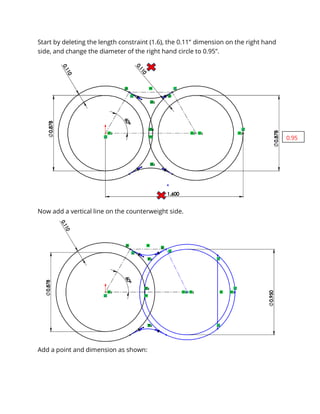

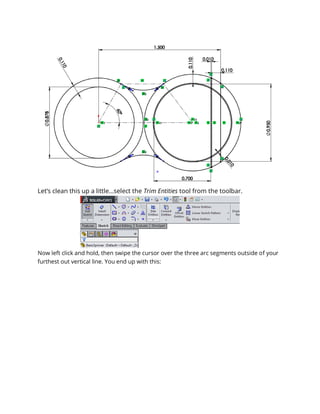

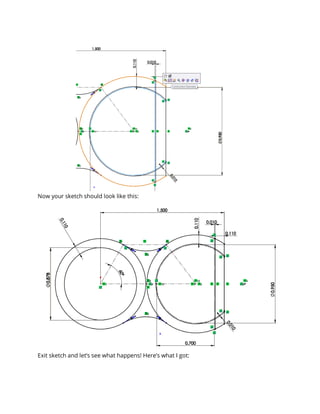

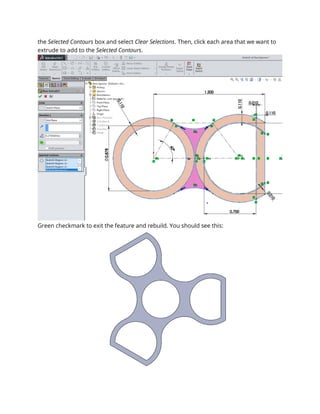

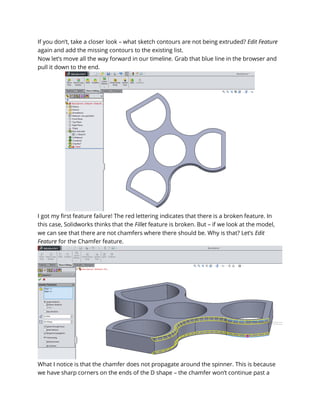

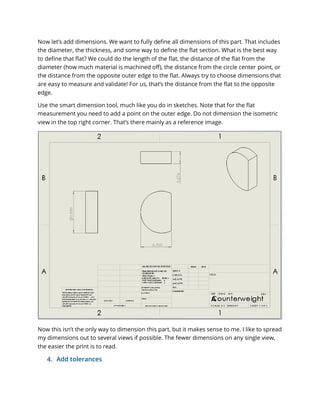

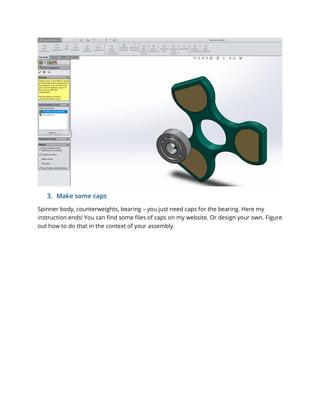

This document is a tutorial on designing a spinner using SolidWorks, detailing the steps for modeling, creating counterweights, and customizing the spinner. It includes instructions on sketching, navigating the software interface, and applying features like extrude, pattern, and refine edges. The tutorial was prepared for a summer camp and is licensed under Creative Commons, allowing users to adapt it for their needs with proper attribution.