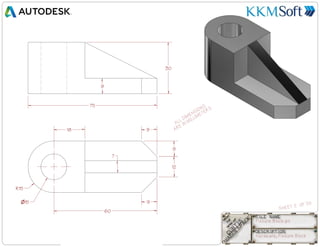

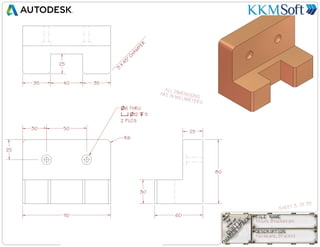

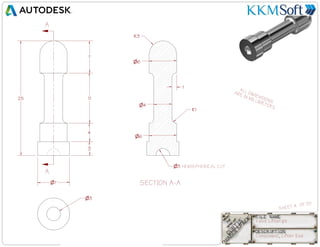

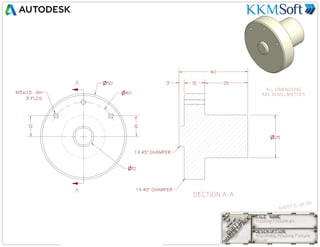

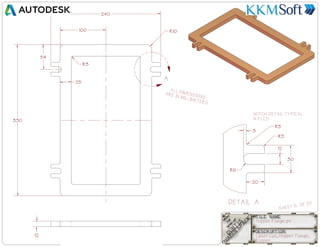

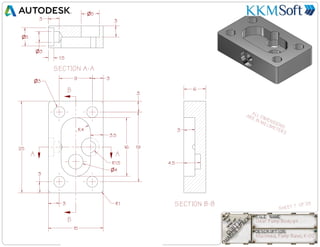

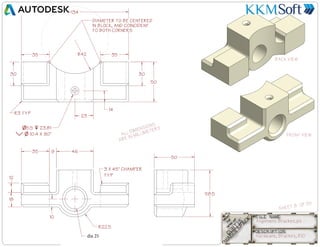

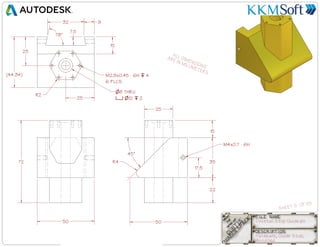

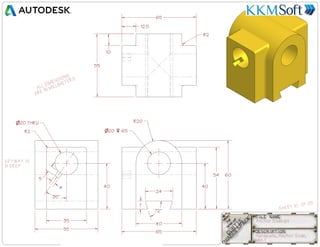

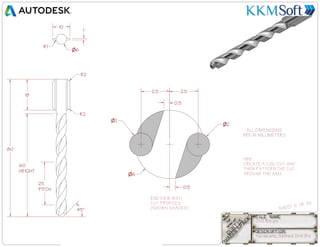

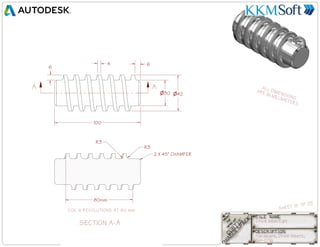

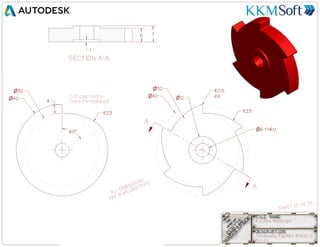

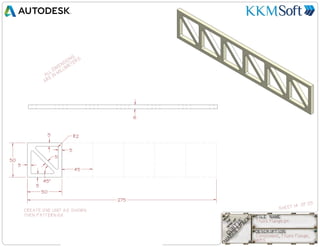

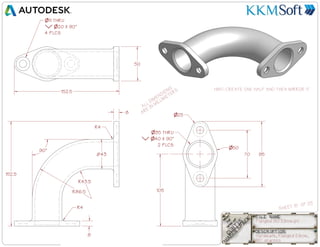

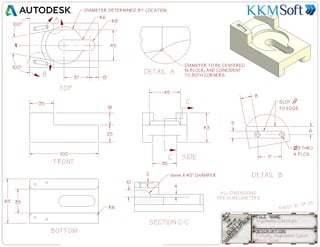

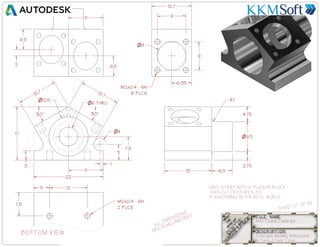

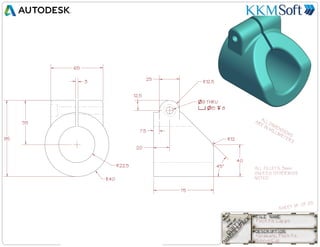

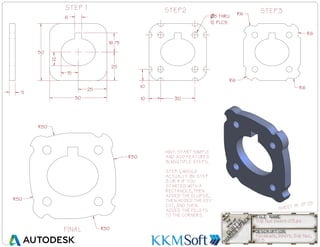

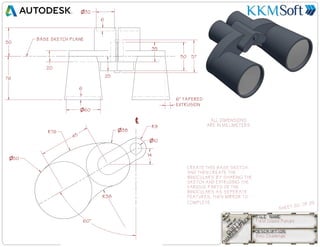

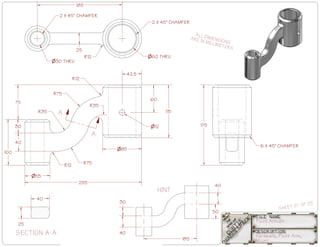

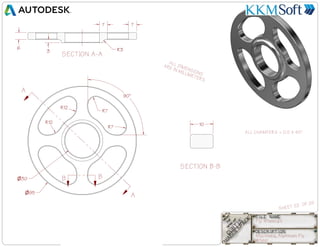

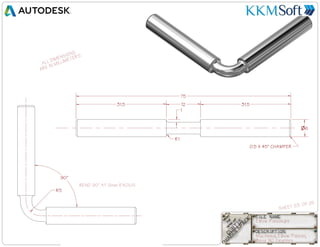

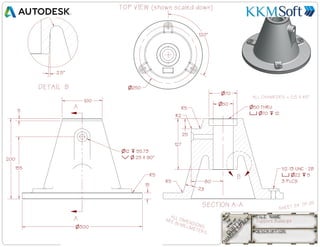

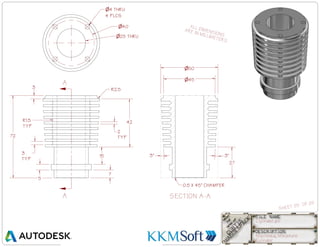

This document contains 25 detailed drawings of miscellaneous mechanical parts for practice modeling in Autodesk Inventor or other 3D CAD software. The parts range in complexity and some hints are provided for specific features. While dimensions may be missing, the goal is for students to practice their modeling skills rather than reproduce the parts exactly. Students should build the parts by creating simple sketches and additive features.