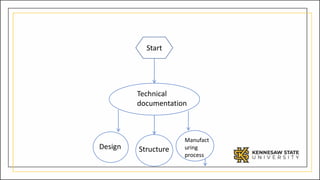

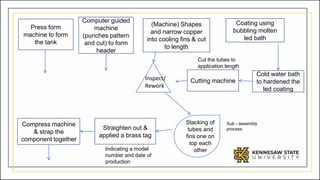

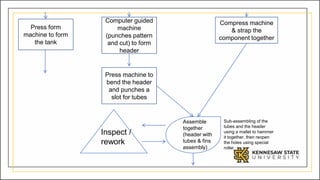

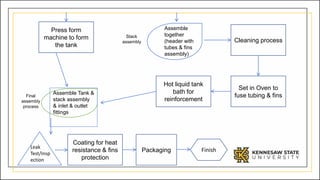

The document provides a flow chart describing the manufacturing process for an automotive radiator. It involves the following key steps:

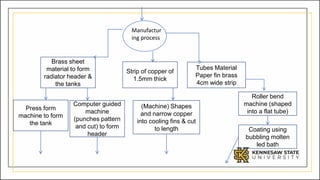

1) Raw materials like copper strips and brass sheets are used.

2) Machines shape the copper into cooling fins and cut them to length. Another machine punches a pattern into brass to form the radiator header.

3) Components like the header and tank are assembled, coated, and tested before final assembly and packaging of the completed radiator.