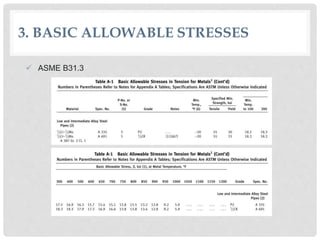

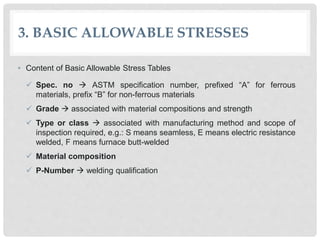

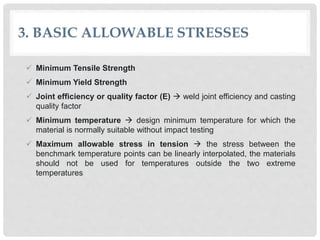

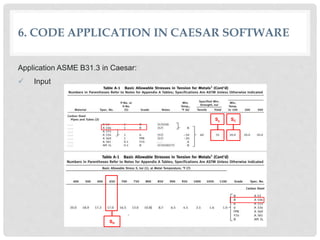

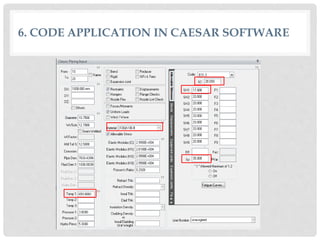

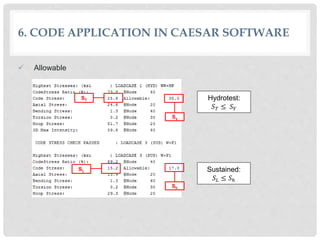

The document summarizes key requirements from piping codes regarding pipe stress analysis. It covers loadings to consider like pressure, temperature, weight; allowable stresses; pressure design of components like straight pipes and bends; stresses from sustained, occasional, and thermal loads; and applying codes in Caesar software. The main objective of piping codes is to ensure structural integrity by satisfying minimum material, design, and safety requirements.