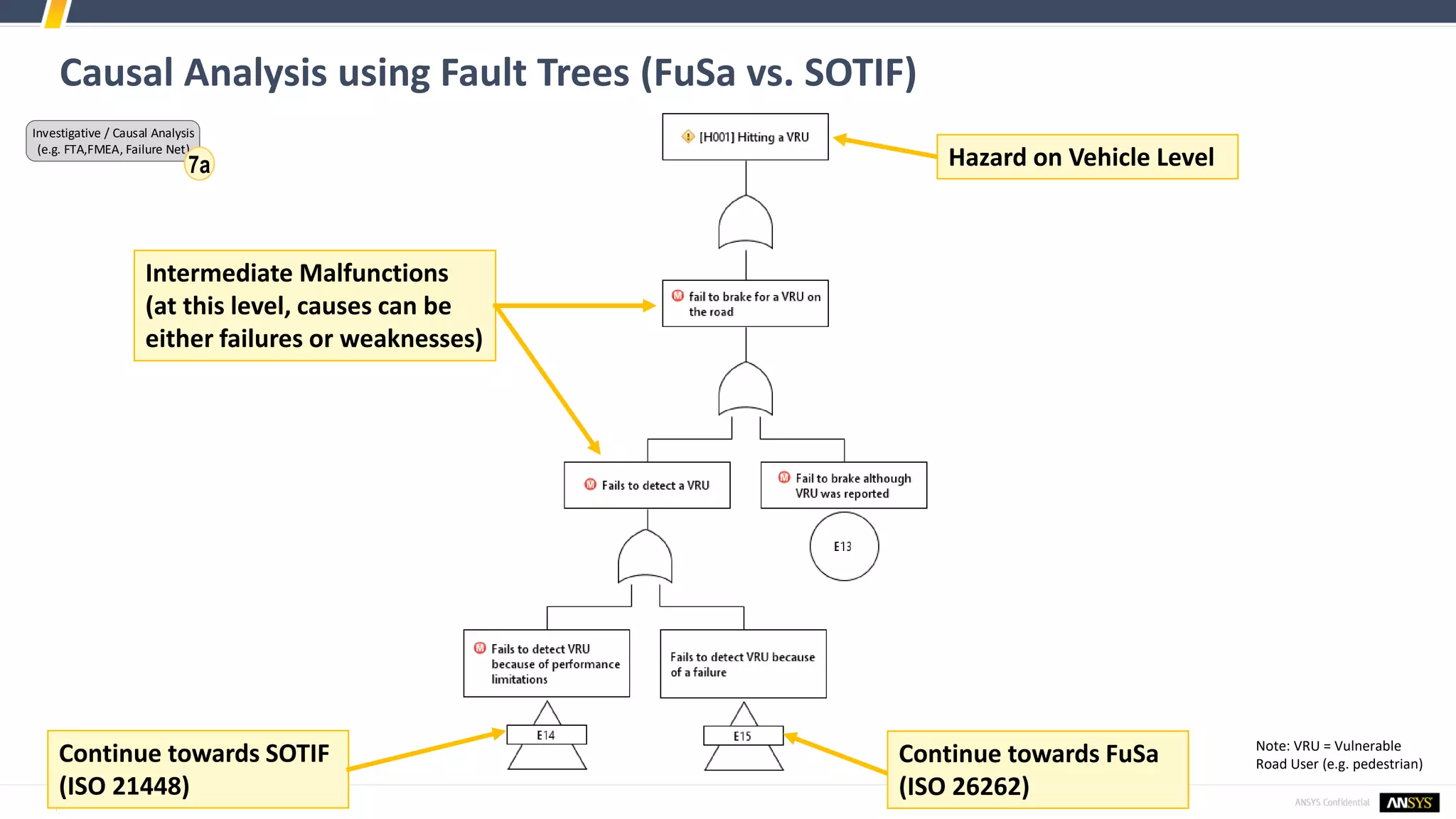

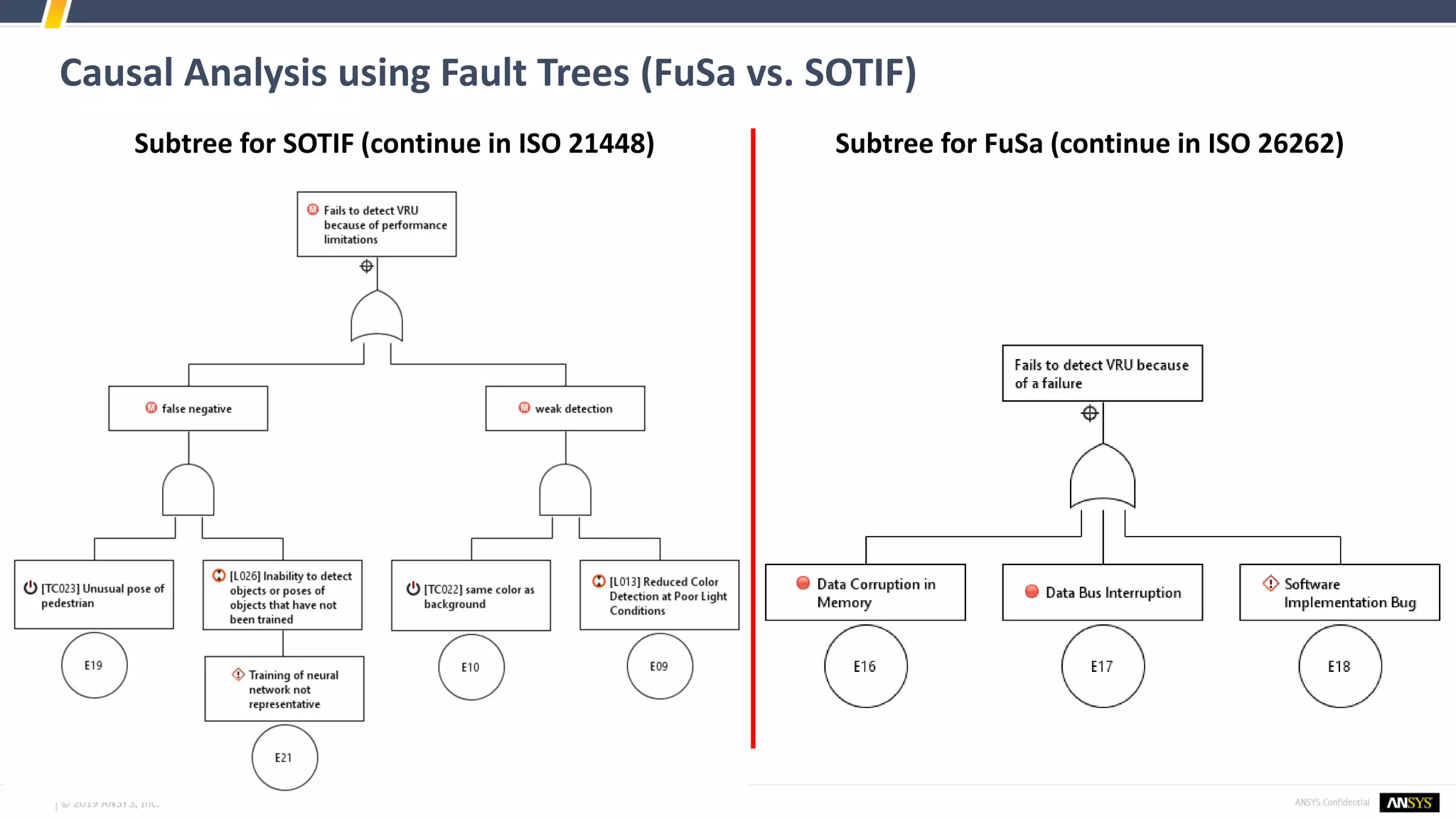

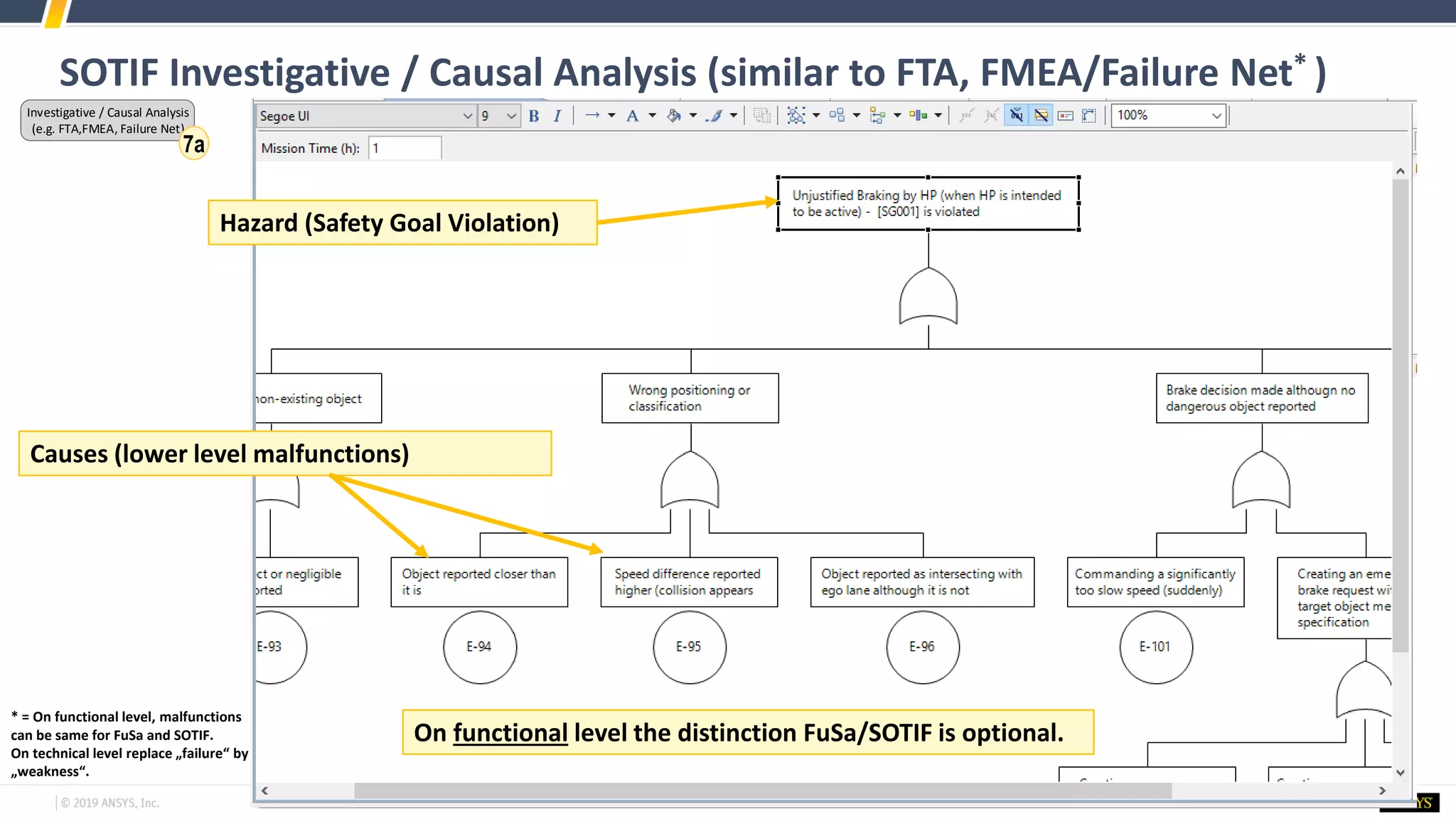

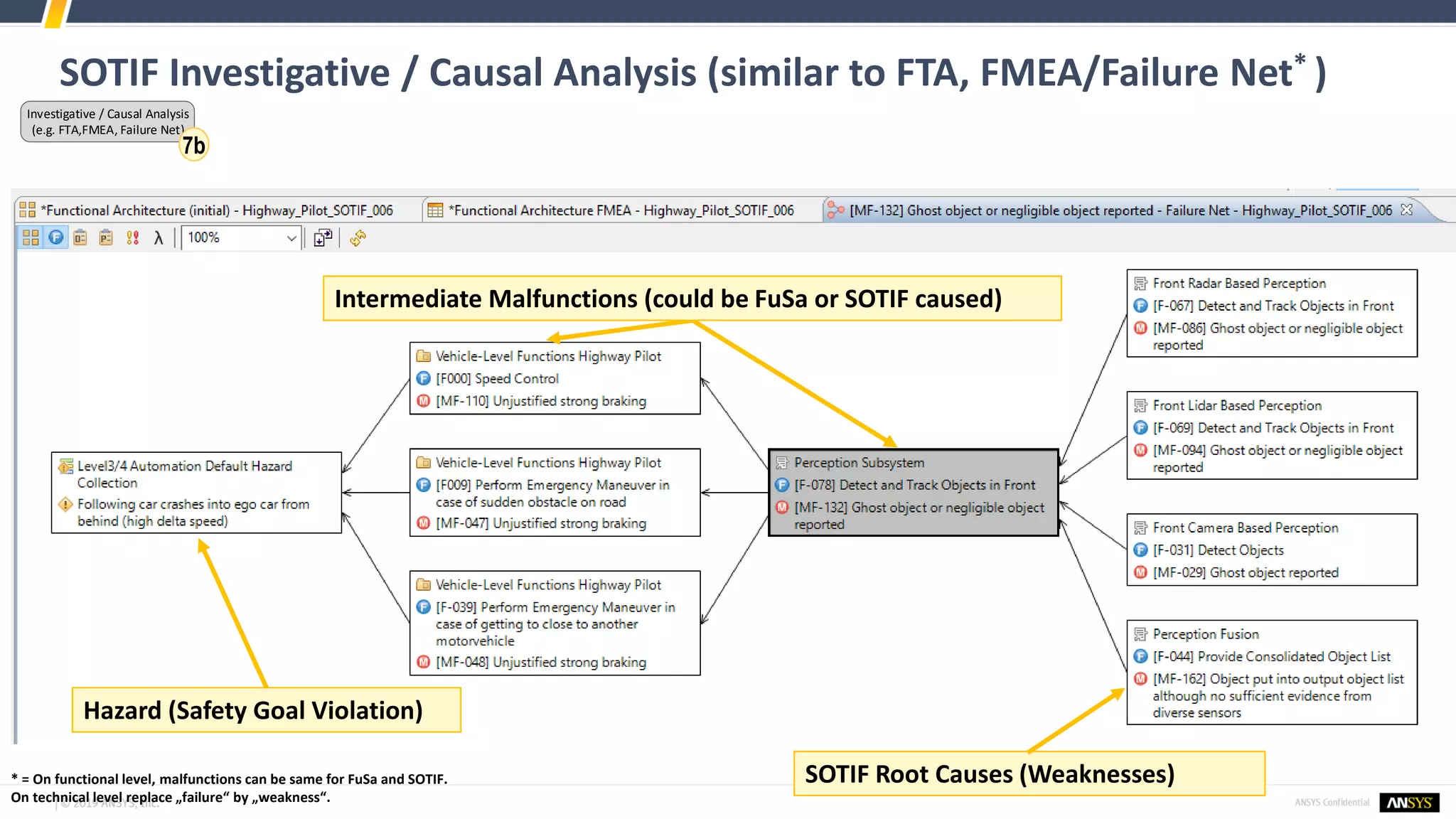

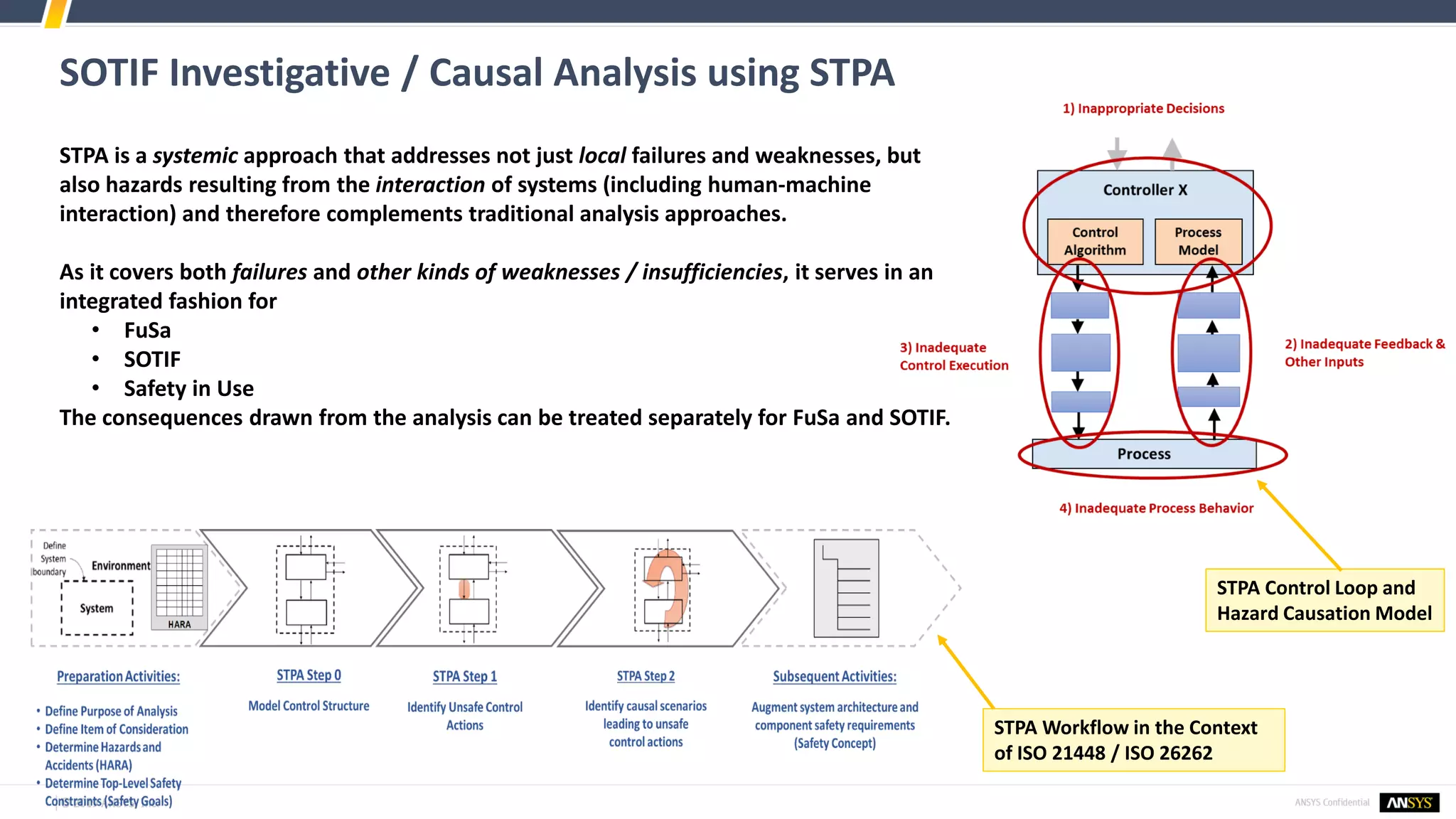

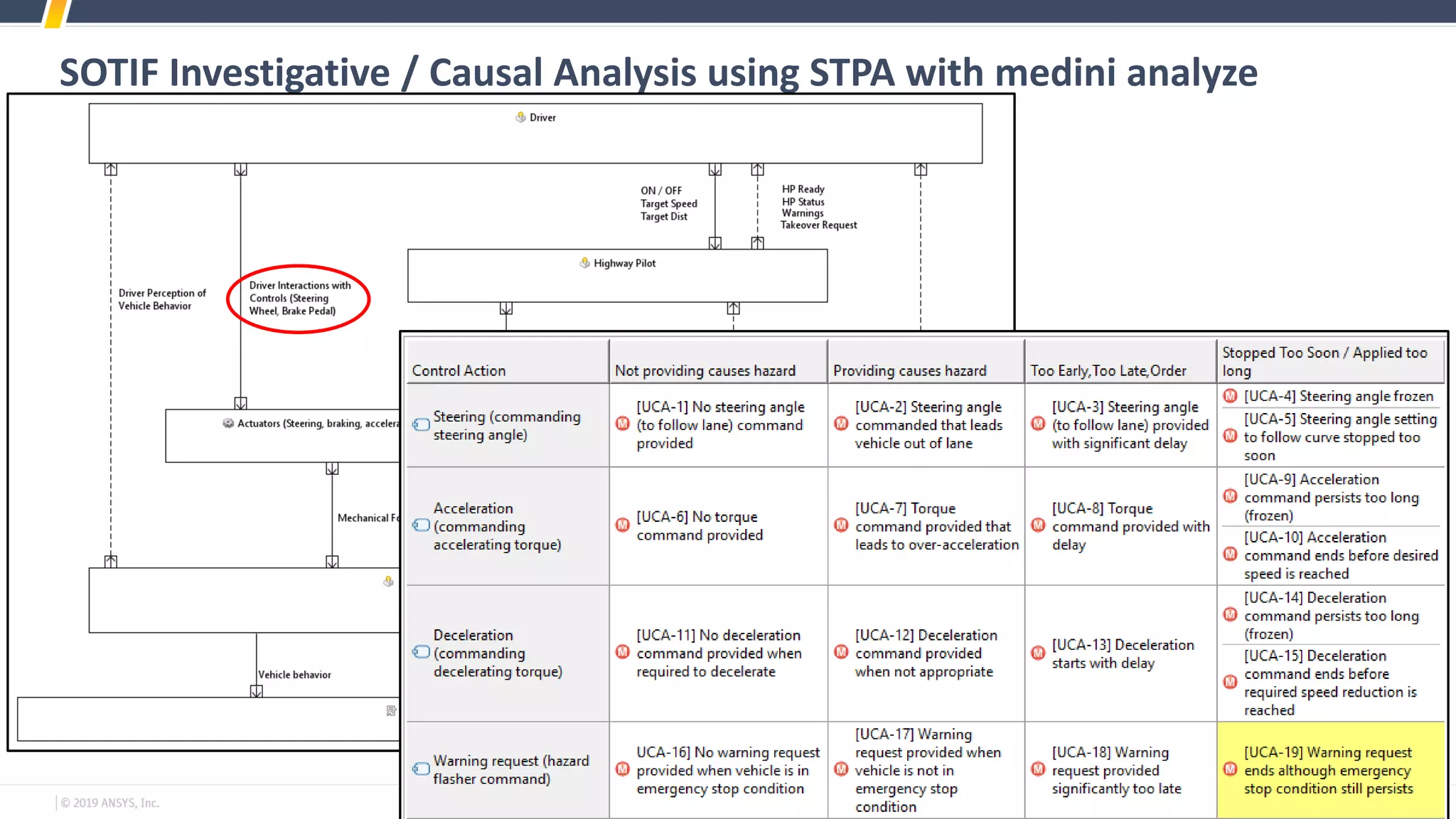

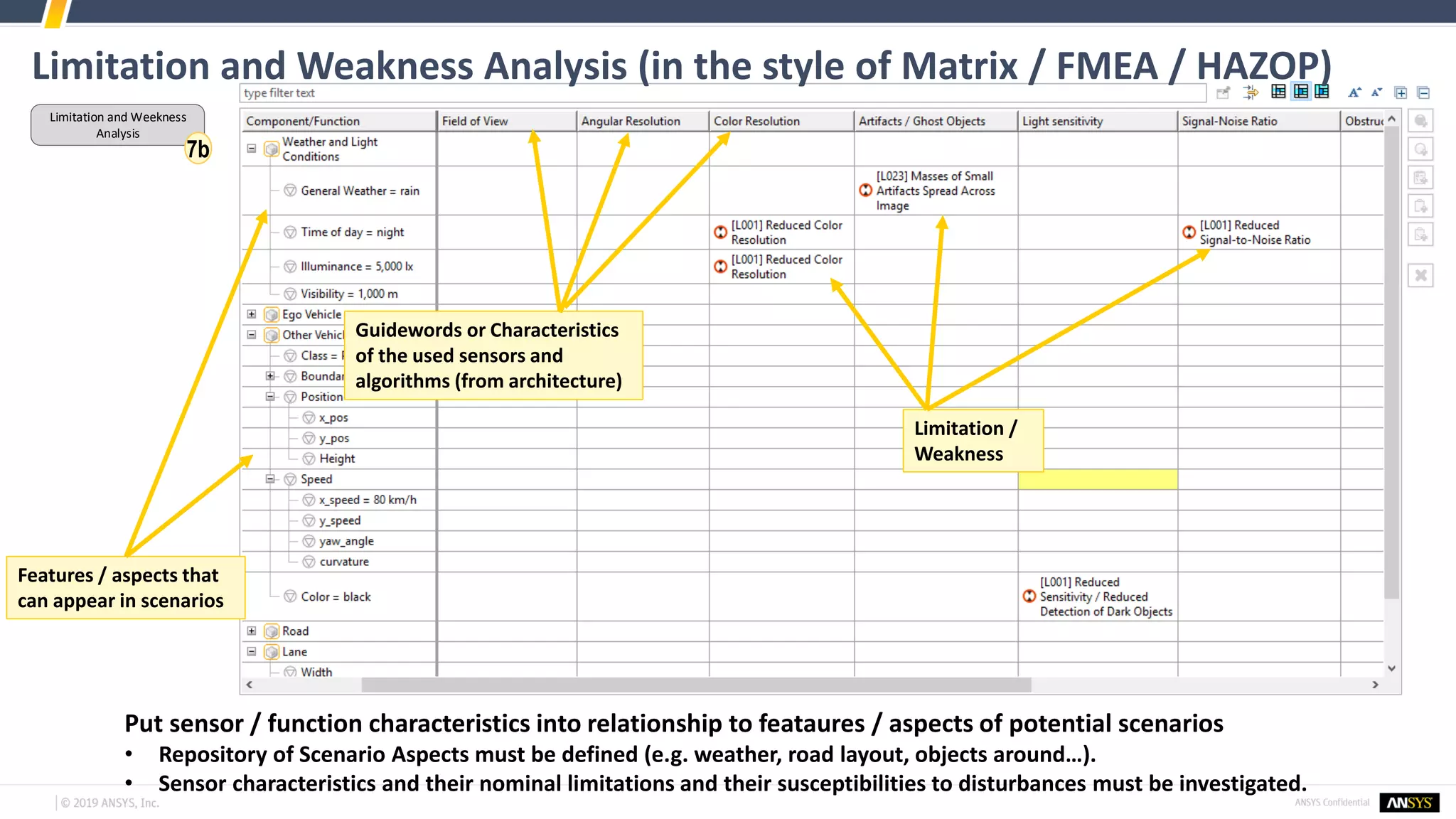

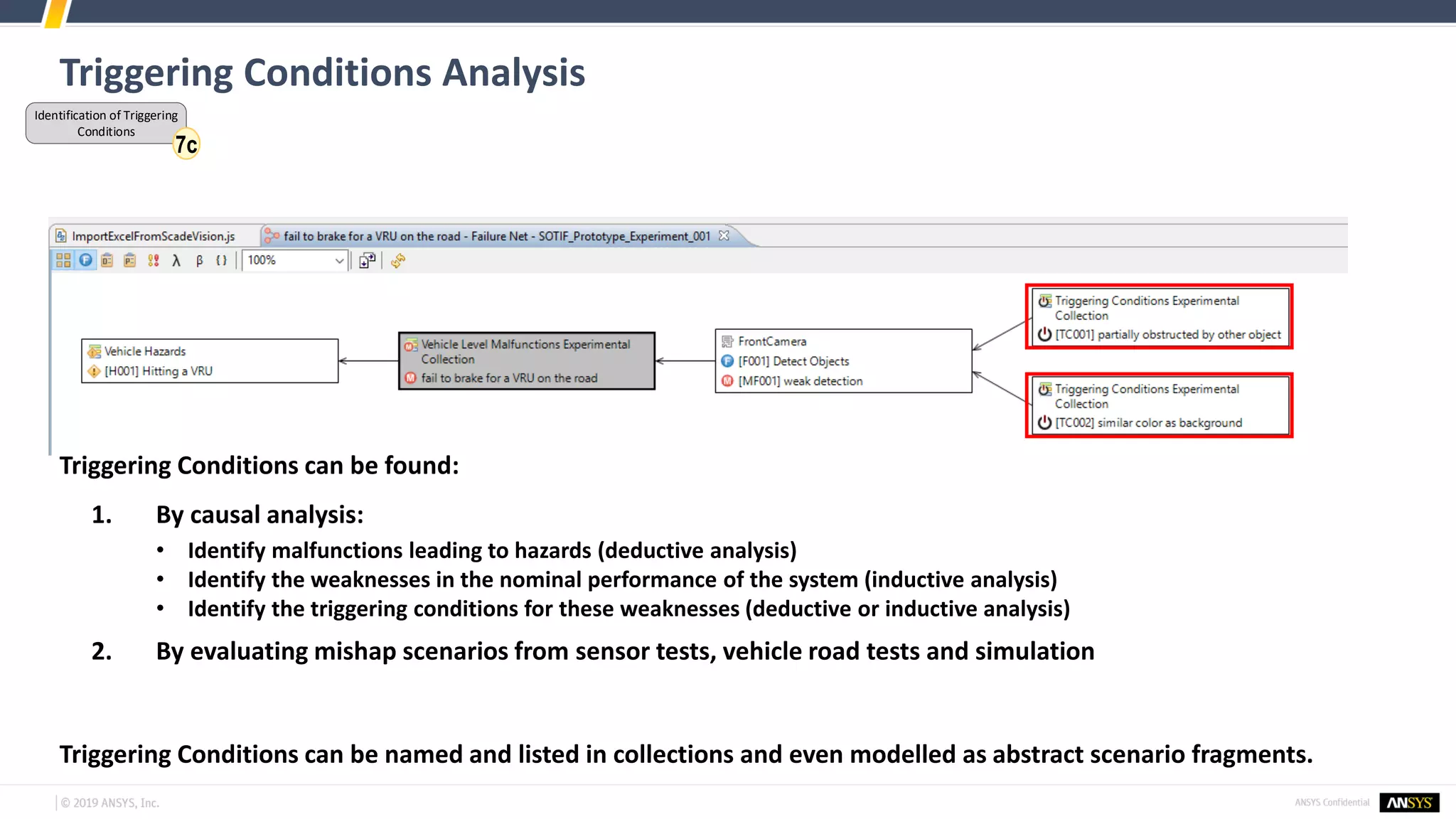

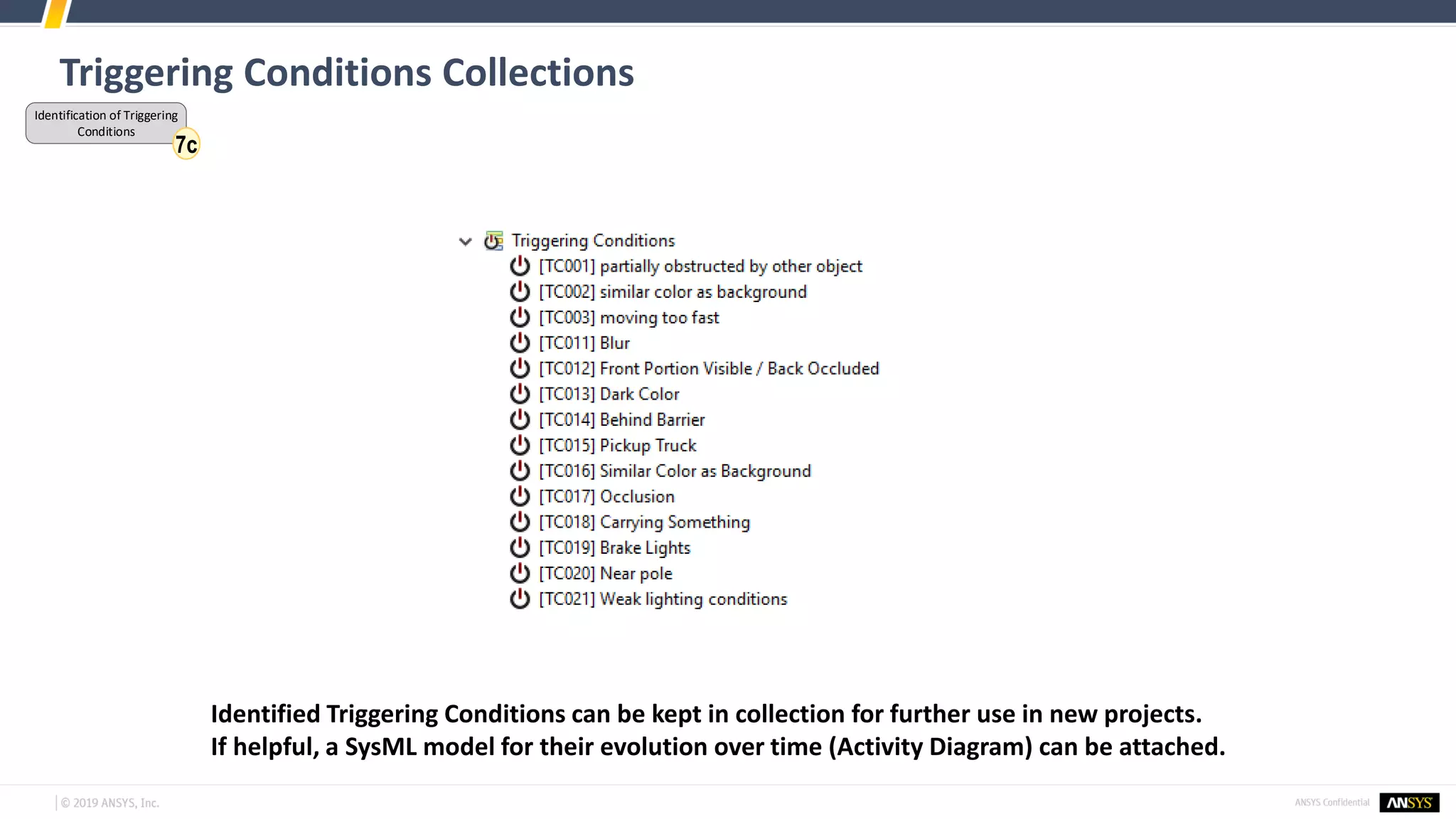

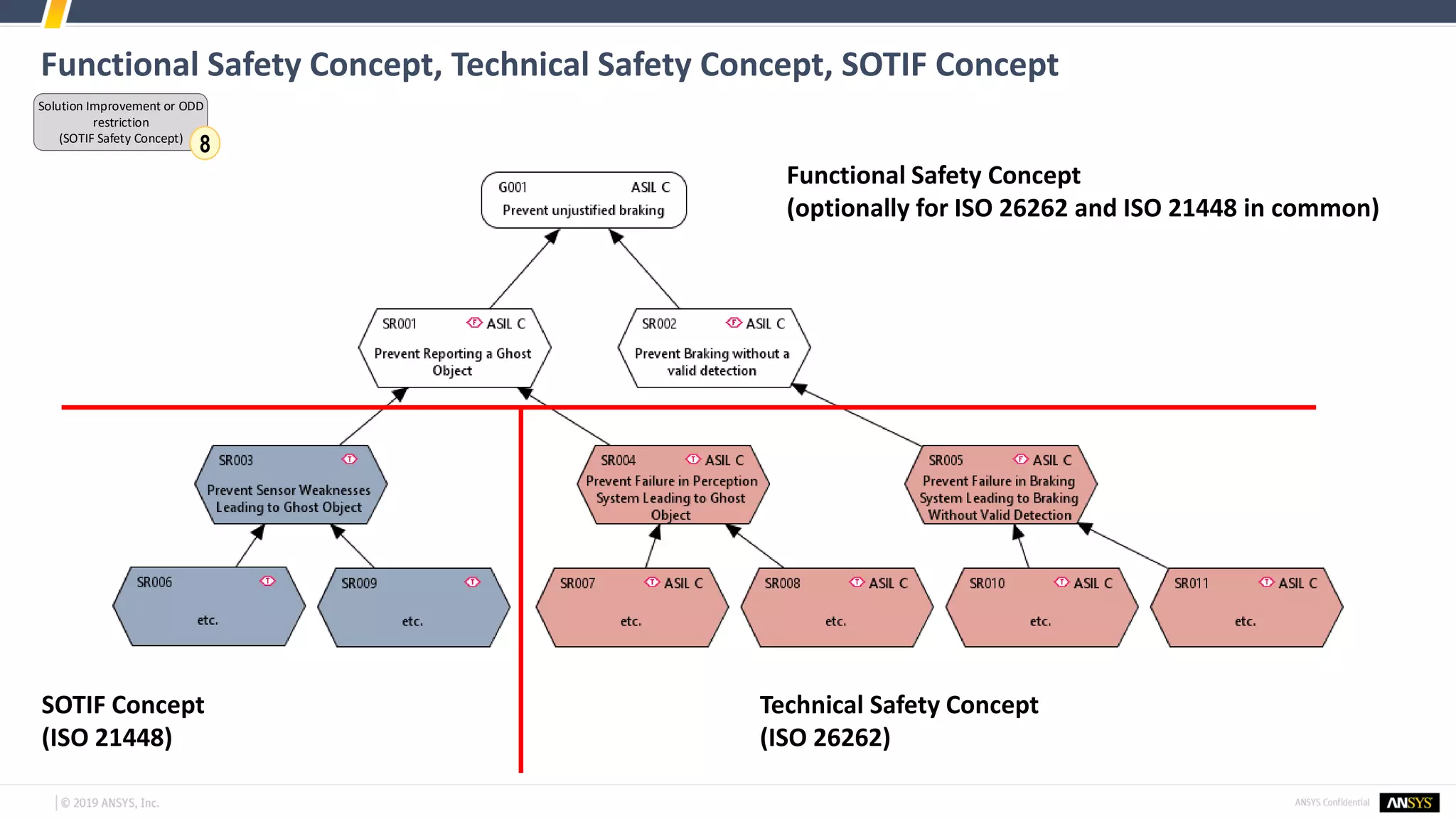

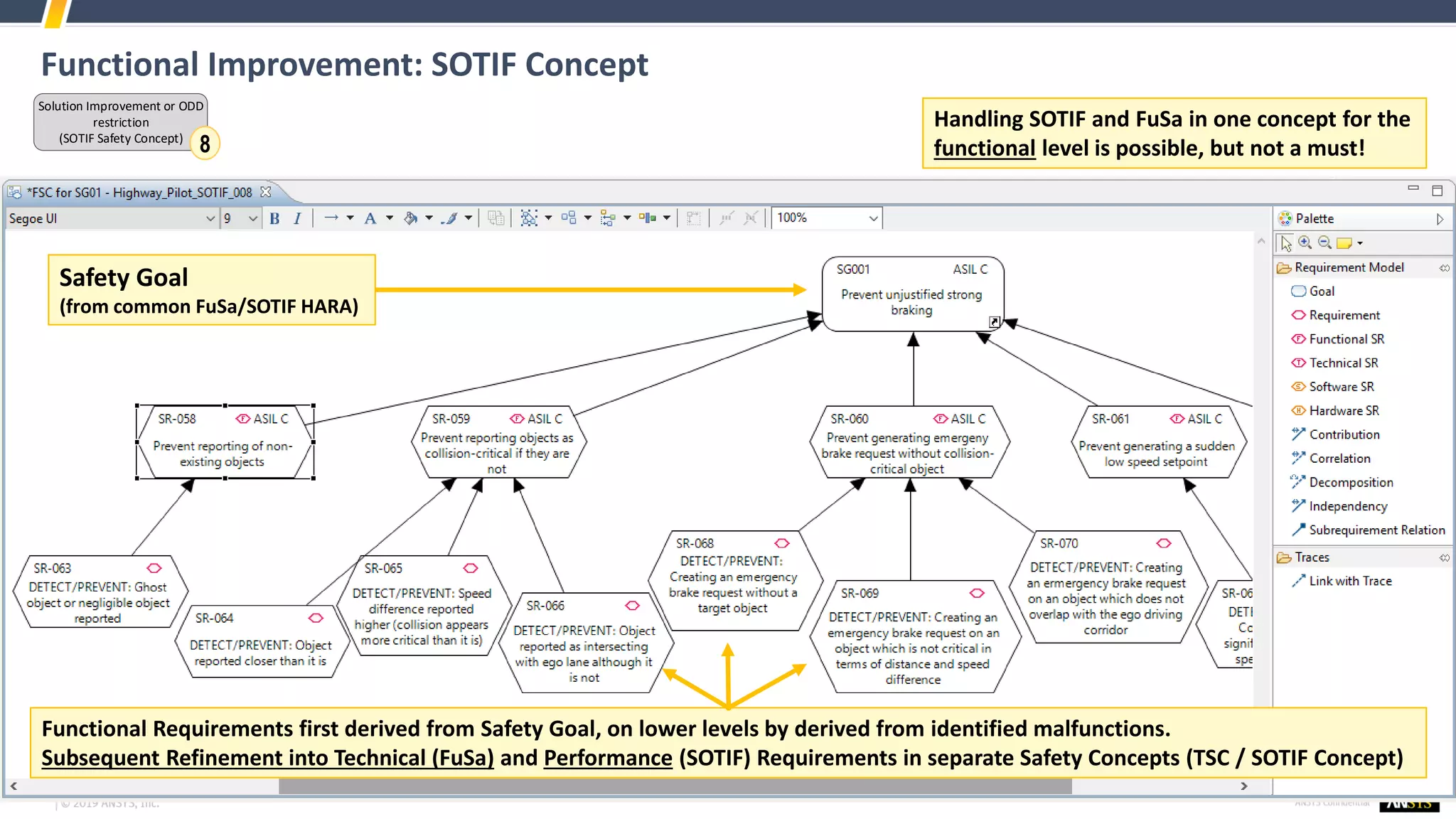

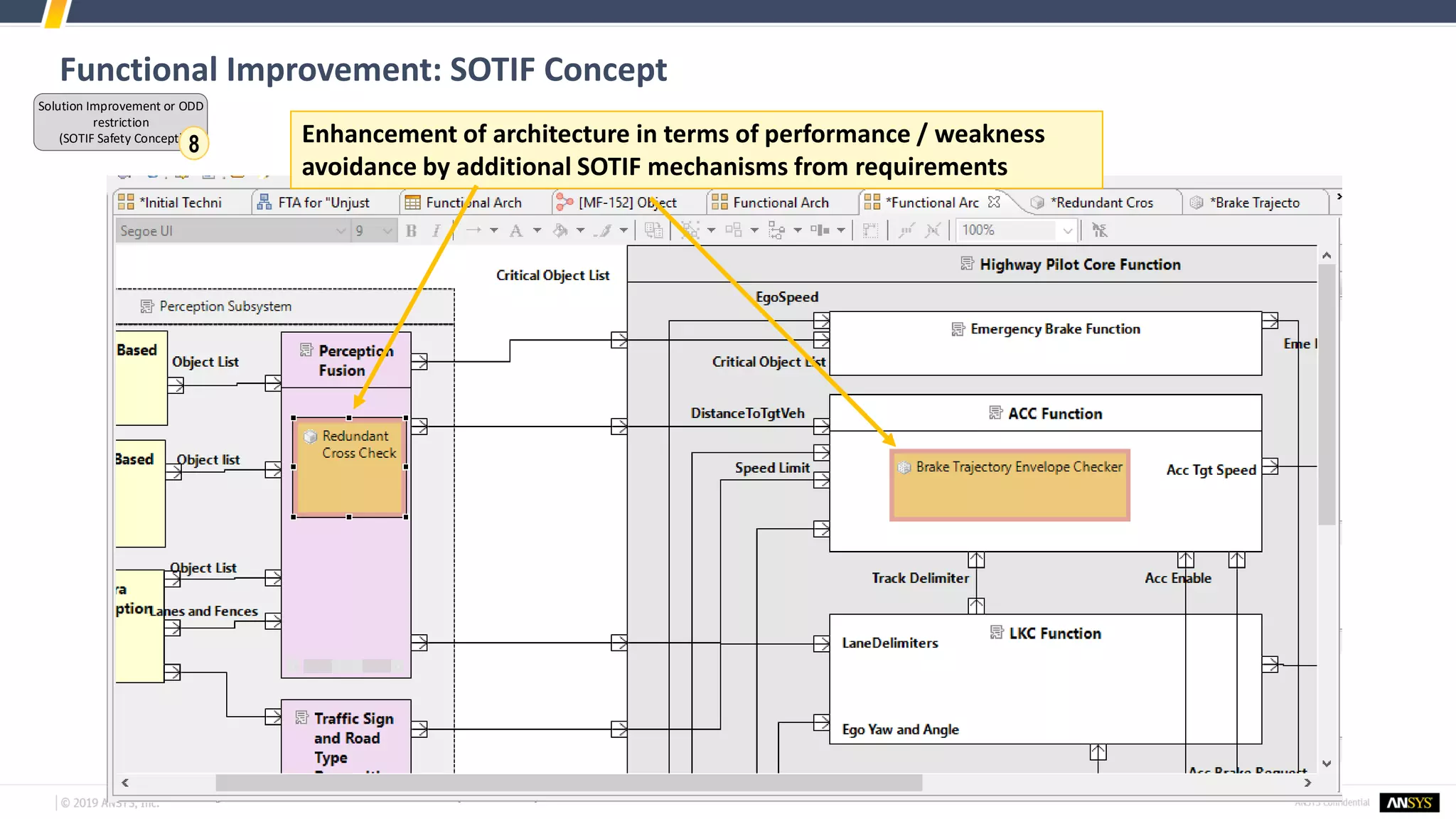

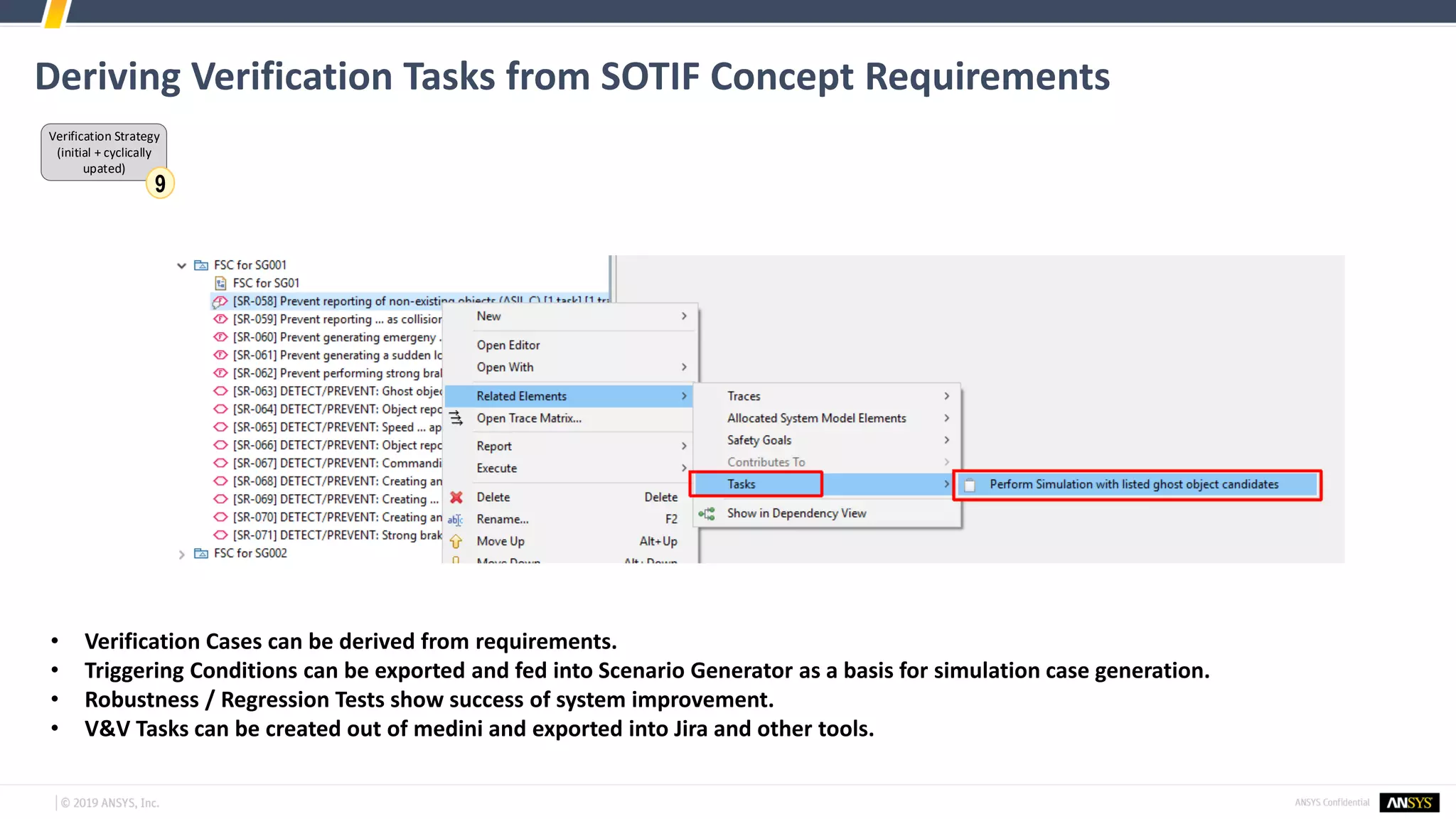

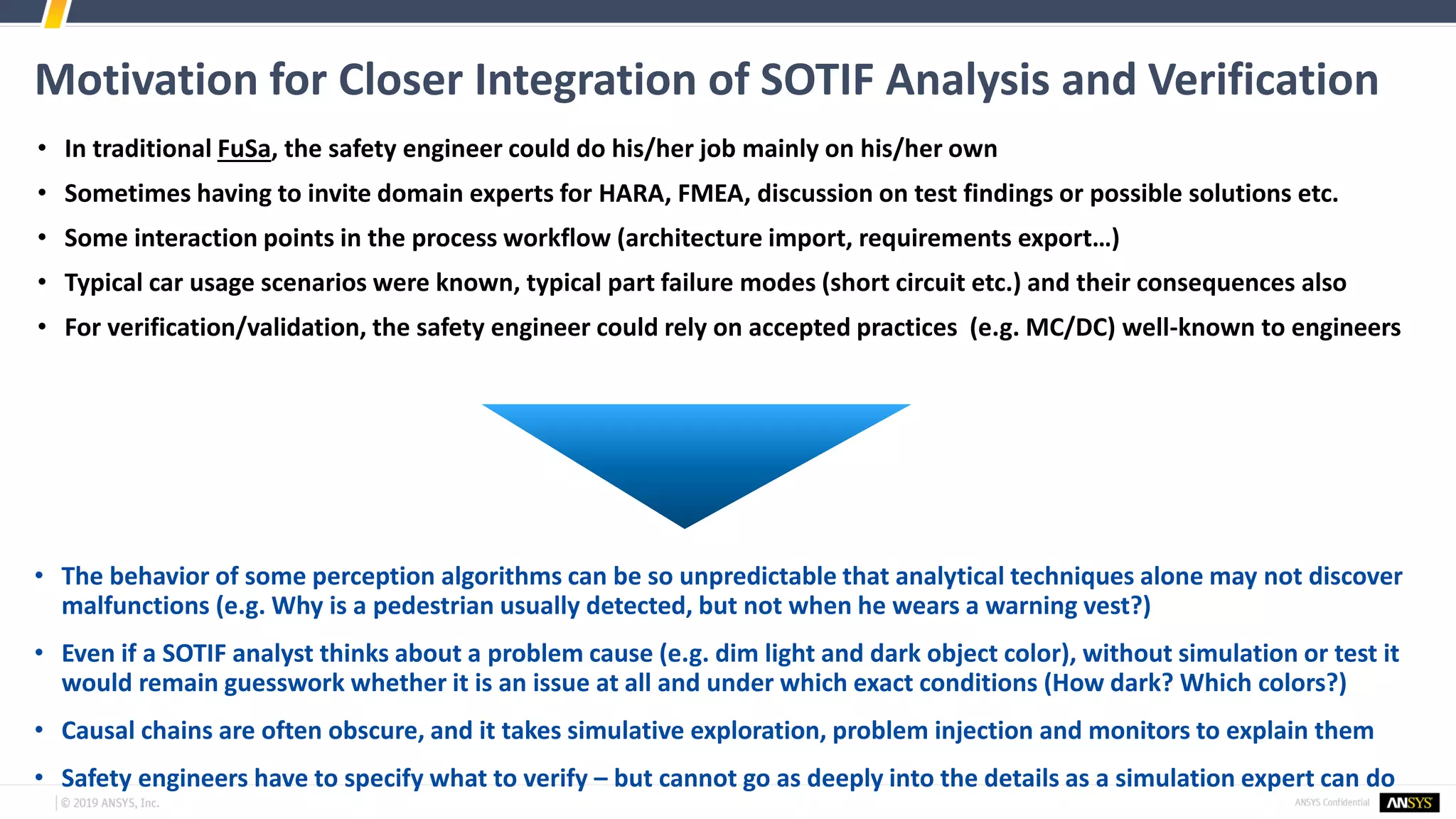

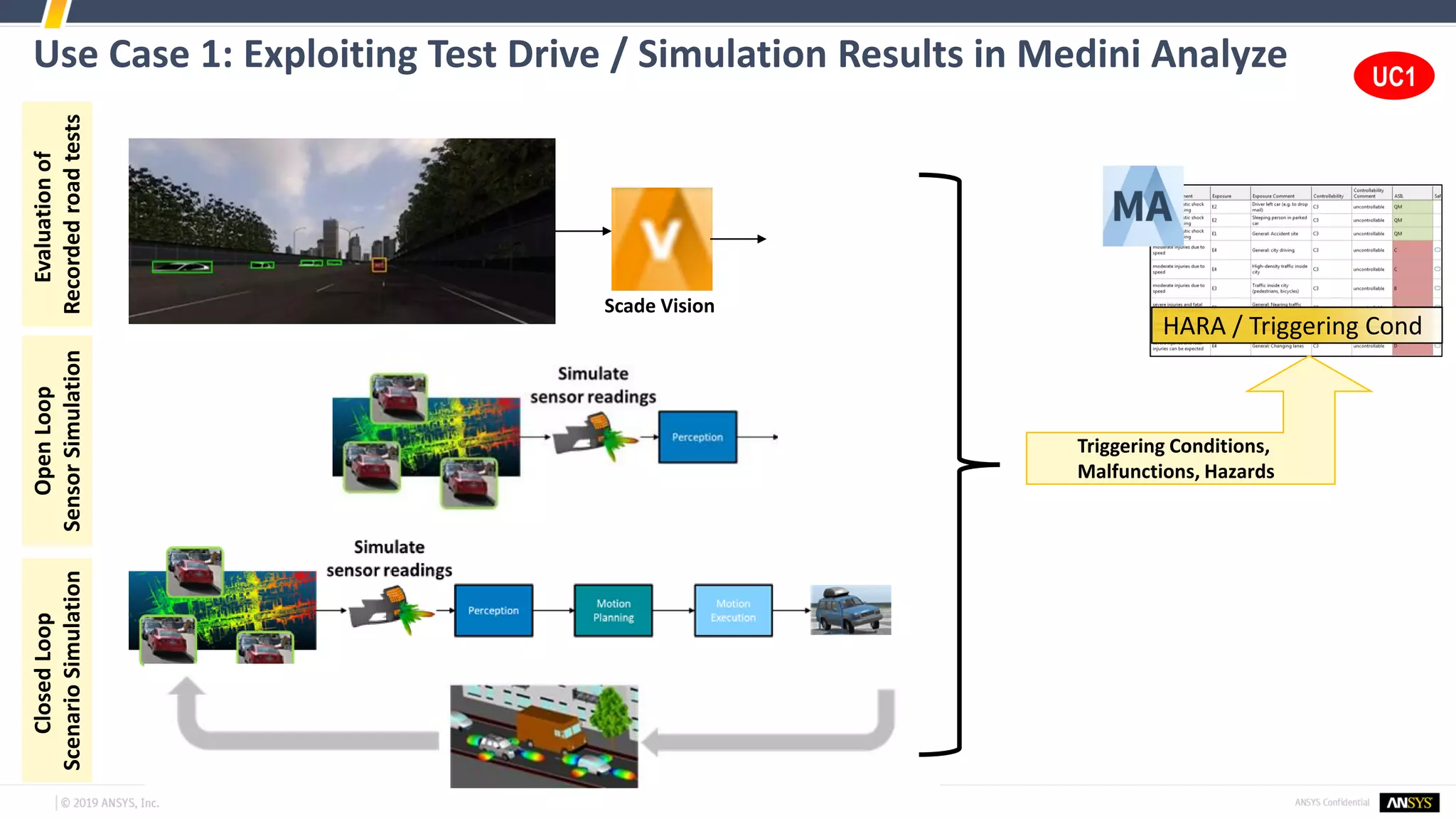

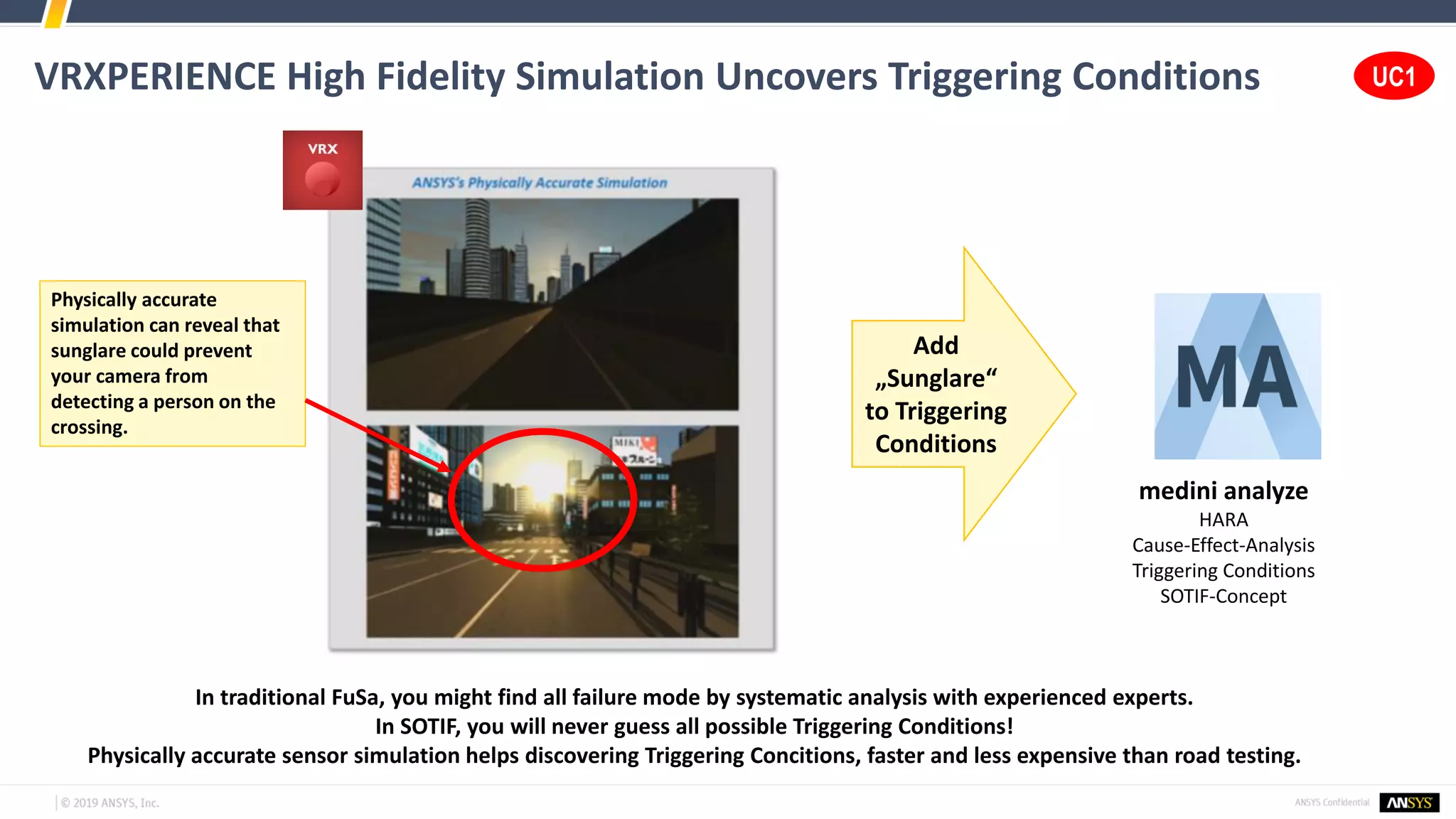

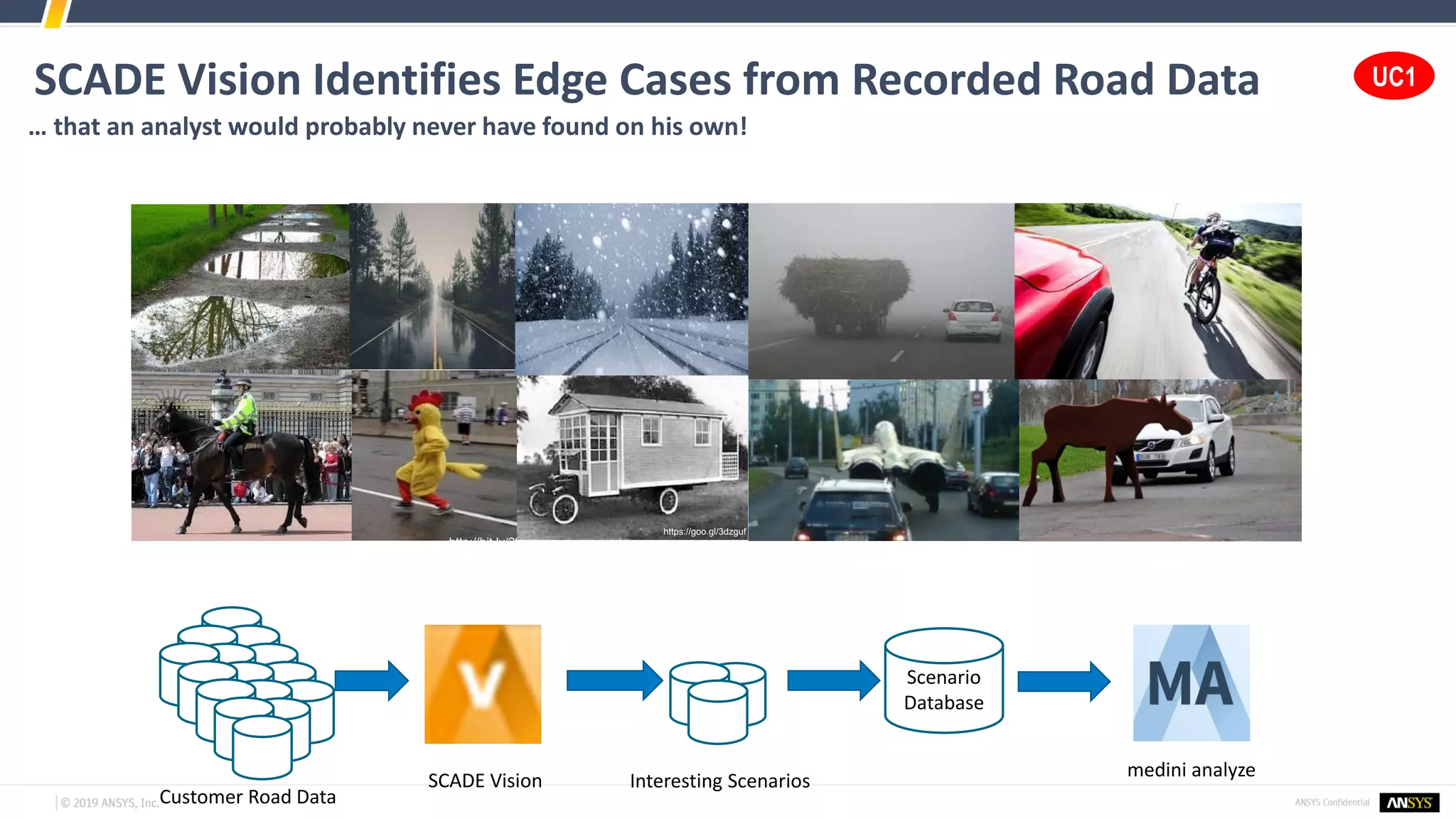

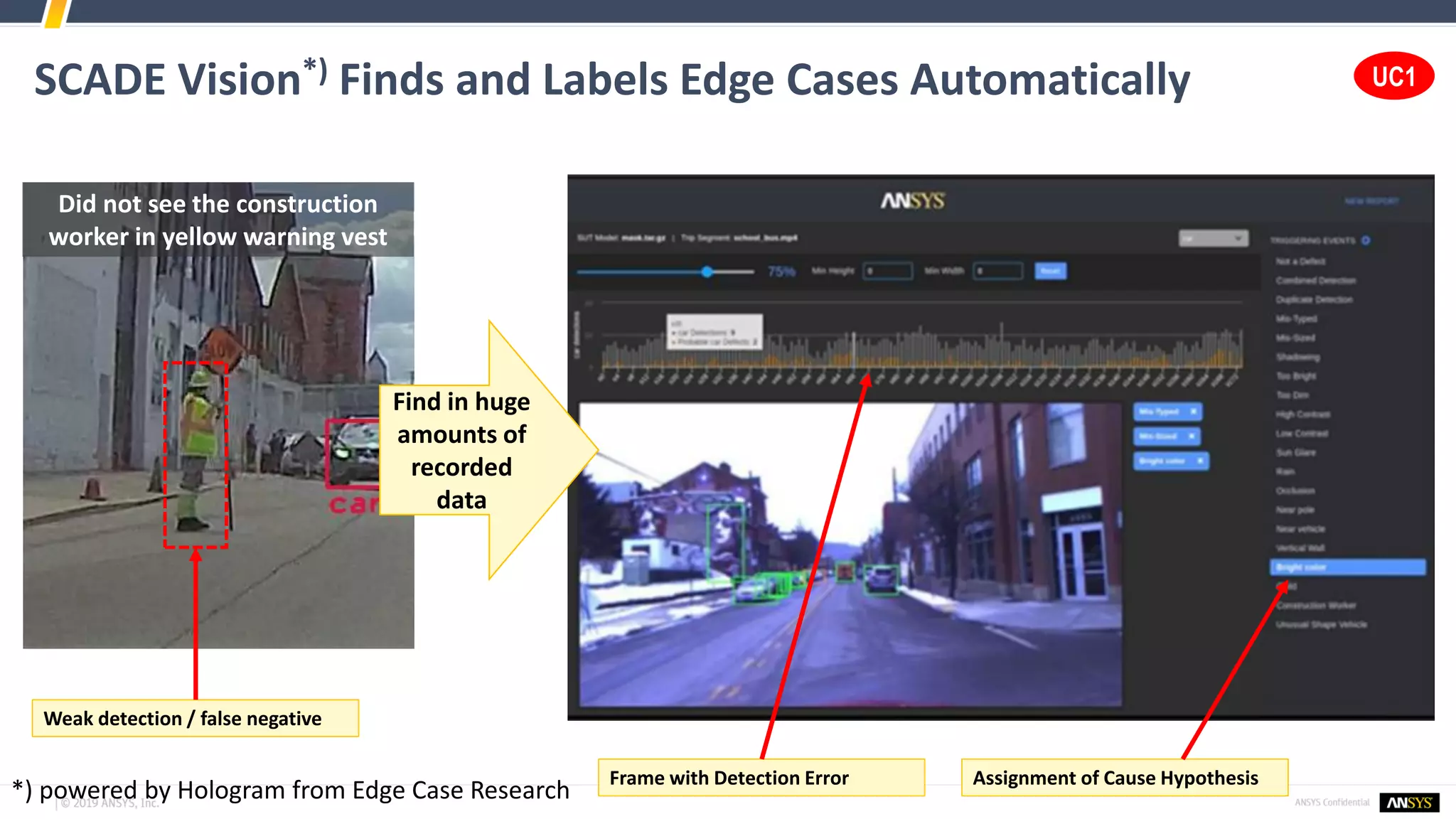

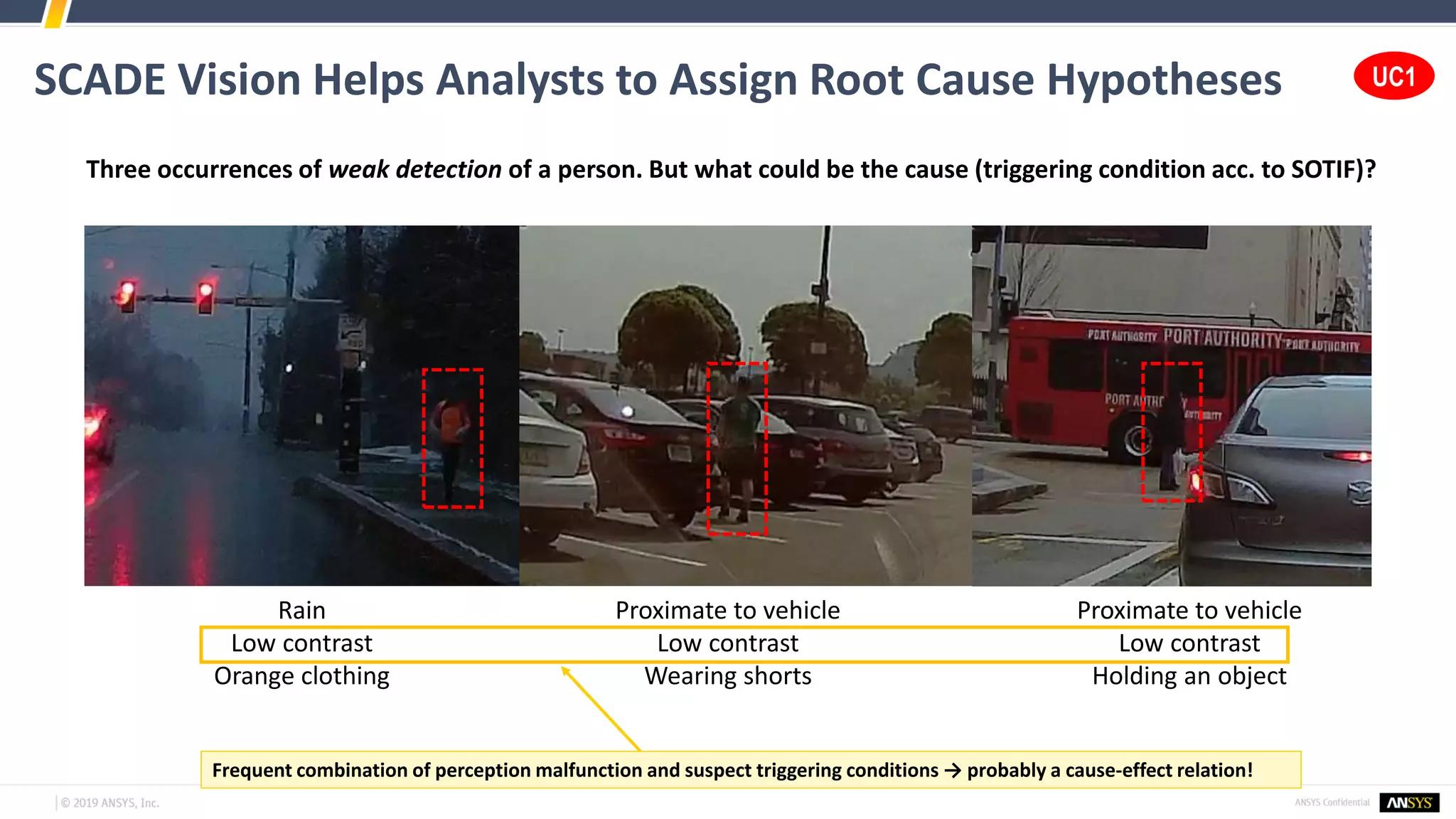

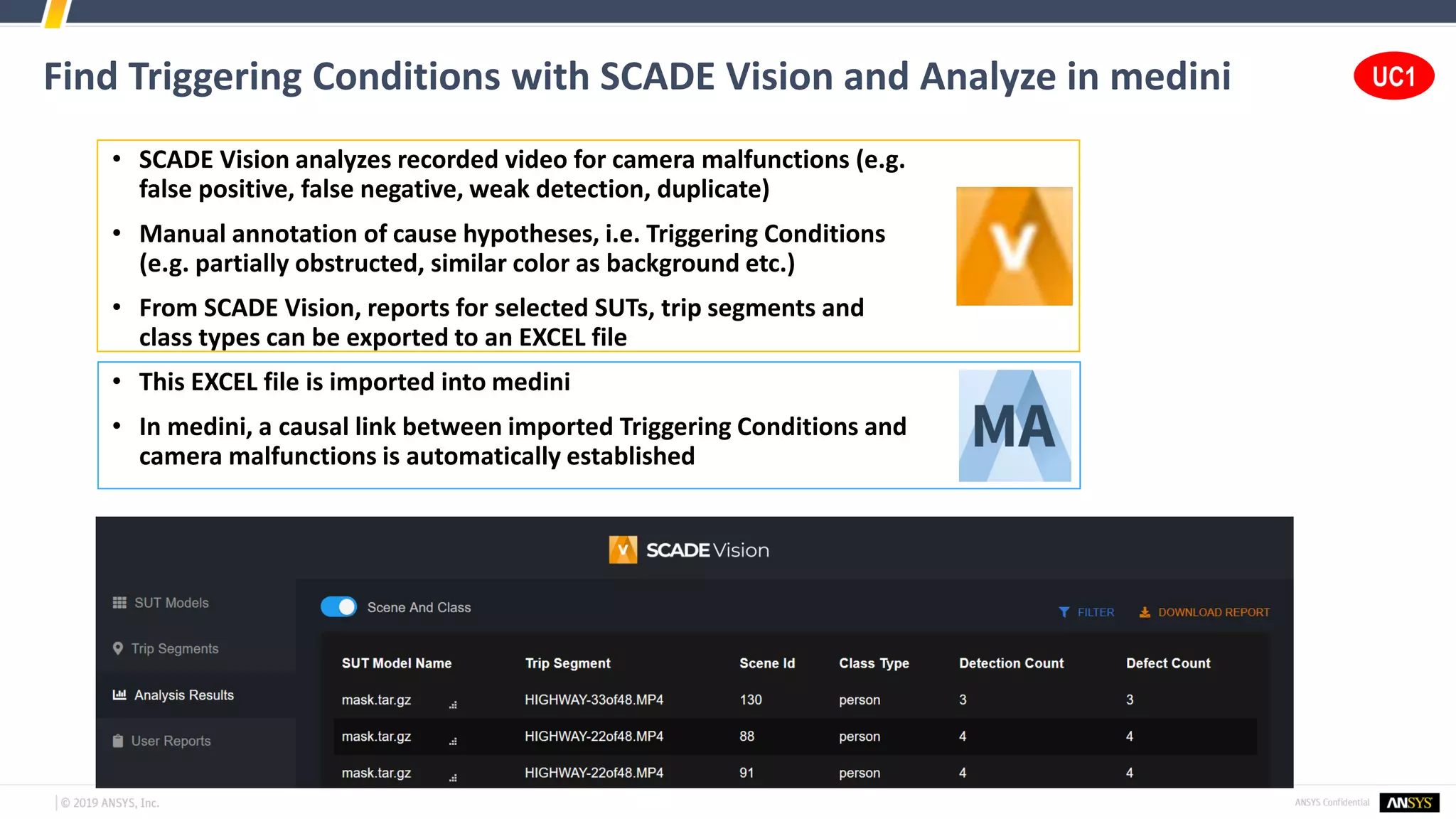

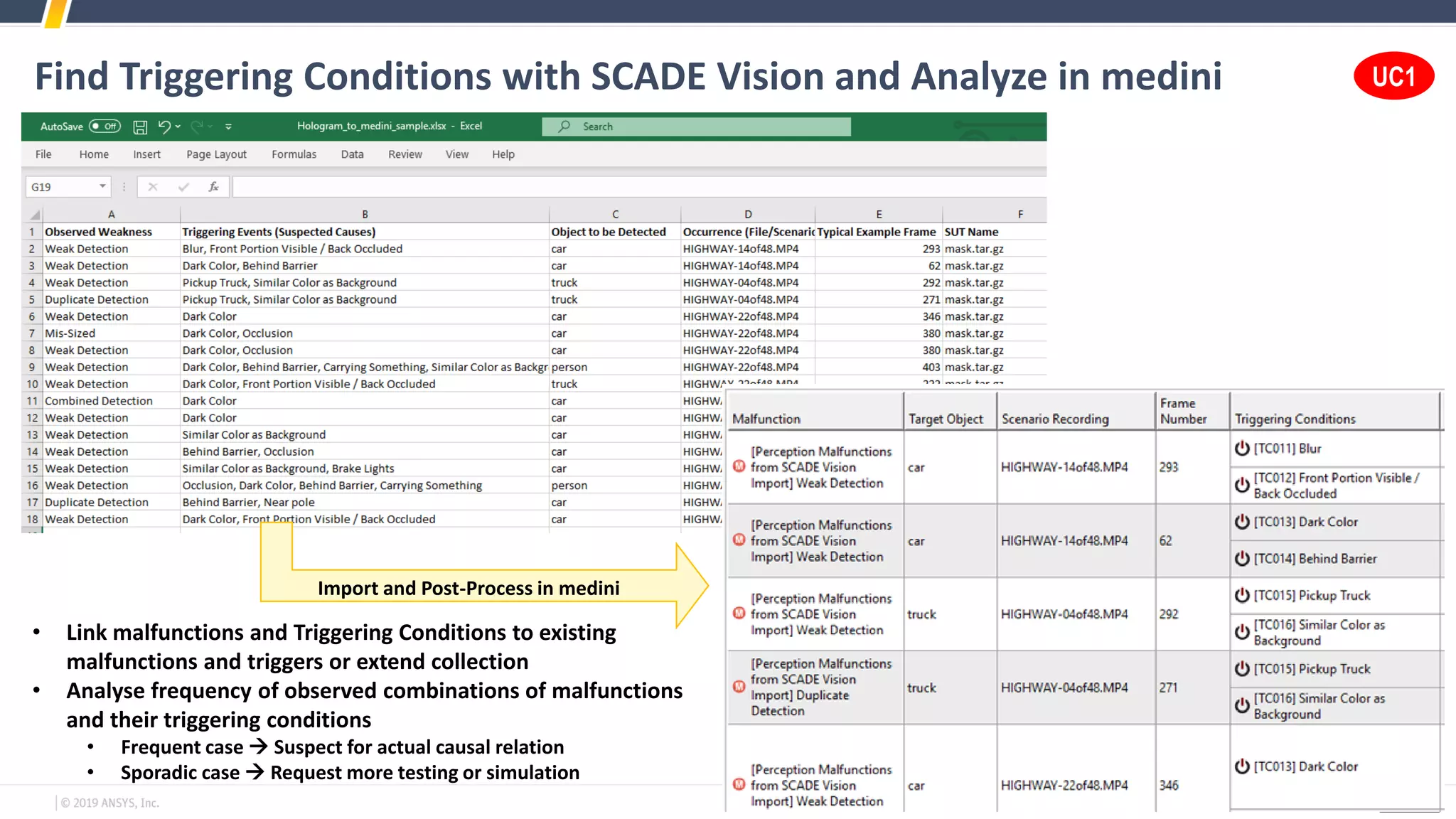

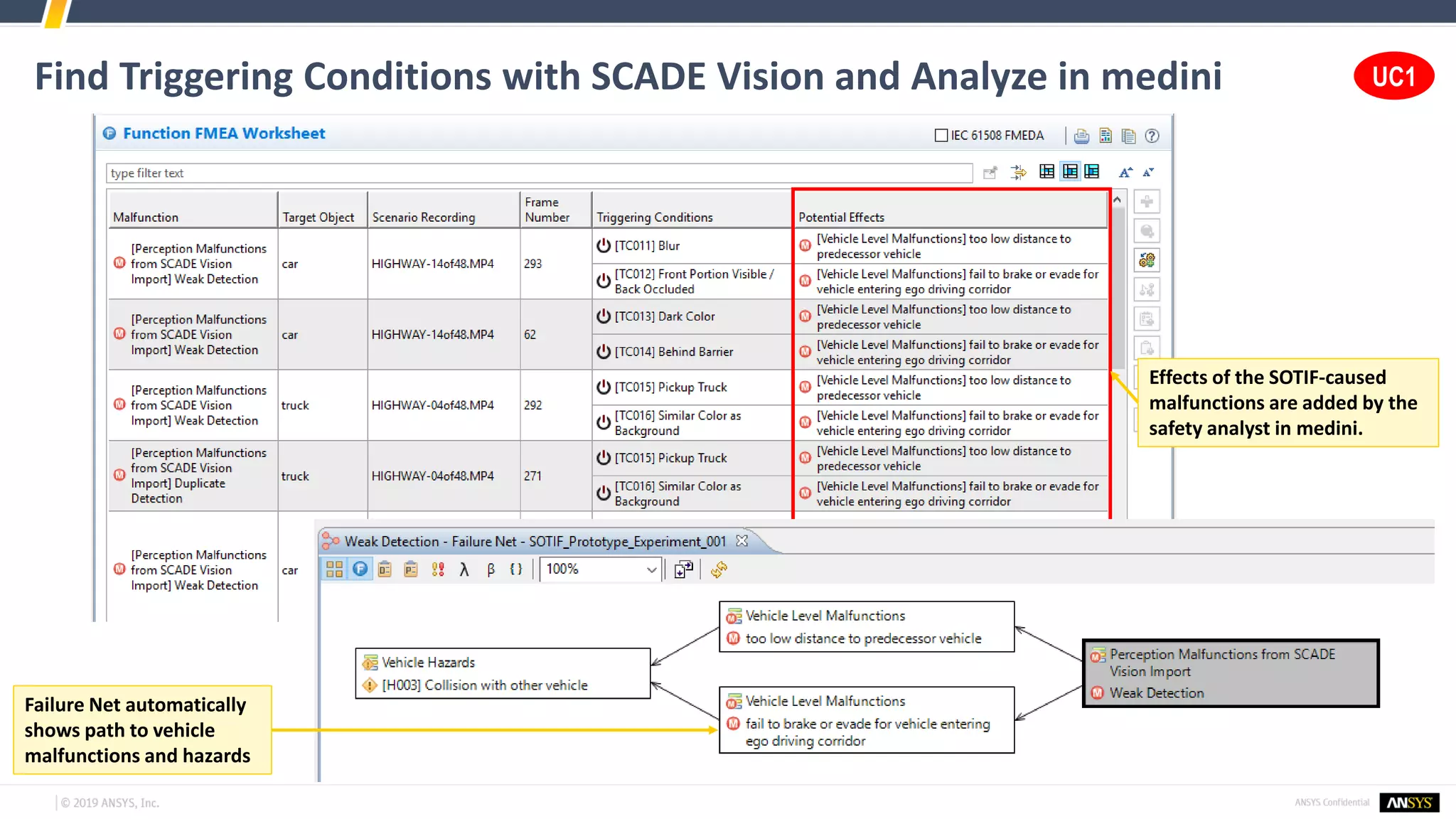

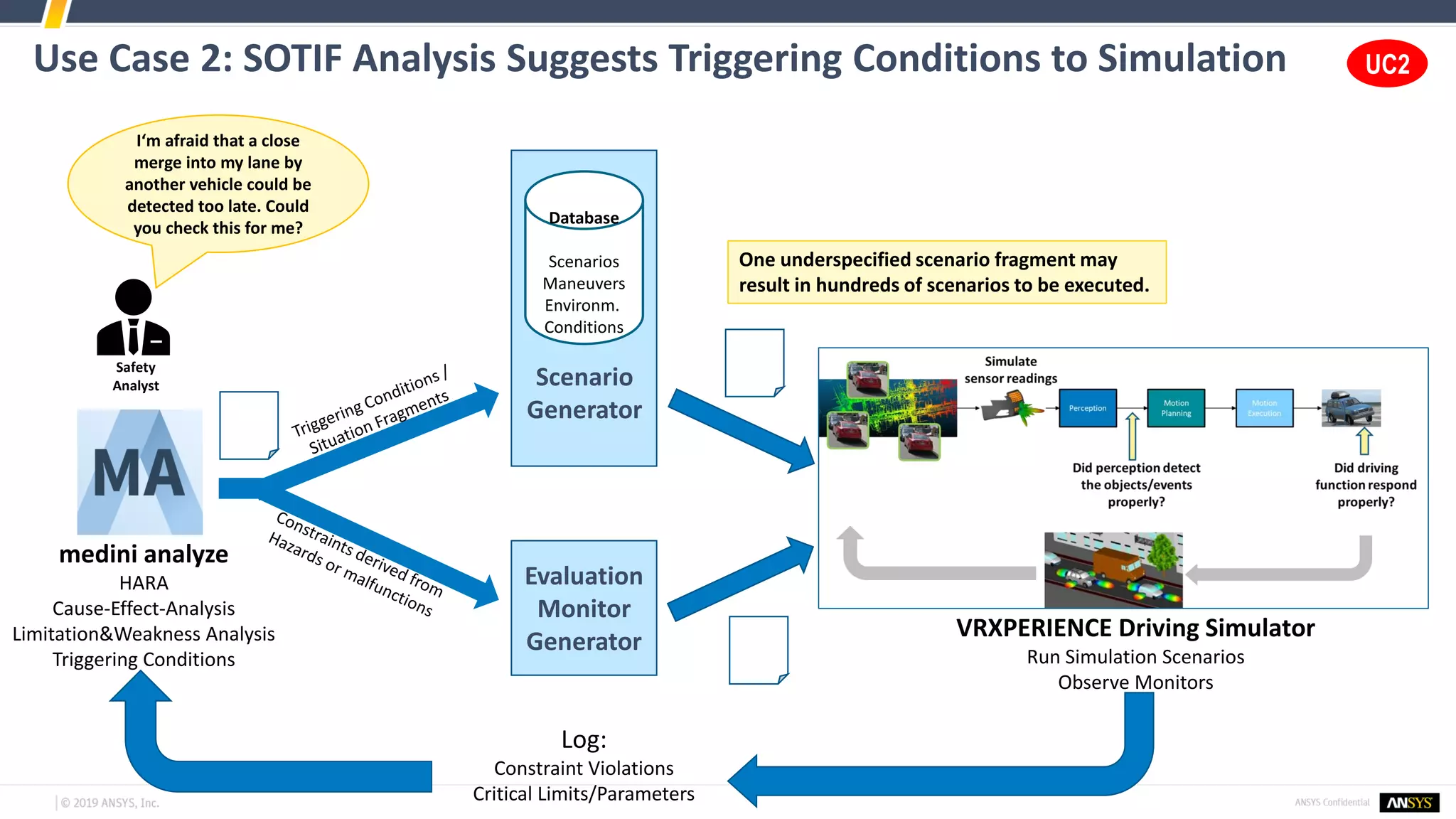

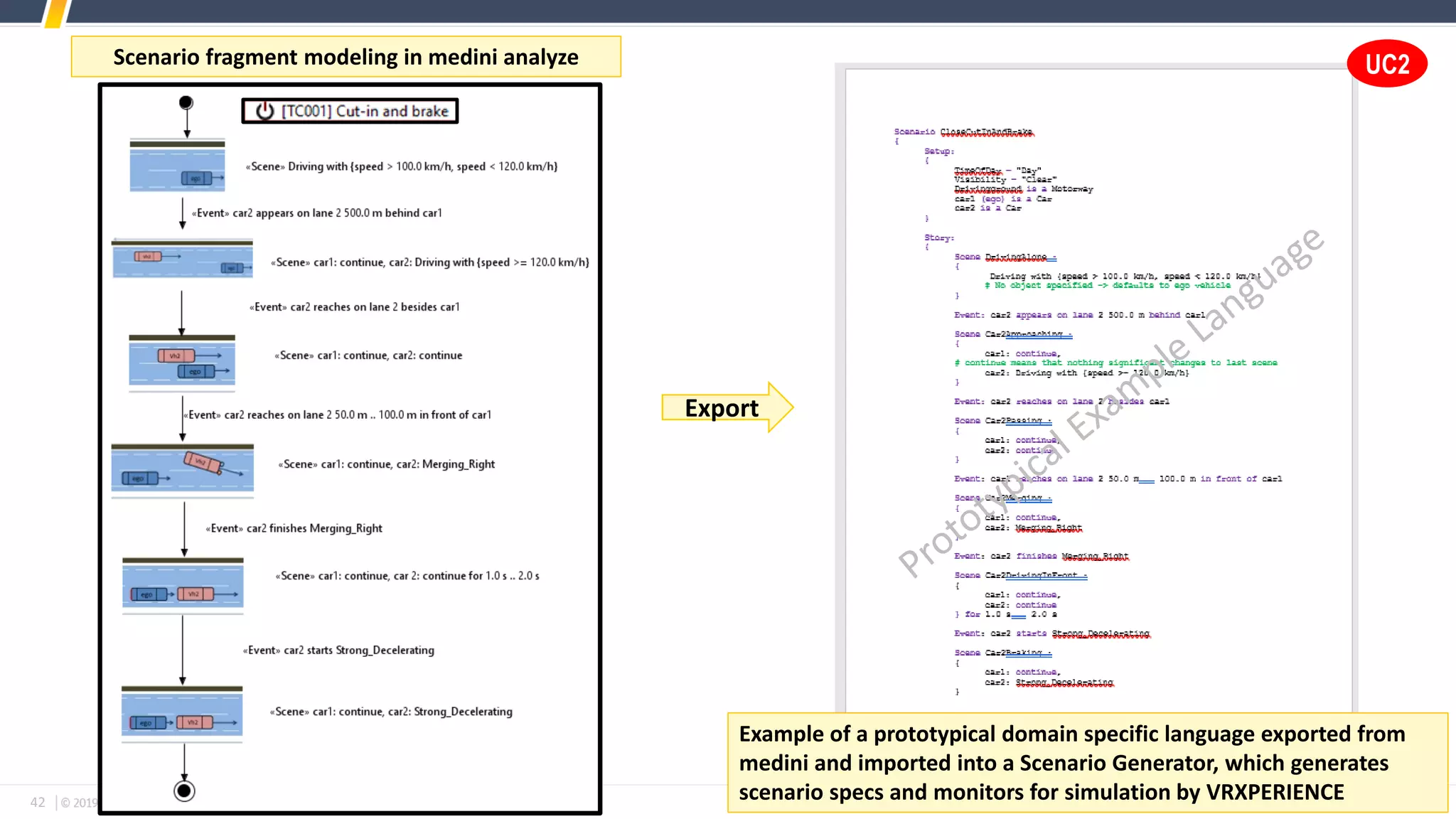

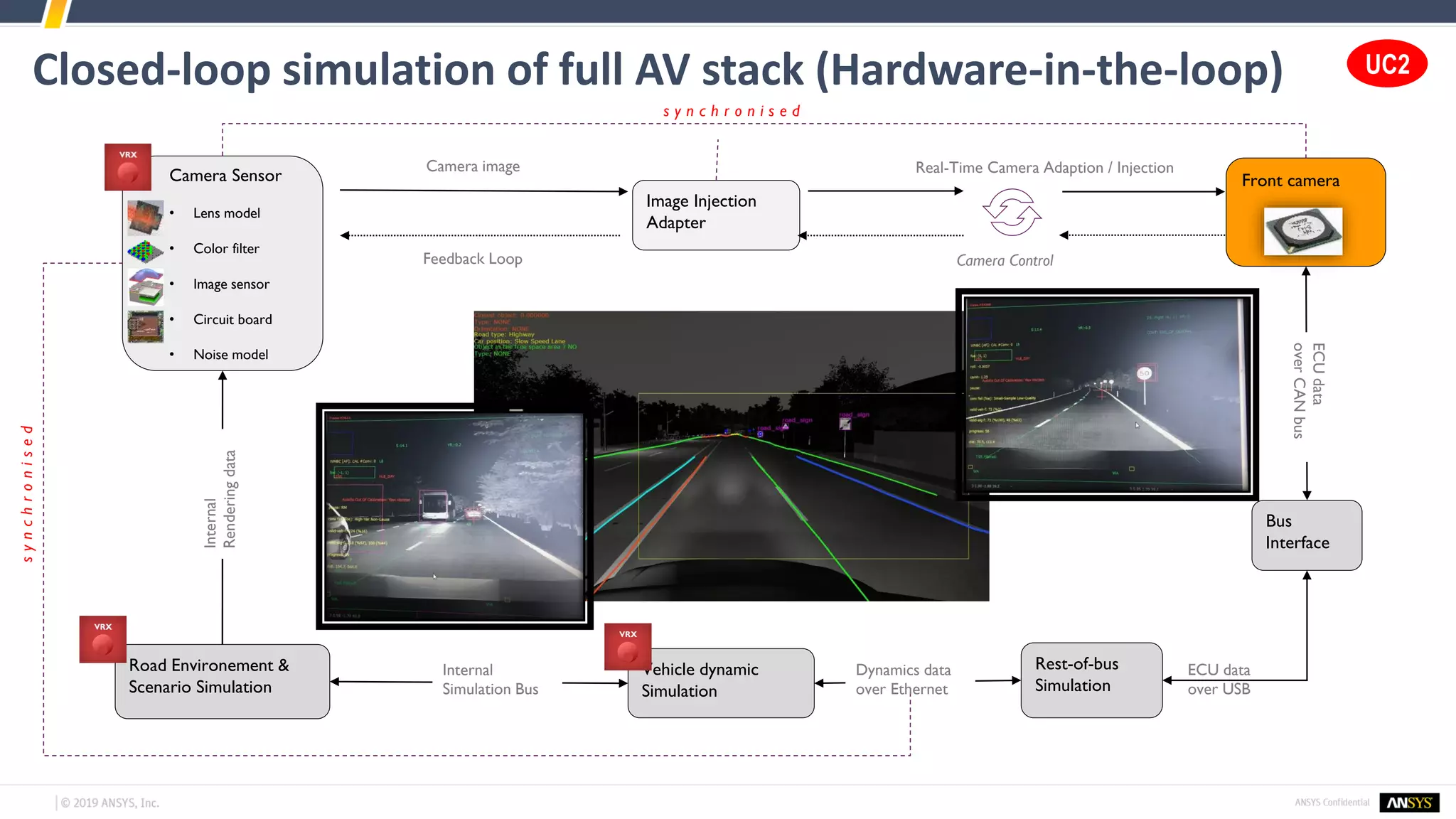

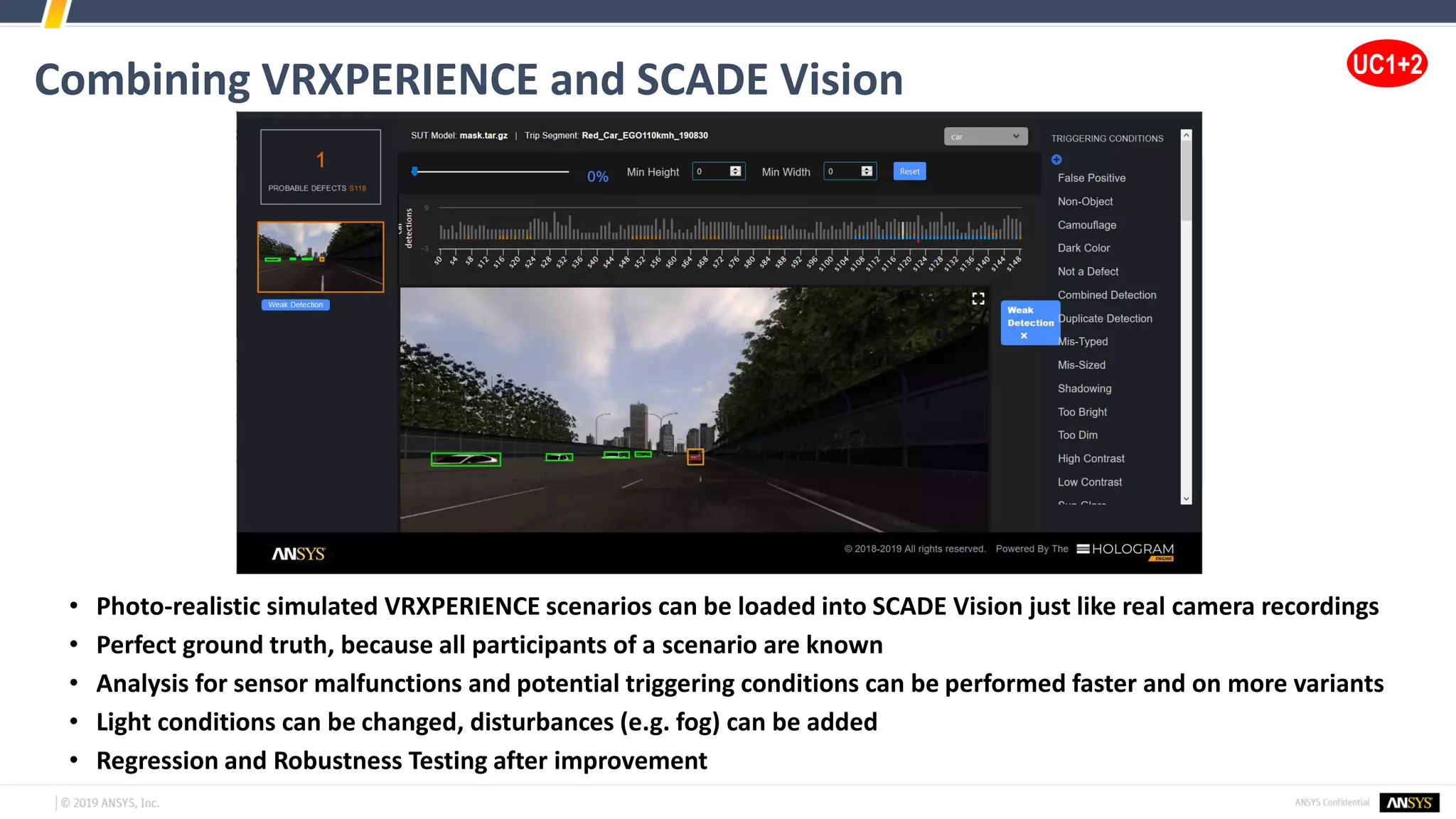

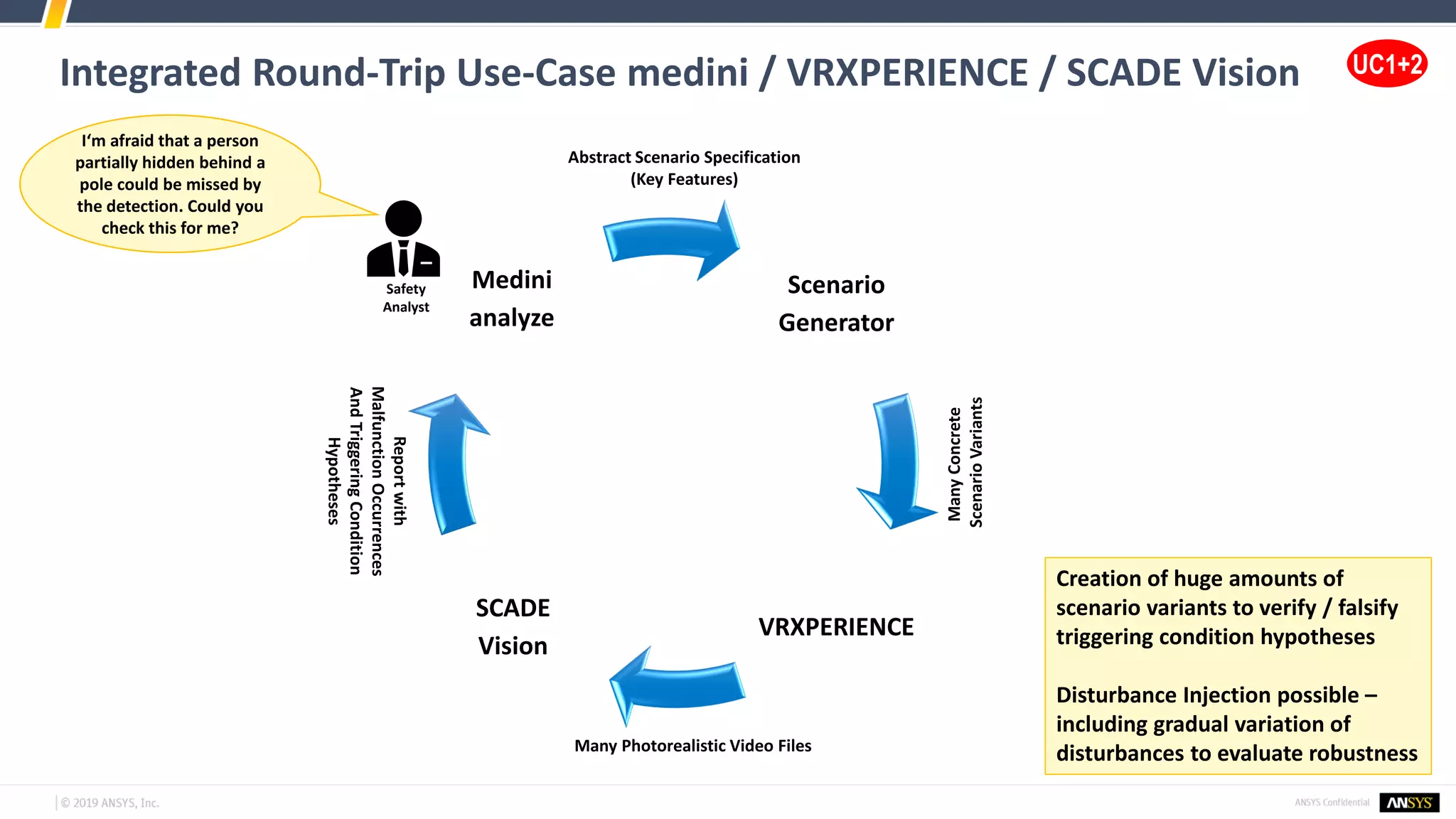

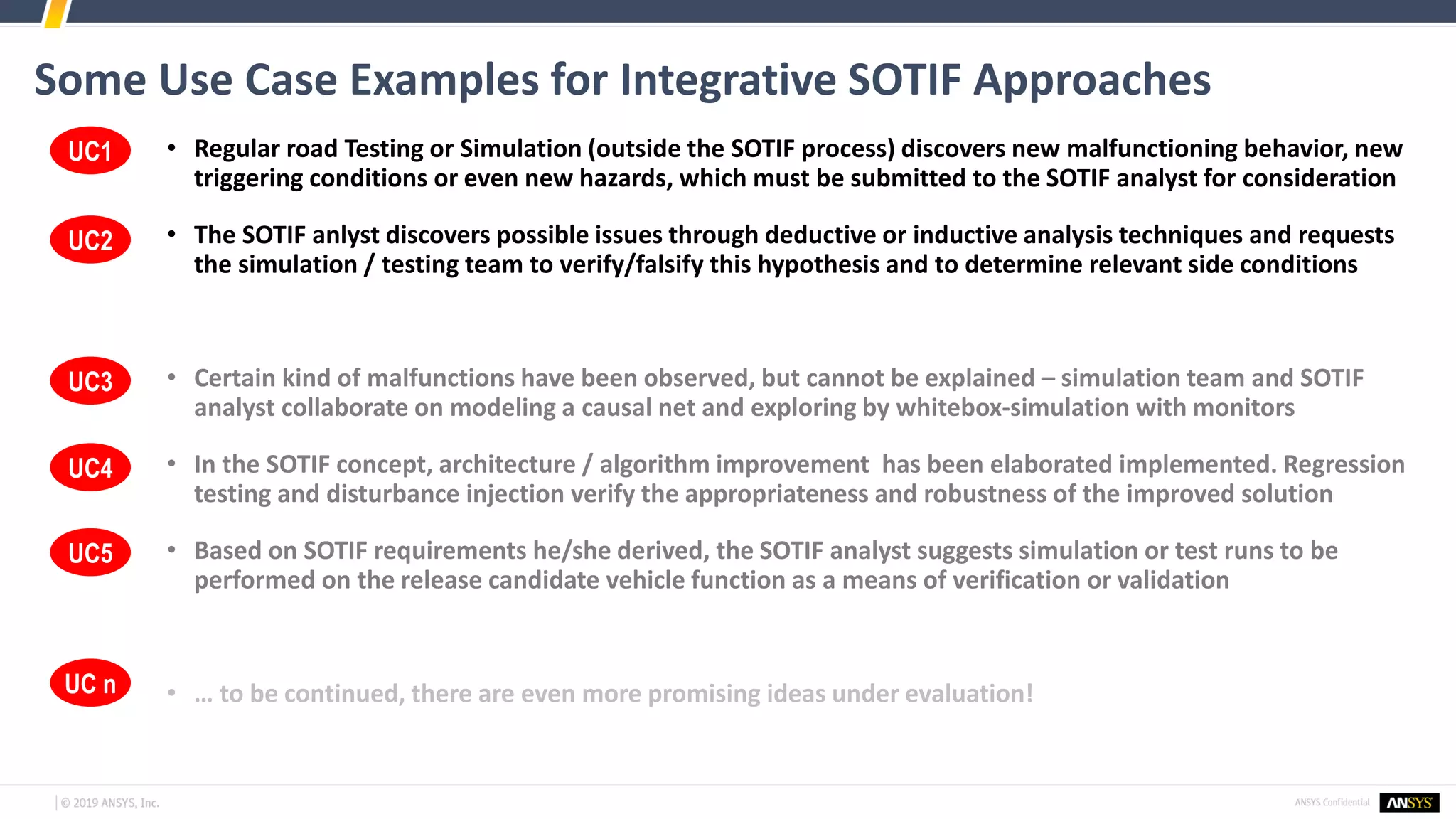

The document discusses the integration of Safety of the Intended Functionality (SOTIF) and Functional Safety (FuSa) for automated vehicles, focusing on the upcoming ISO 21448 standard. It outlines the differences in hazard analysis and safety processes required for both approaches, emphasizing the need for more detailed functional specifications and dynamic risk evaluations. The document also highlights the importance of using simulation tools to identify and analyze triggering conditions that may lead to safety hazards beyond traditional failure modes.