- The Metric Handbook provides guidance on notation, drawing office practice, and dimensional coordination when using metric units.

- It outlines conventions for decimal markers, symbols, notation, and other drafting standards to ensure clear understanding.

- Dimensional coordination is important, with components generally expressed in consistent units, and distinctions made between metric and imperial units of measurement.

![2-6 Basic design data

2.8 a Computer workstation

5

4

3

2

1

character

height

(mm)

200 400 600 800 1000 1200

viewing distance (mm)

b Viewing distance

surface is the top of the keyboard) are available 30 mm lower.

Chairs for sitting workers are now by legislation required to

provide for vertical adjustment so that each individual can find the

right relationship with the worktop. However, it is important that

the feet remain in contact with the ground, and where this is not

possible, footrests should be provided.

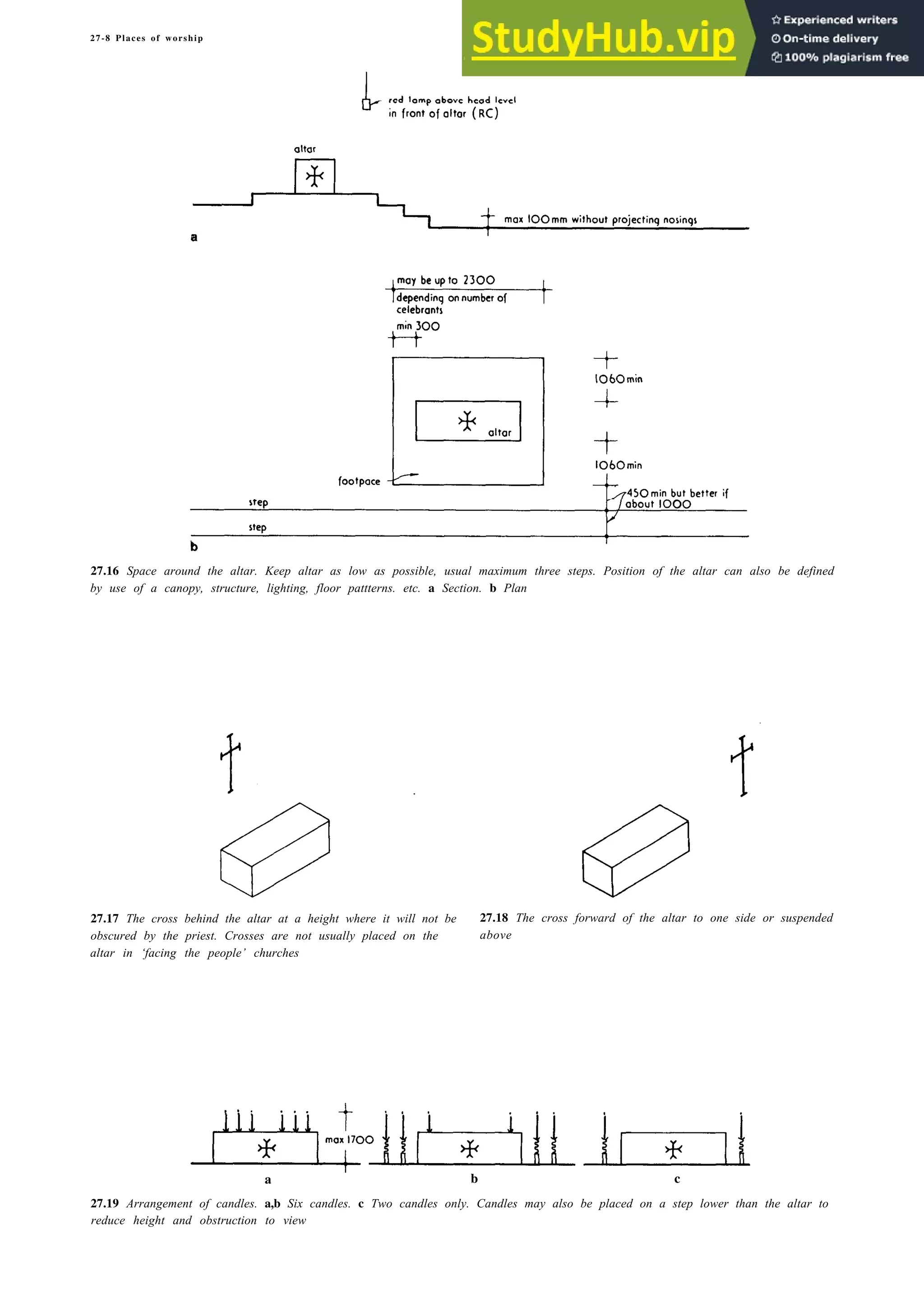

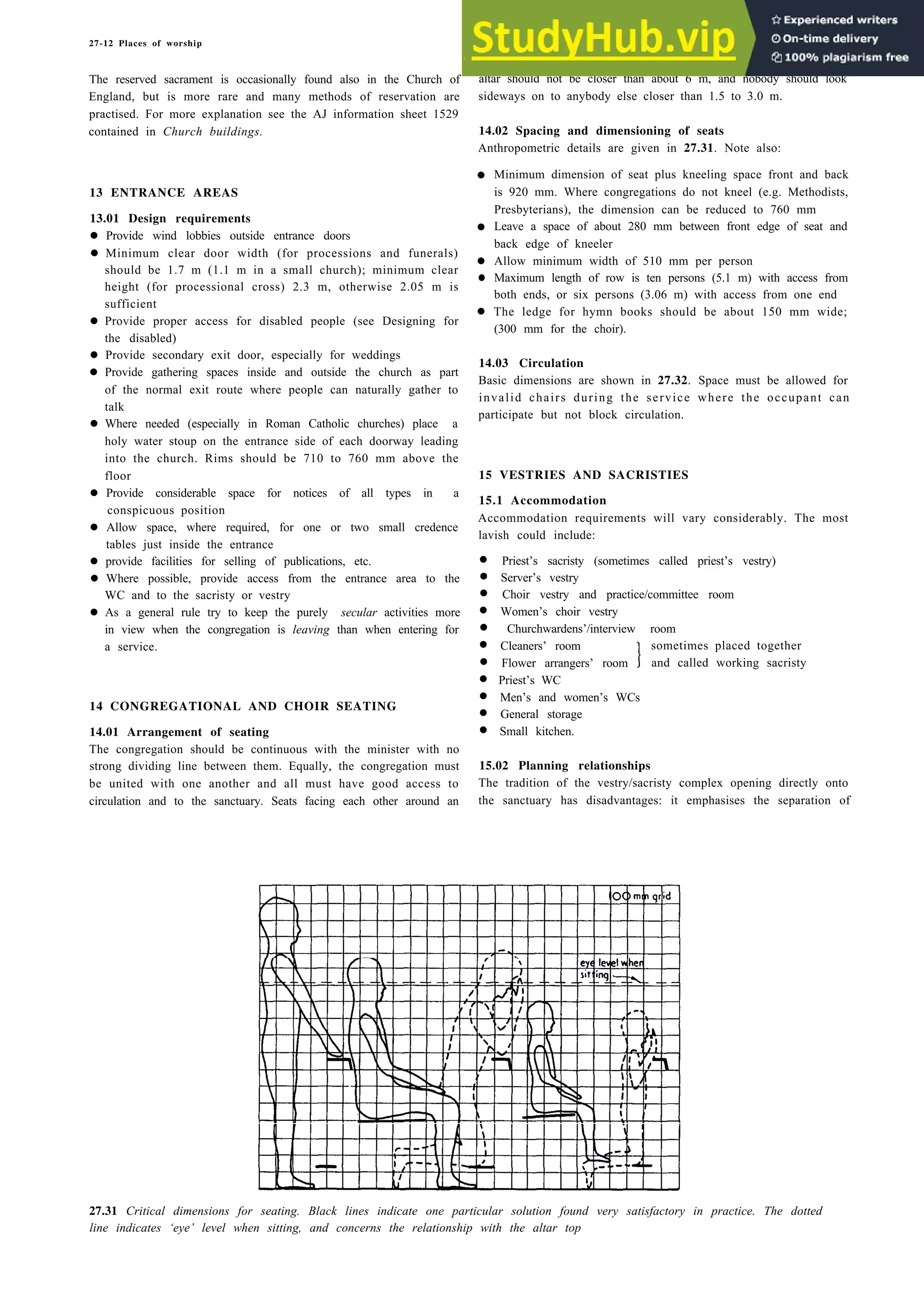

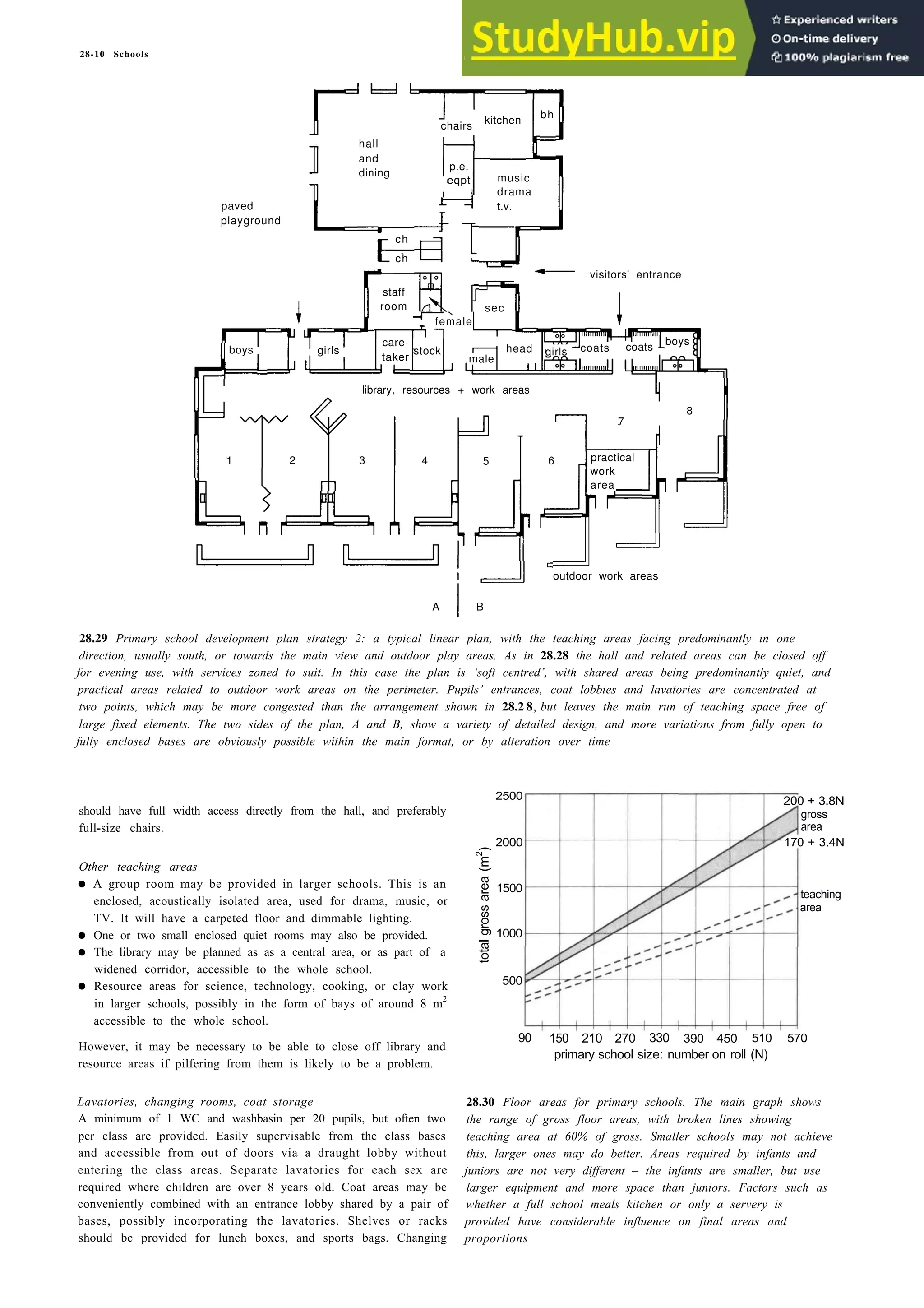

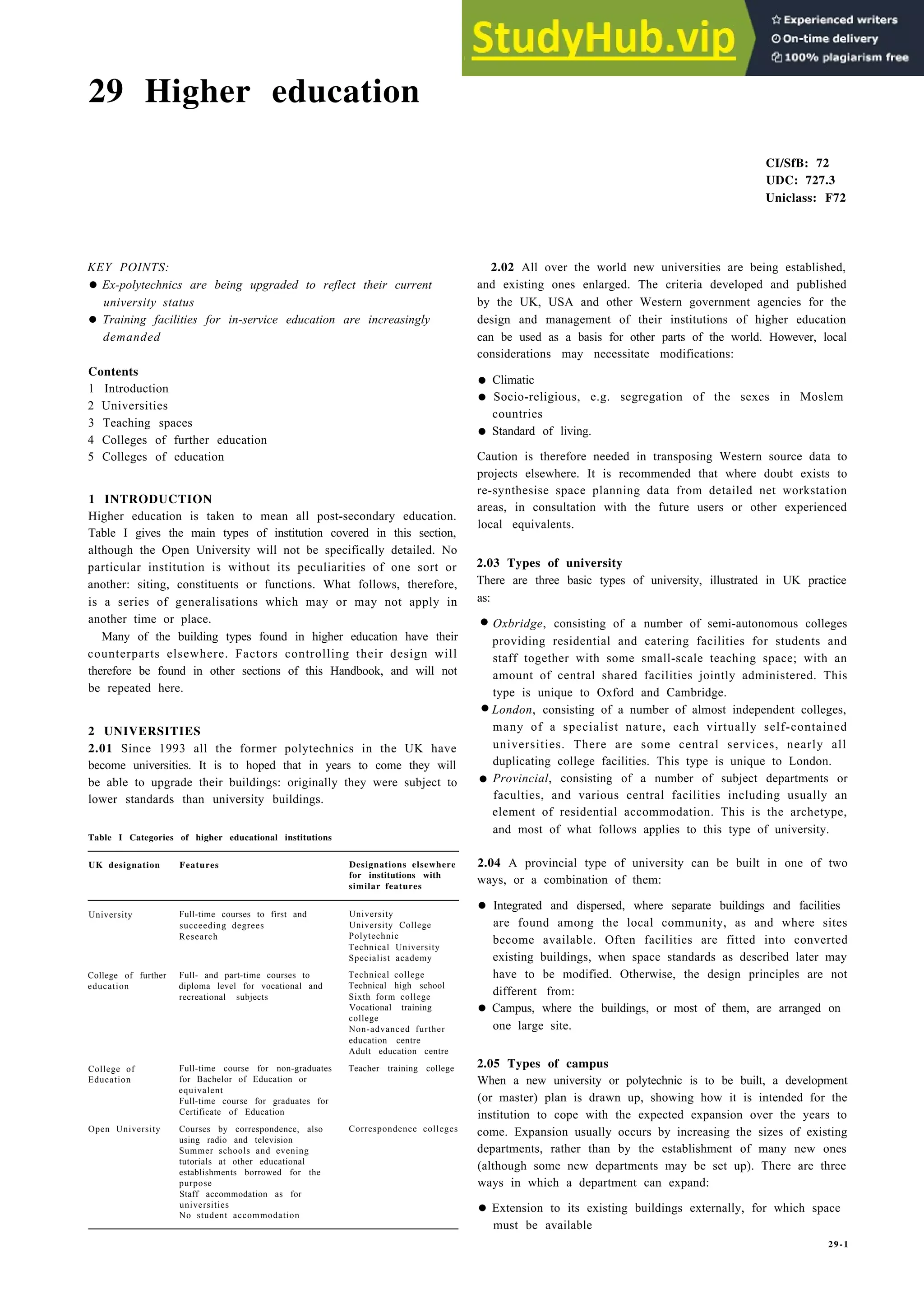

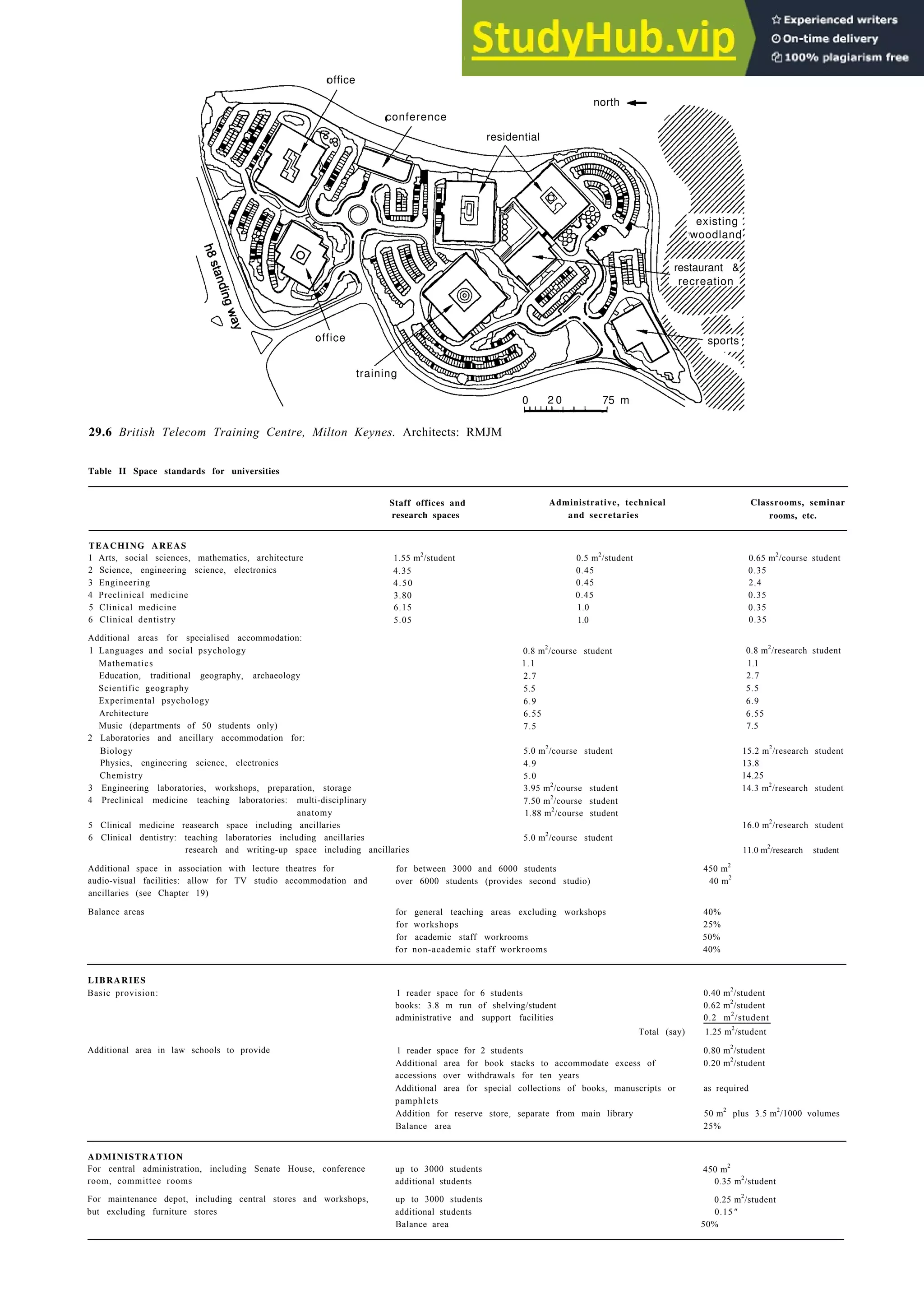

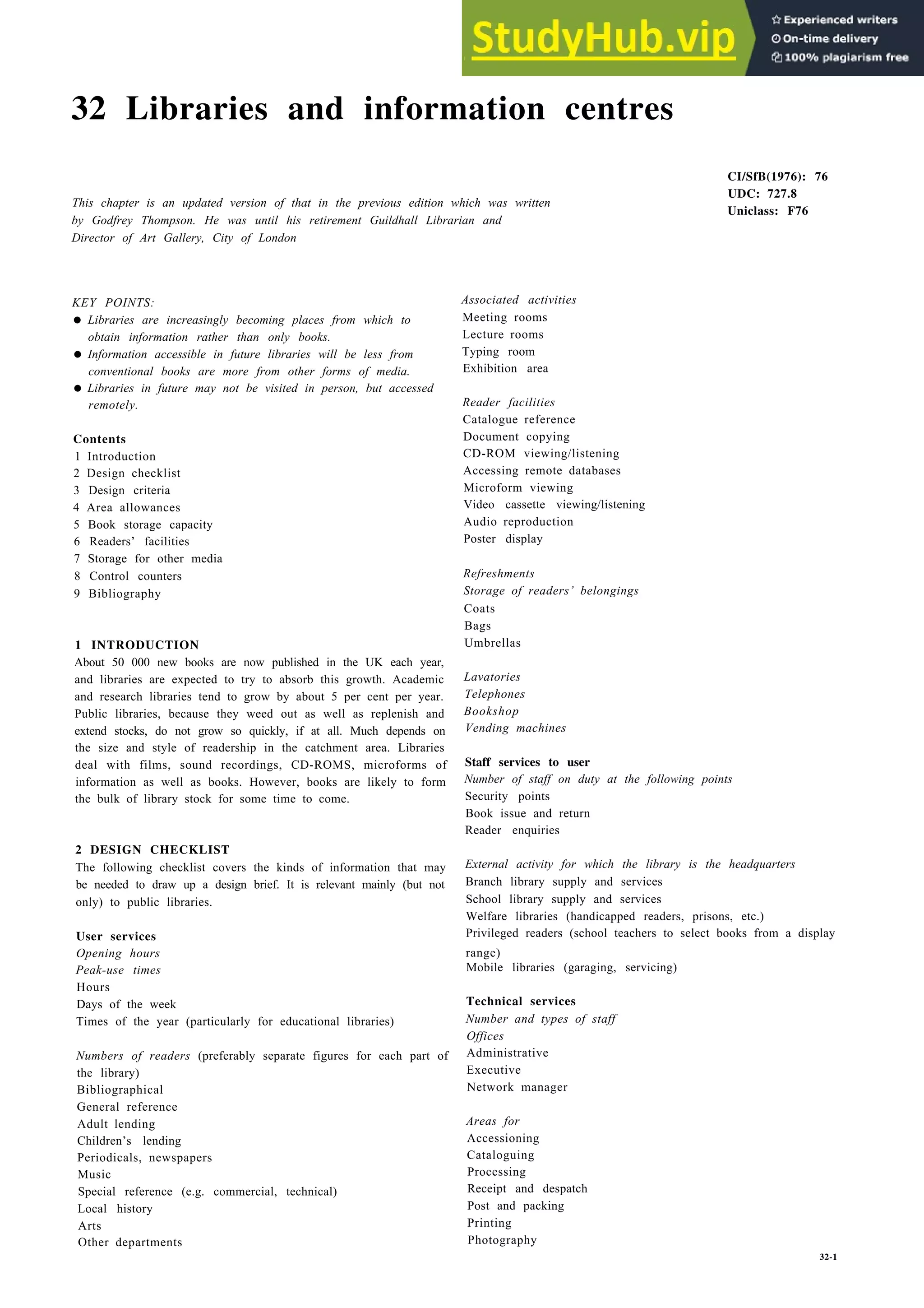

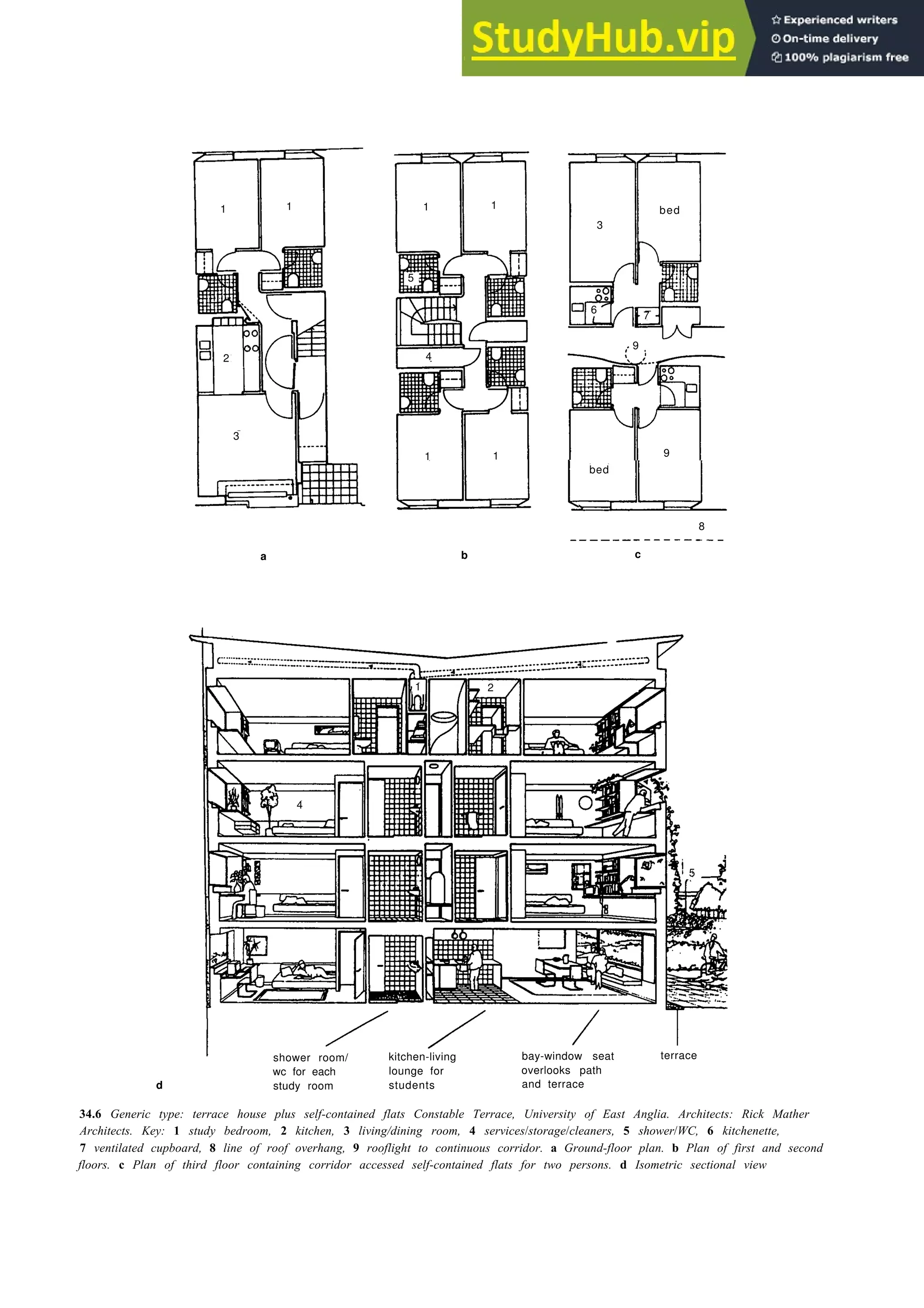

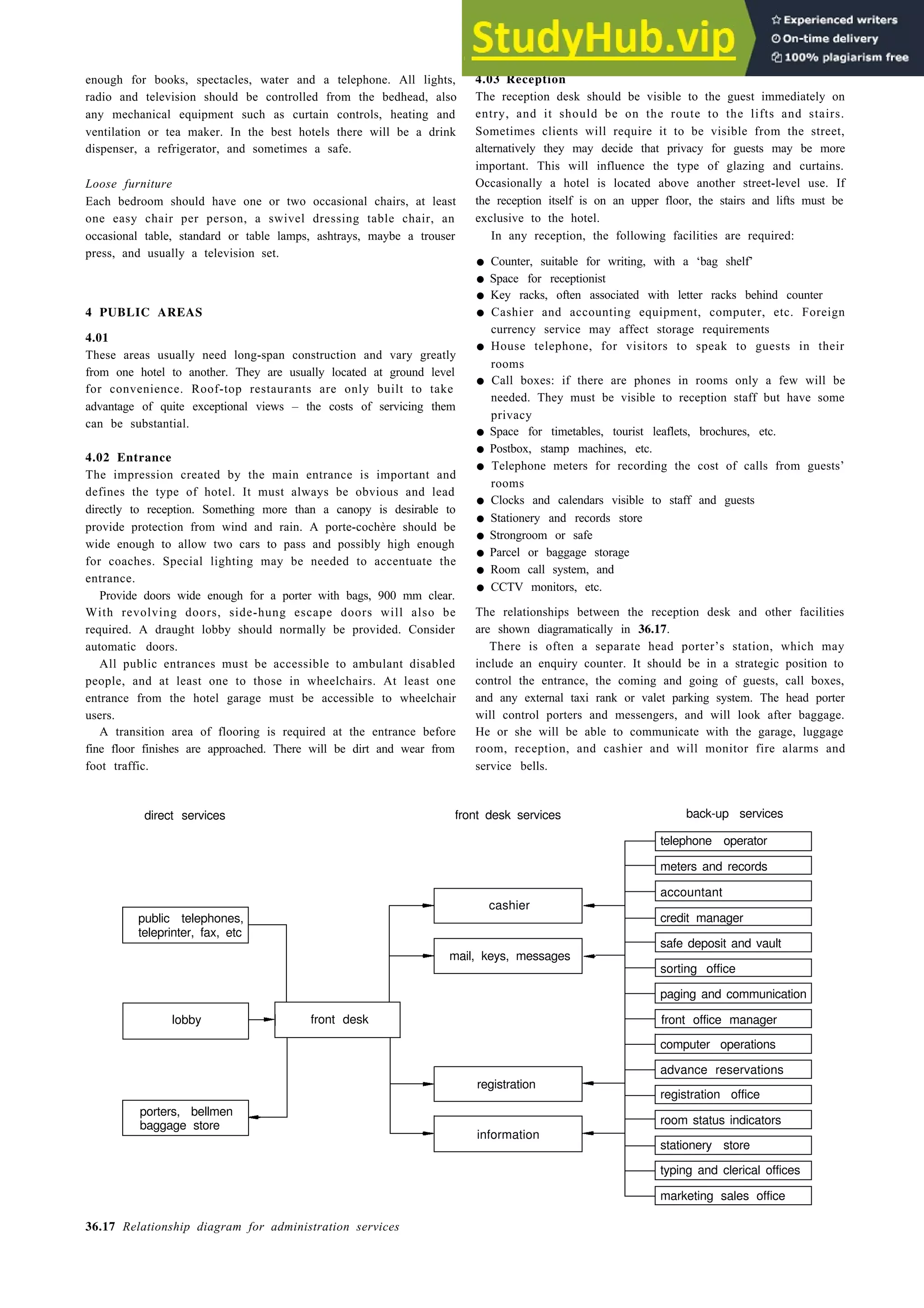

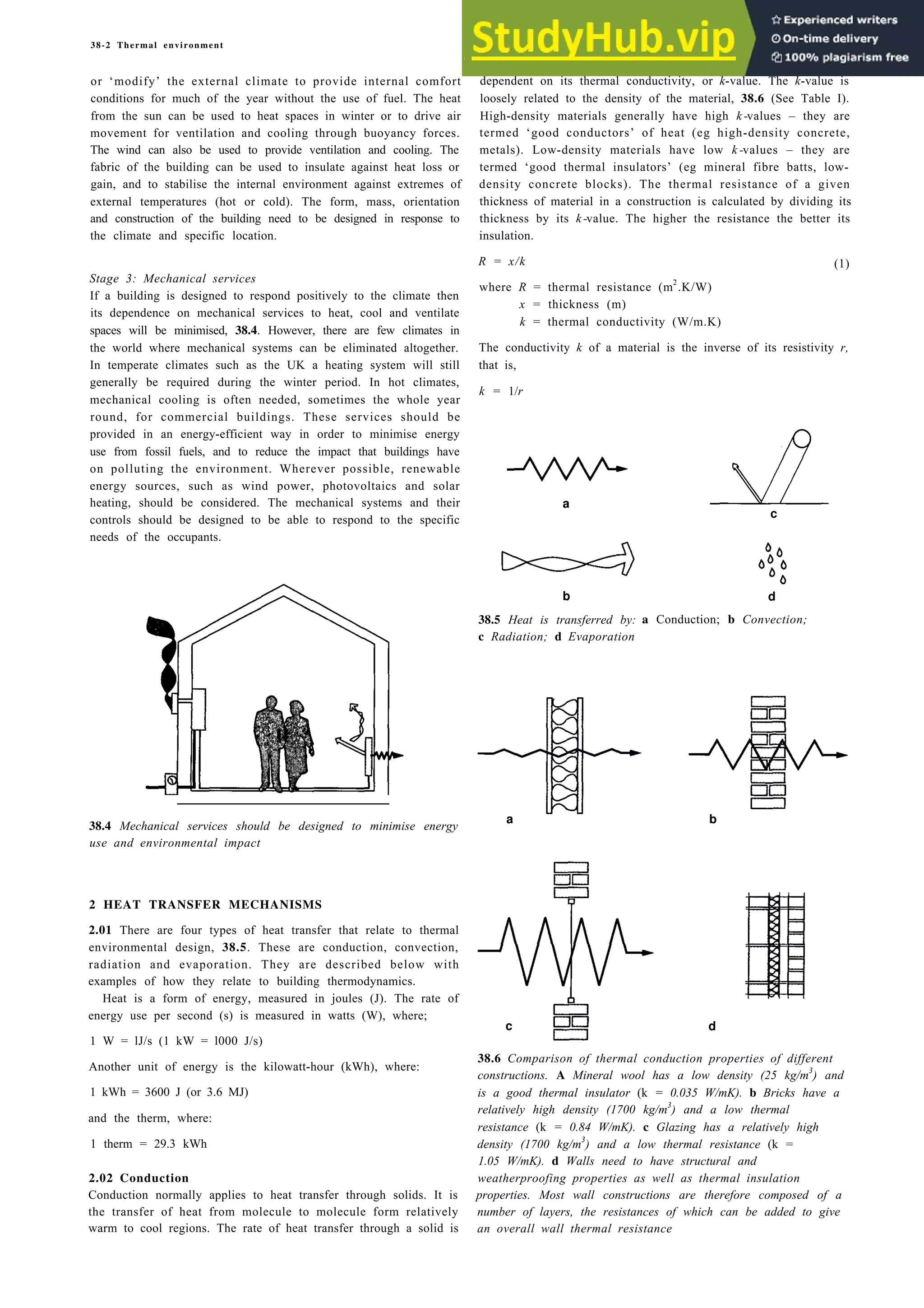

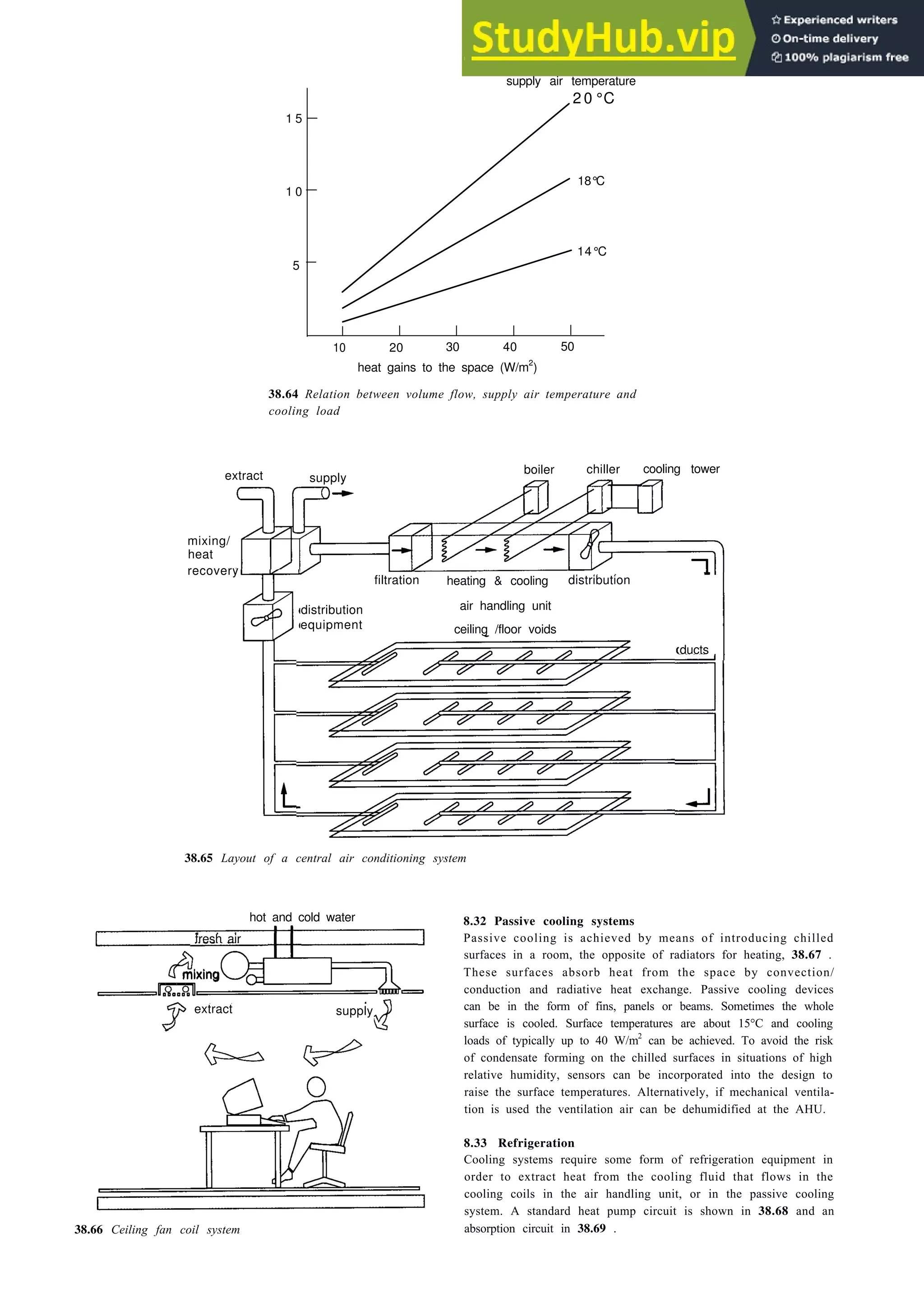

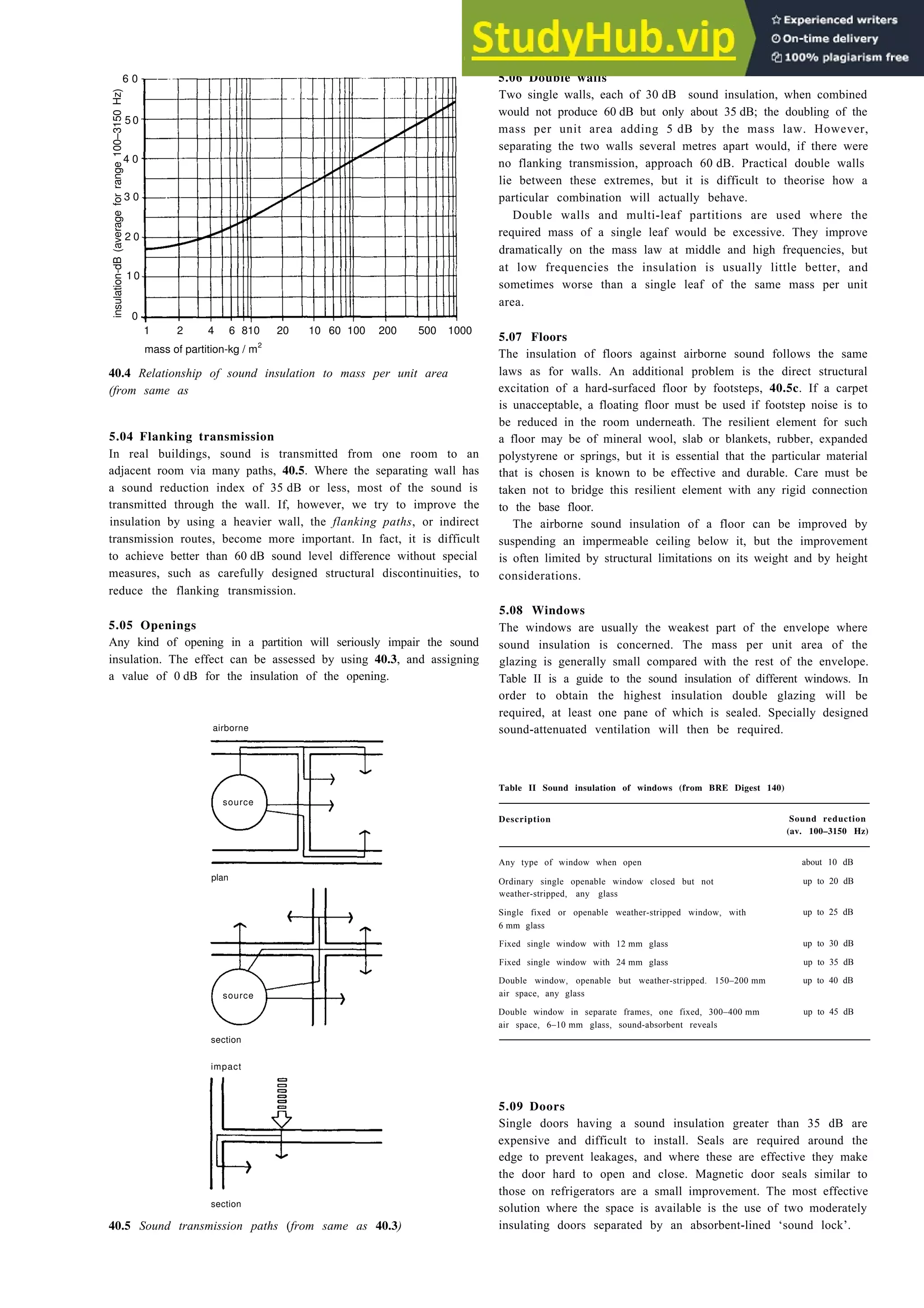

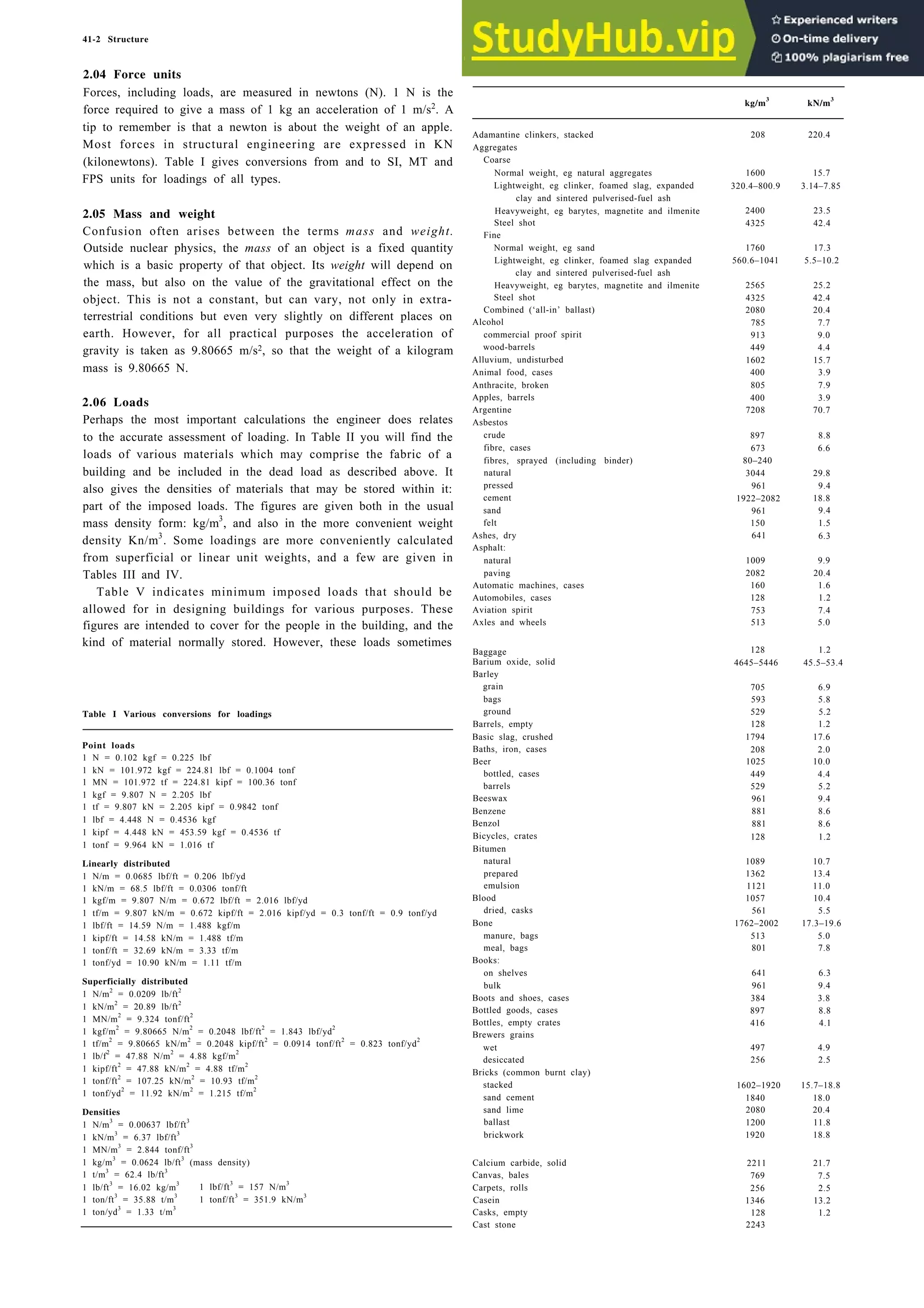

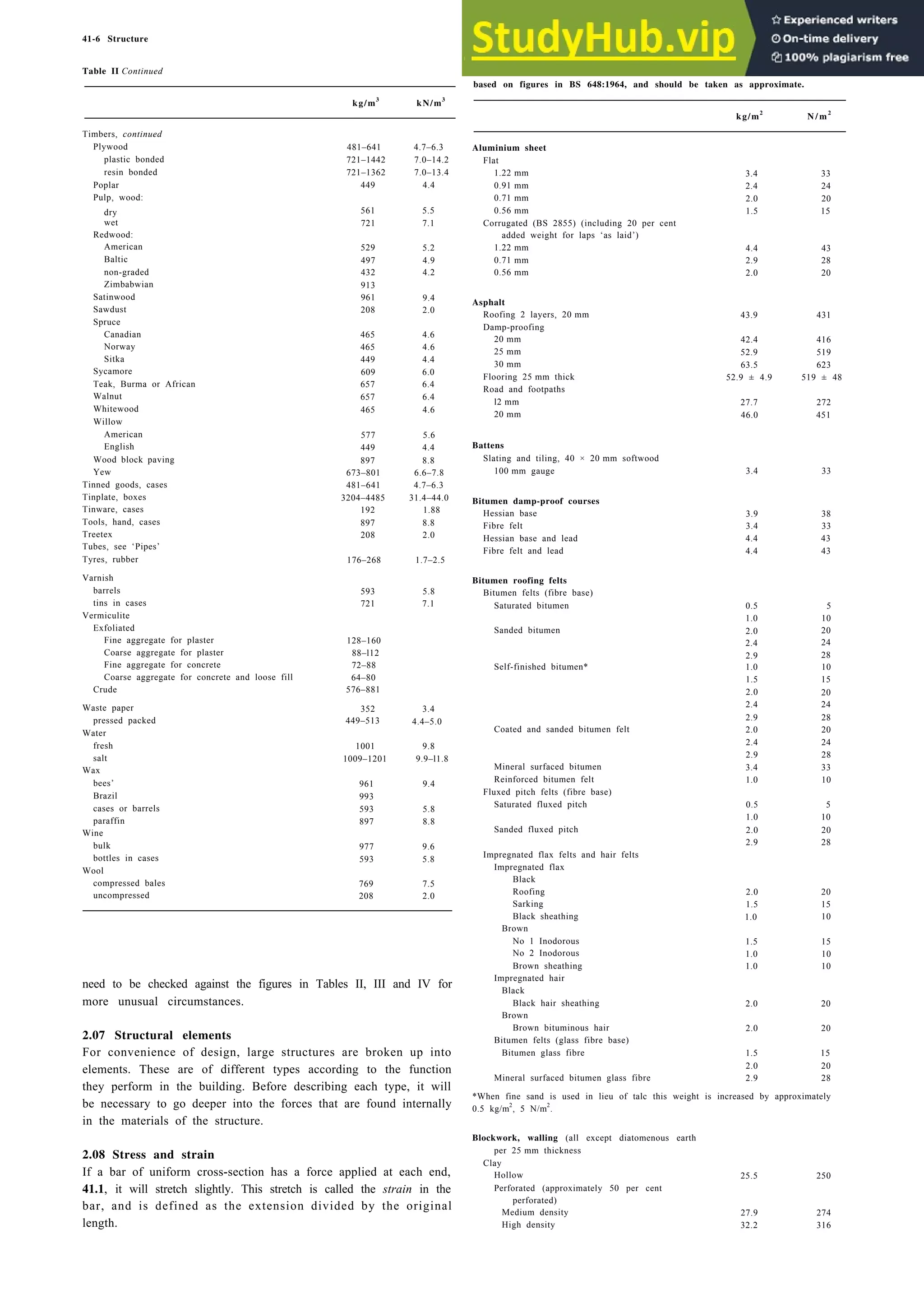

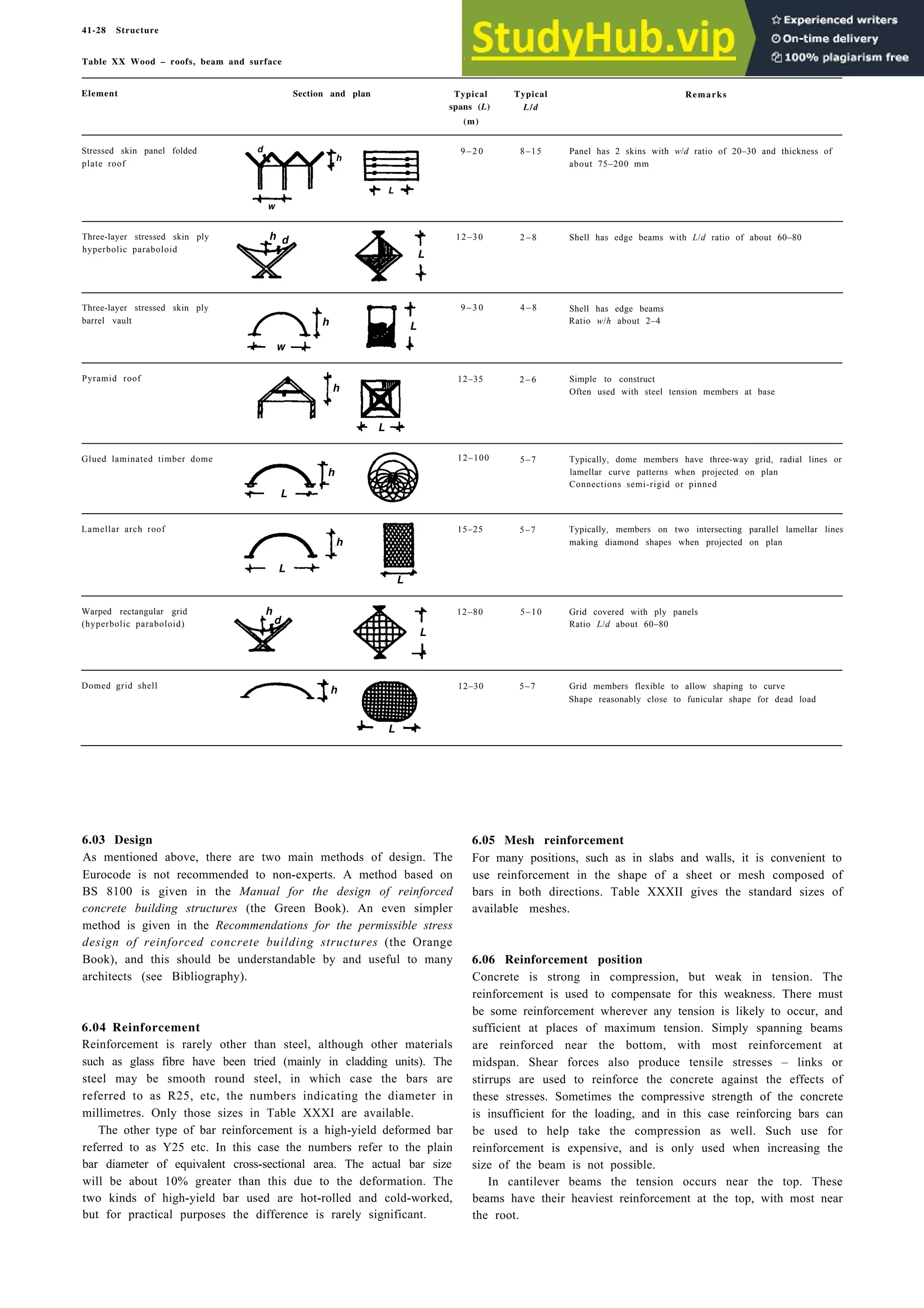

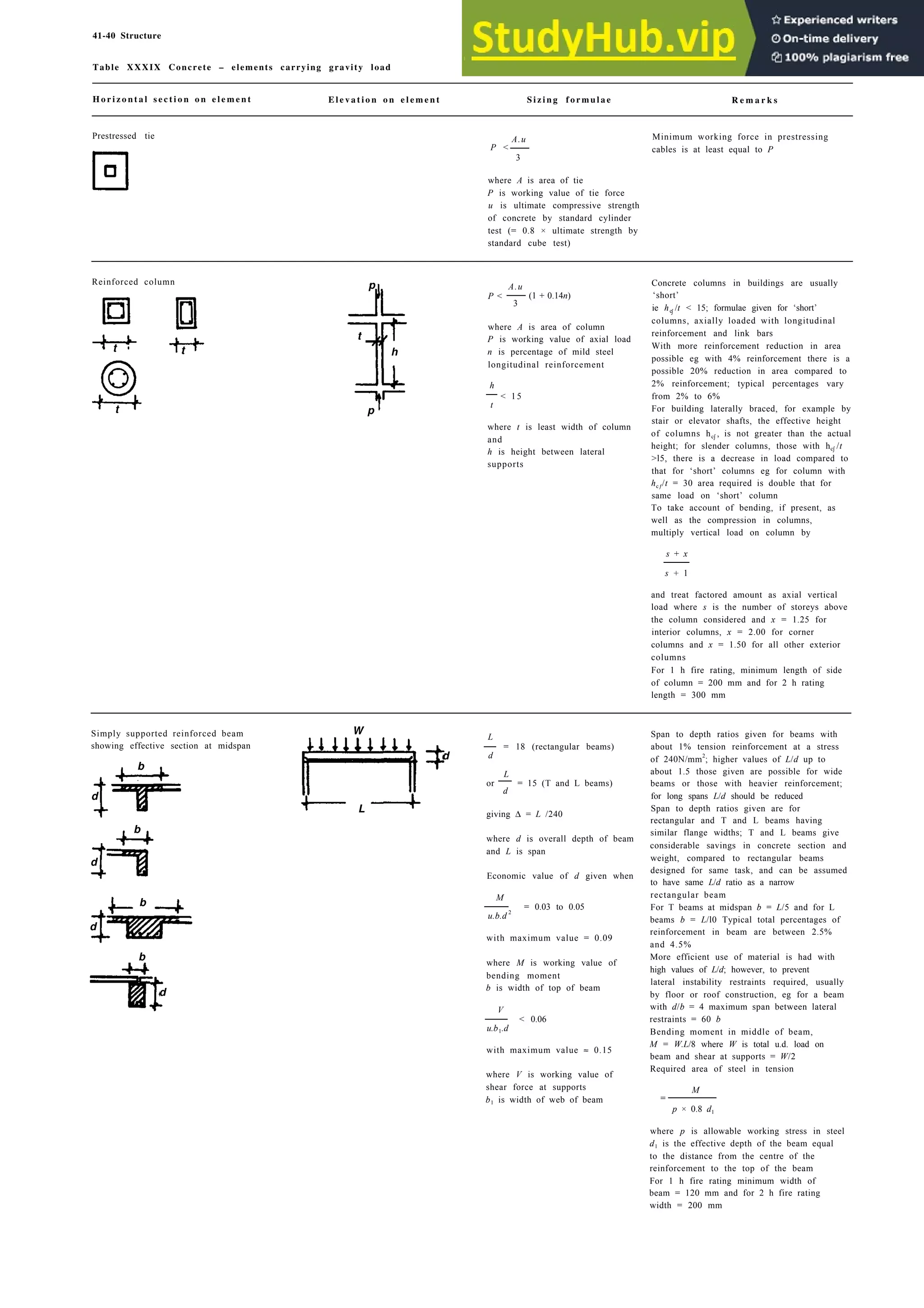

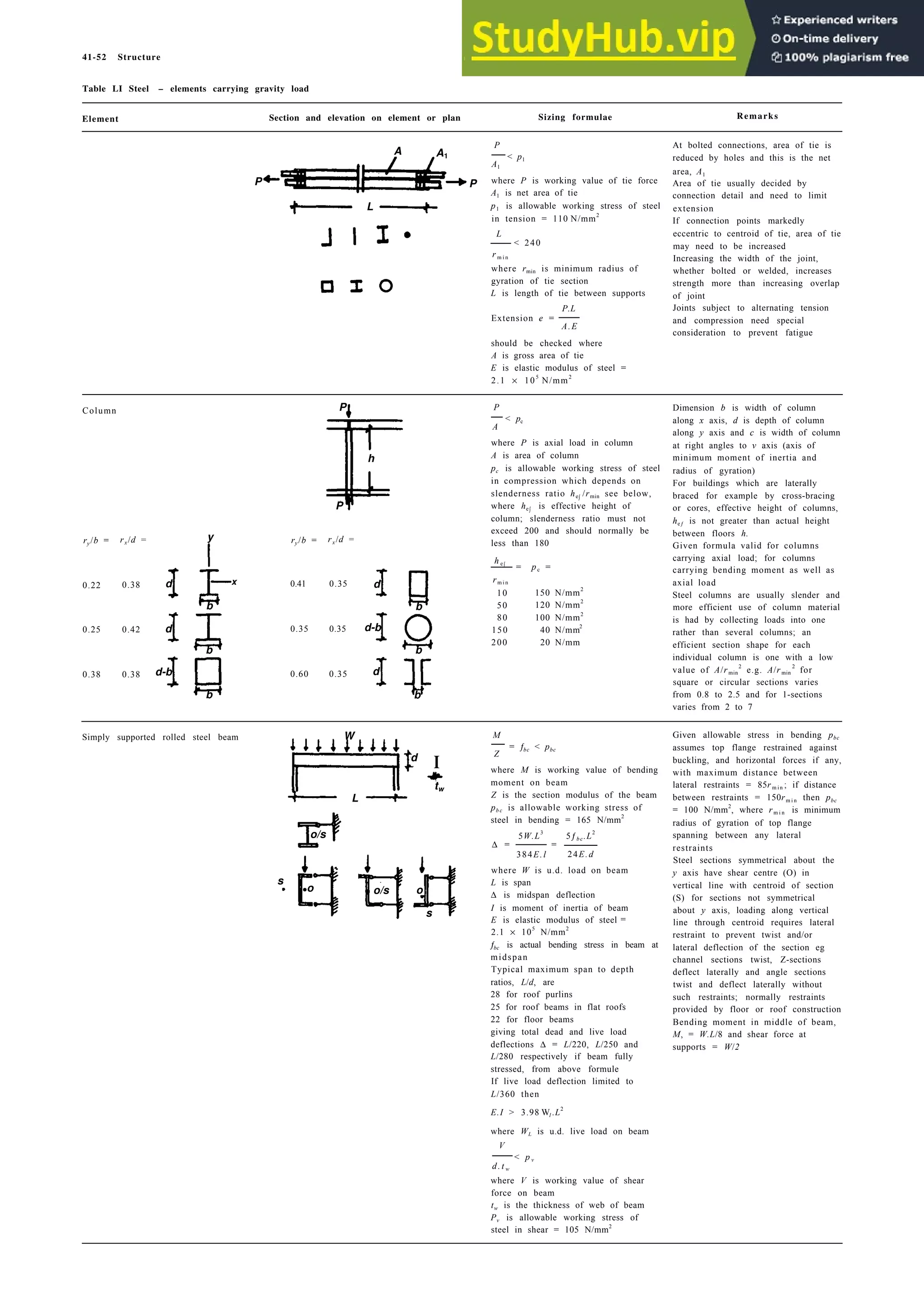

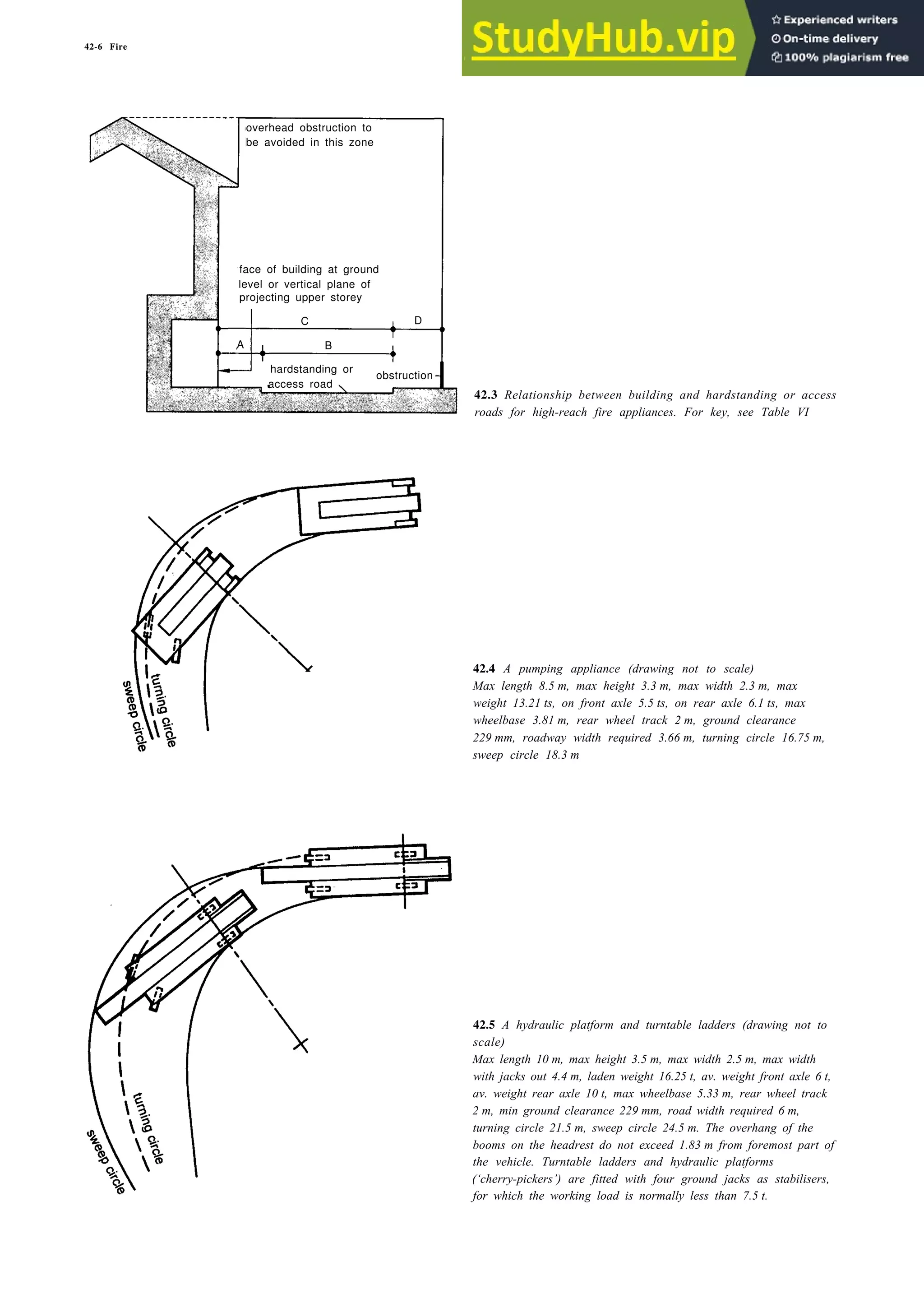

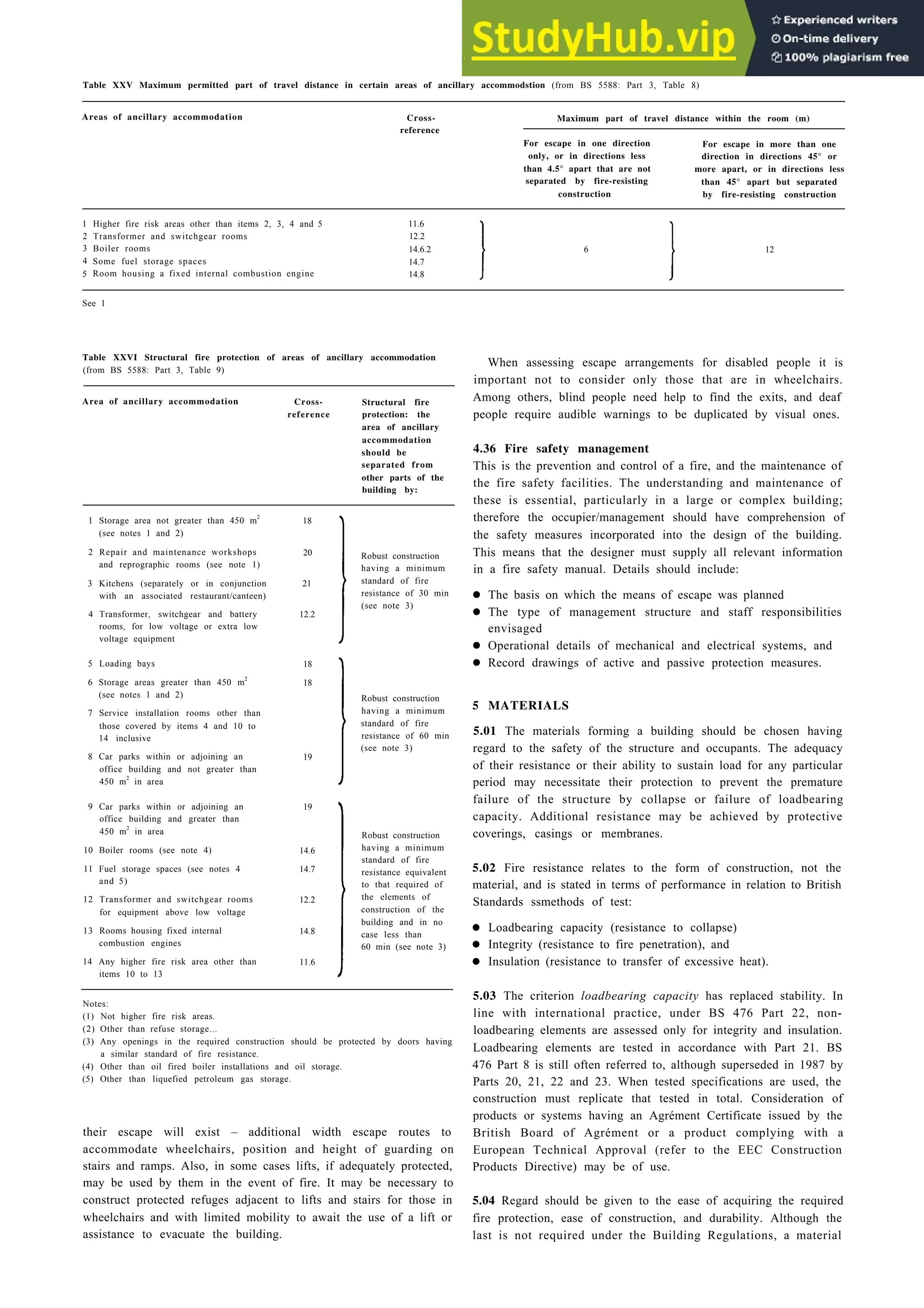

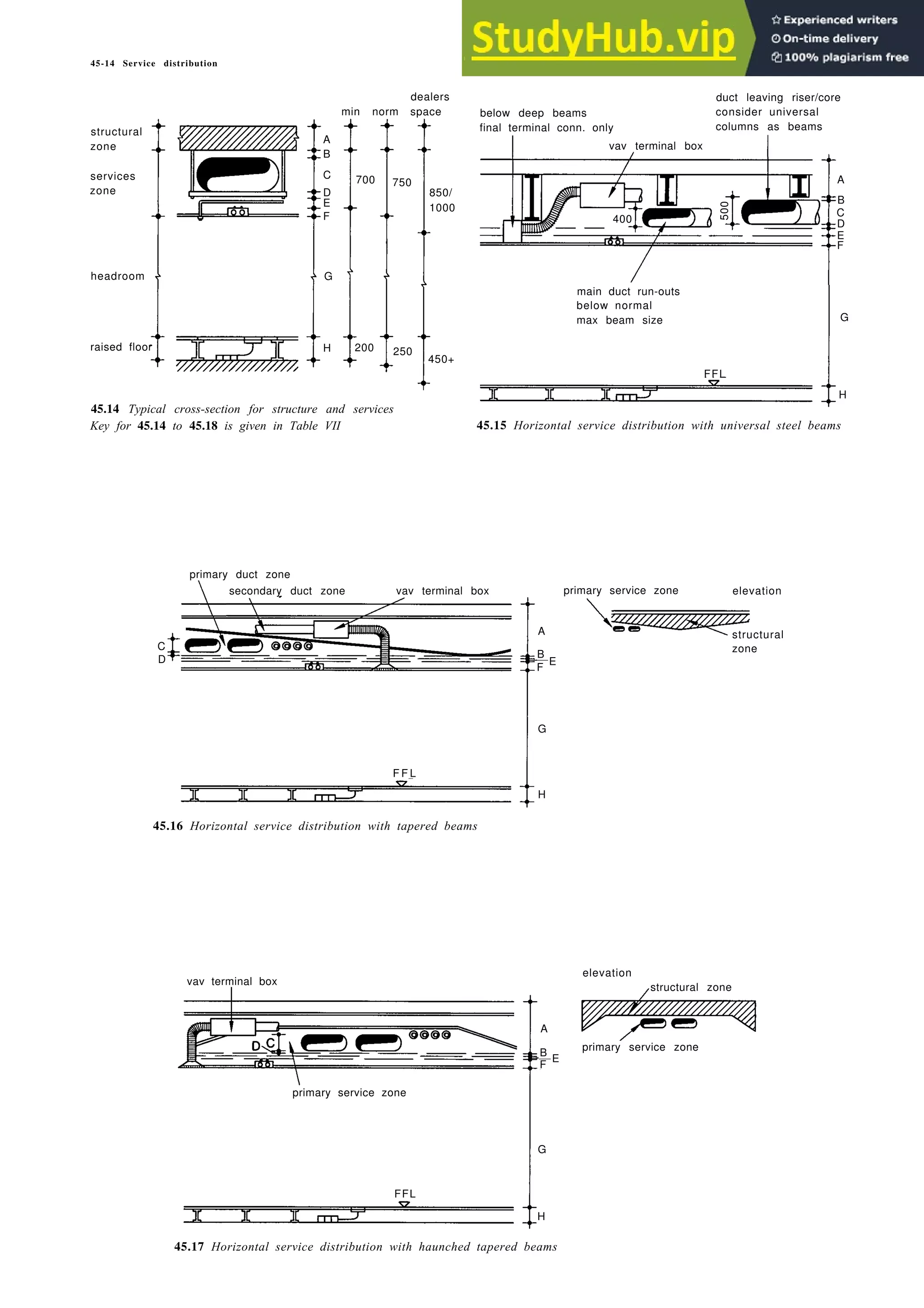

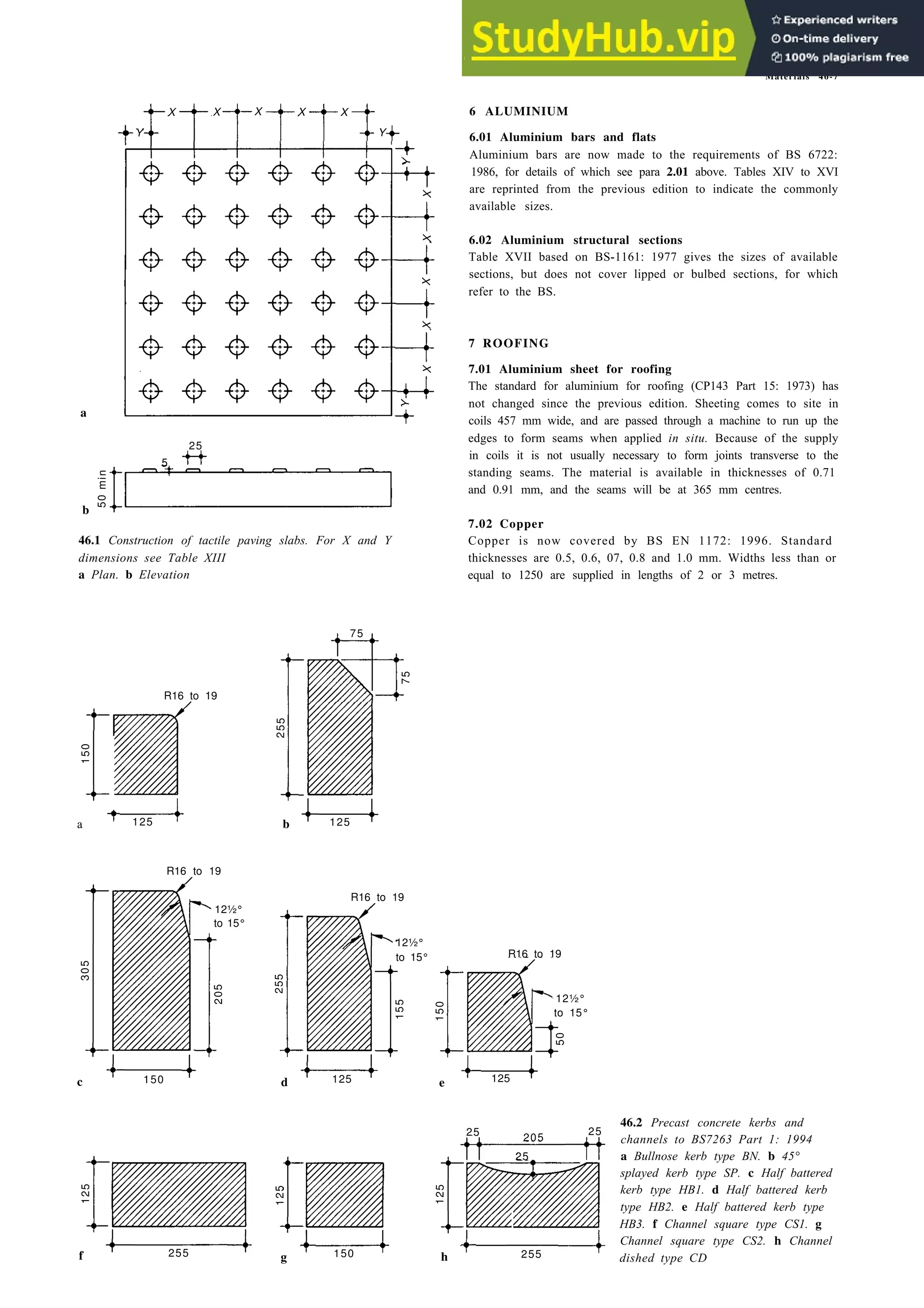

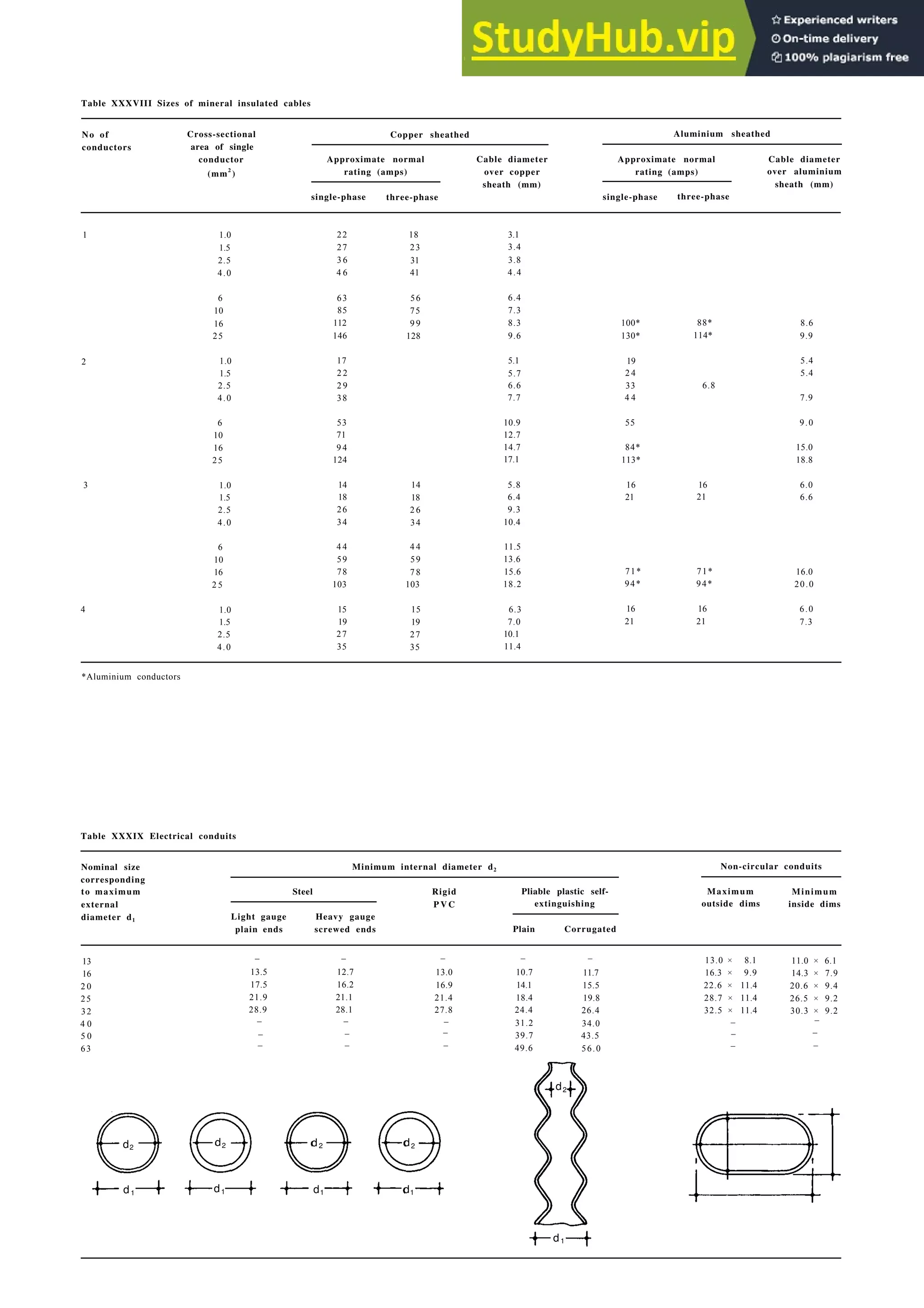

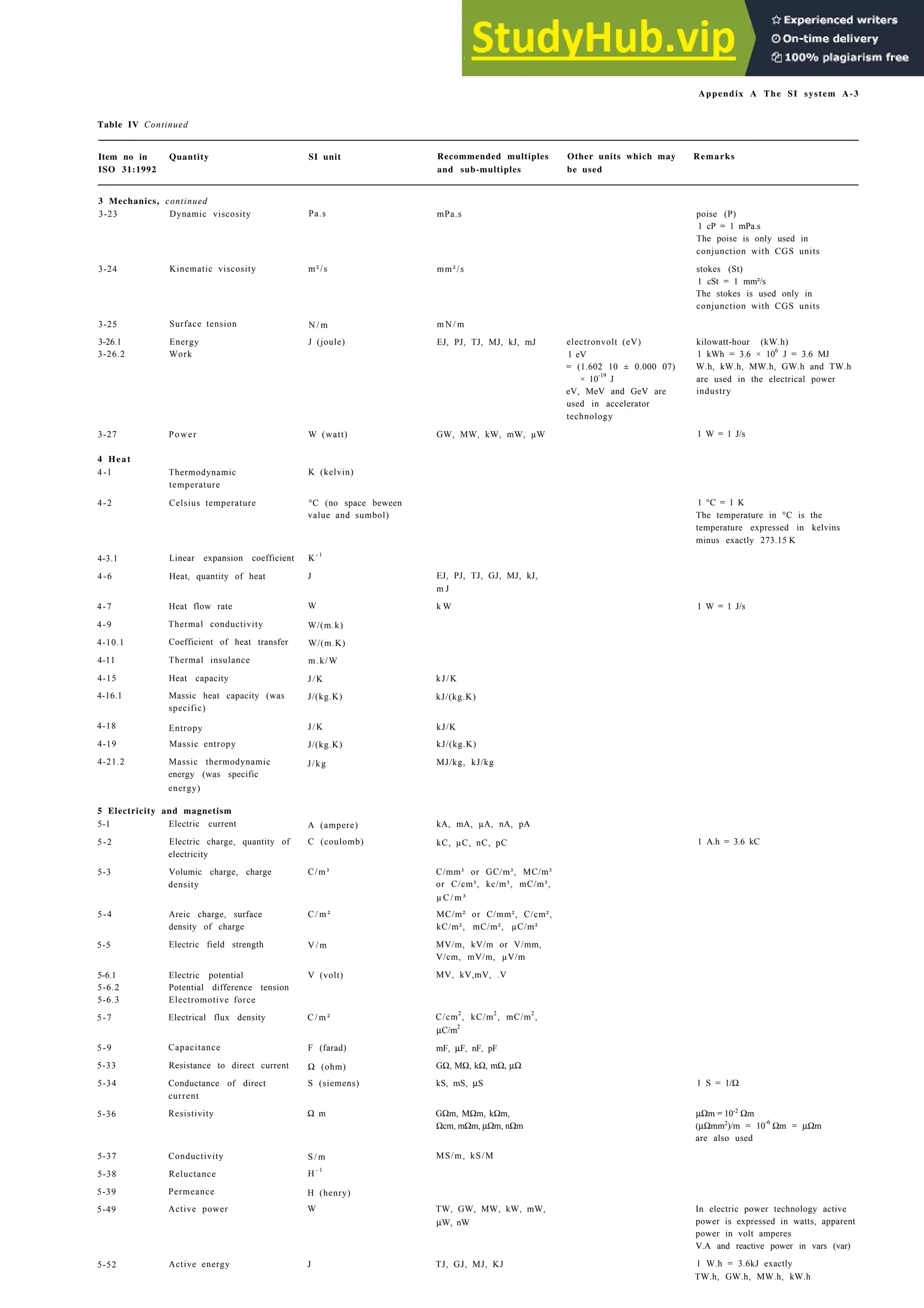

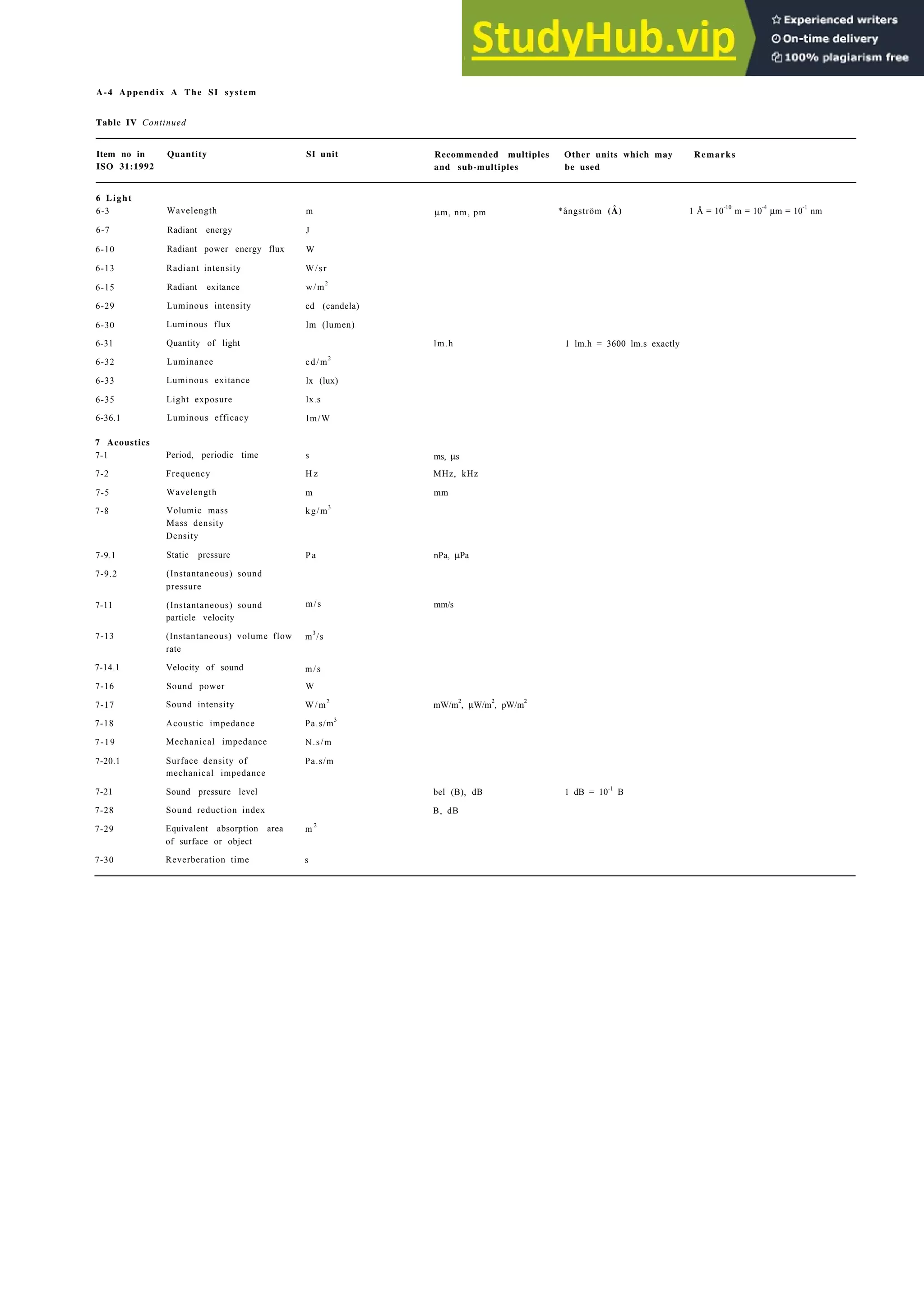

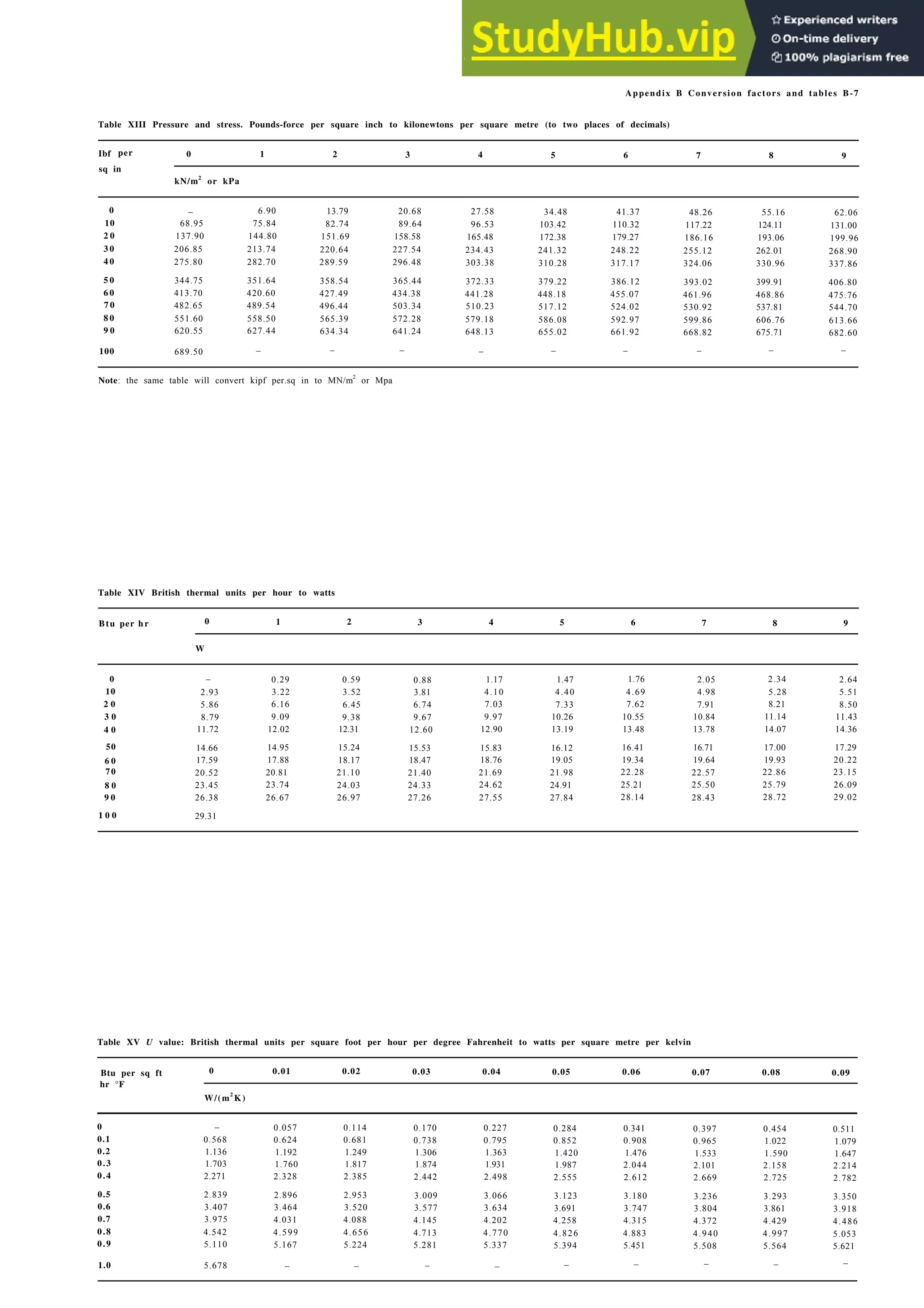

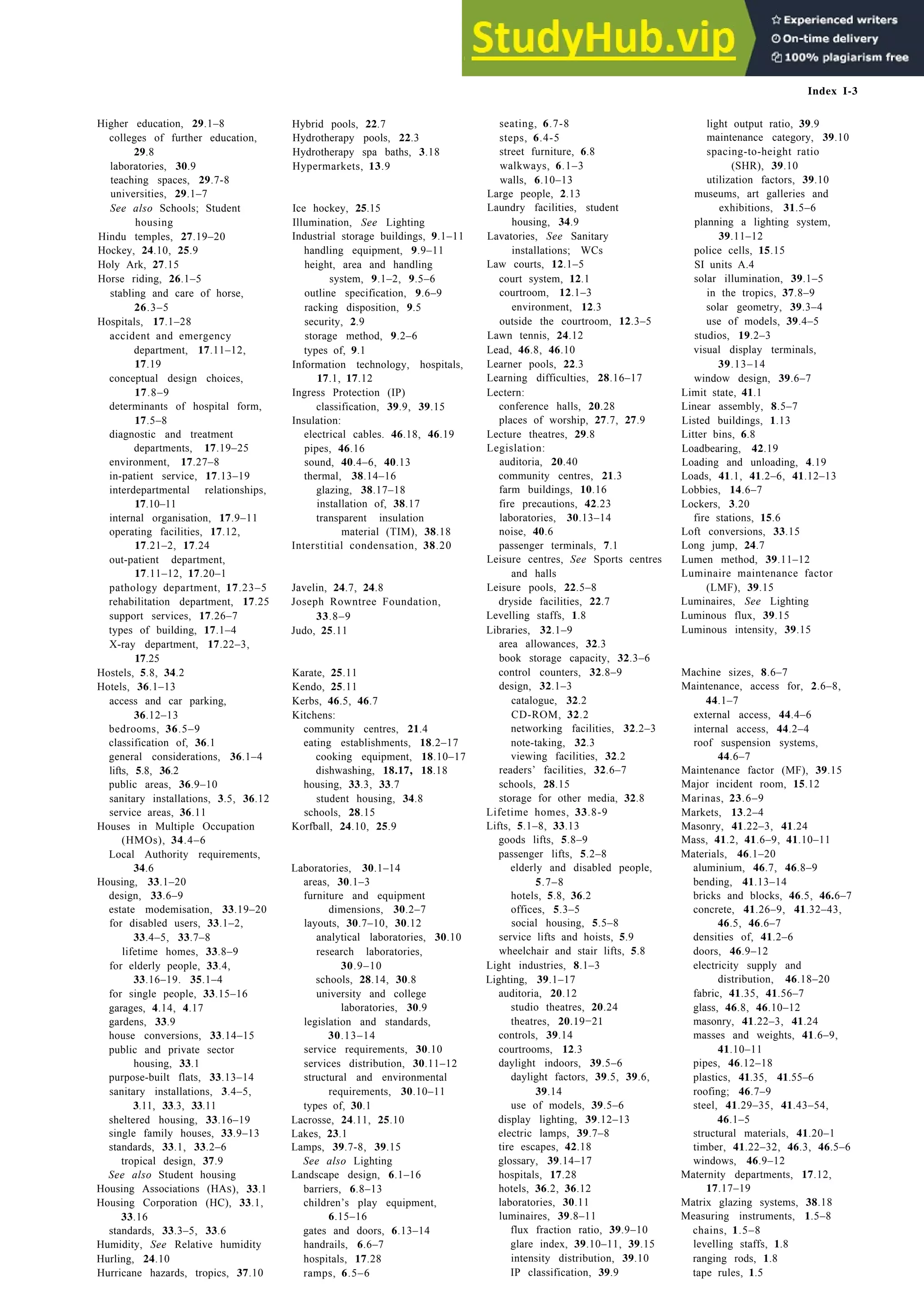

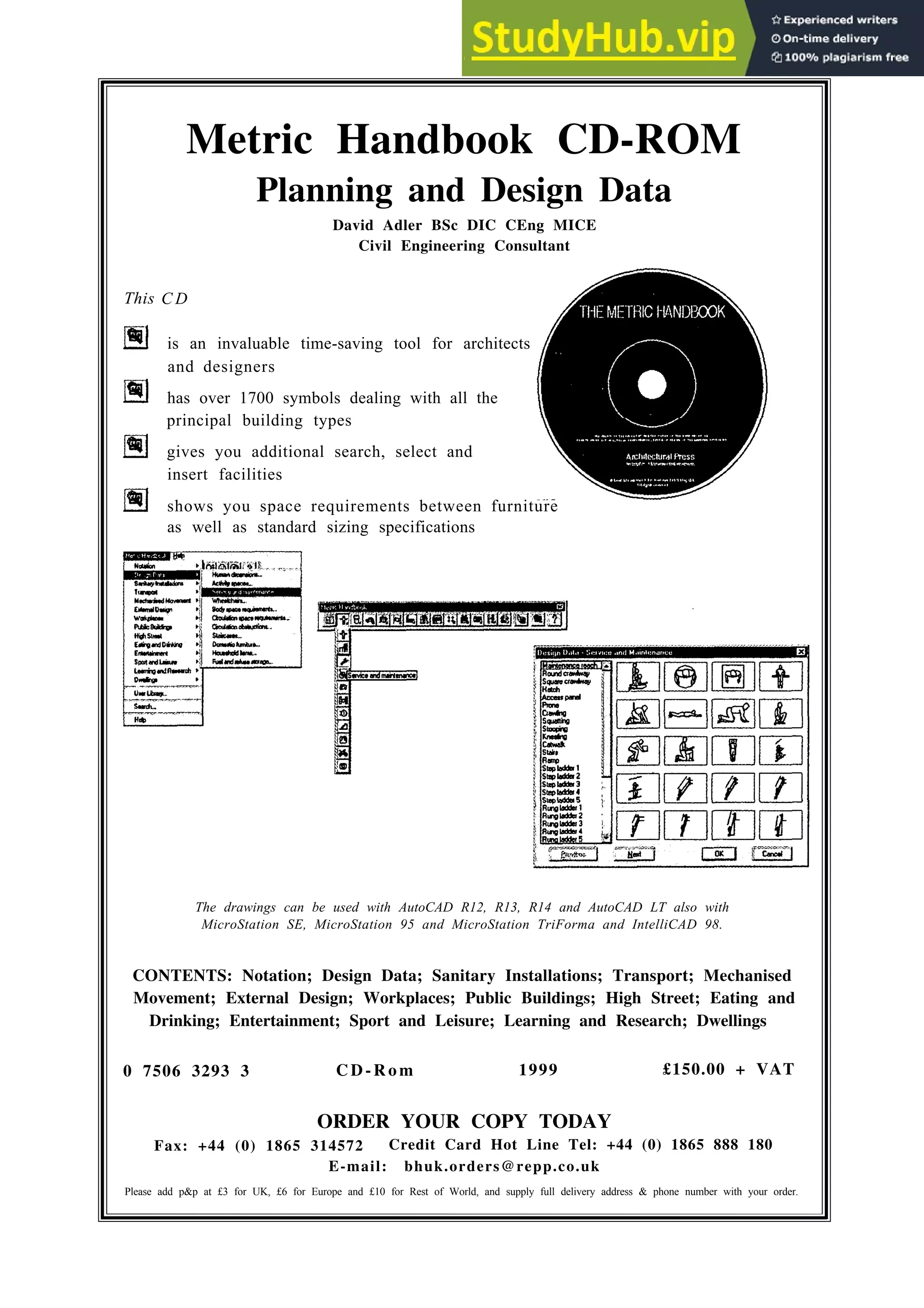

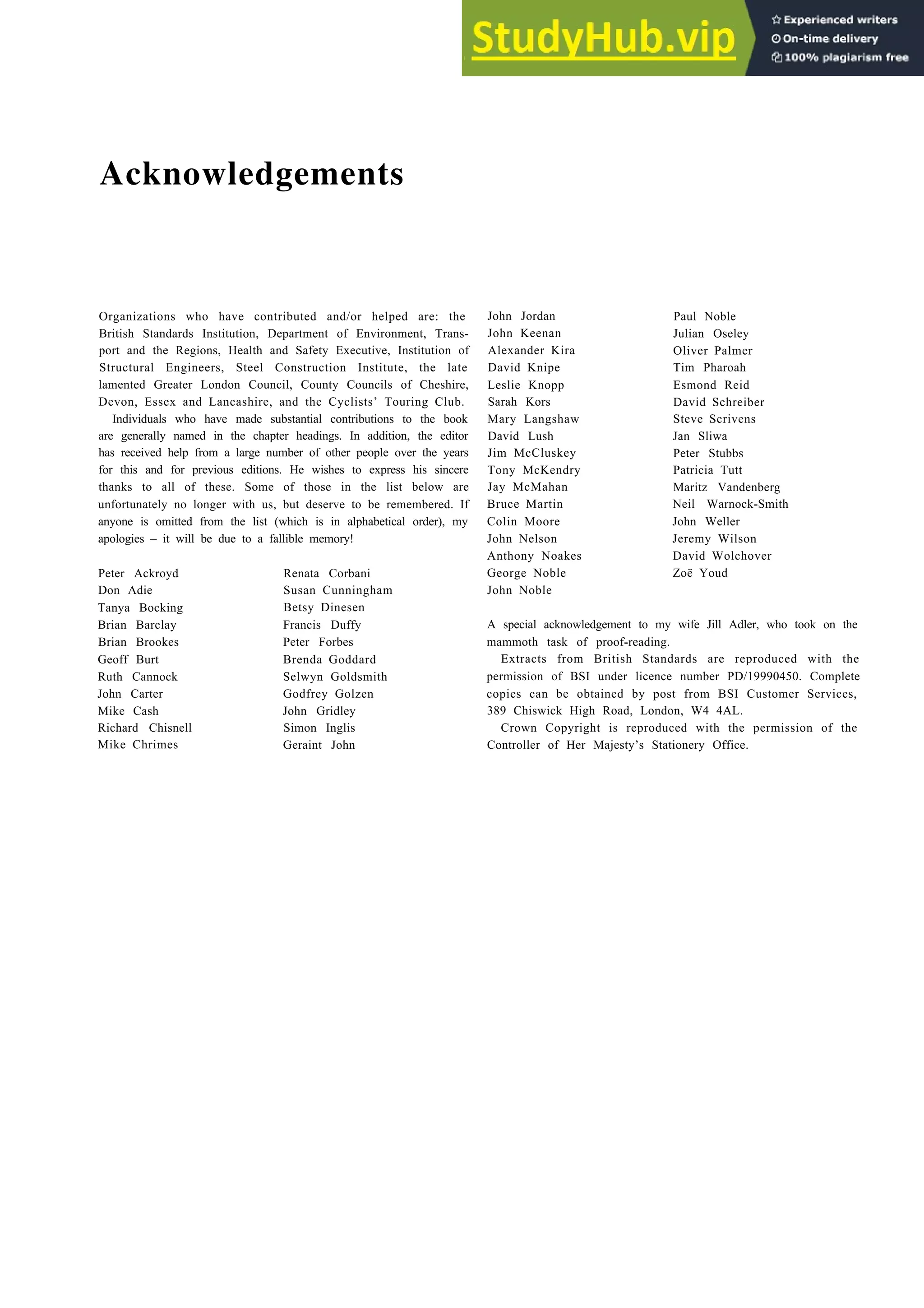

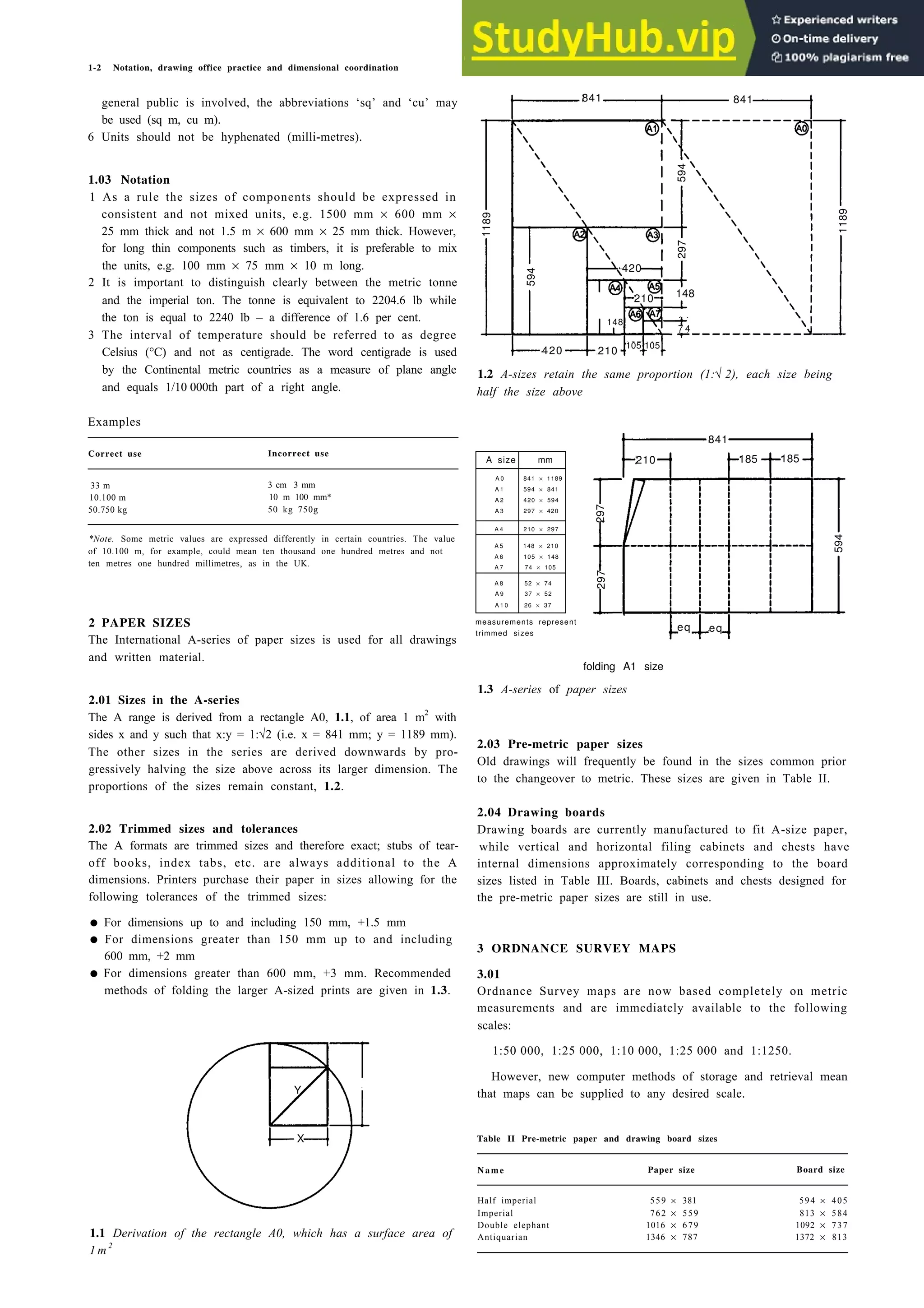

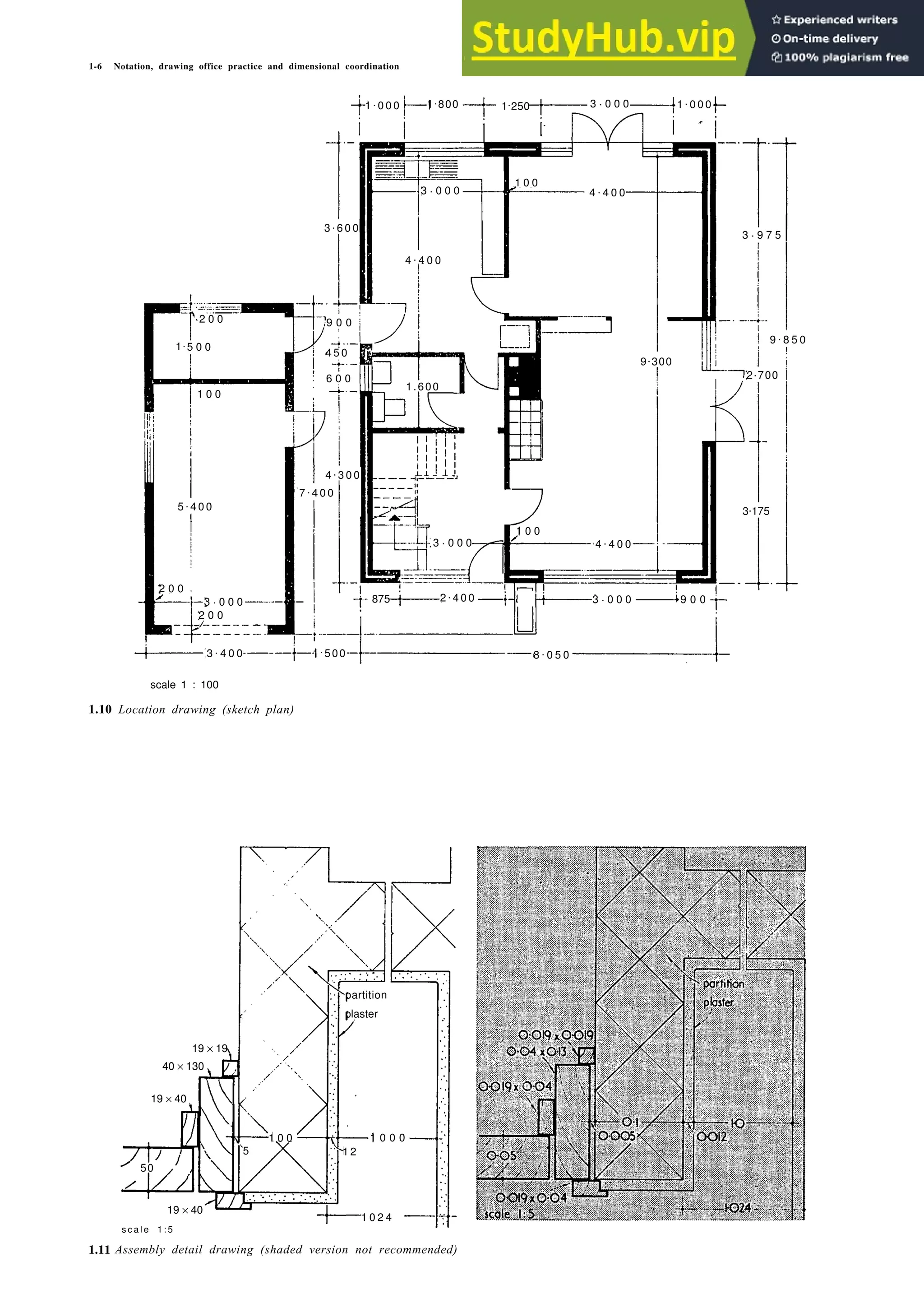

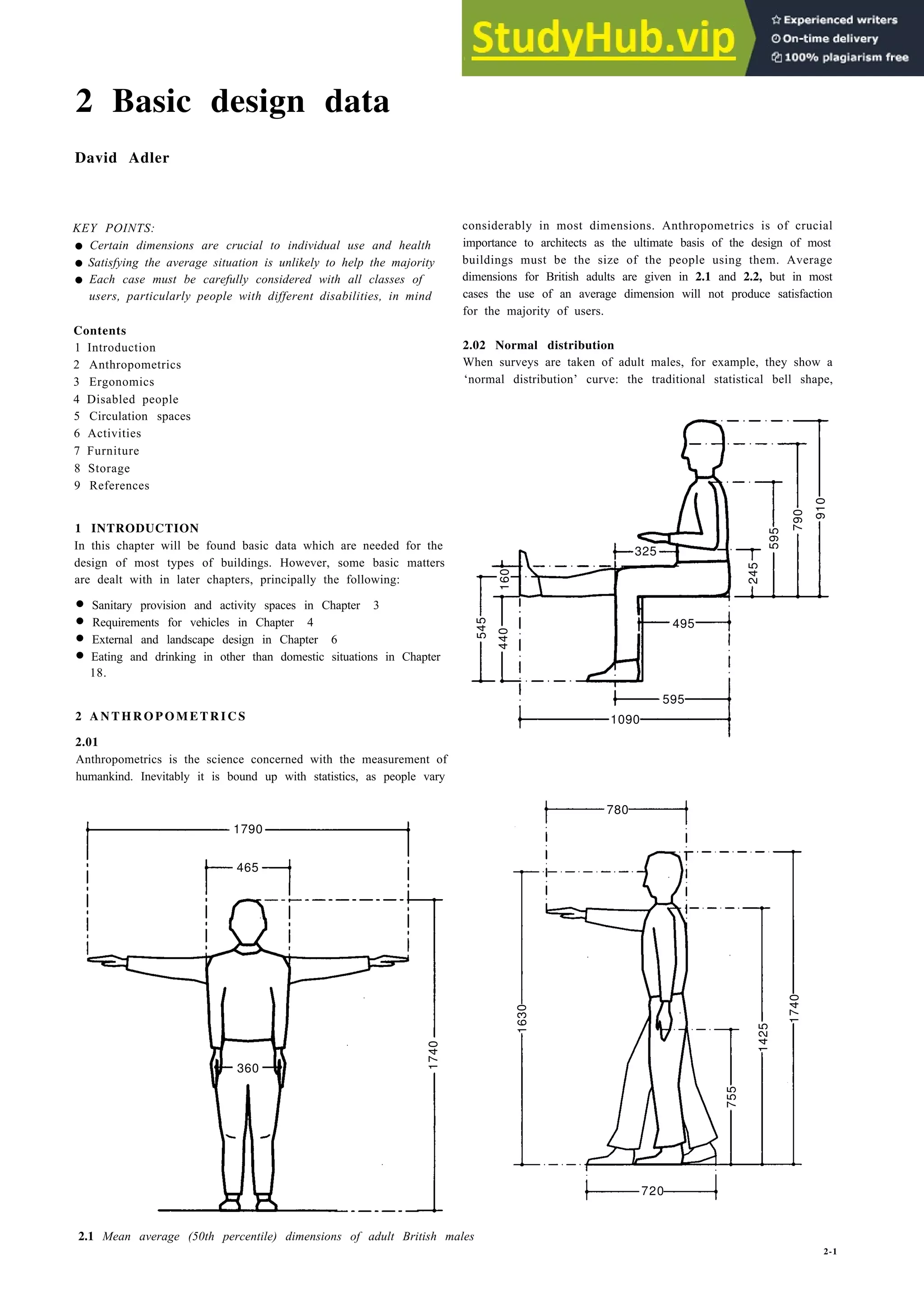

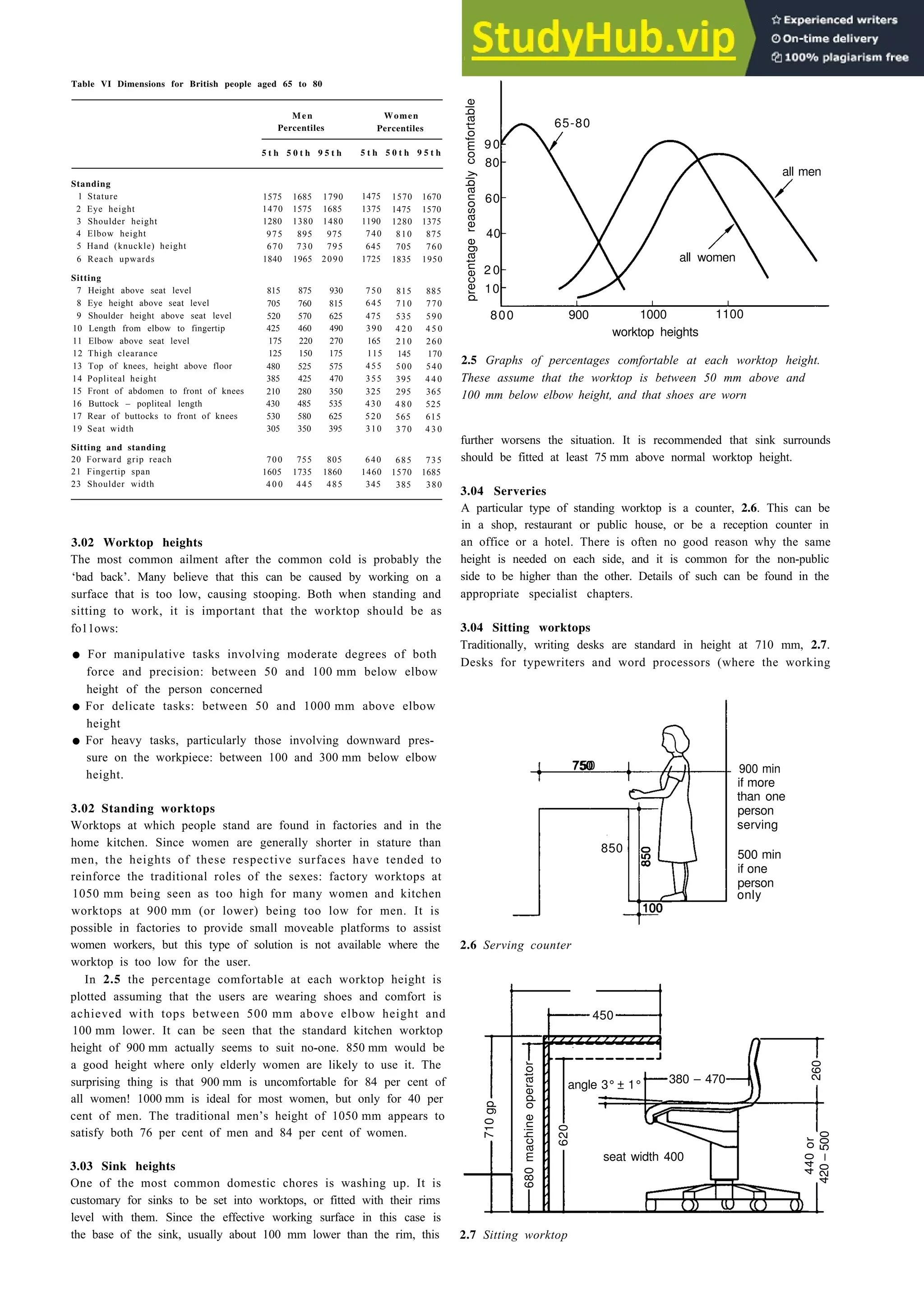

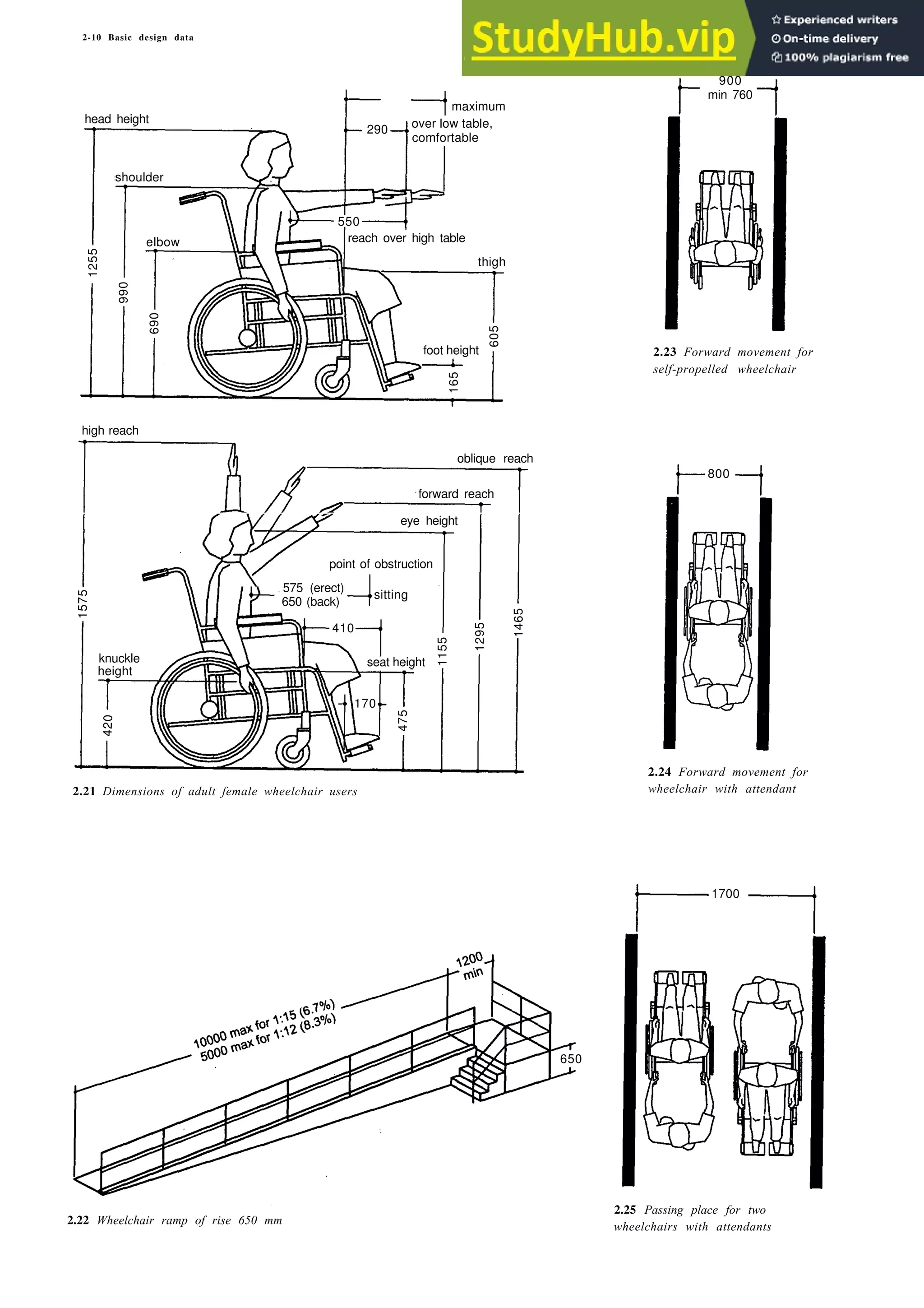

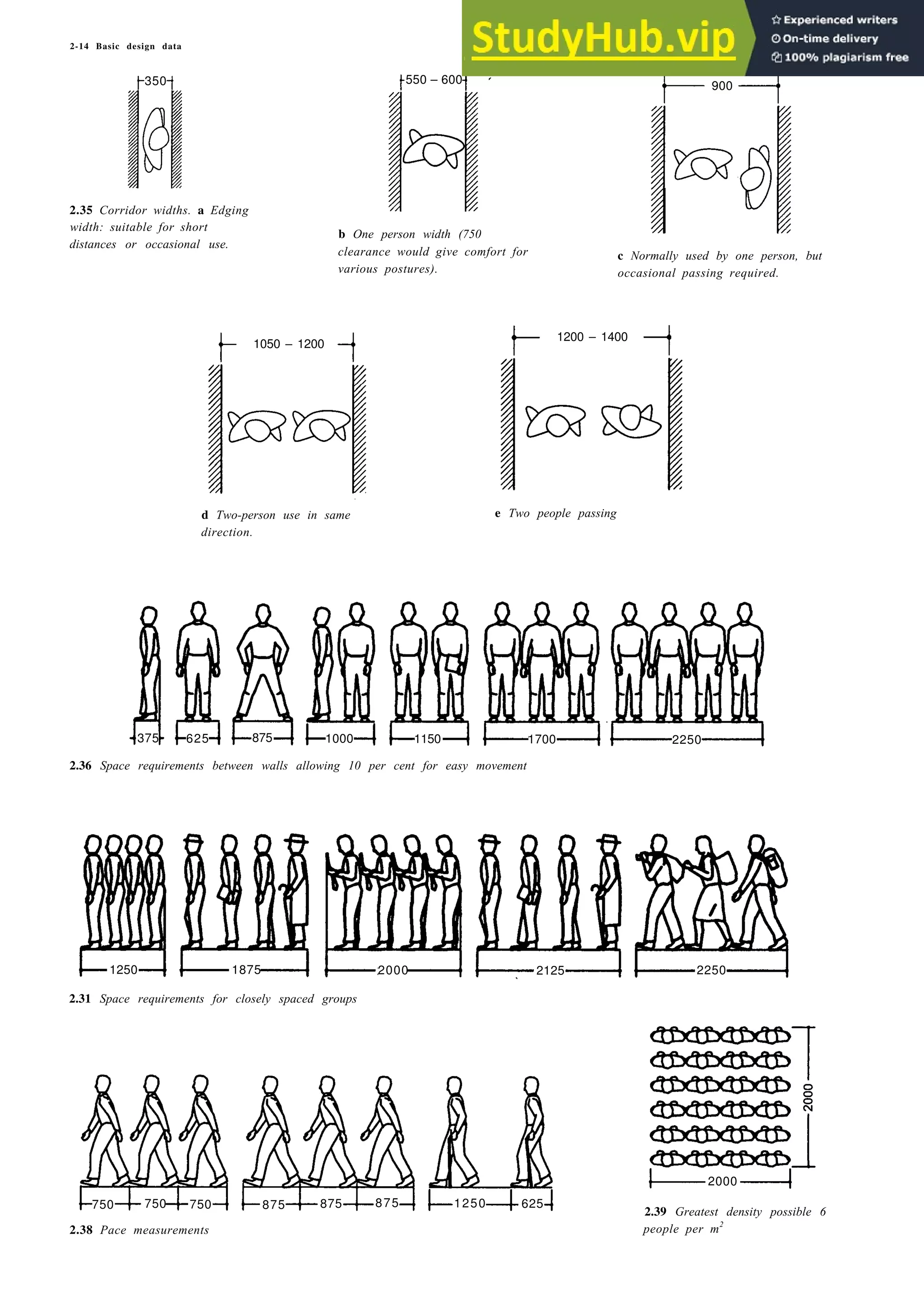

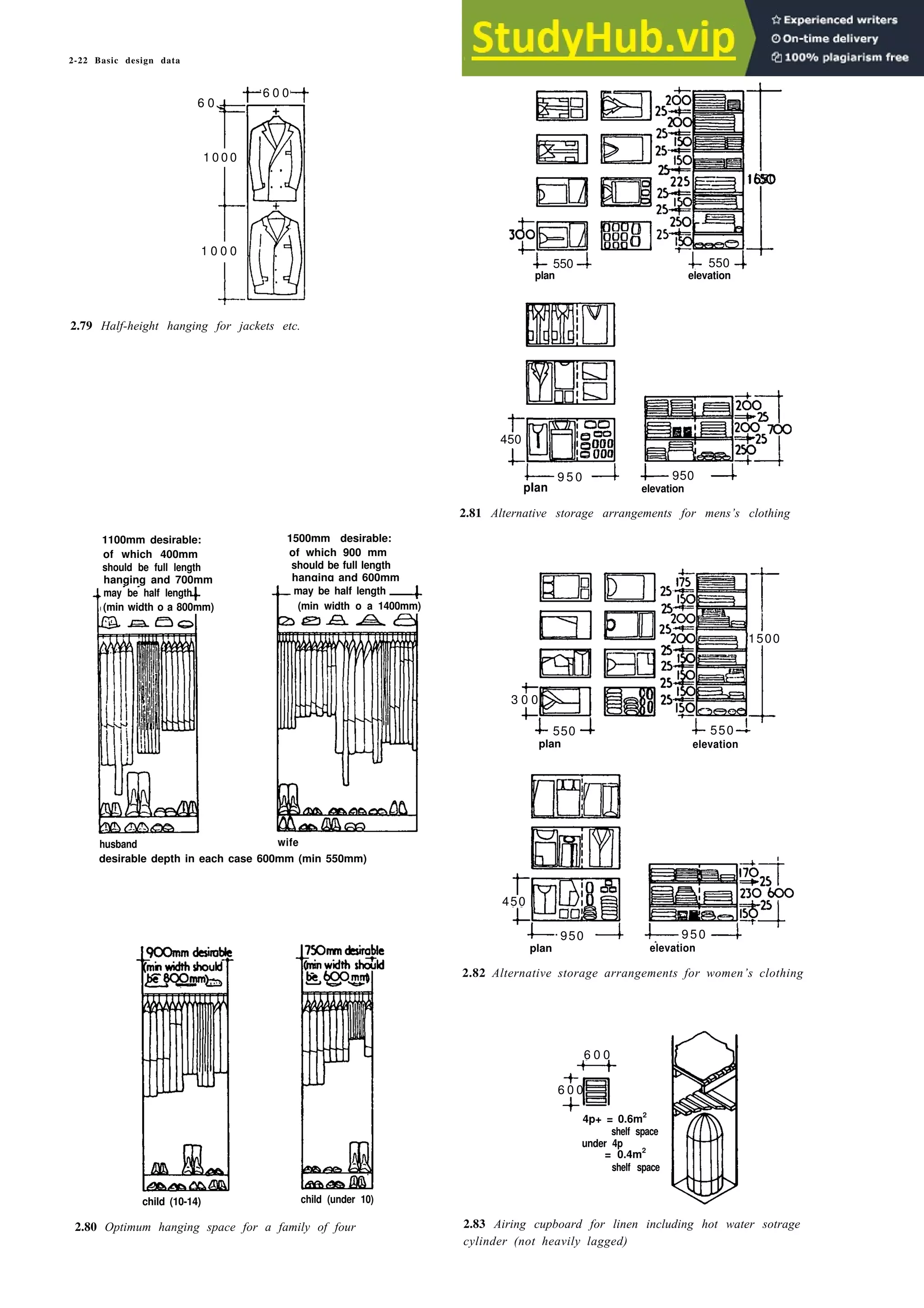

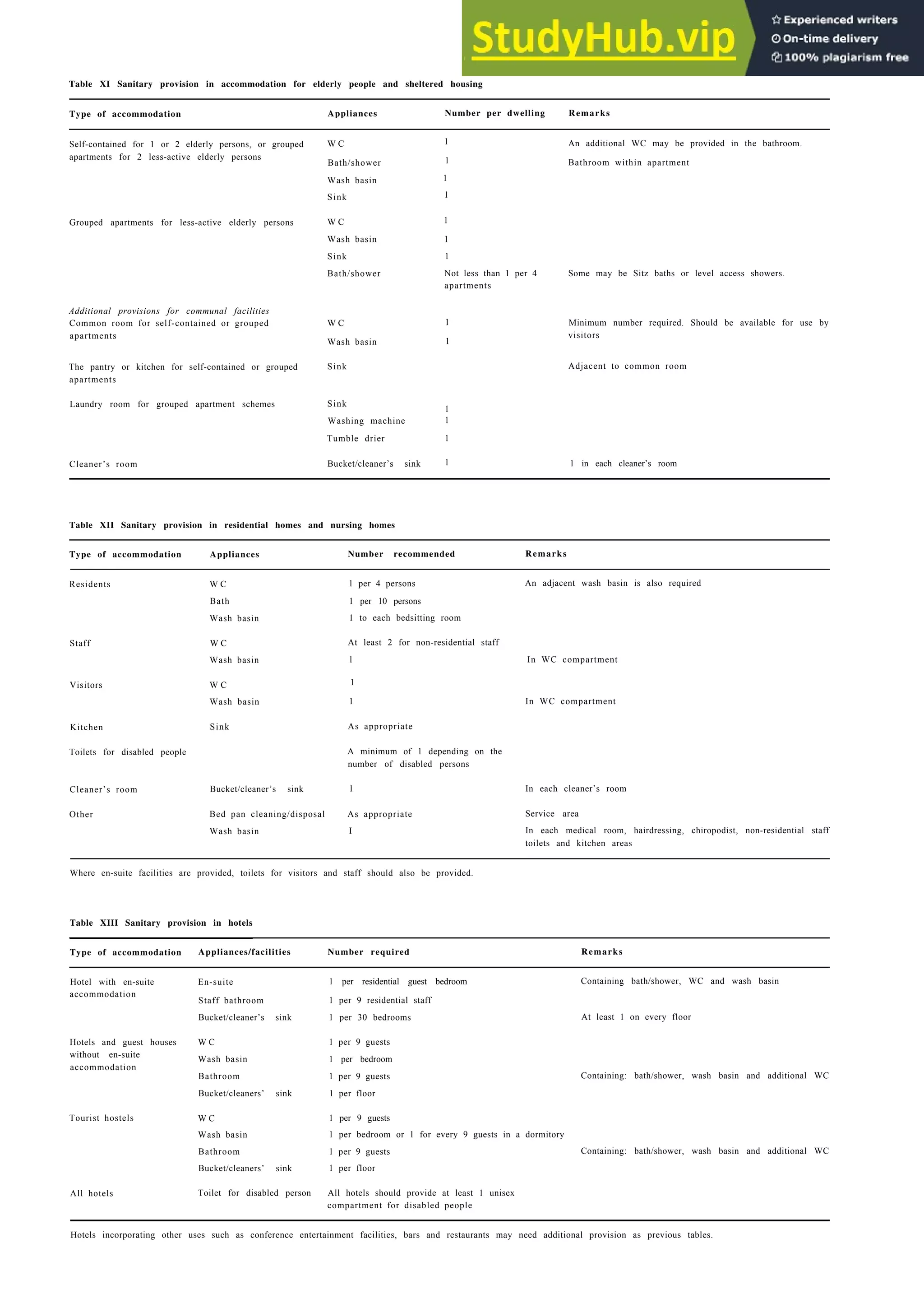

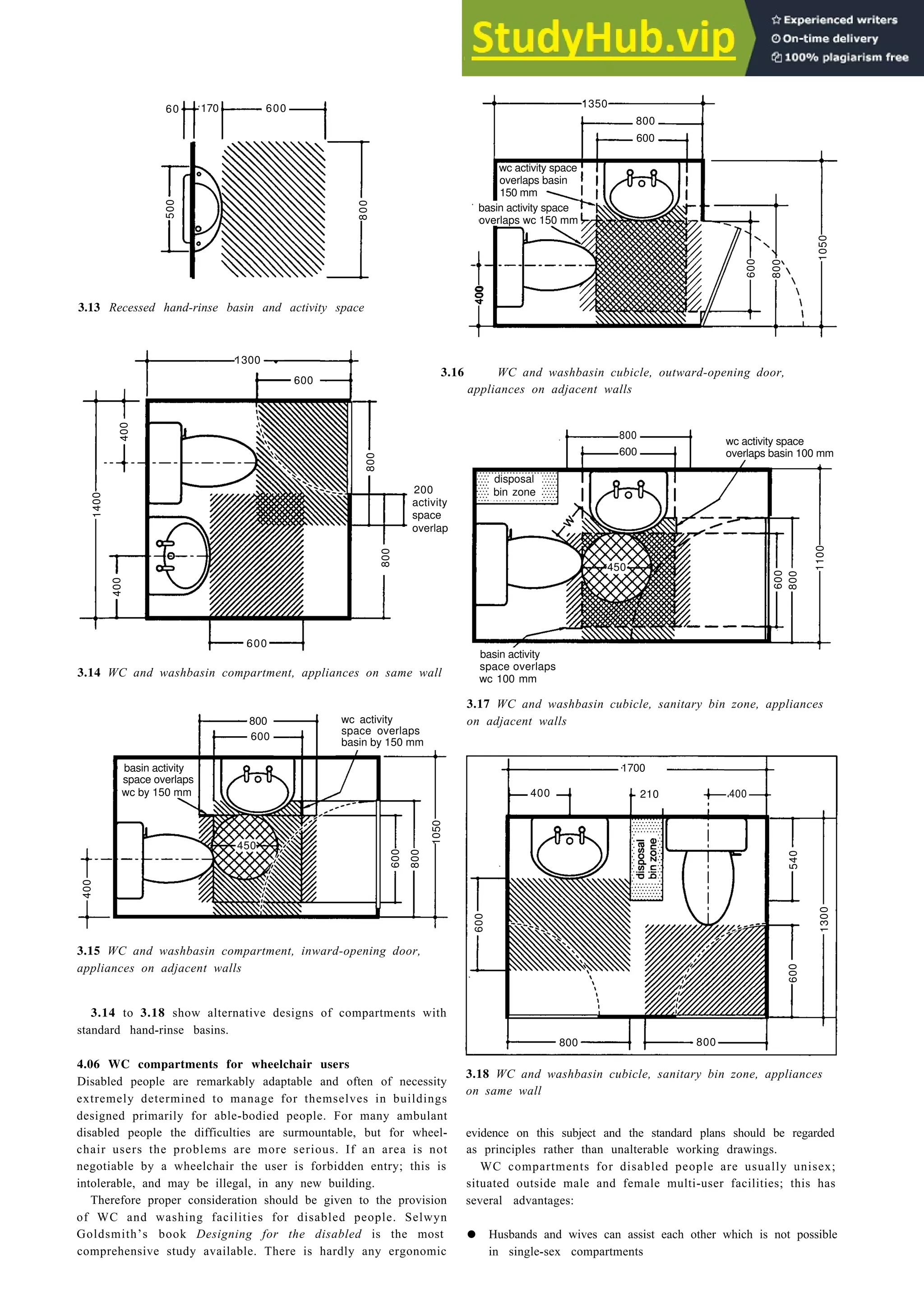

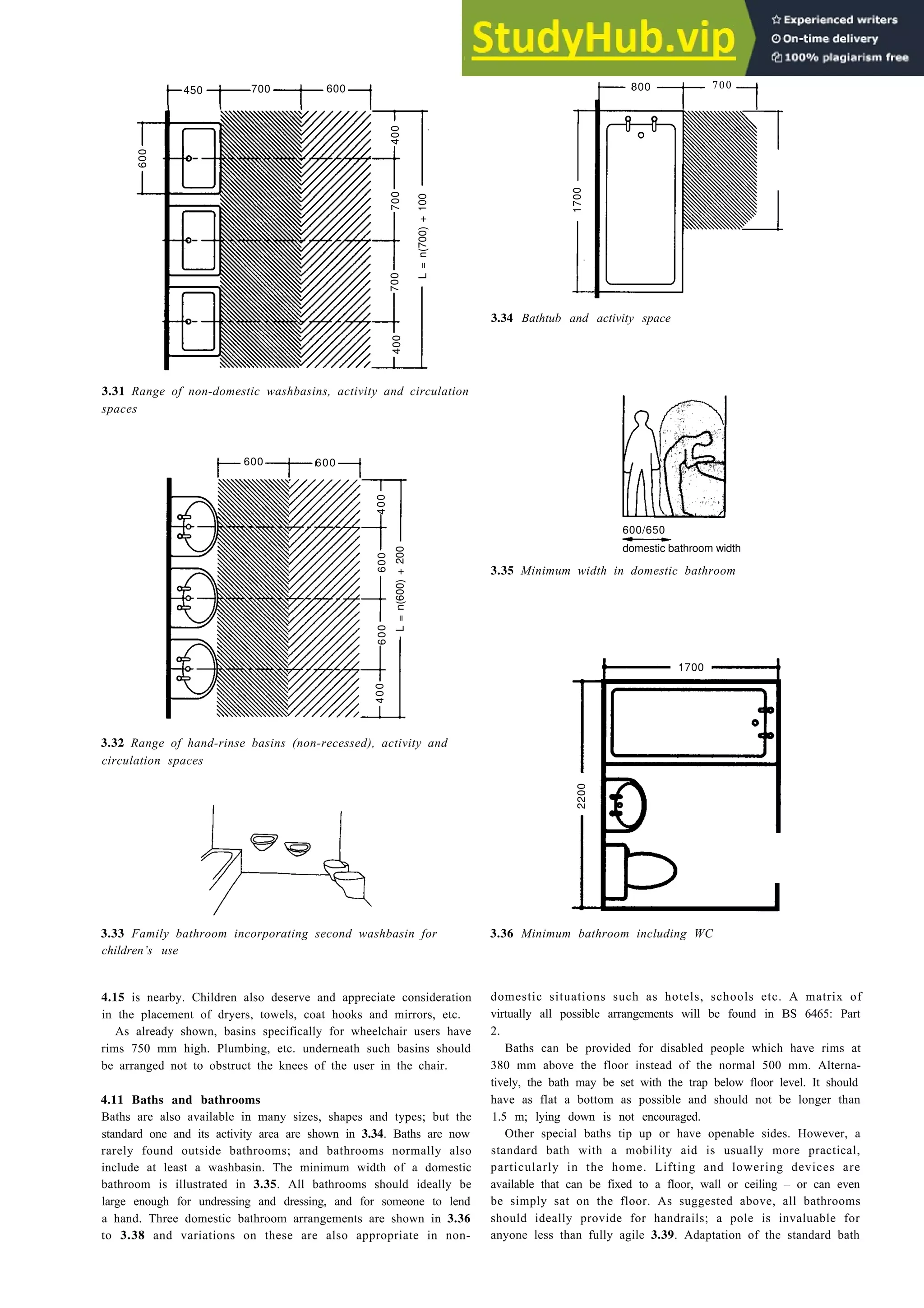

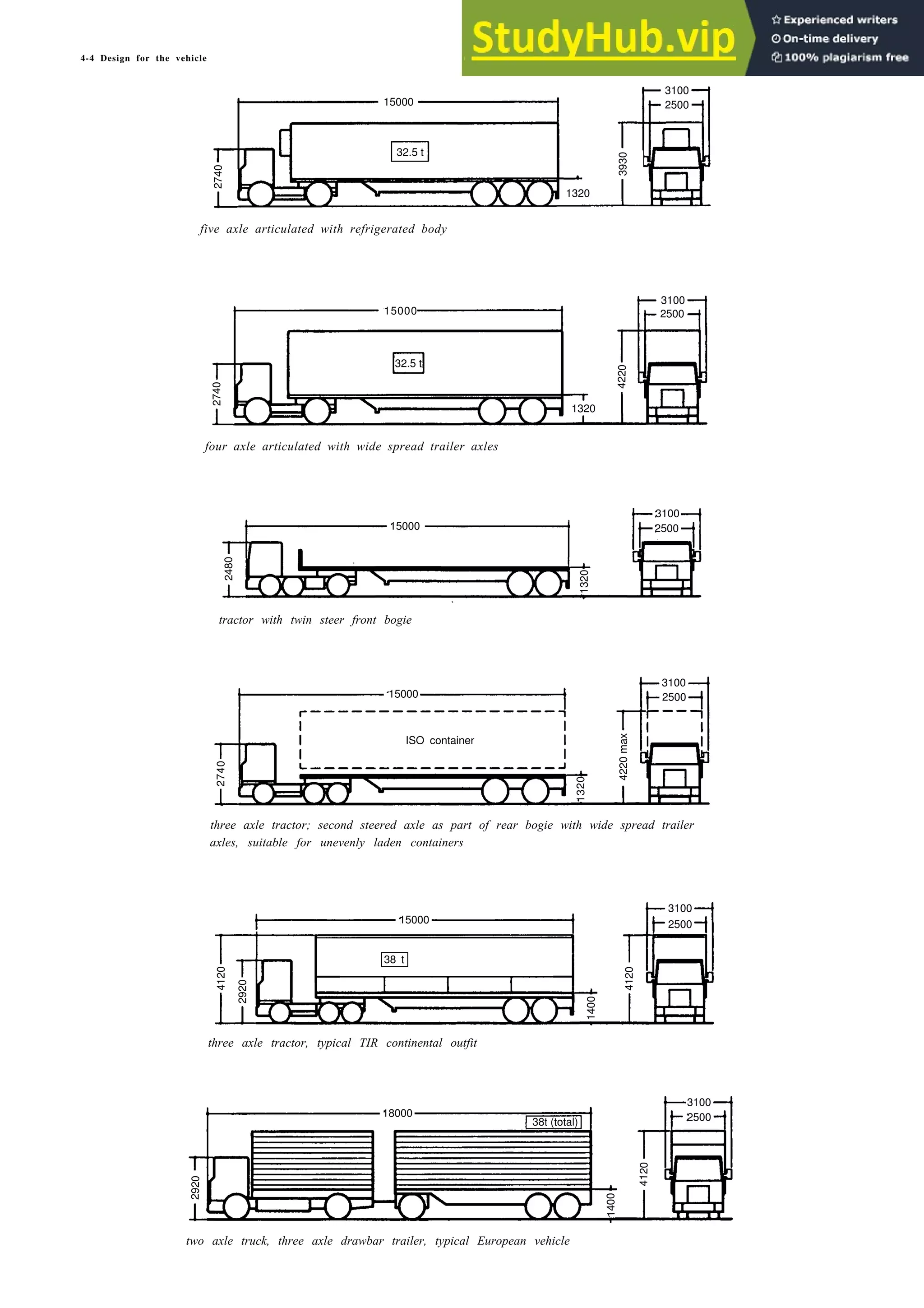

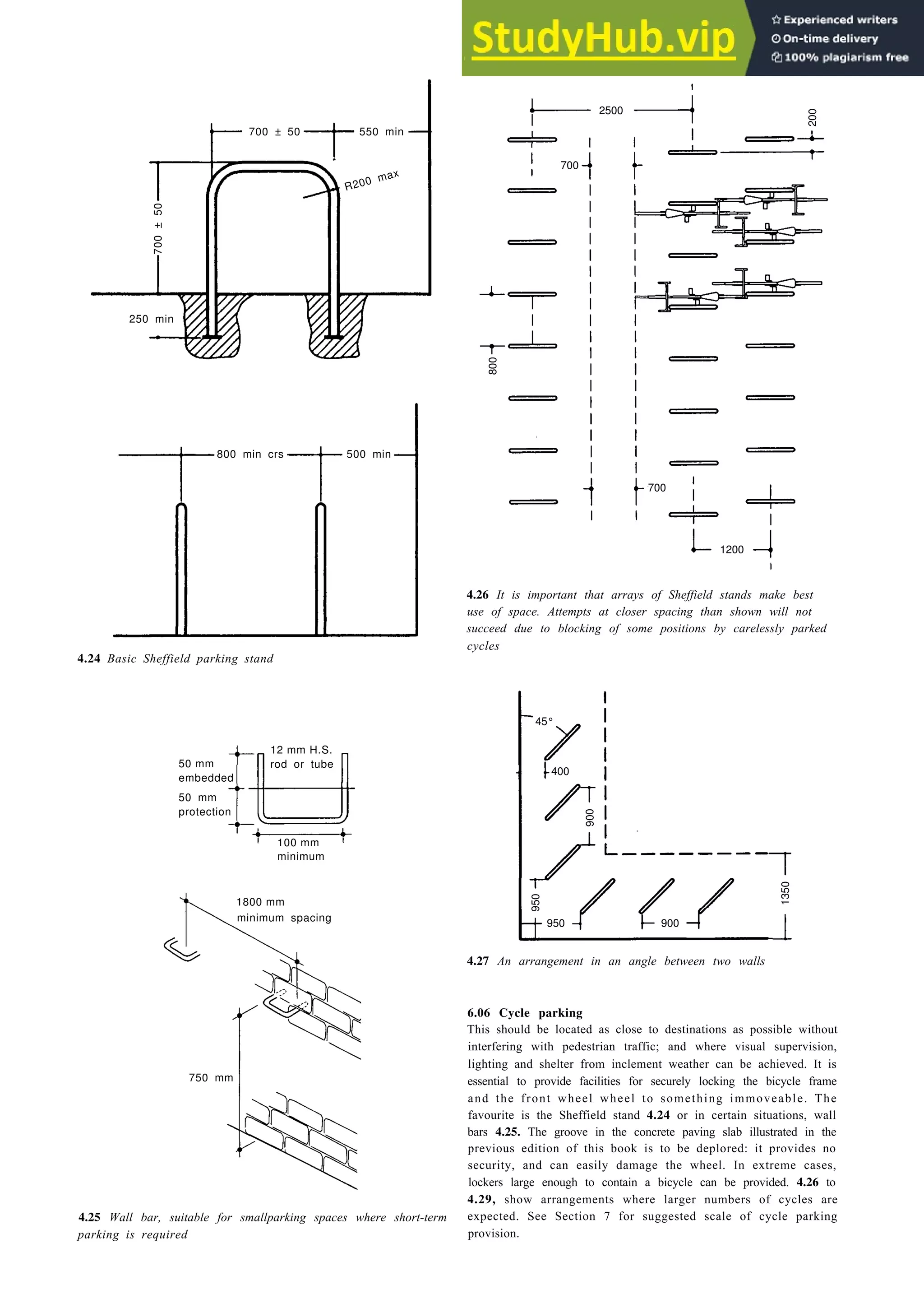

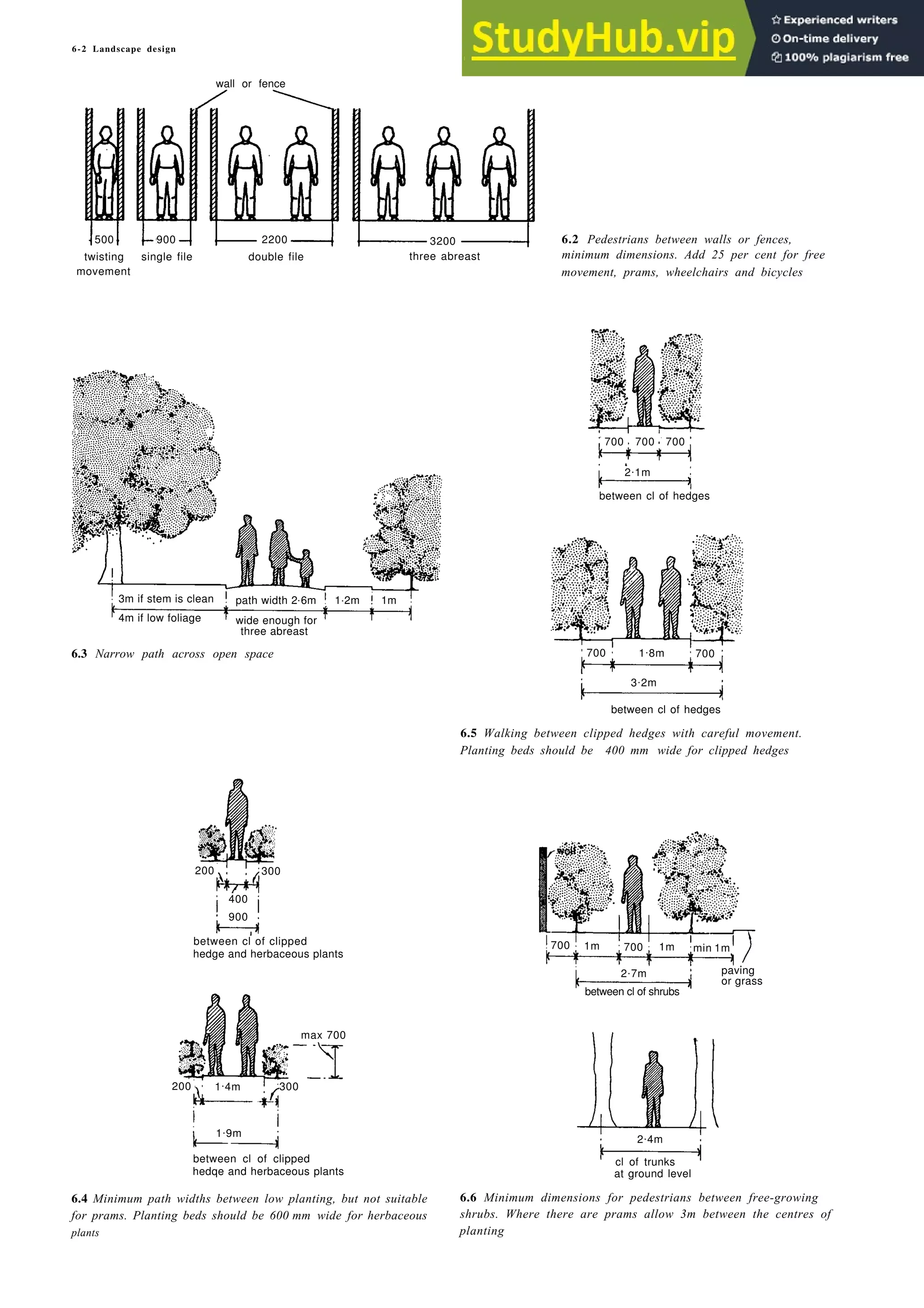

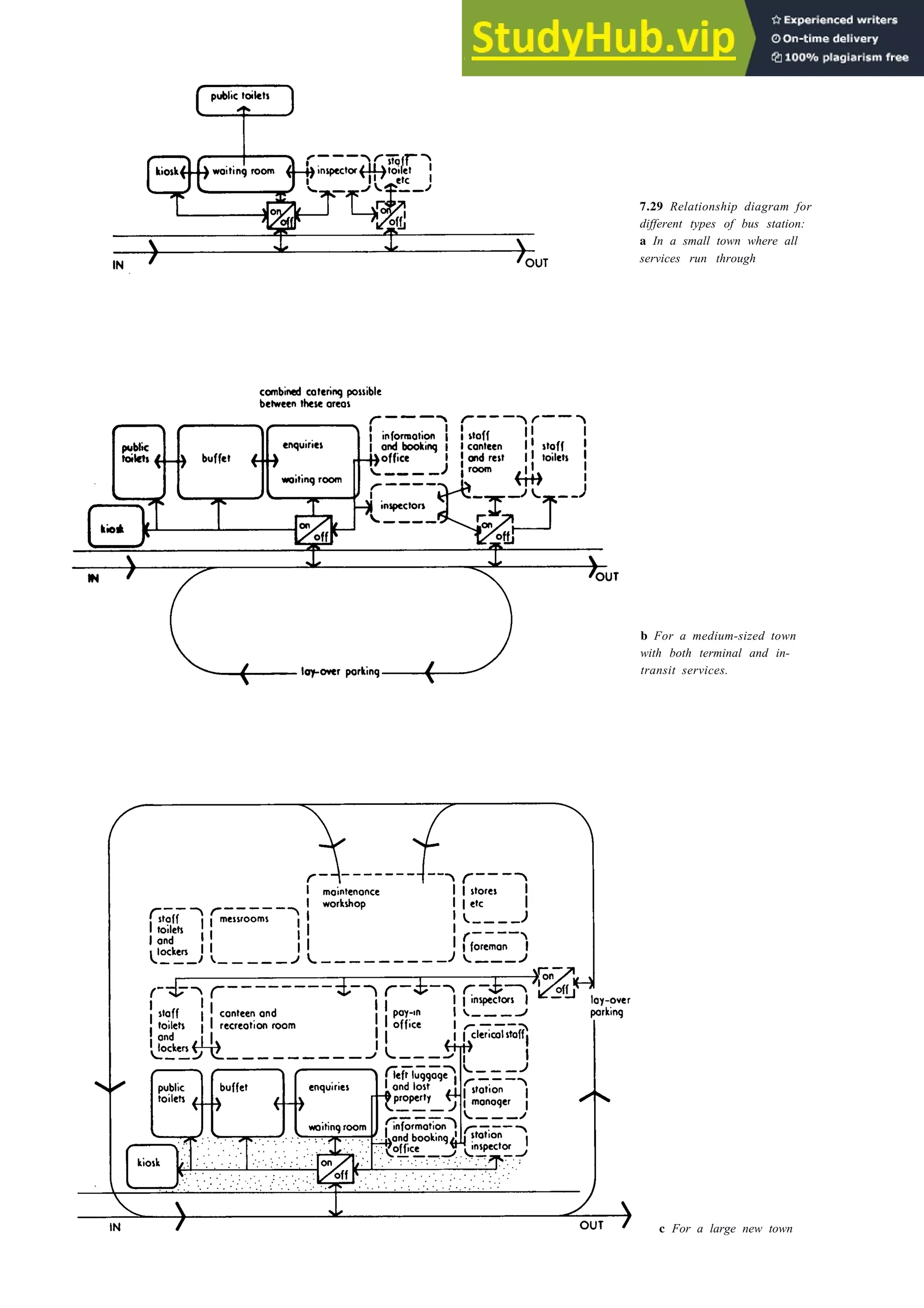

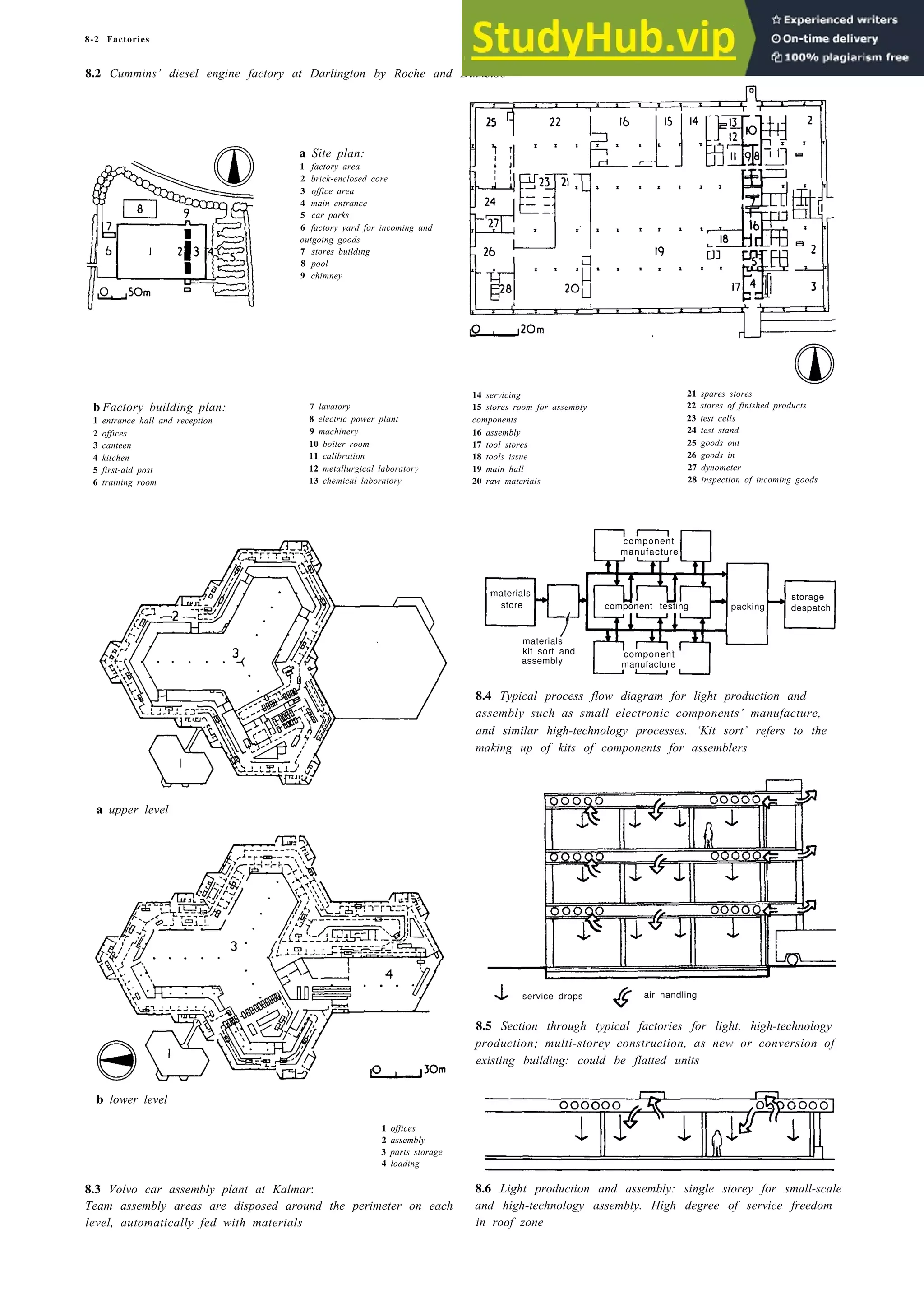

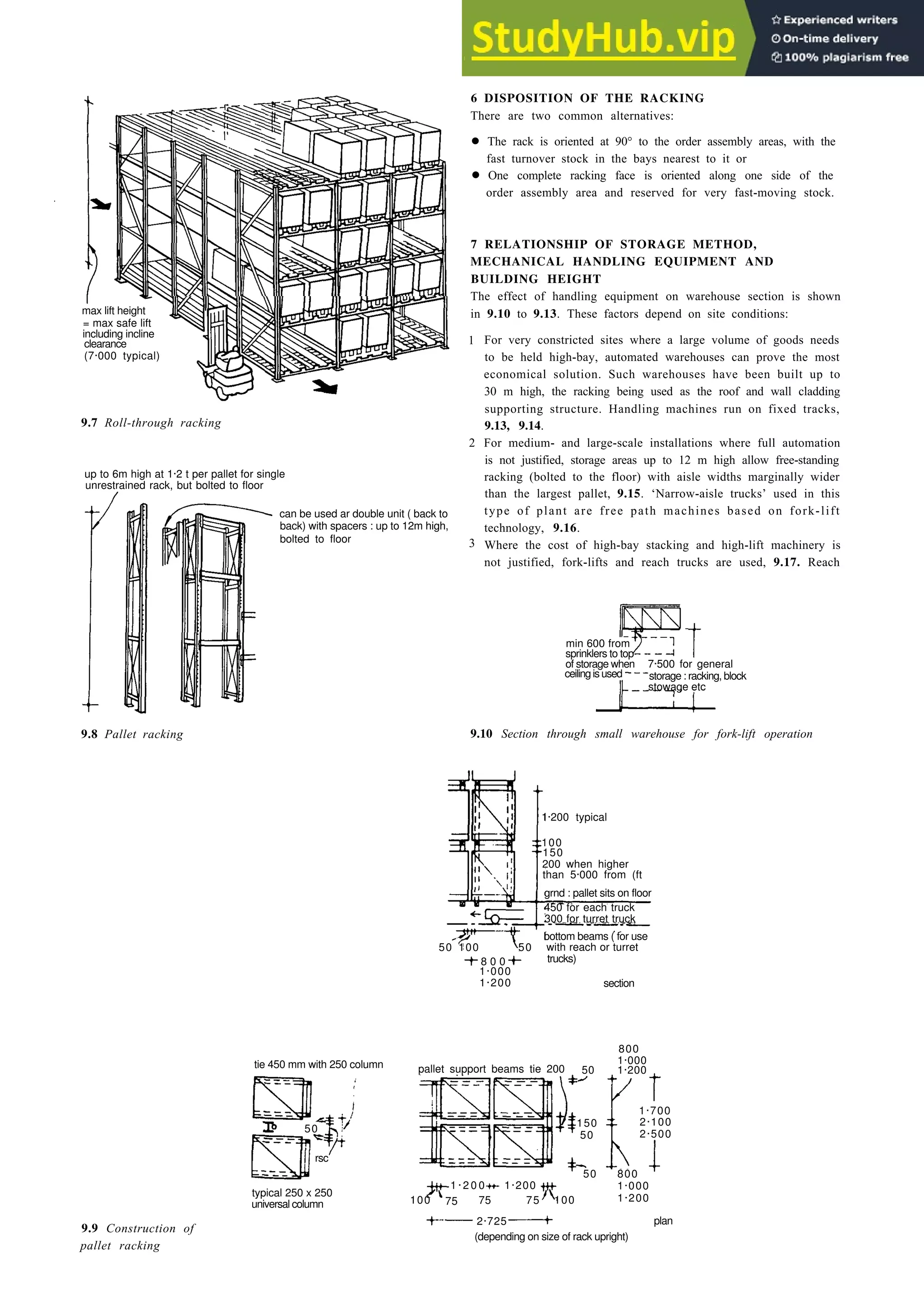

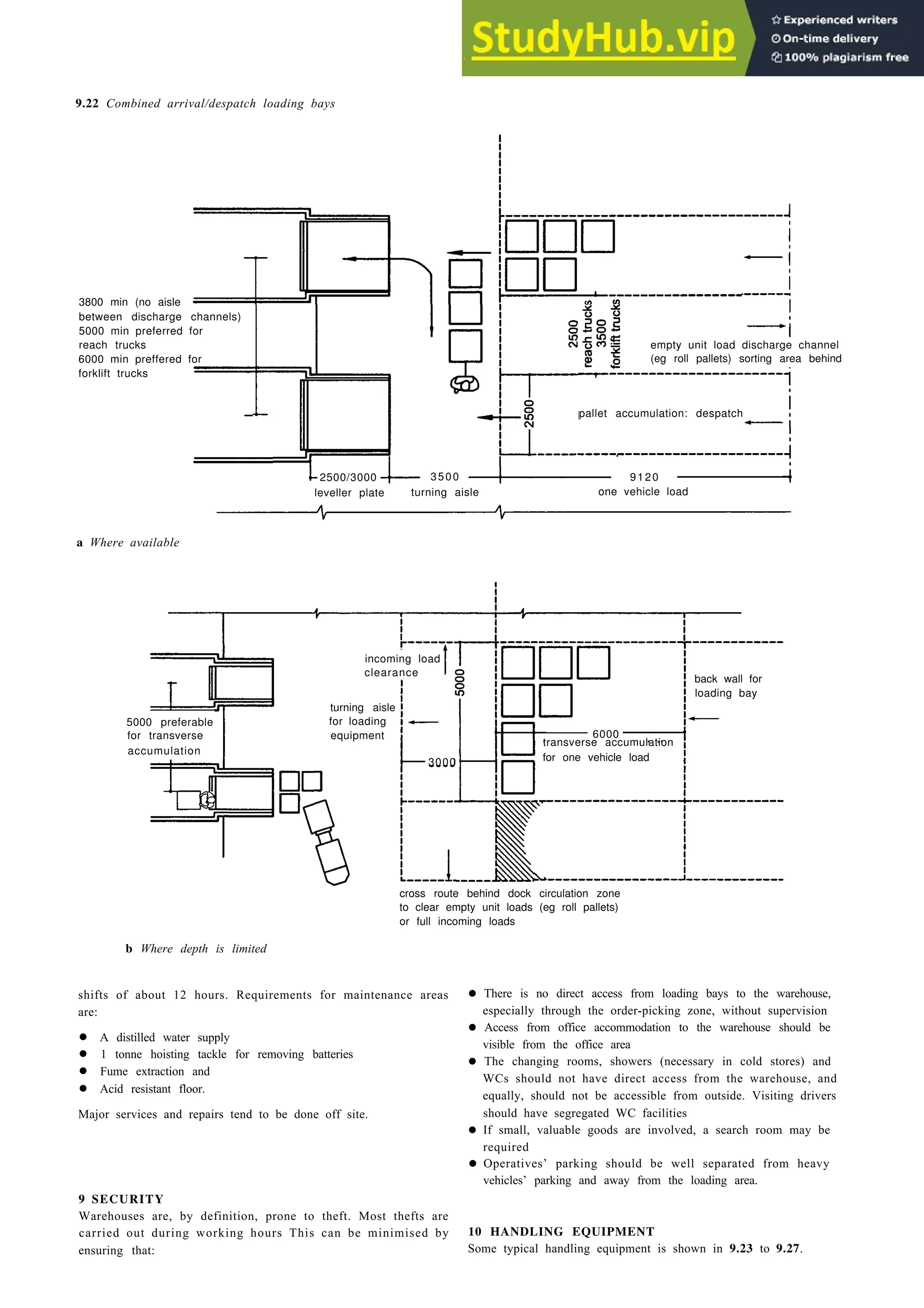

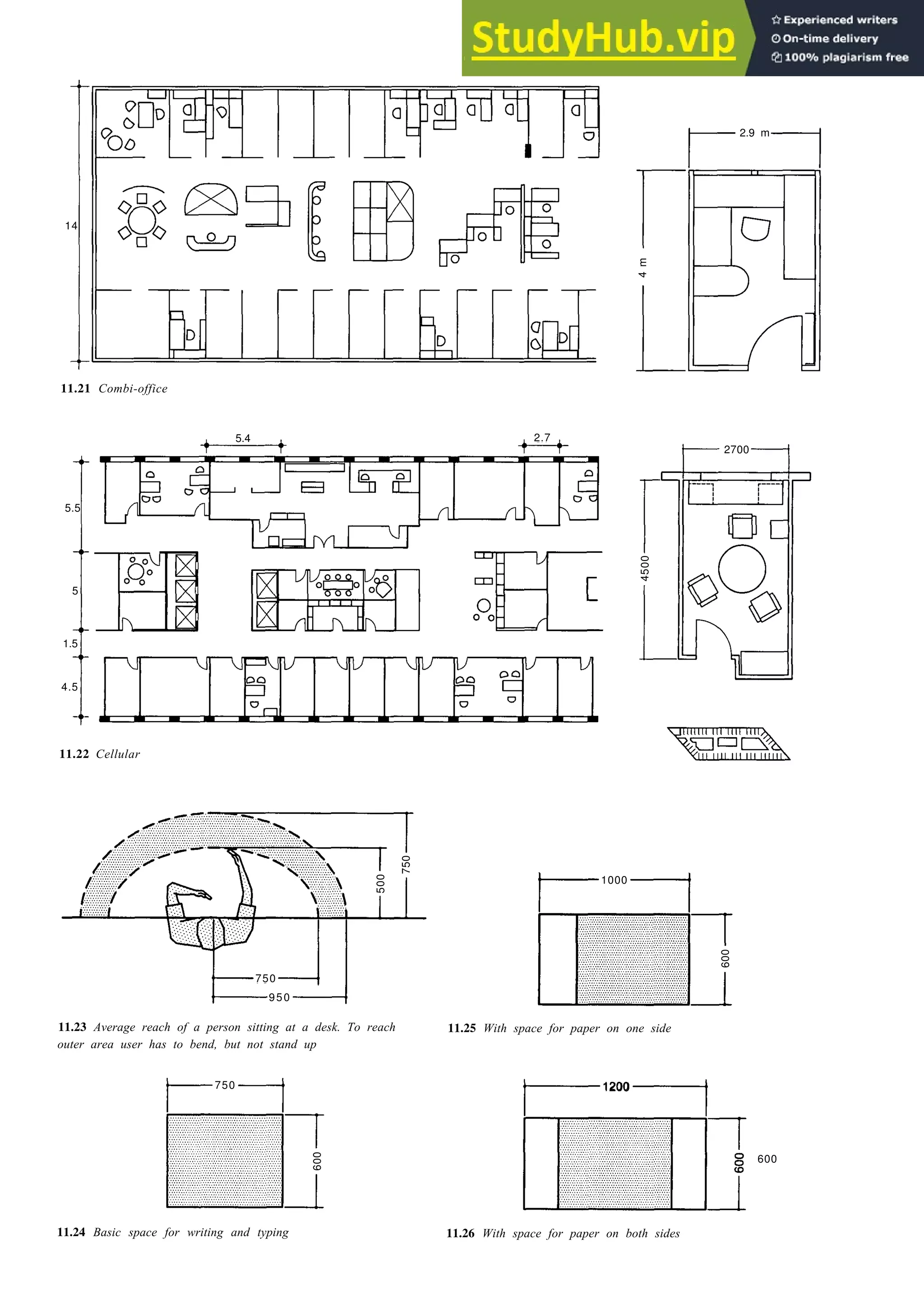

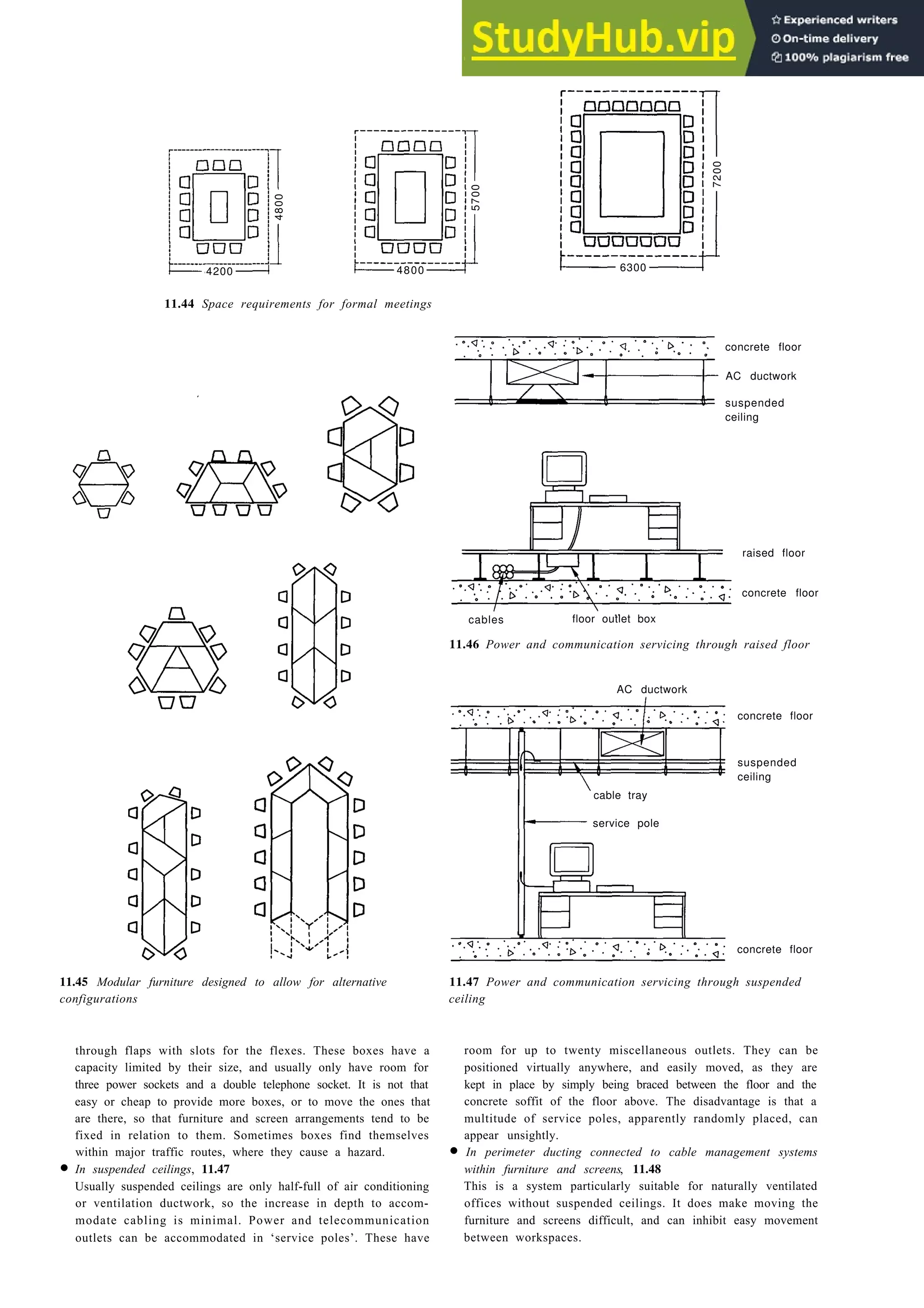

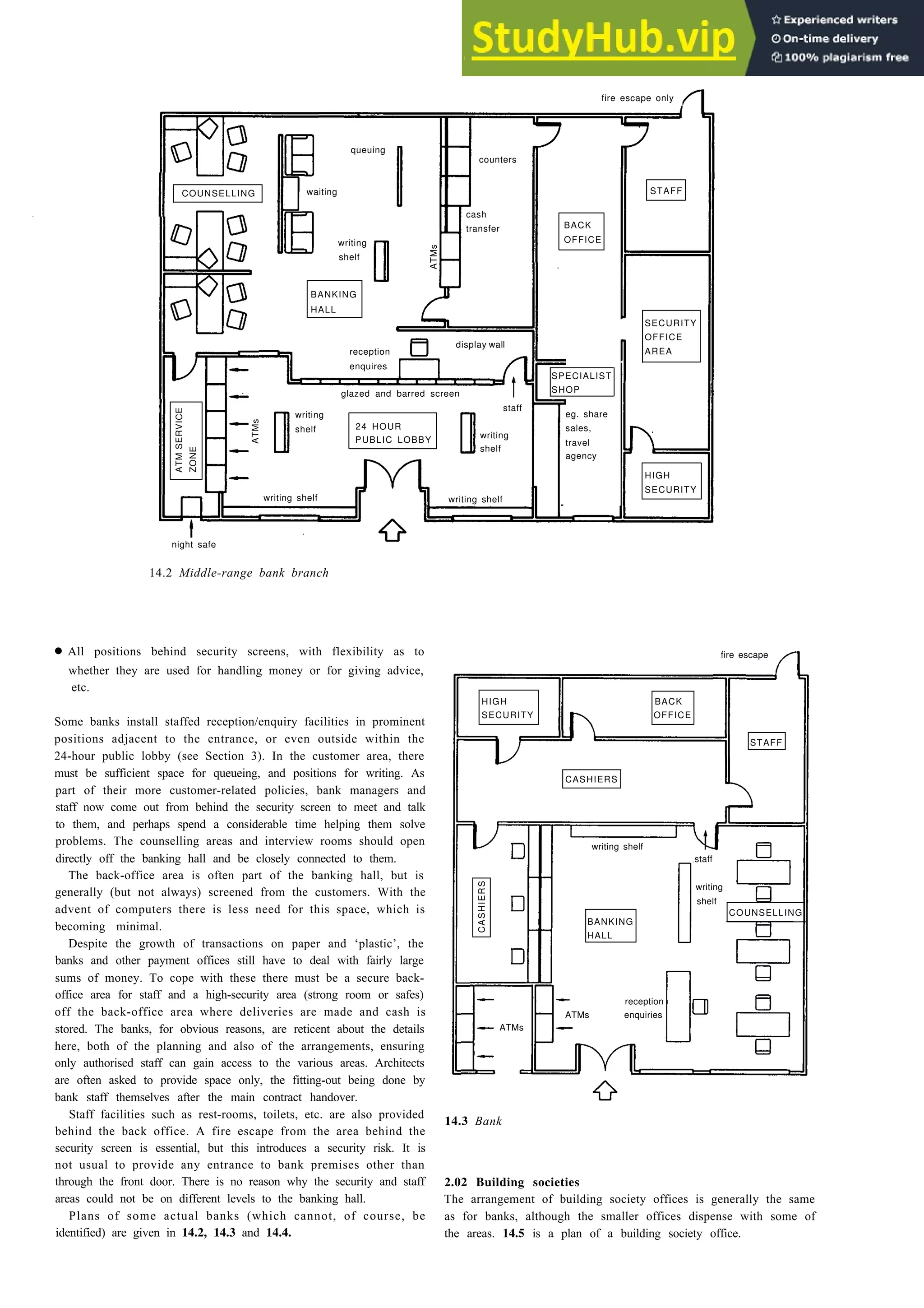

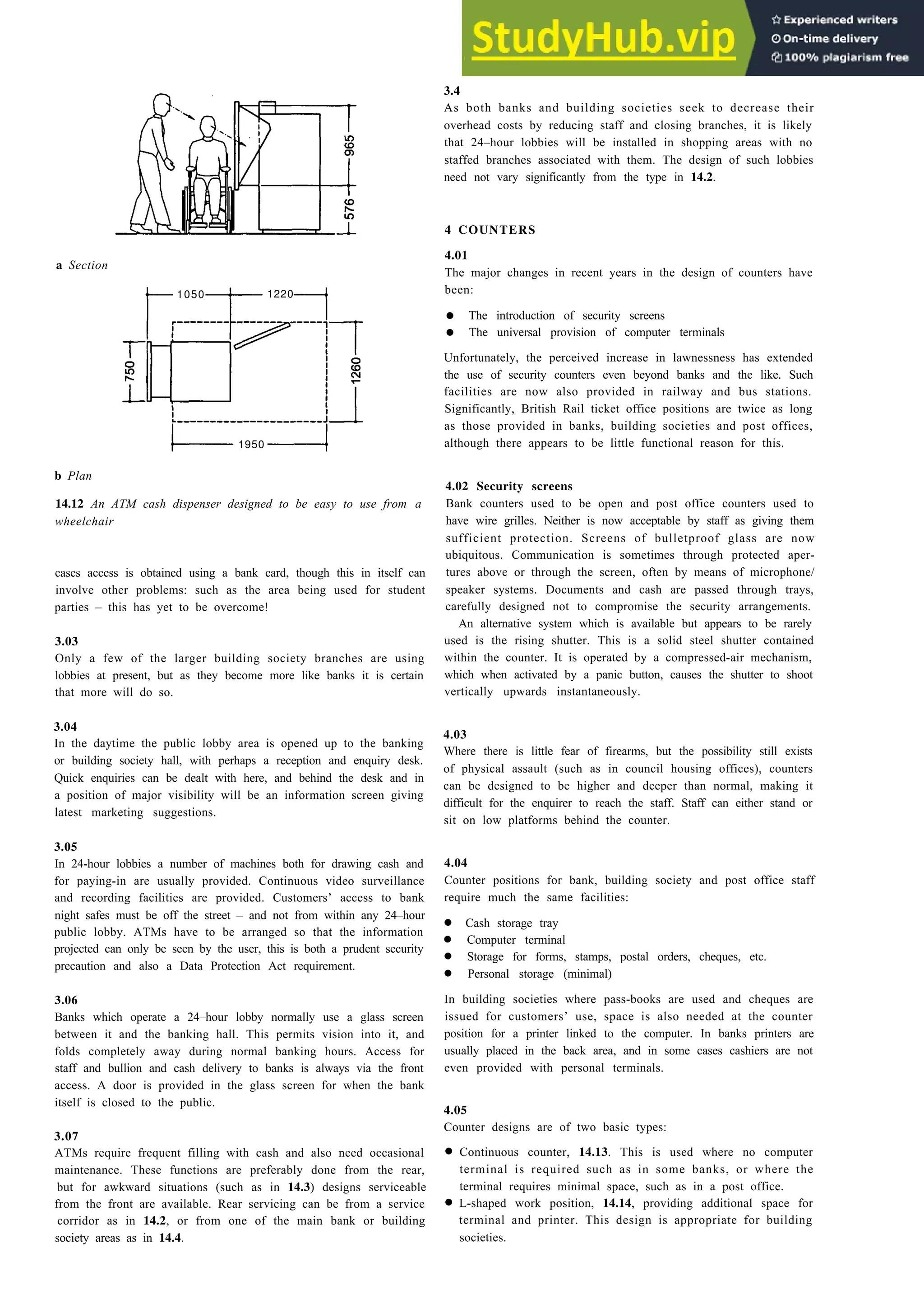

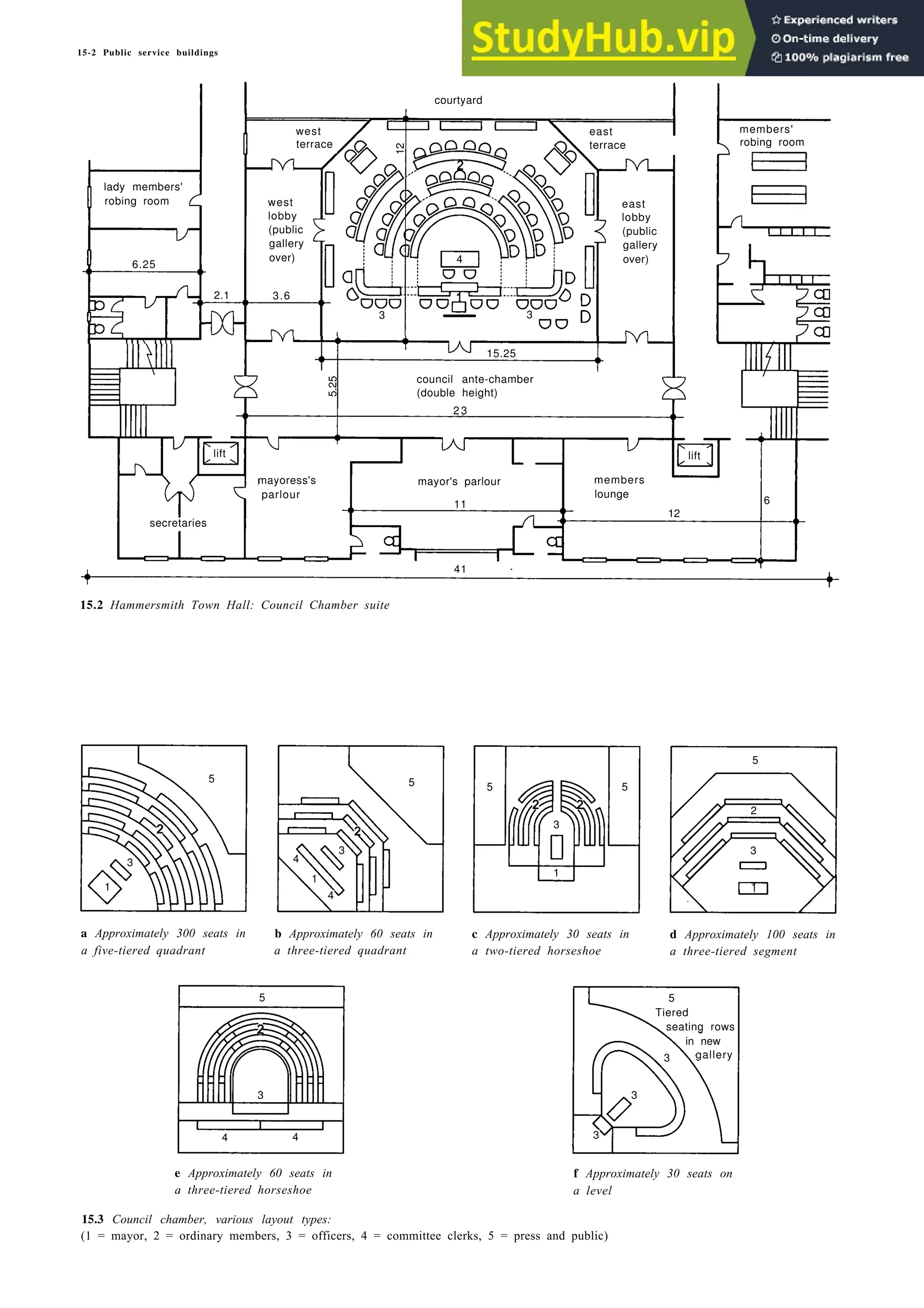

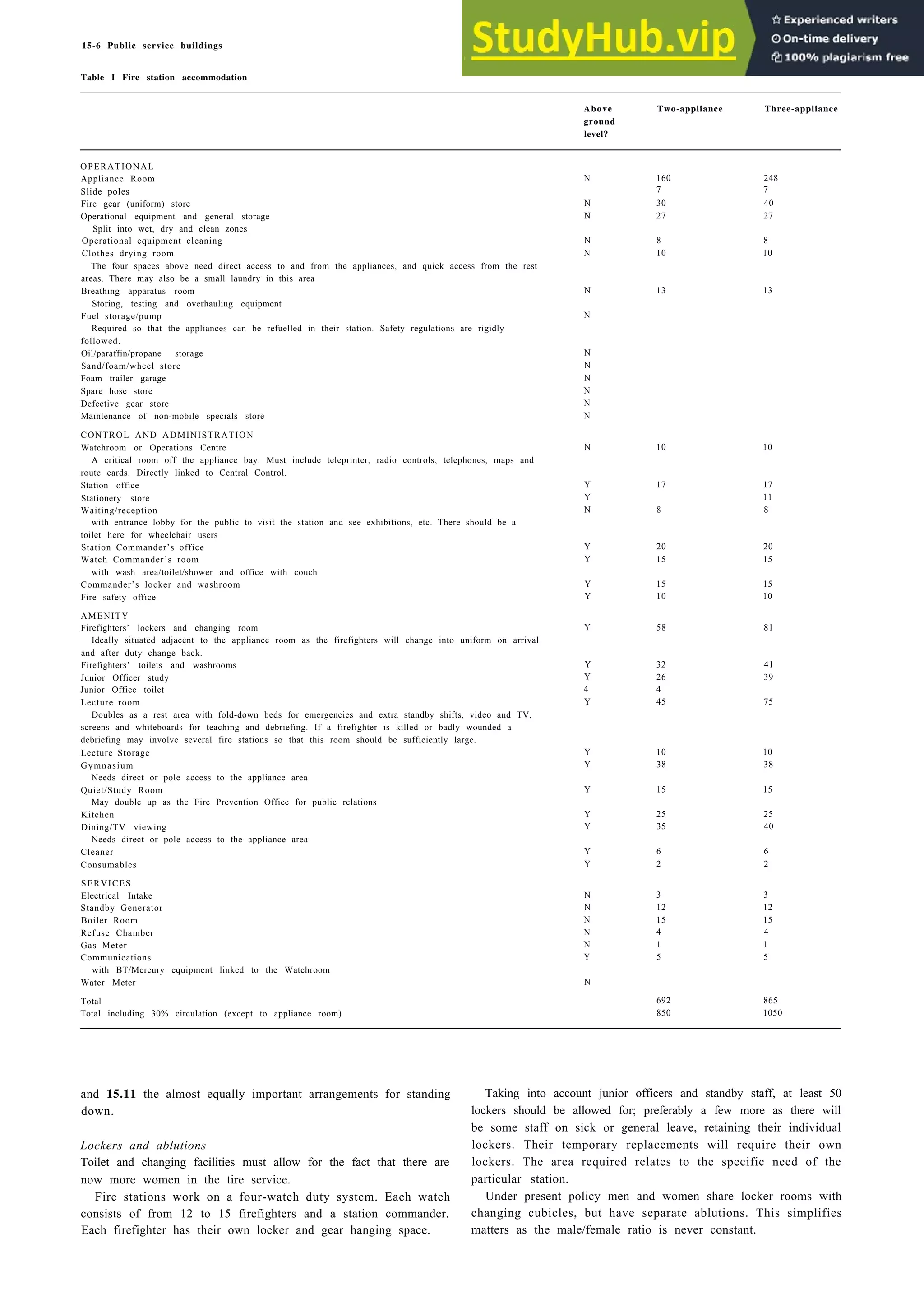

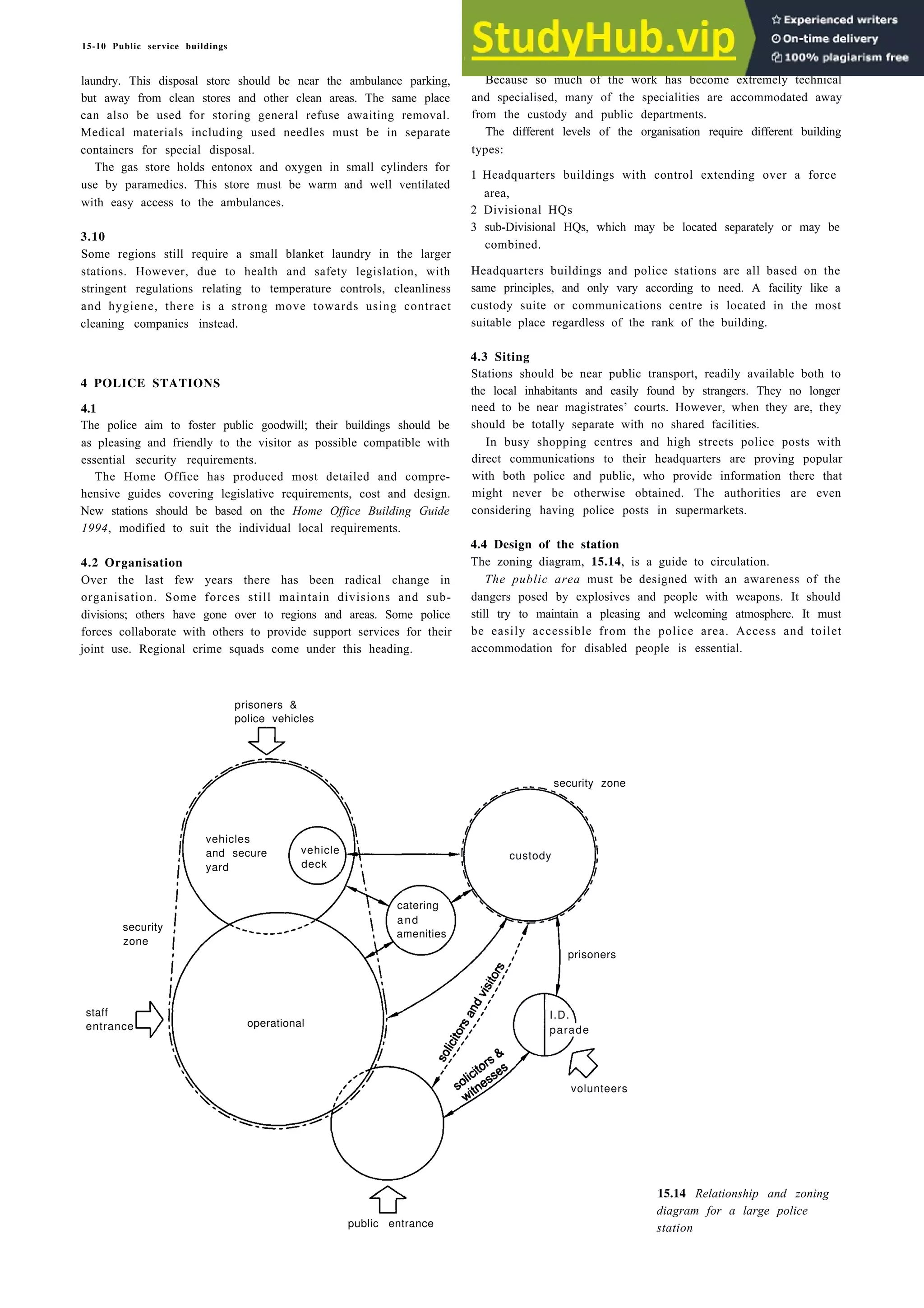

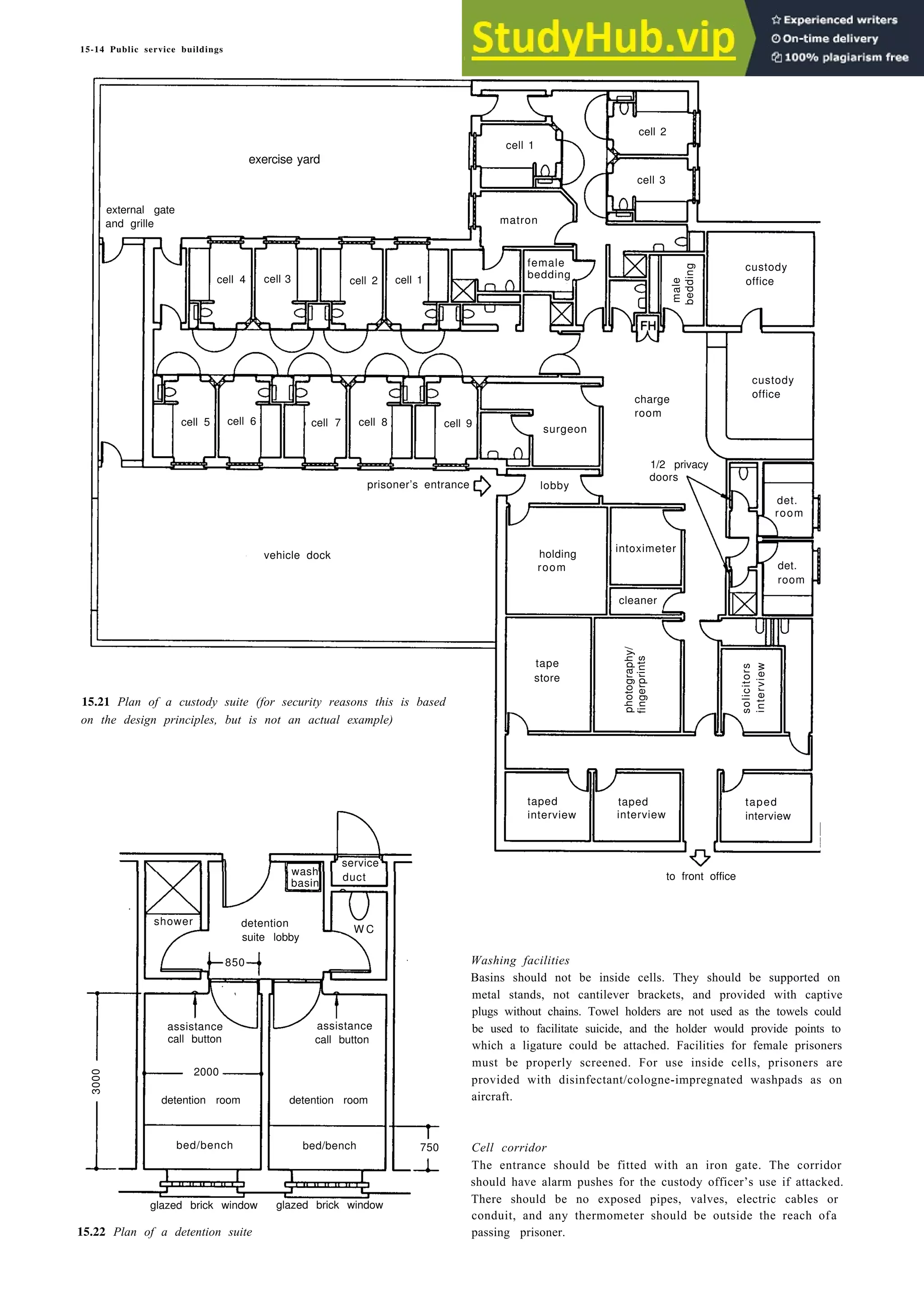

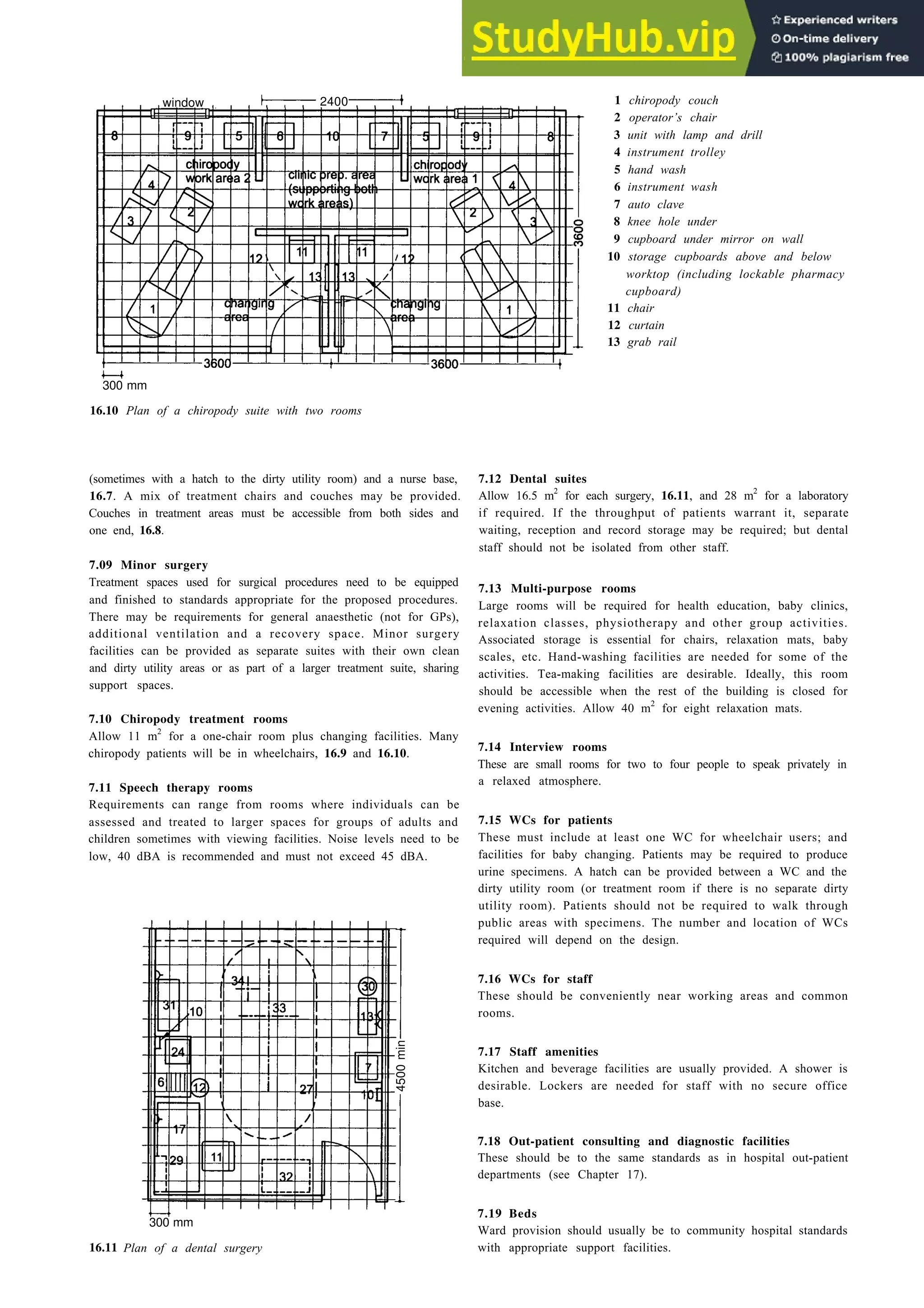

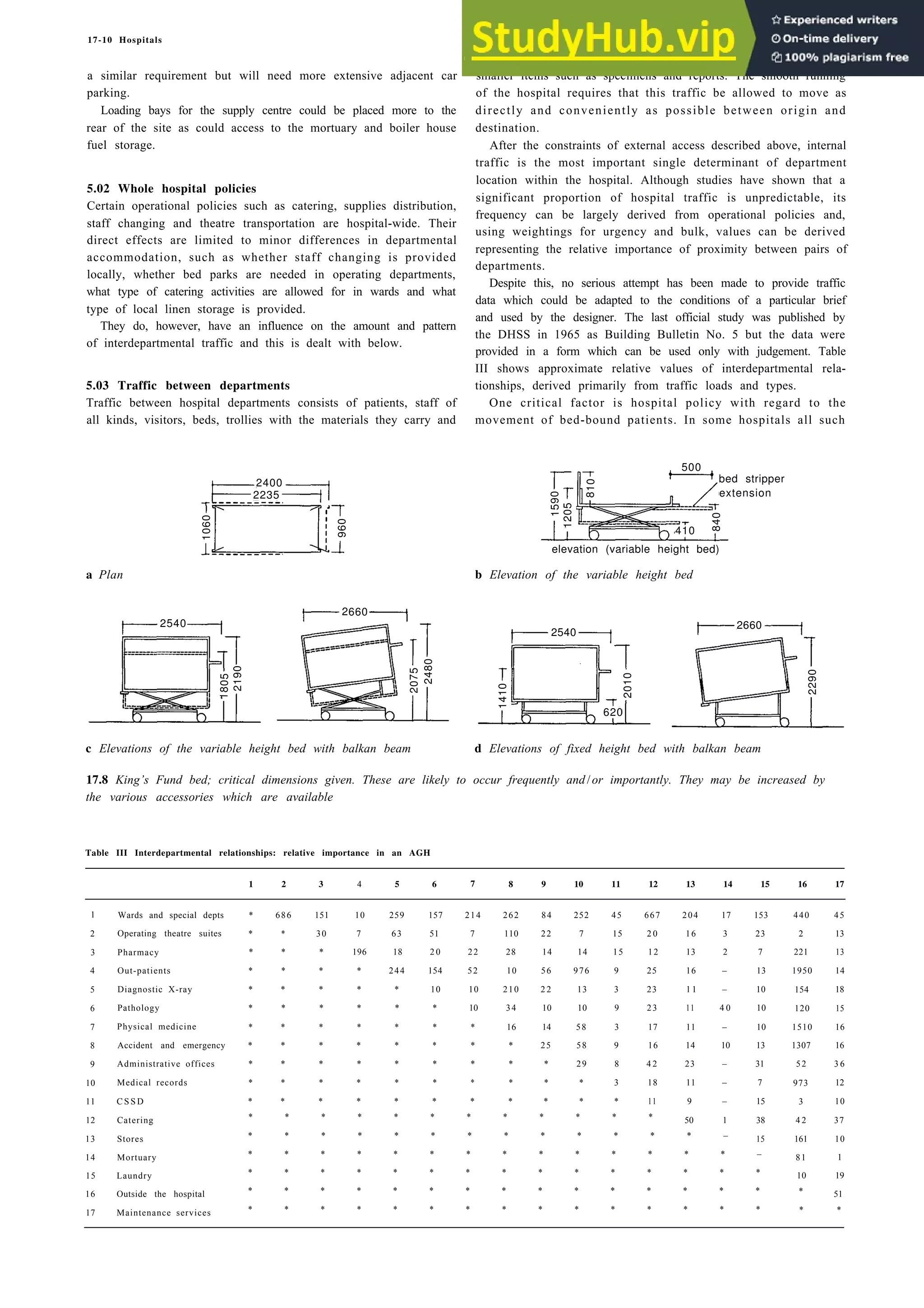

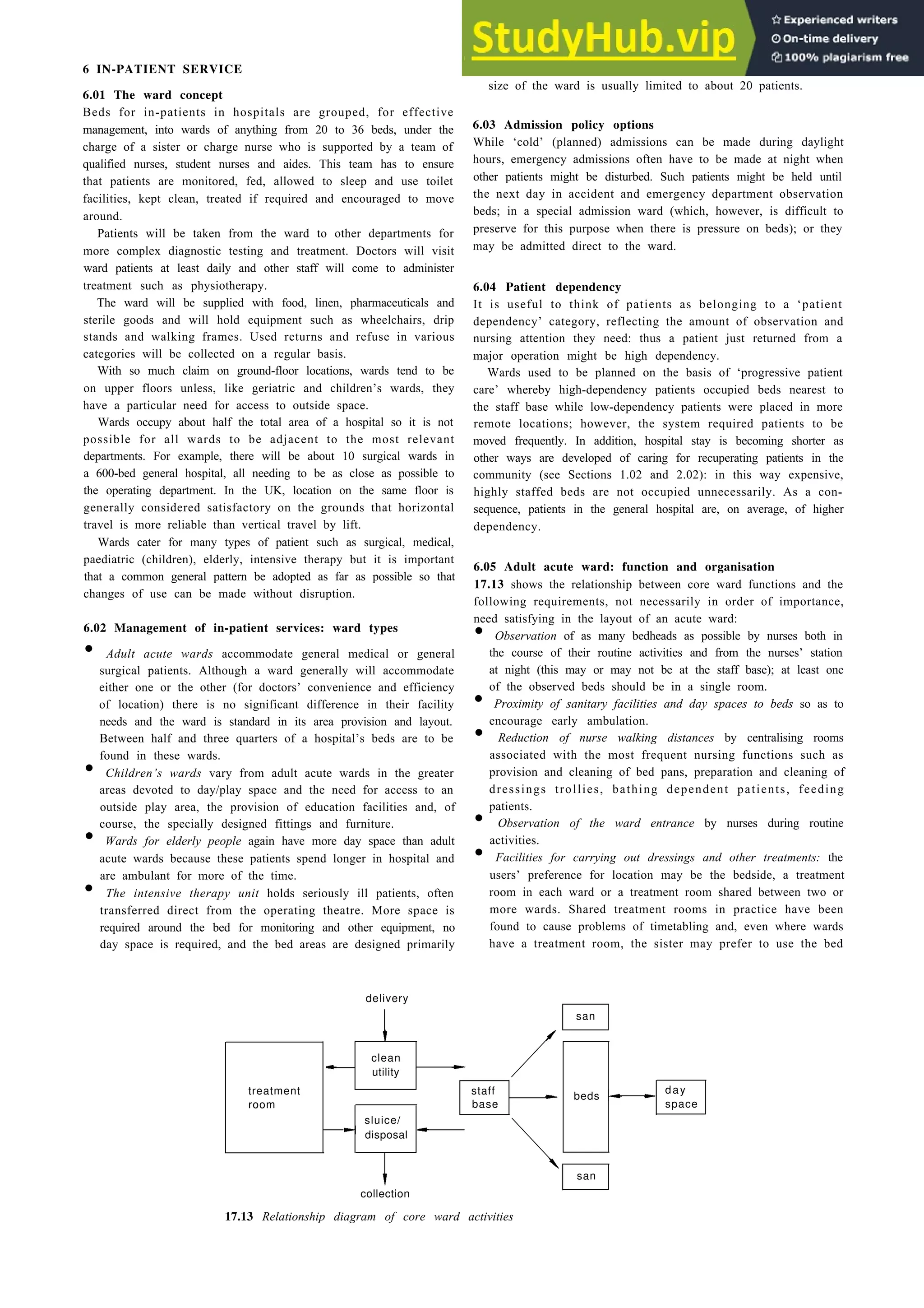

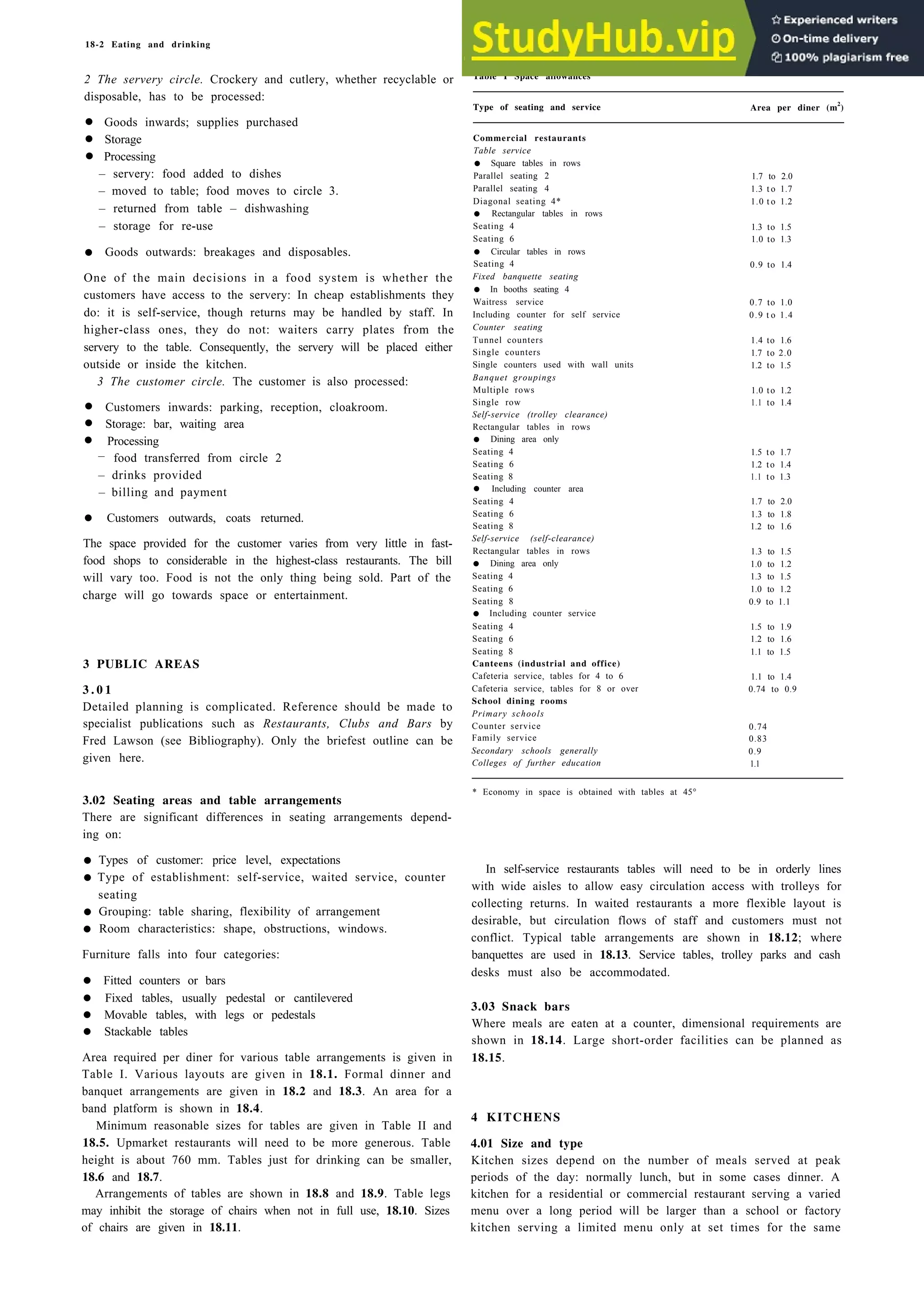

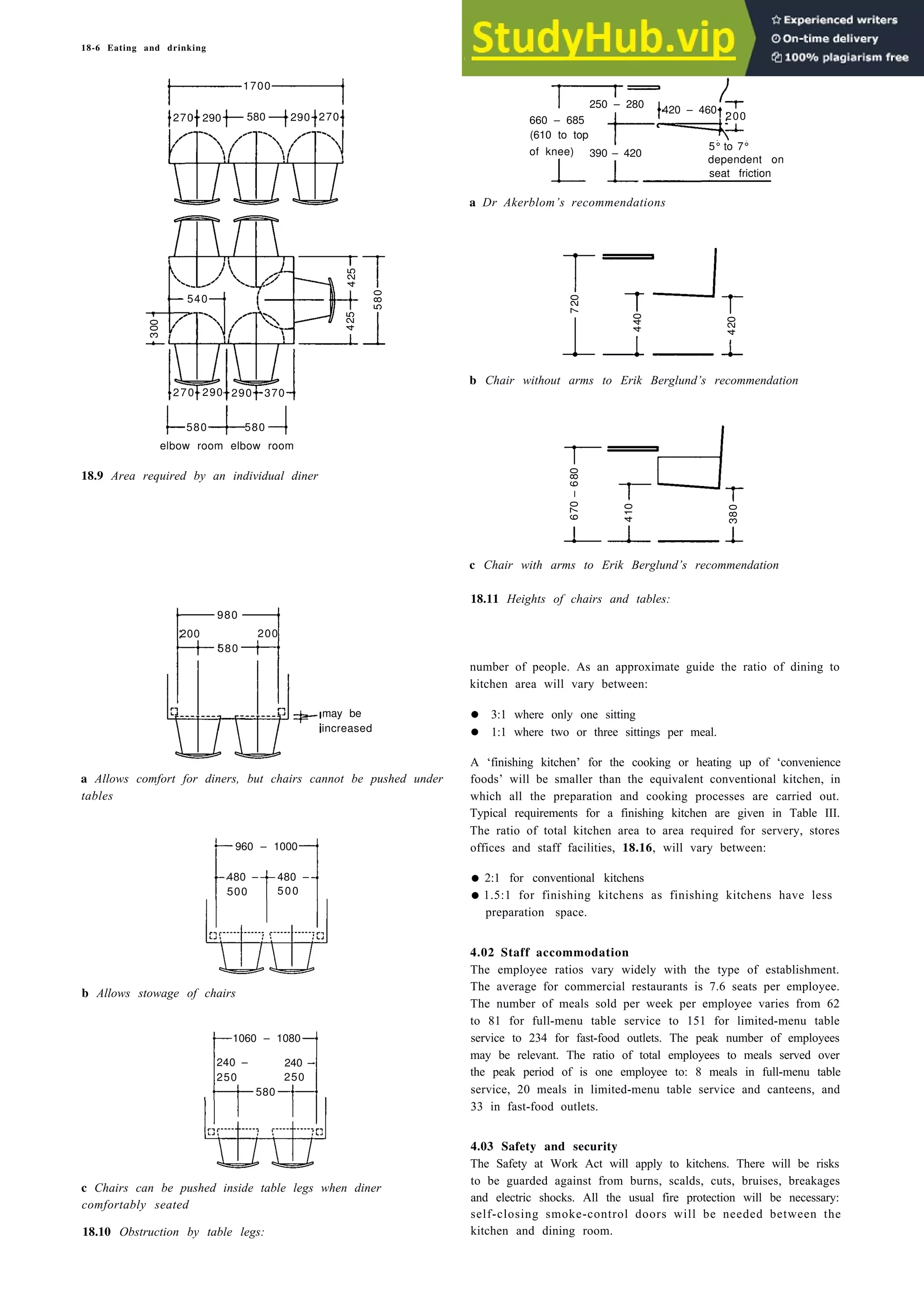

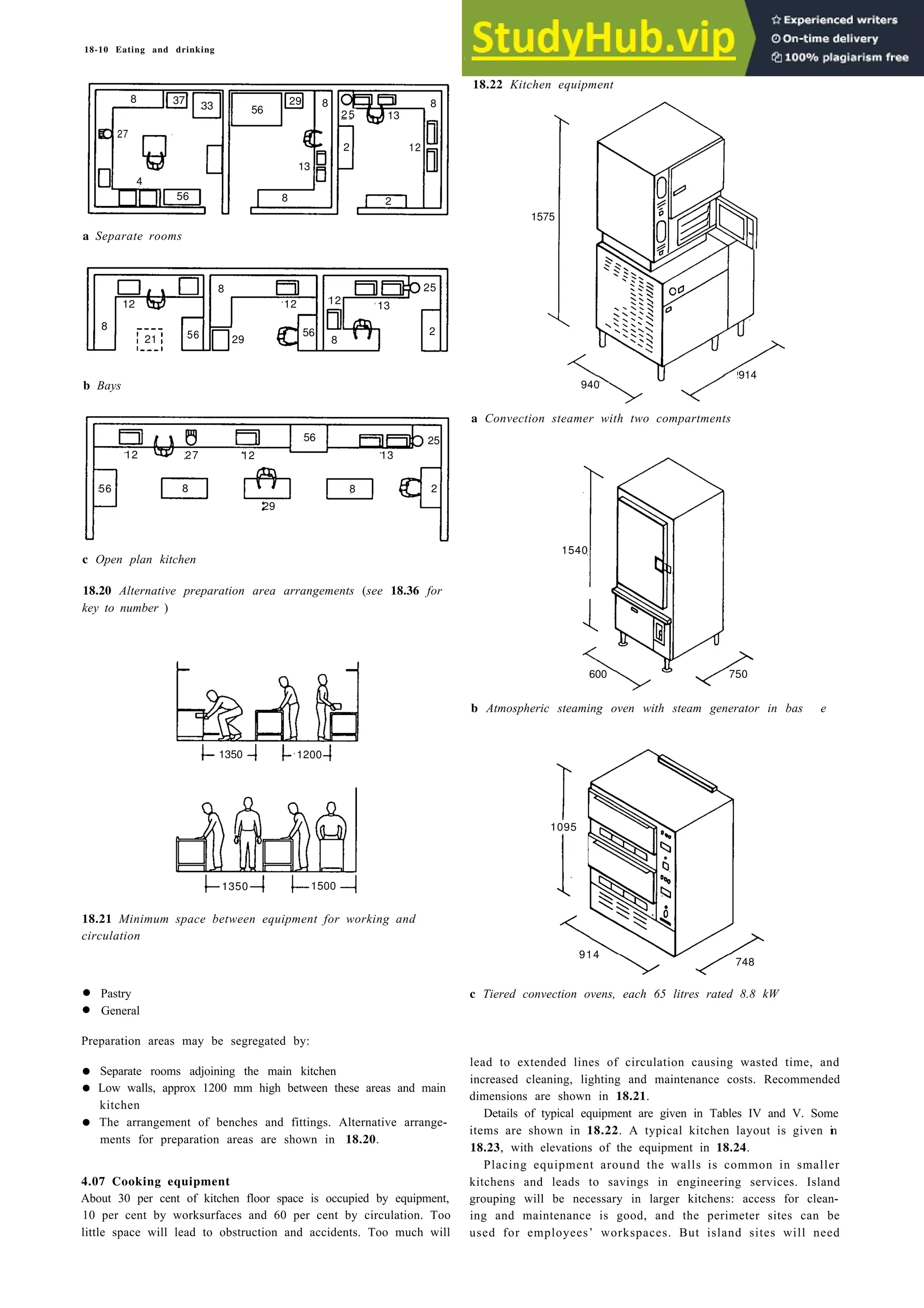

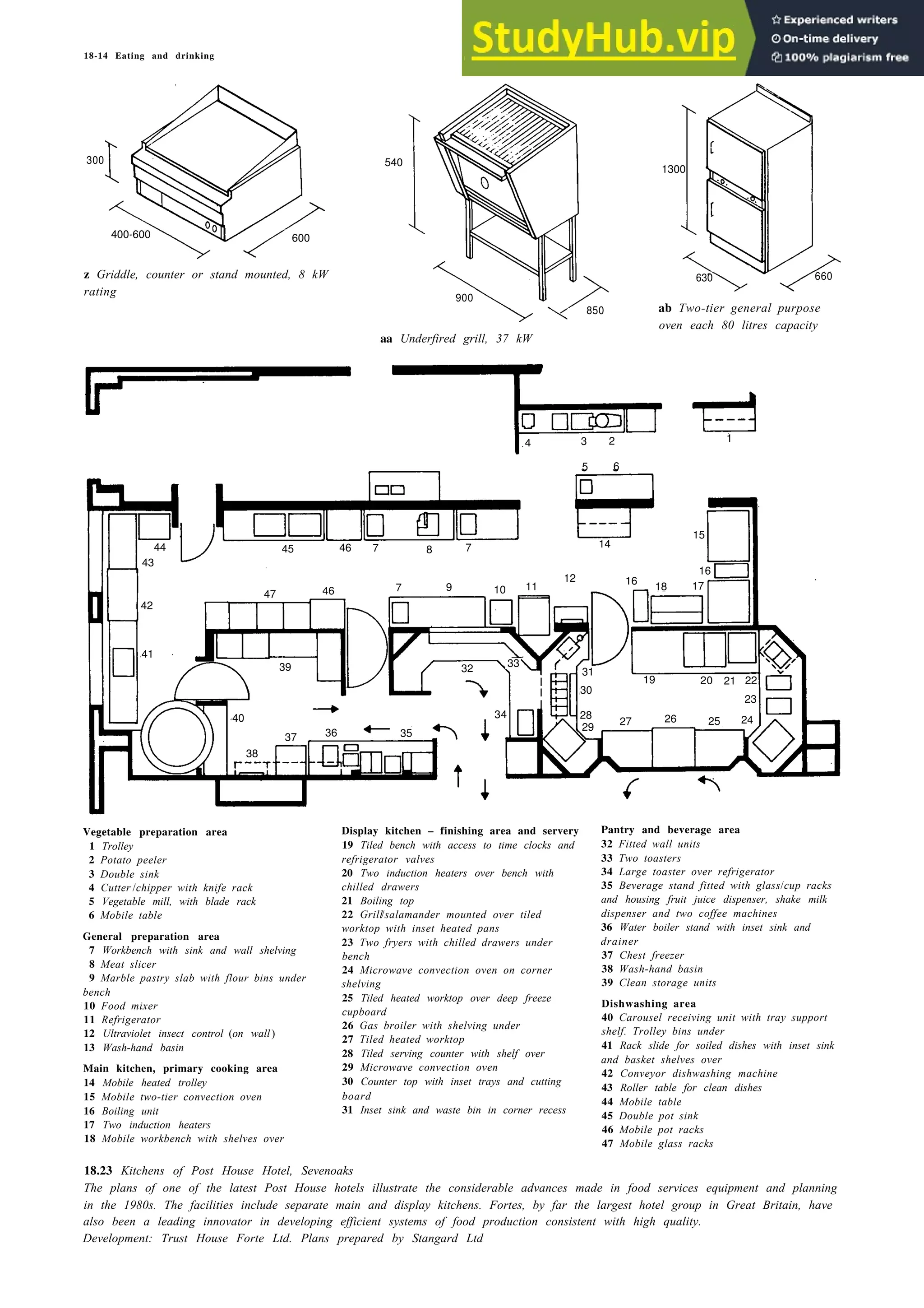

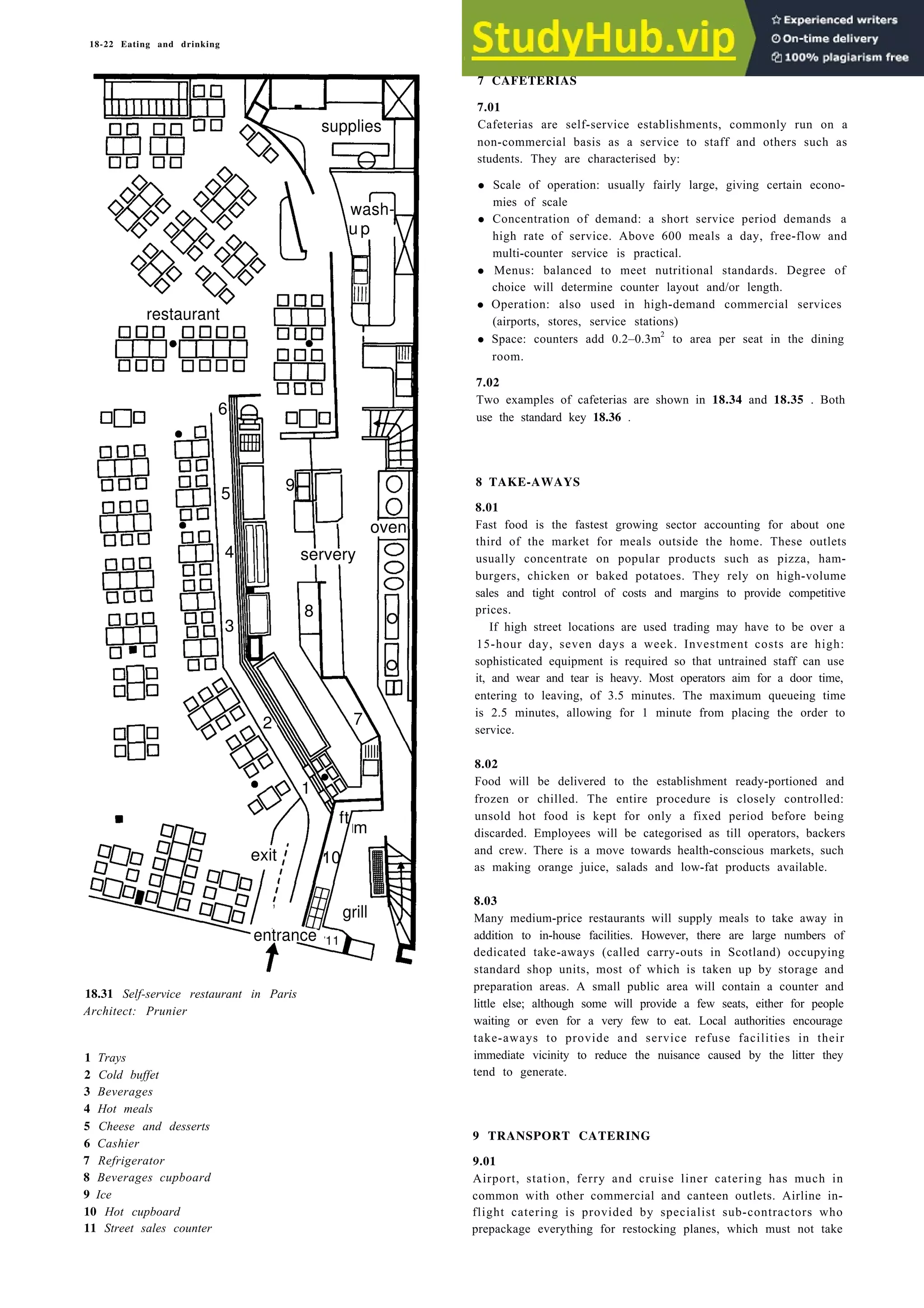

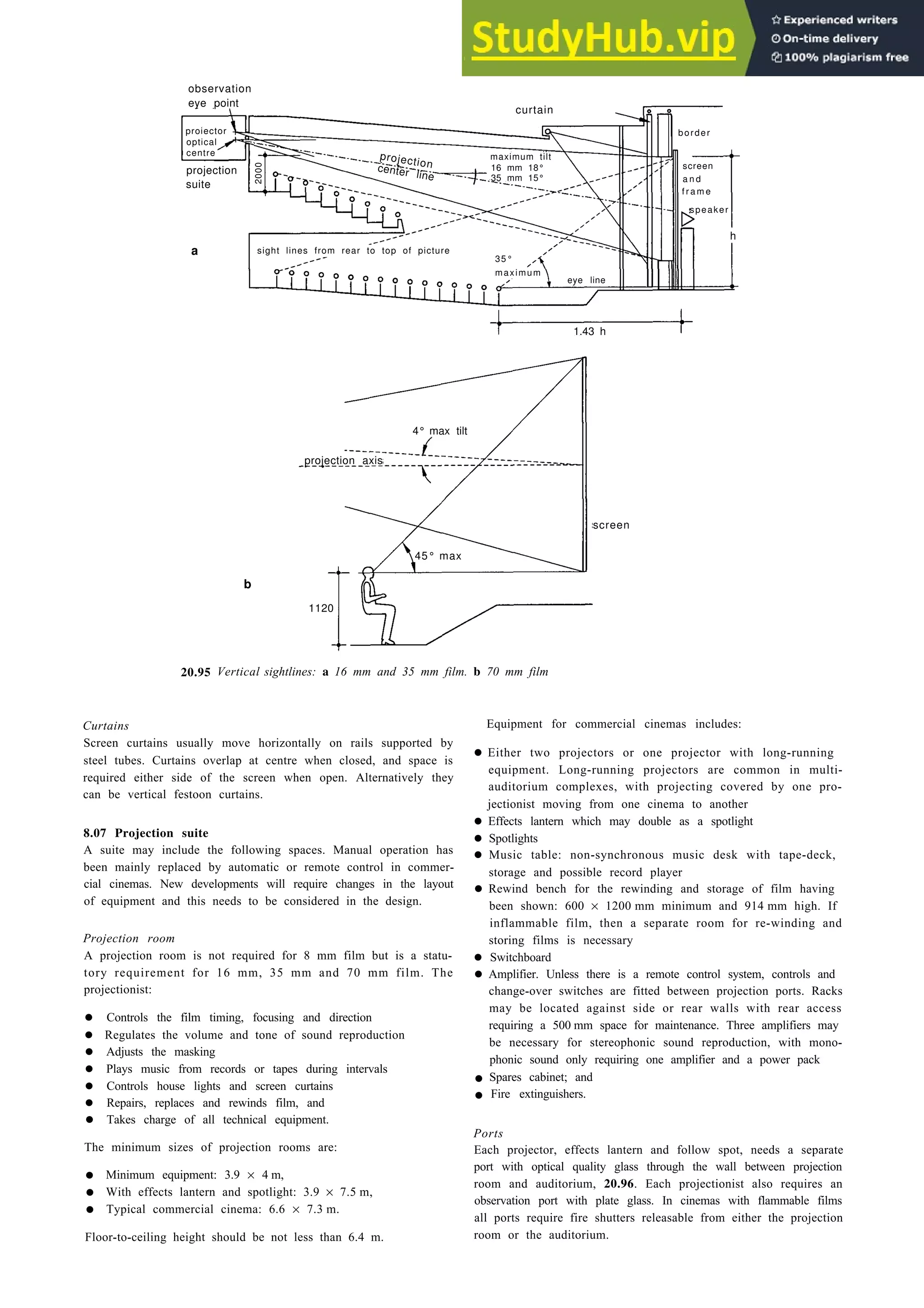

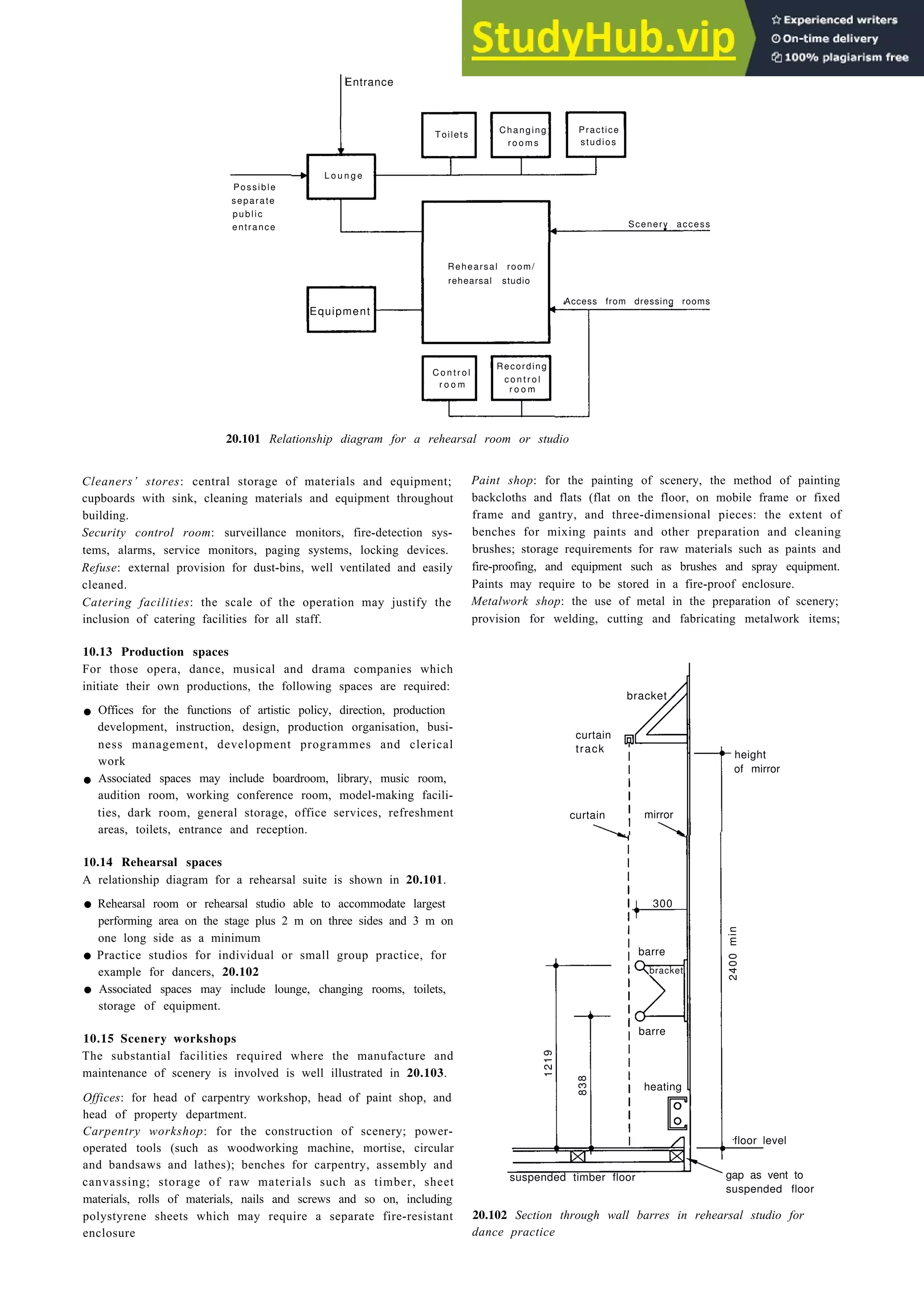

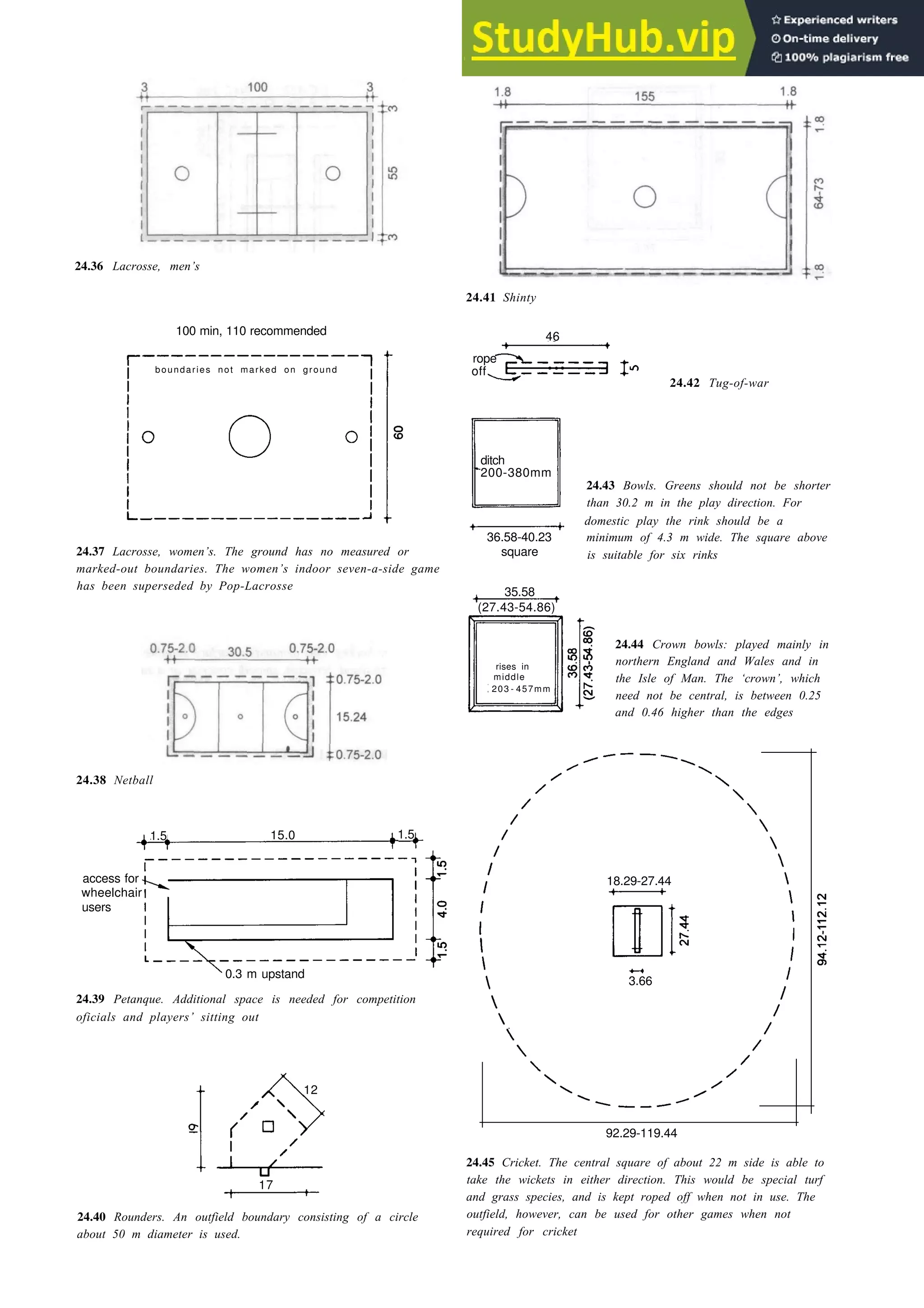

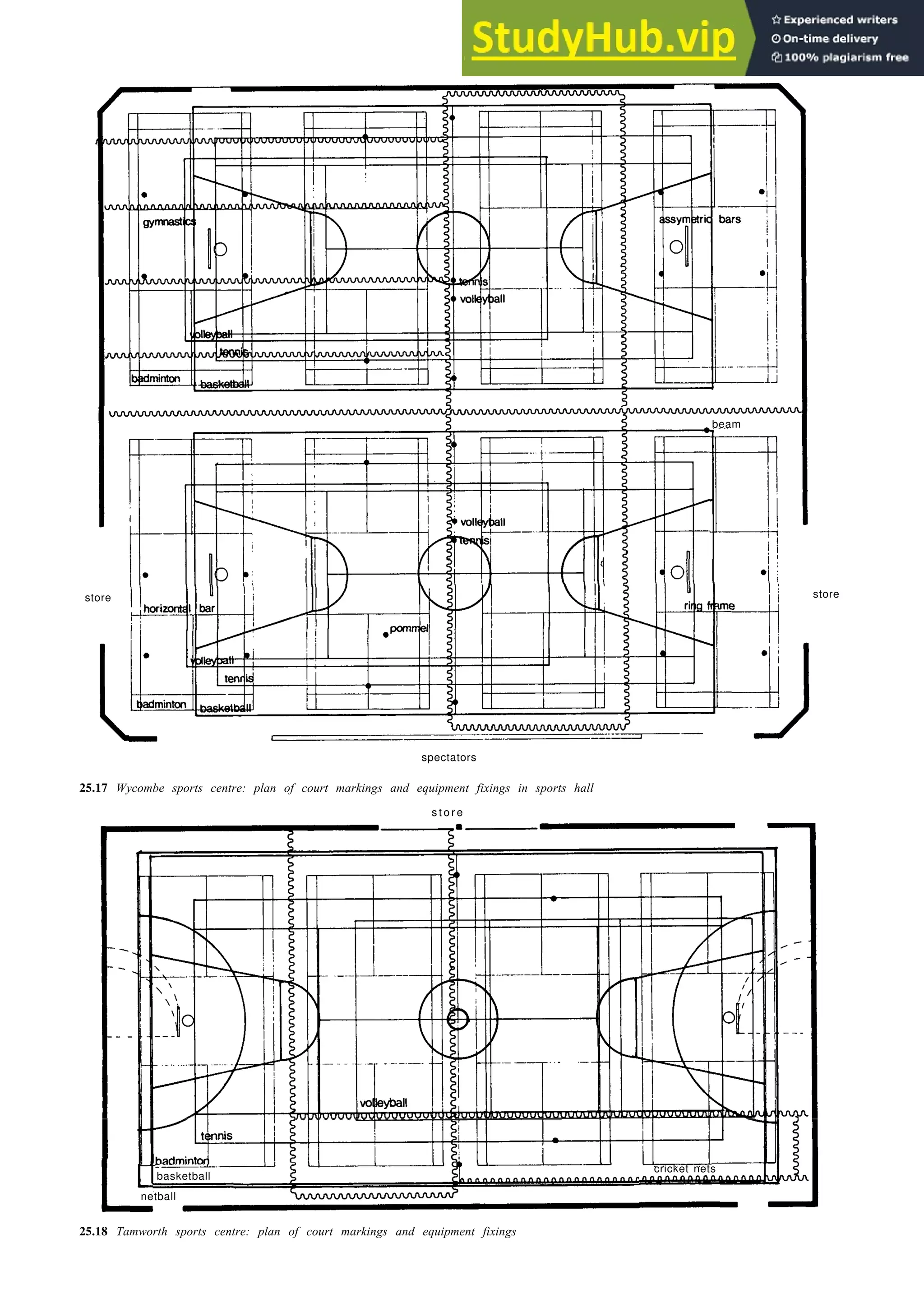

3.05 Computer work stations

Many office workers now work with visual display units (VDUs),

and these introduce further requirements for comfortable and

healthy working. People often find working at a screen tiring to the

eyes. 2.8 gives the recommended dimensions for minimising

fatigue; some people may need special spectacles. Most VDUs are

placed at or above eye level so that normal bifocals do not help.

Opticians are now used to supplying ‘intermediate’ spectacles with

the normal bifocal facility for viewing the keyboard and material

on the desk, with the upper part allowing focus on the near

distance. This permits the VDU to be placed between 900 to

1000 mm distant from the user.

accessibility

50%

accessibility

83%

inaccessible

not easily accessible

accessible

easily accessible

fixed

shelves

2.9 Accessibility of storage:

a Zones of accessibility.

adjustable wall

unit shelves

pull-out base

unit shelves

b Frequently needed

articles.

c Less frequently needed

articles higher

d Less frequently needed

articles lower

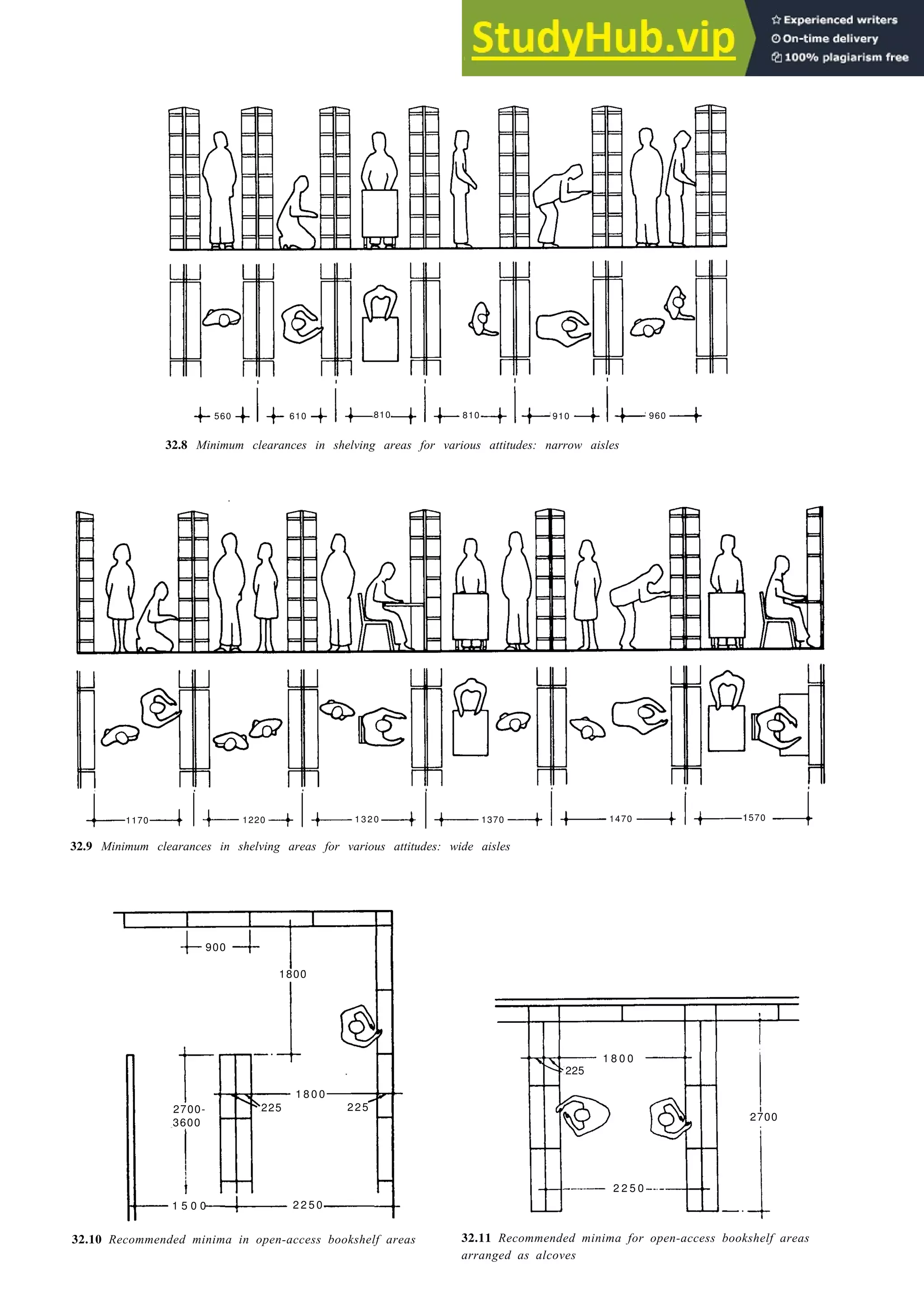

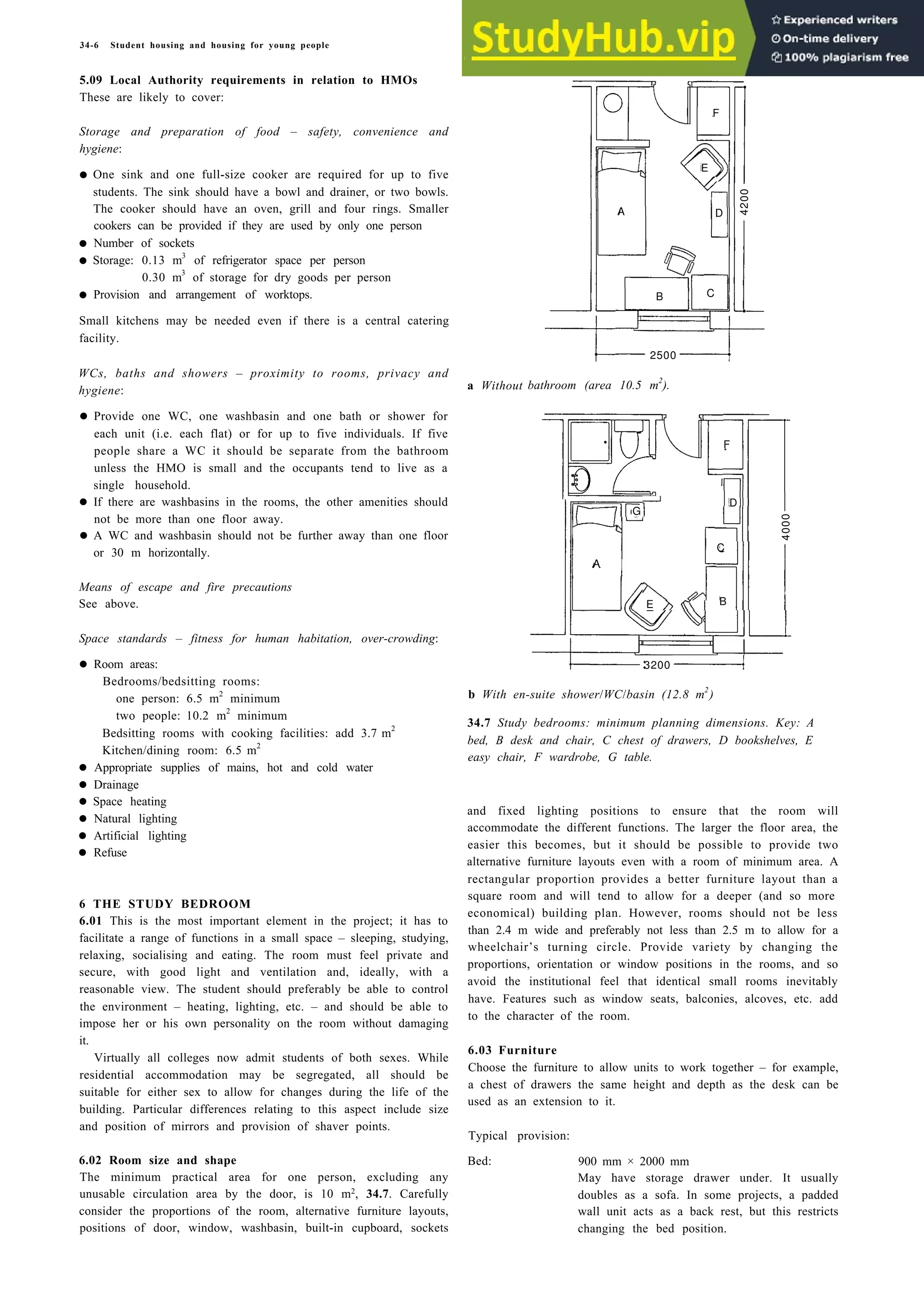

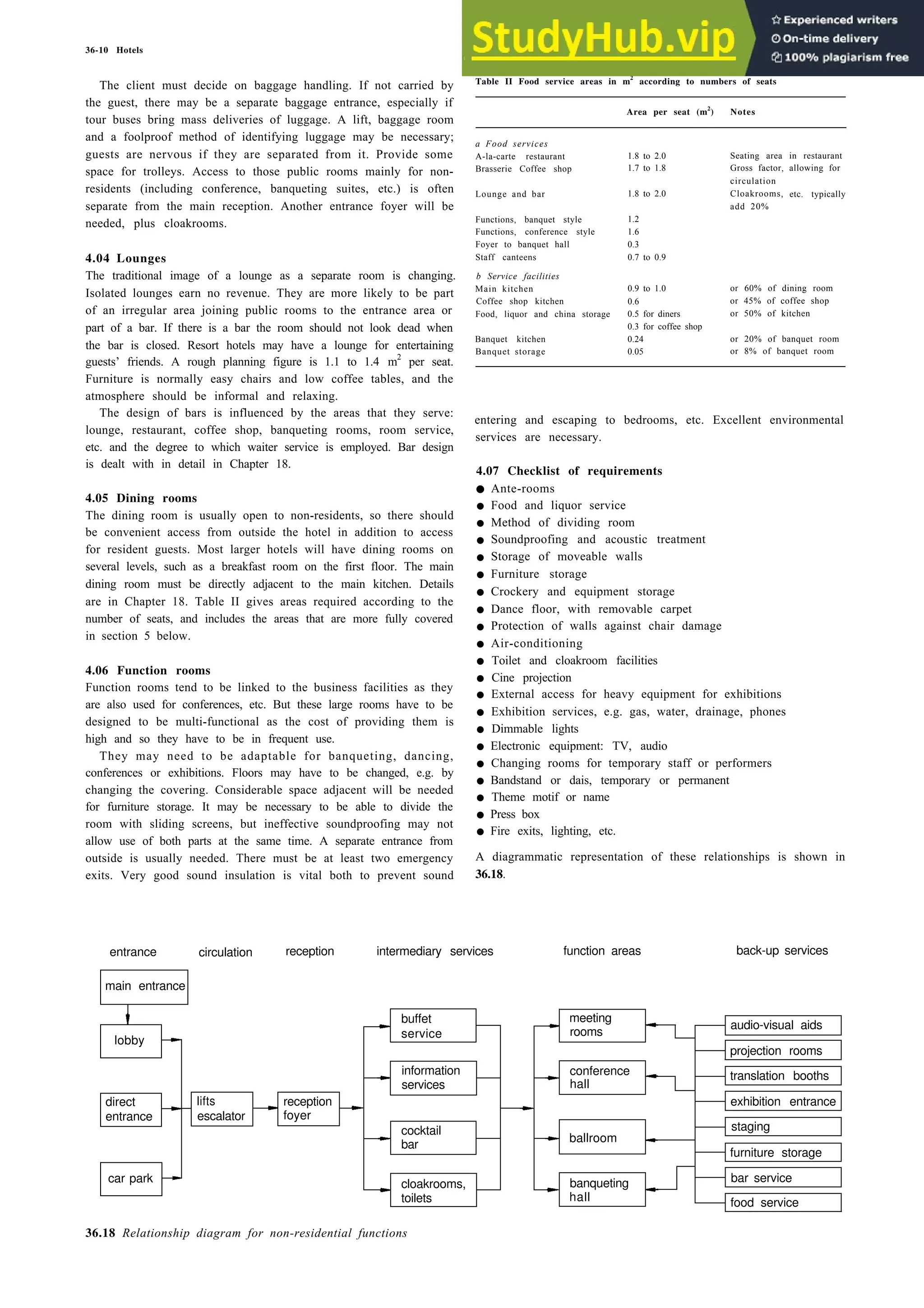

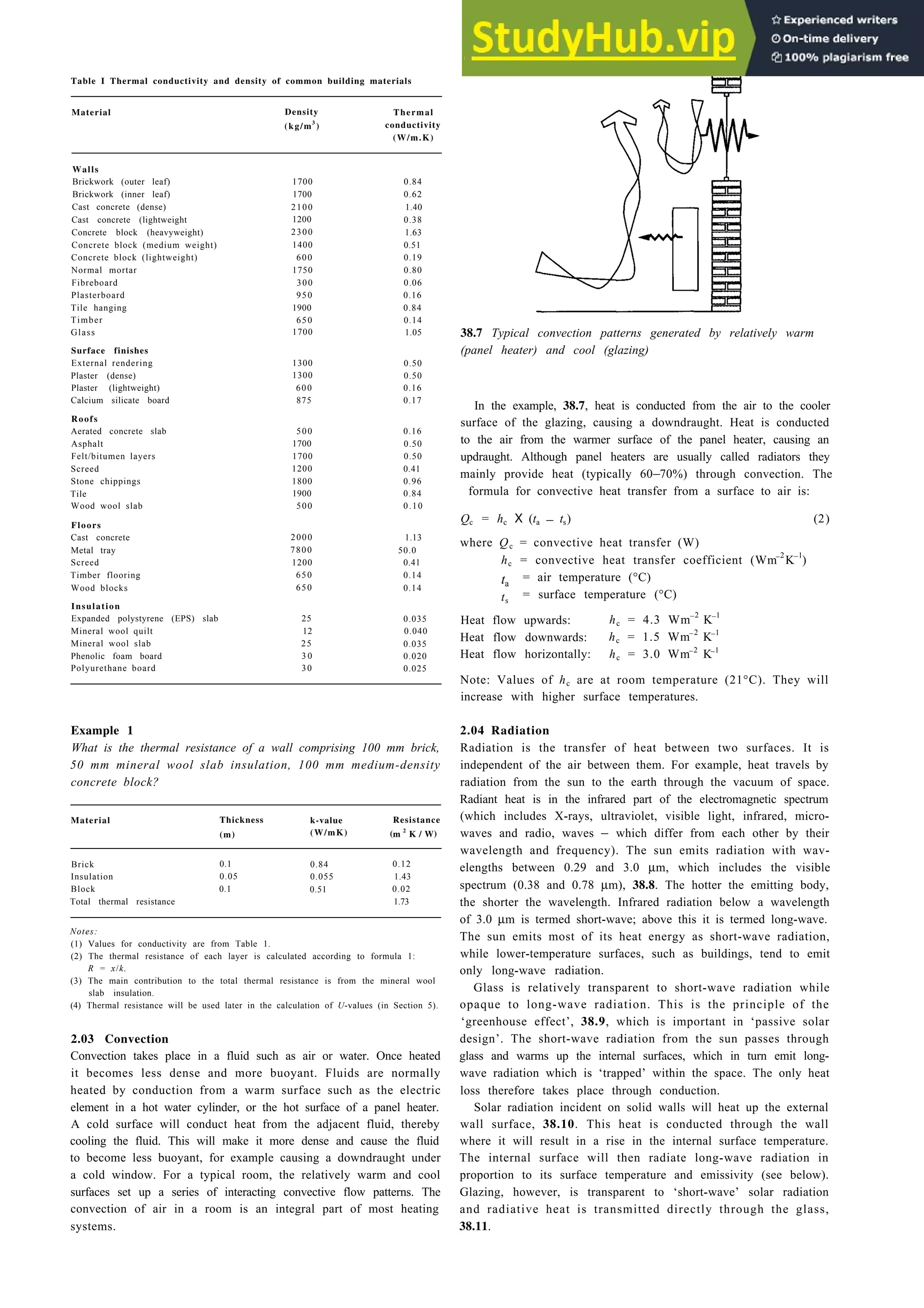

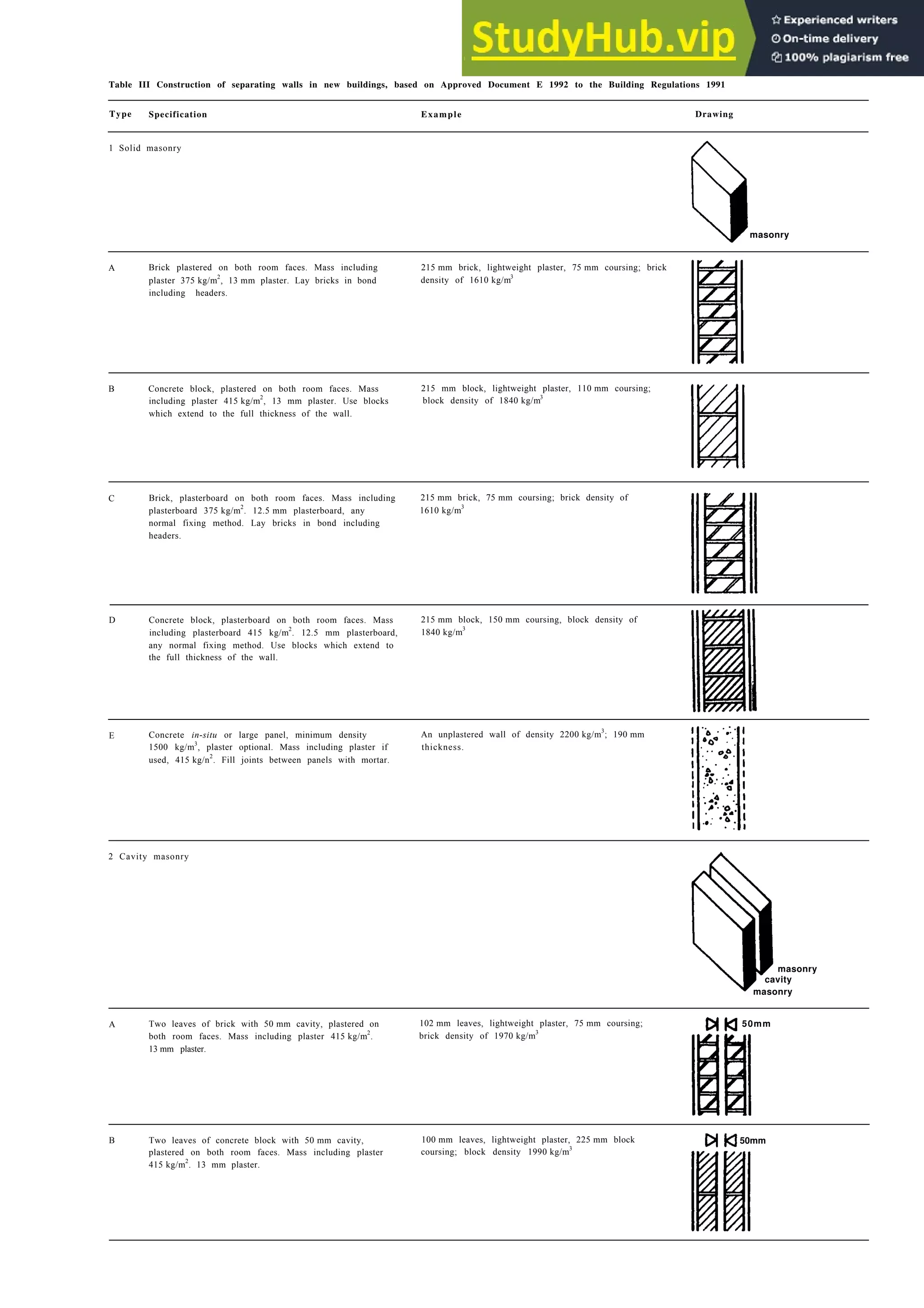

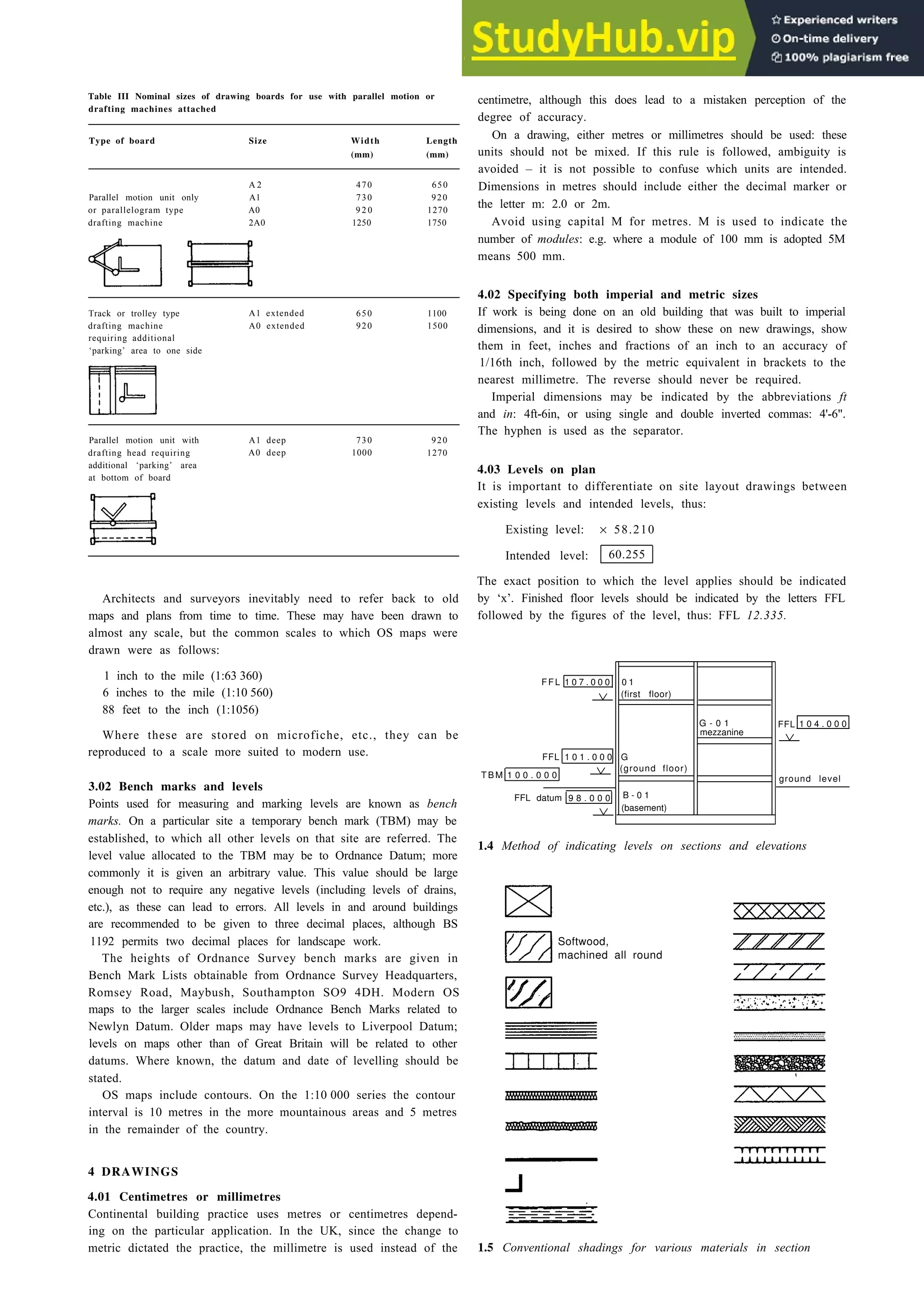

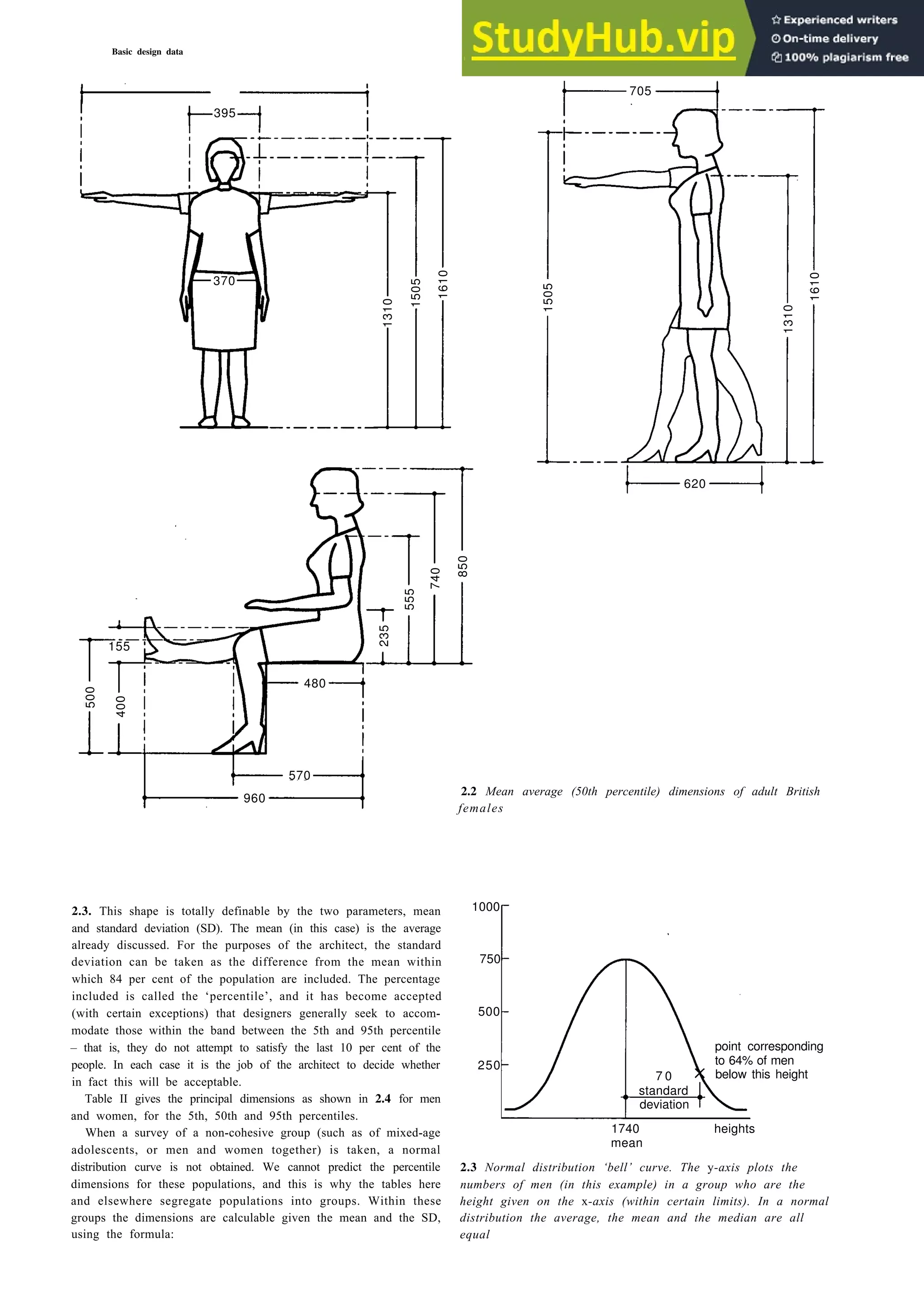

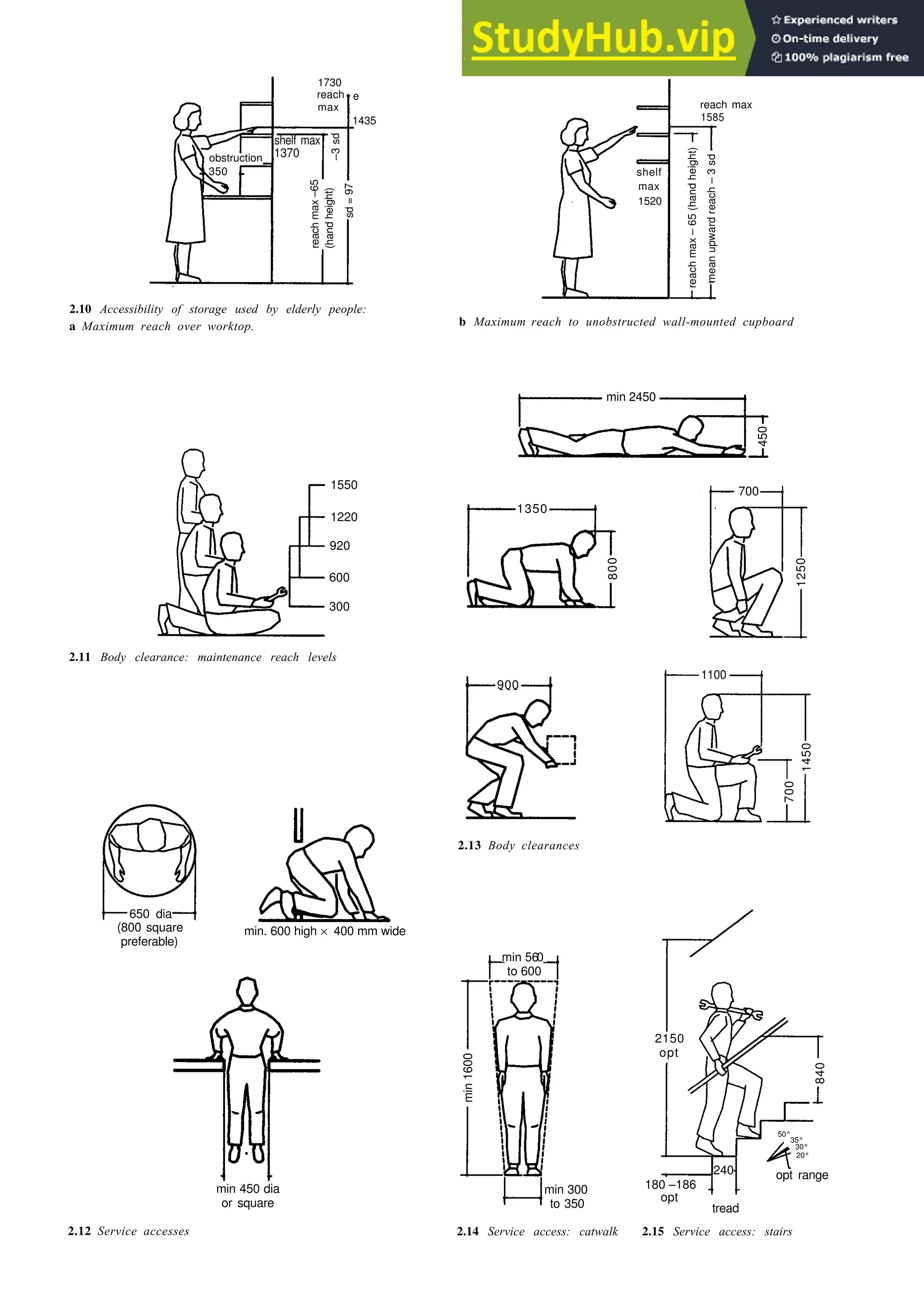

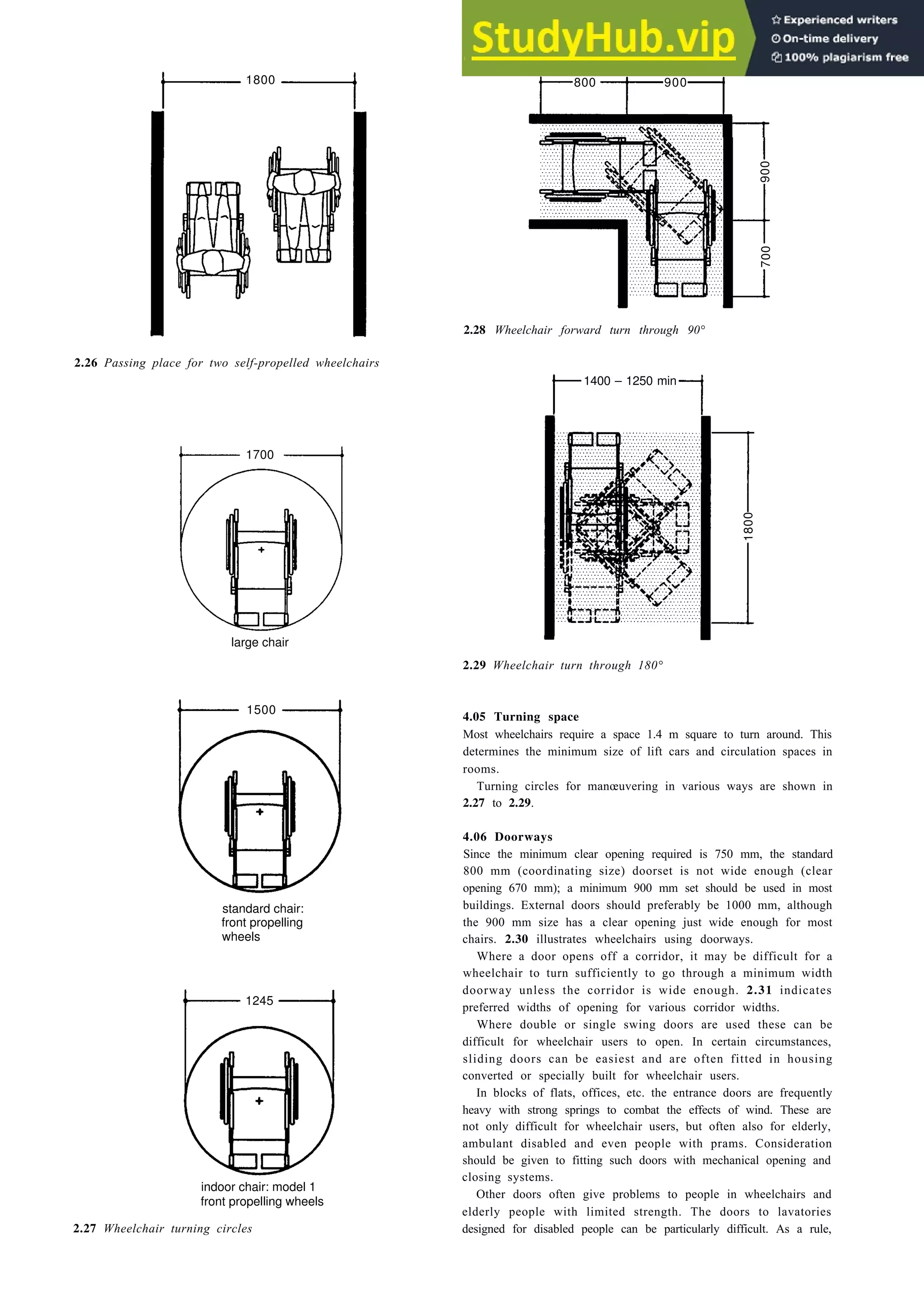

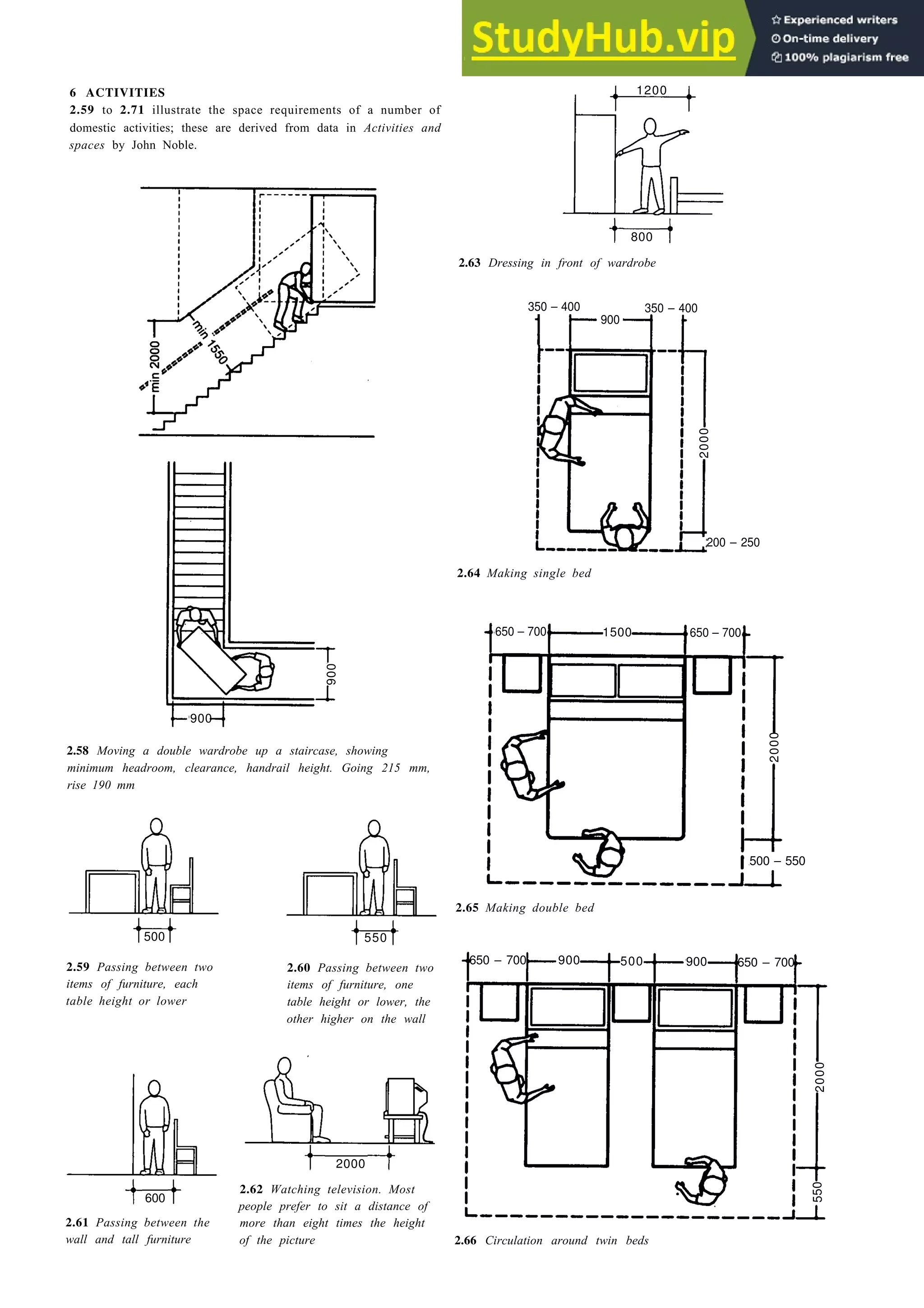

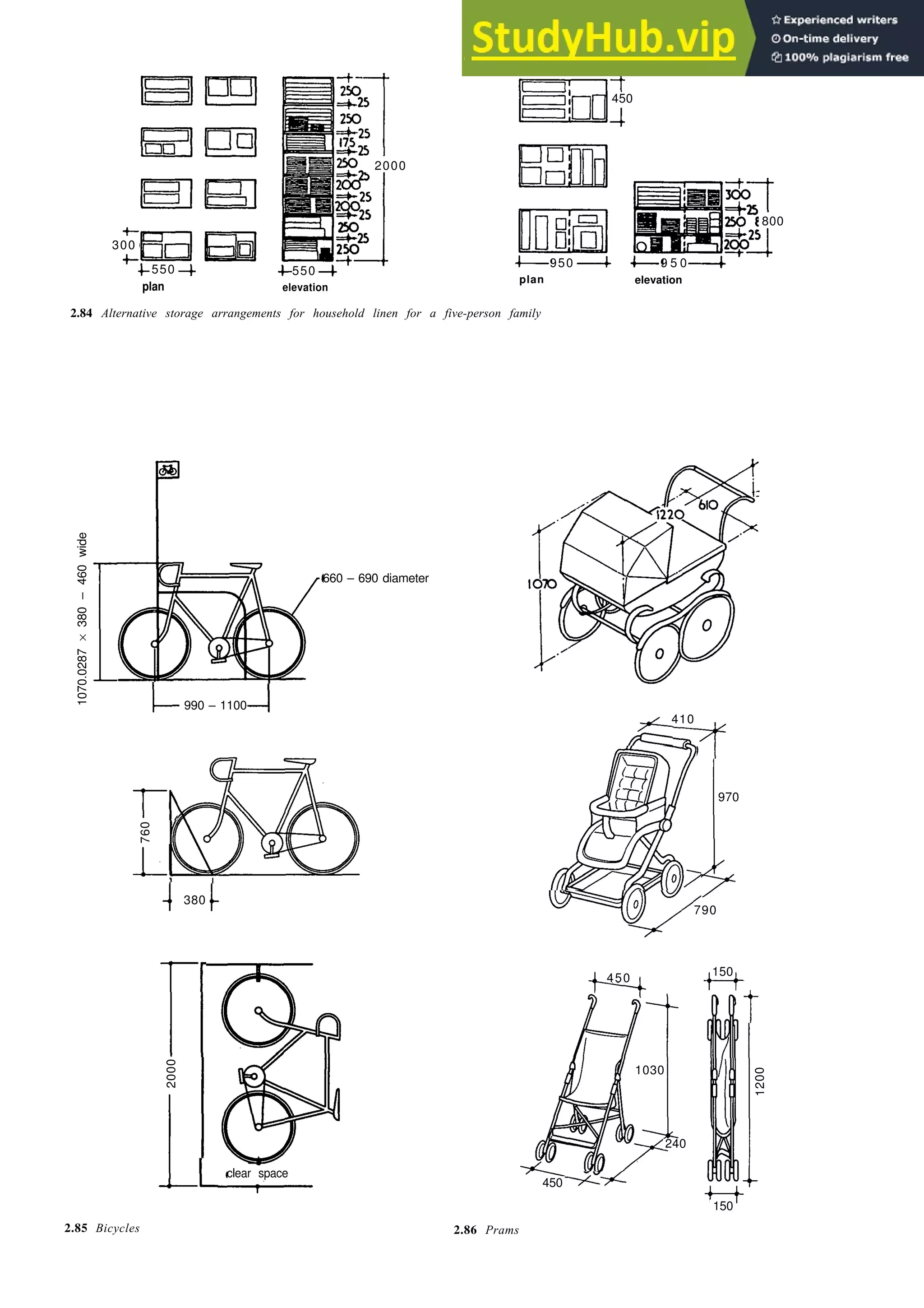

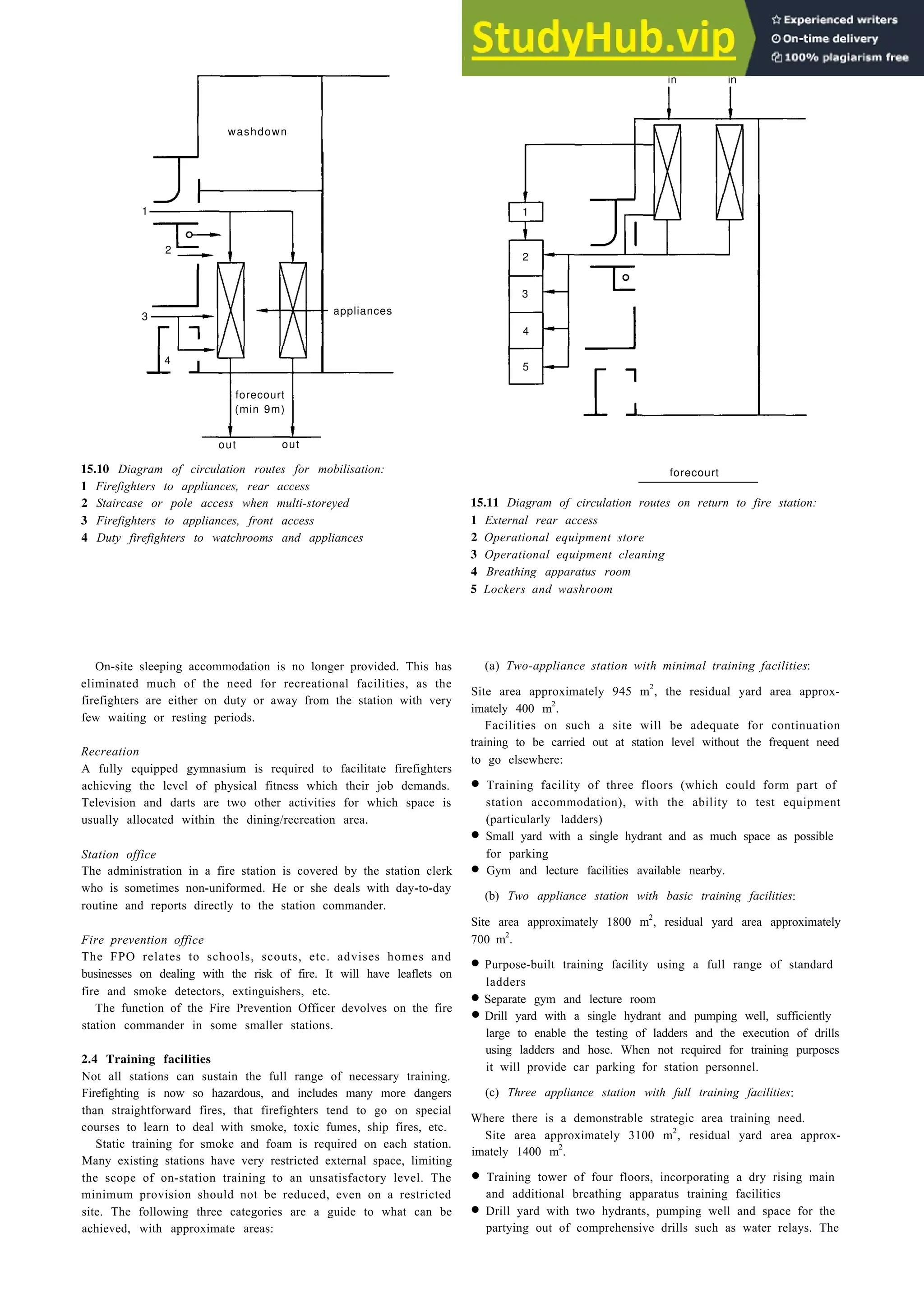

3.06 Storage

Two of the commonest operations at work and in the home is the

stowage and retrieval of items into and from storage. 2.9 shows the

recommended heights for various storage areas for general use;

2.10 gives particular requirements where elderly people are

concerned.

3.07 Maintenance

Buildings and the services and plant therein need constant

maintenance. Something frequently forgotten is the need for easy

access to certain areas. It is reasonable to assume that people

employed on maintenance work will be sufficiently agile and not

greatly above average size. The dimensions shown in 2.11 to 2.18

are therefore less than would be required for use by the general

public.

viewing distance

refer to 2.8b

47°

150

min

450

600

620

[781,5] [859,5]

[1075,5]

normal

minimum

distance

from screen

400 mm

minimum

distance

from touch

screen

300 mm

preferred

visual angle

between 20

and 22 minutes

700

1300

1900

500](https://image.slidesharecdn.com/architectureebookmetrichandbookplanninganddesigndata-230807180049-33007df6/75/Architecture-Ebook-Metric-Handbook-Planning-and-Design-Data-pdf-28-2048.jpg)

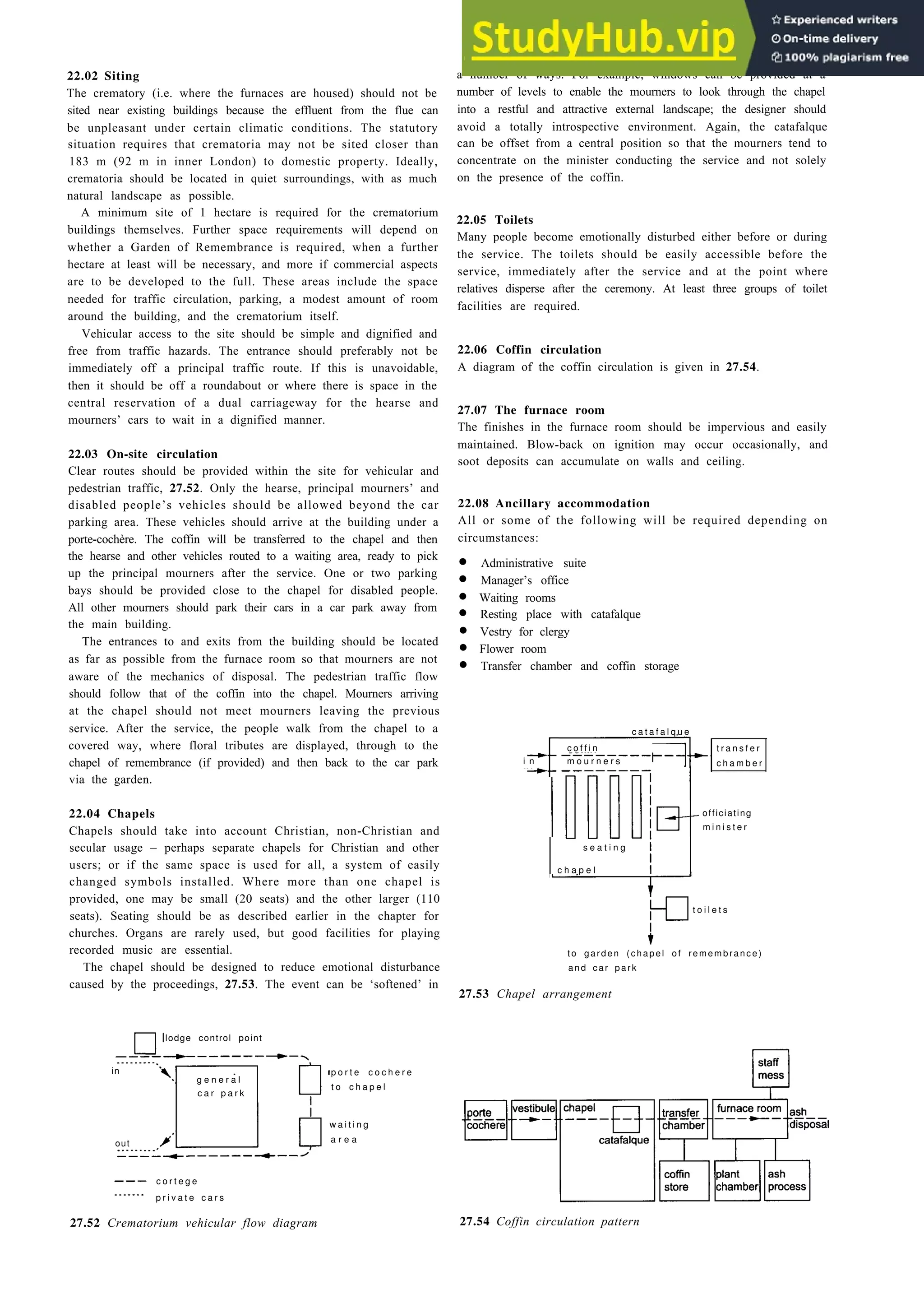

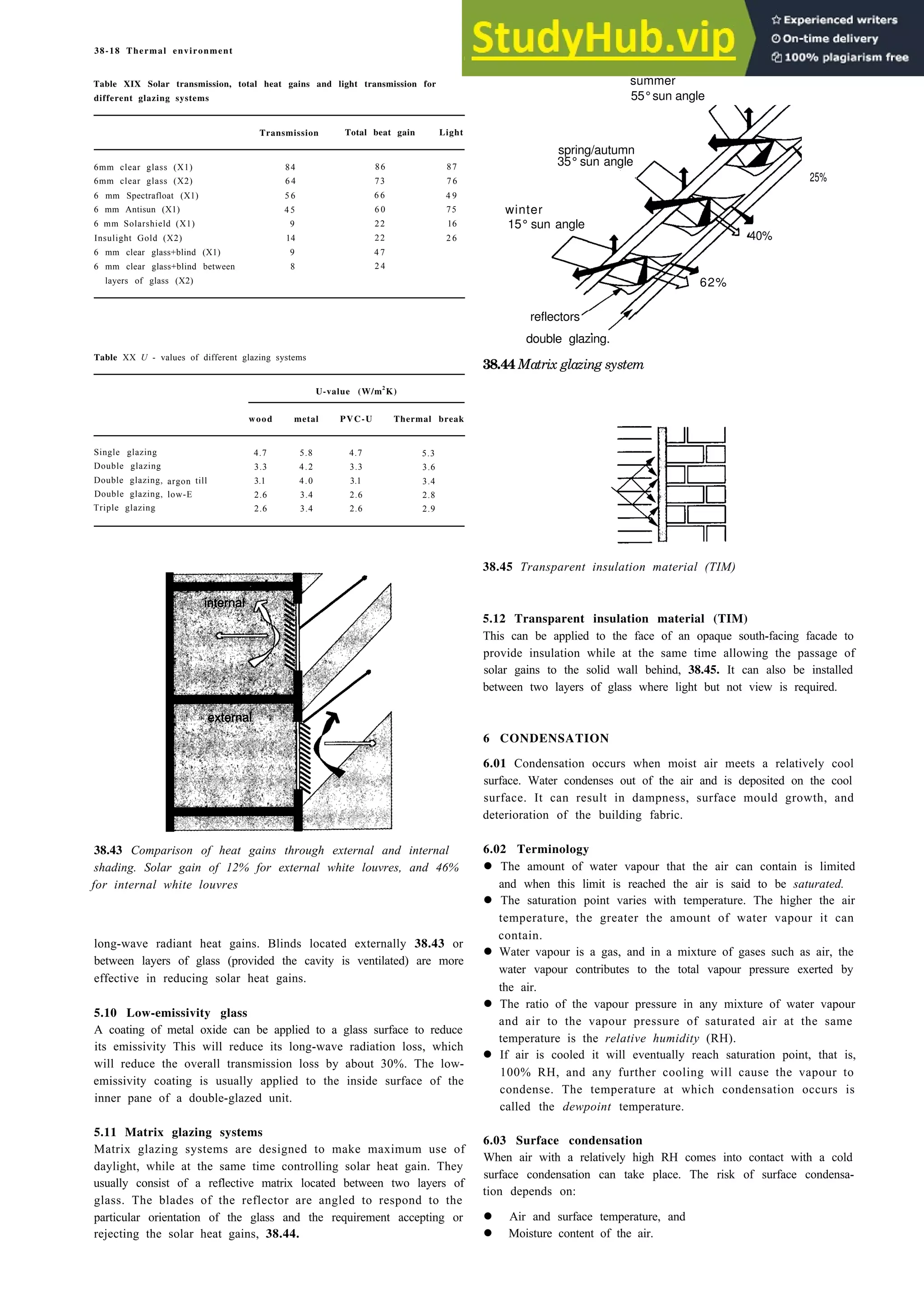

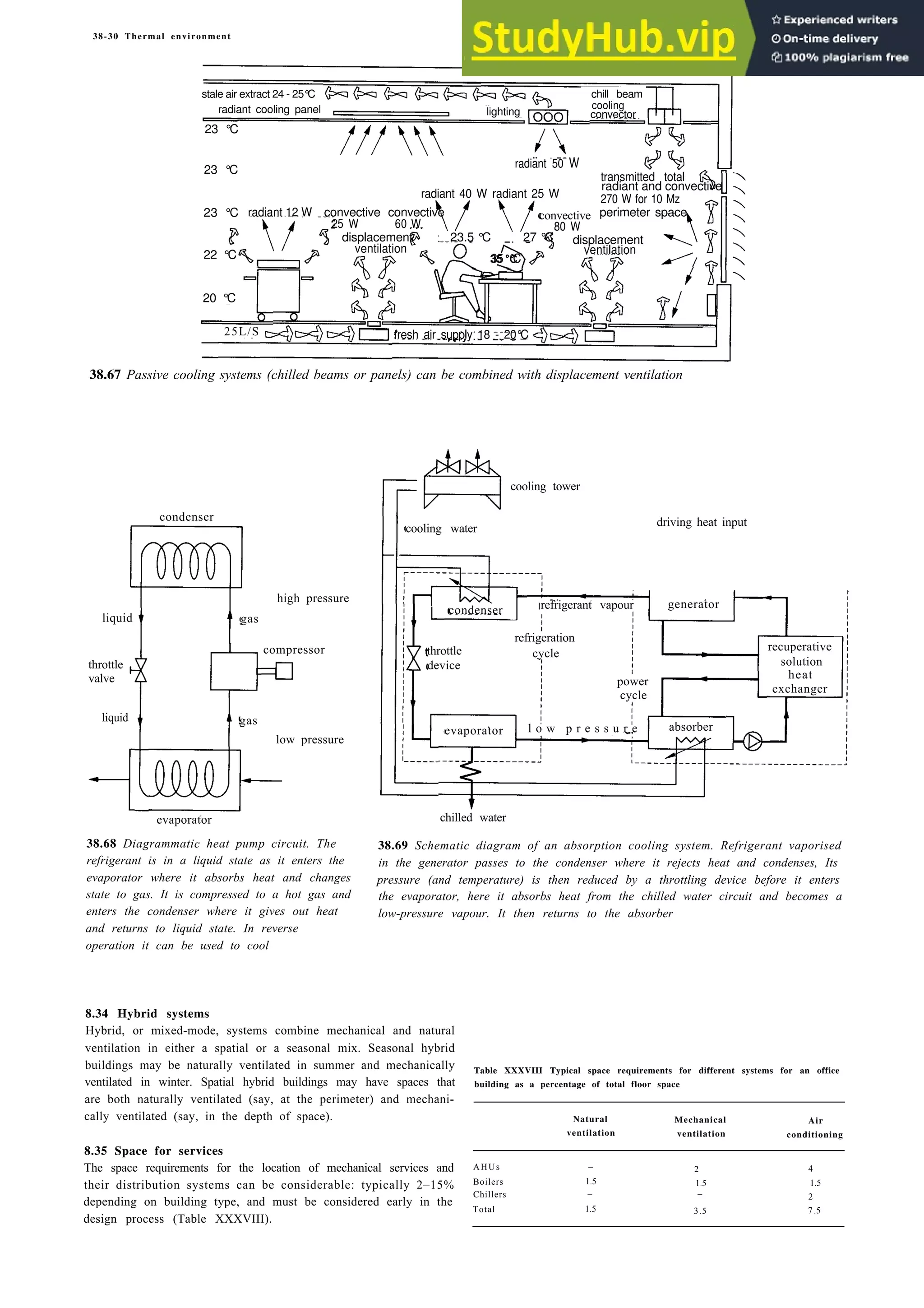

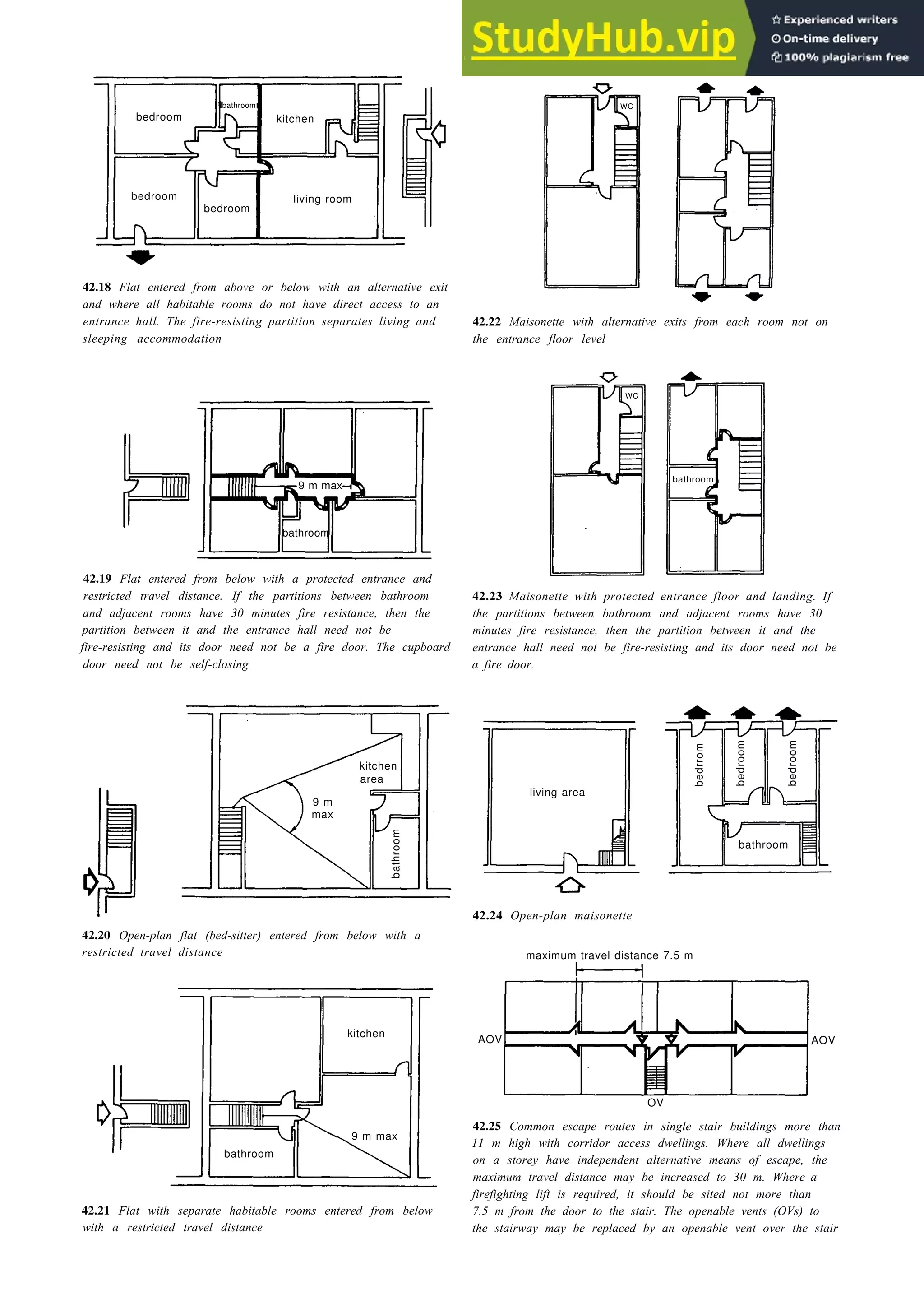

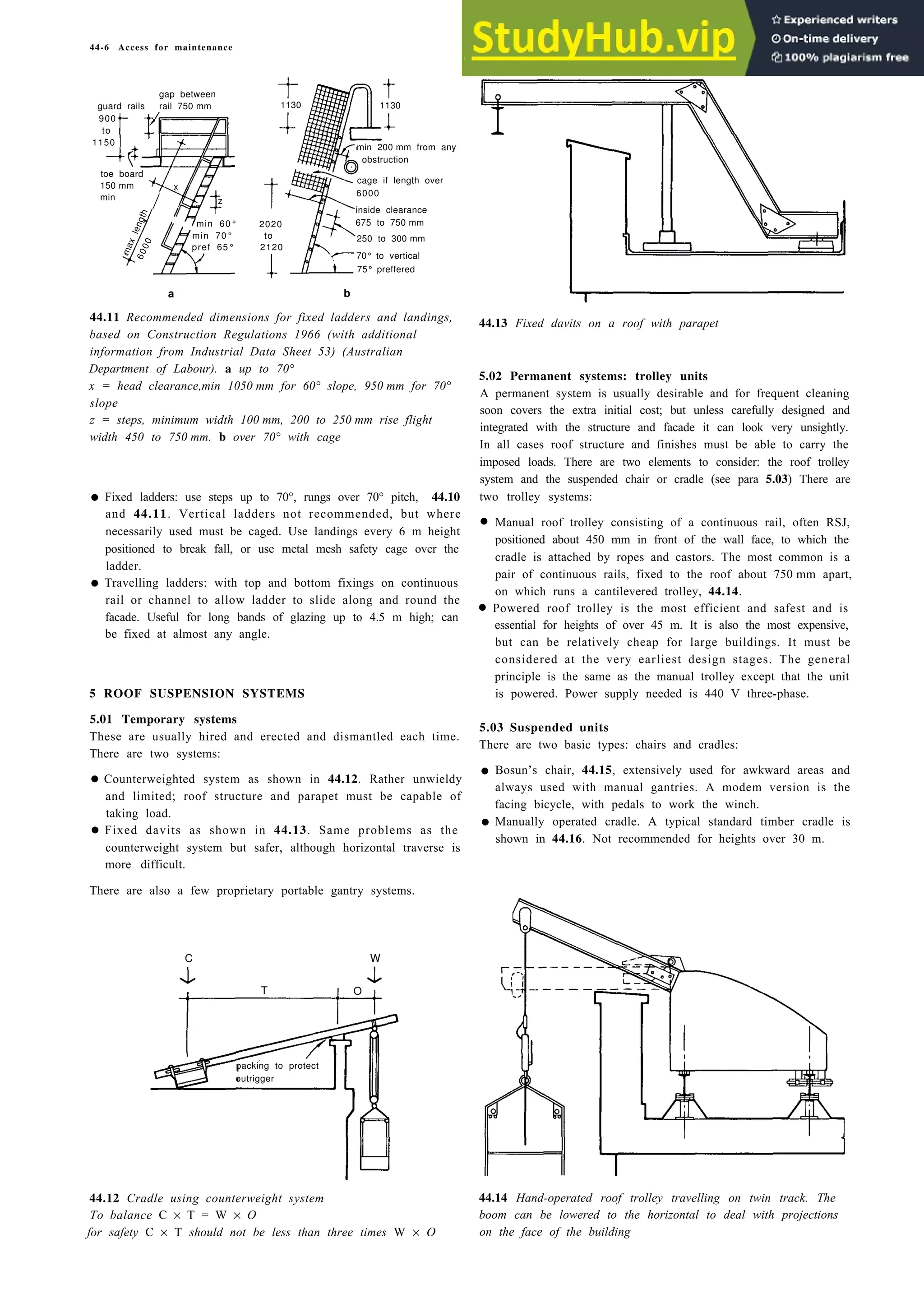

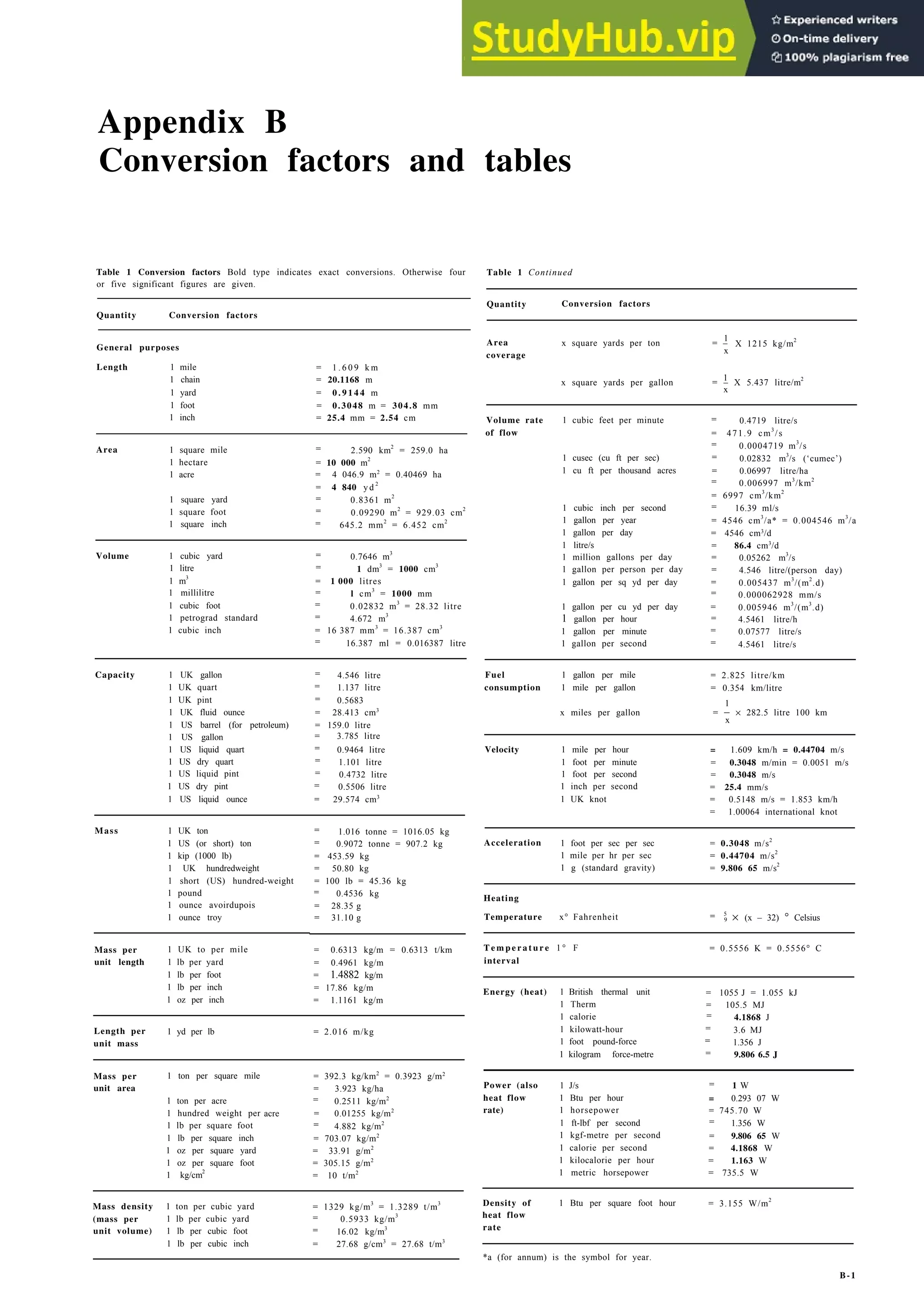

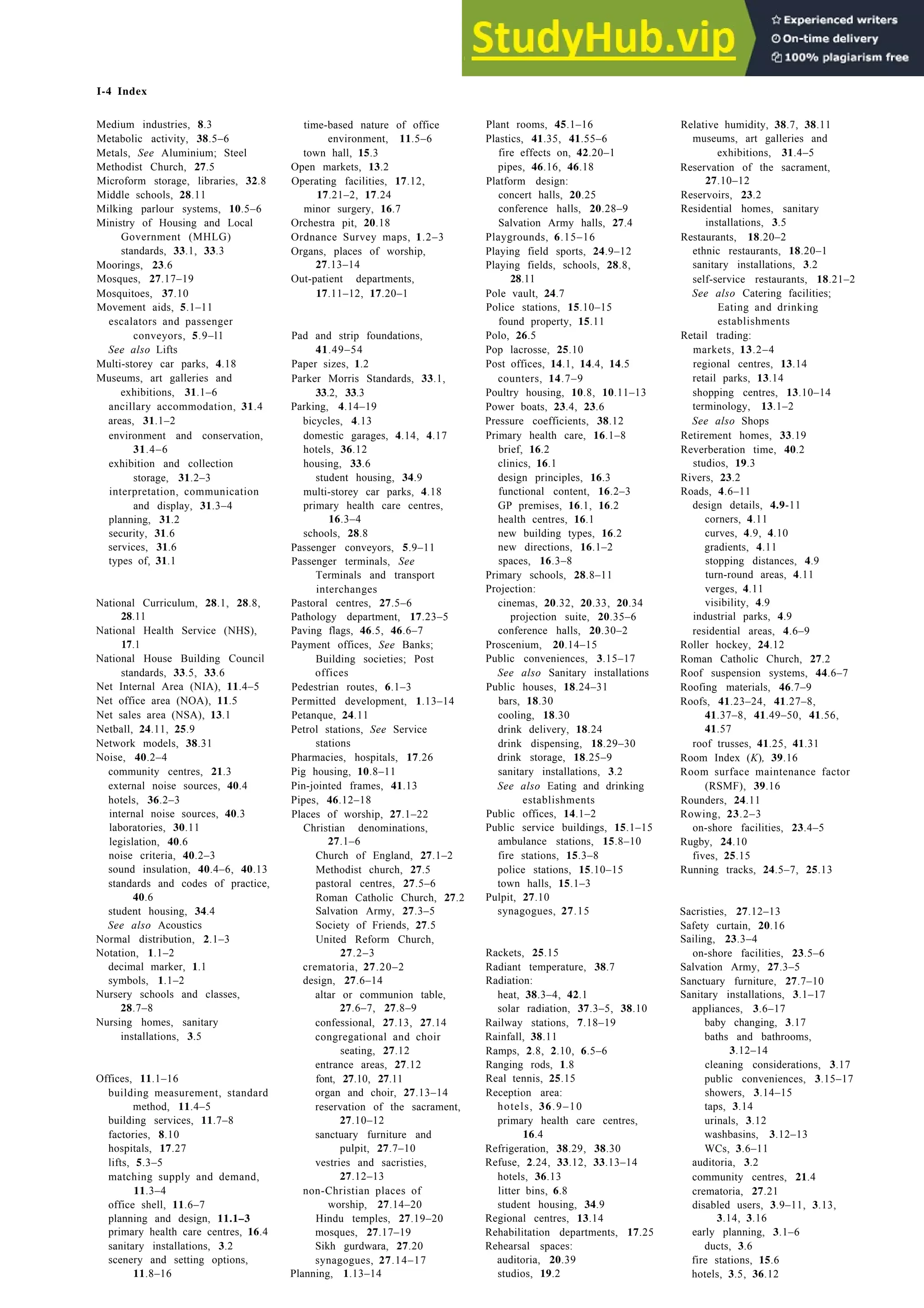

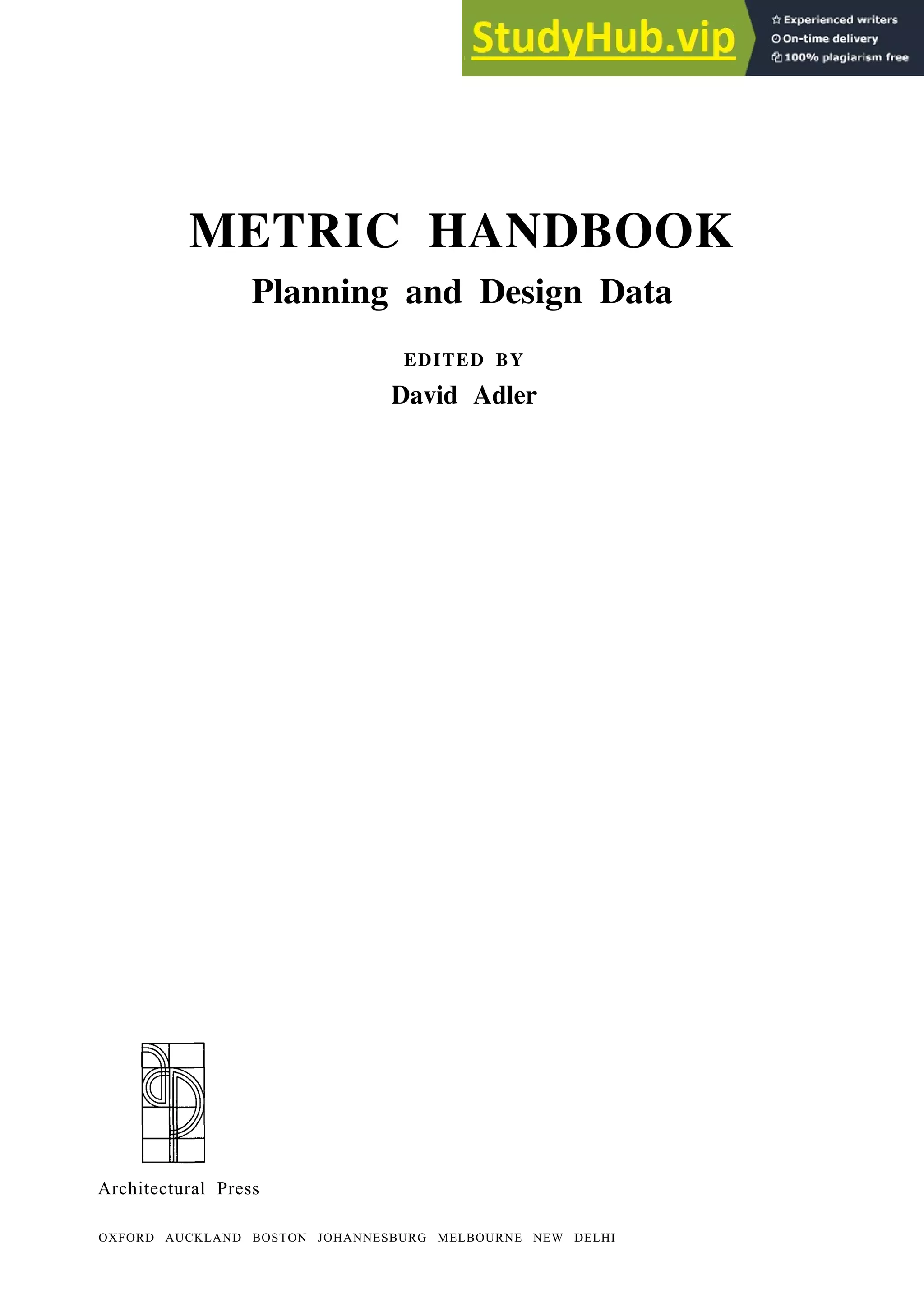

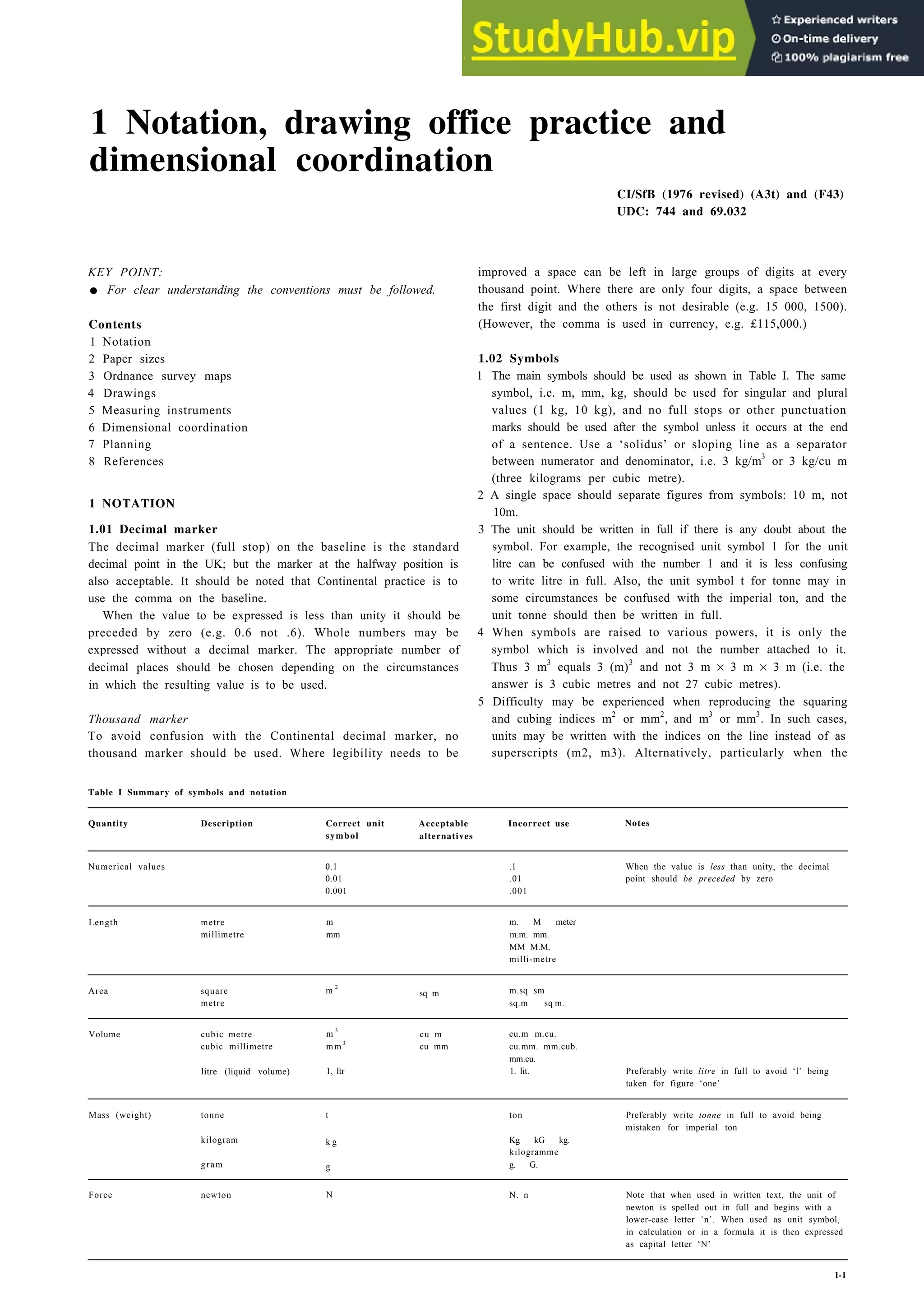

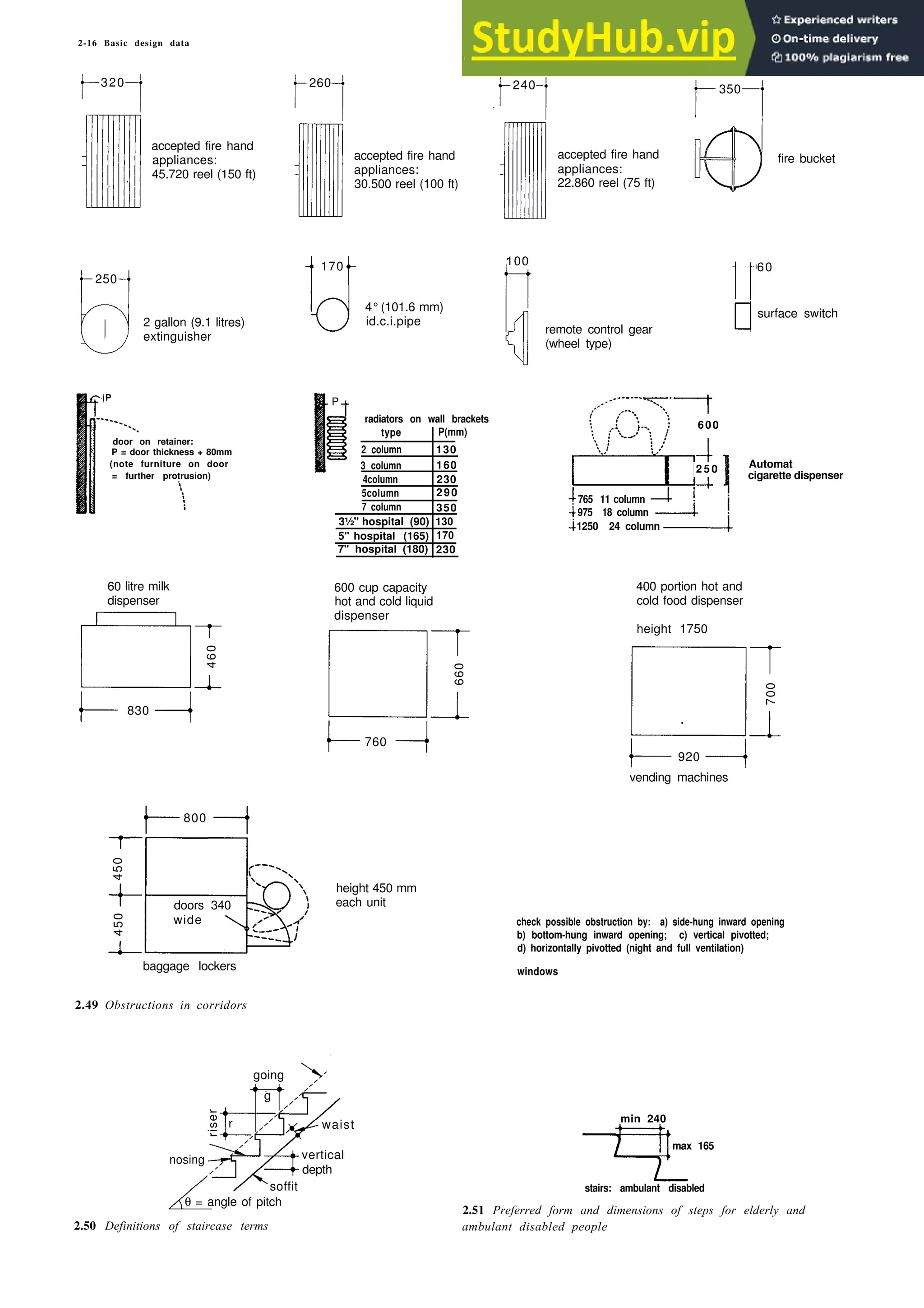

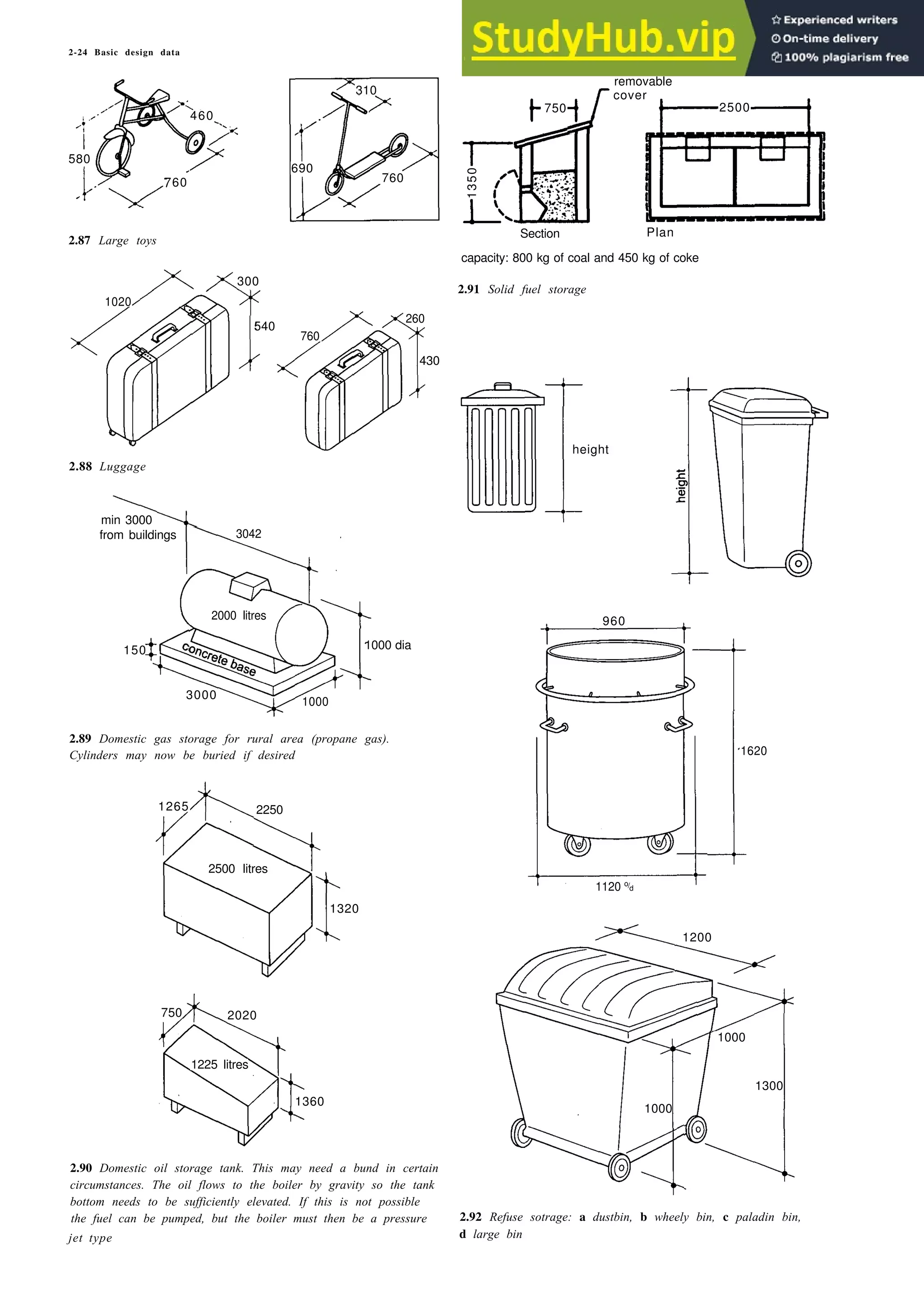

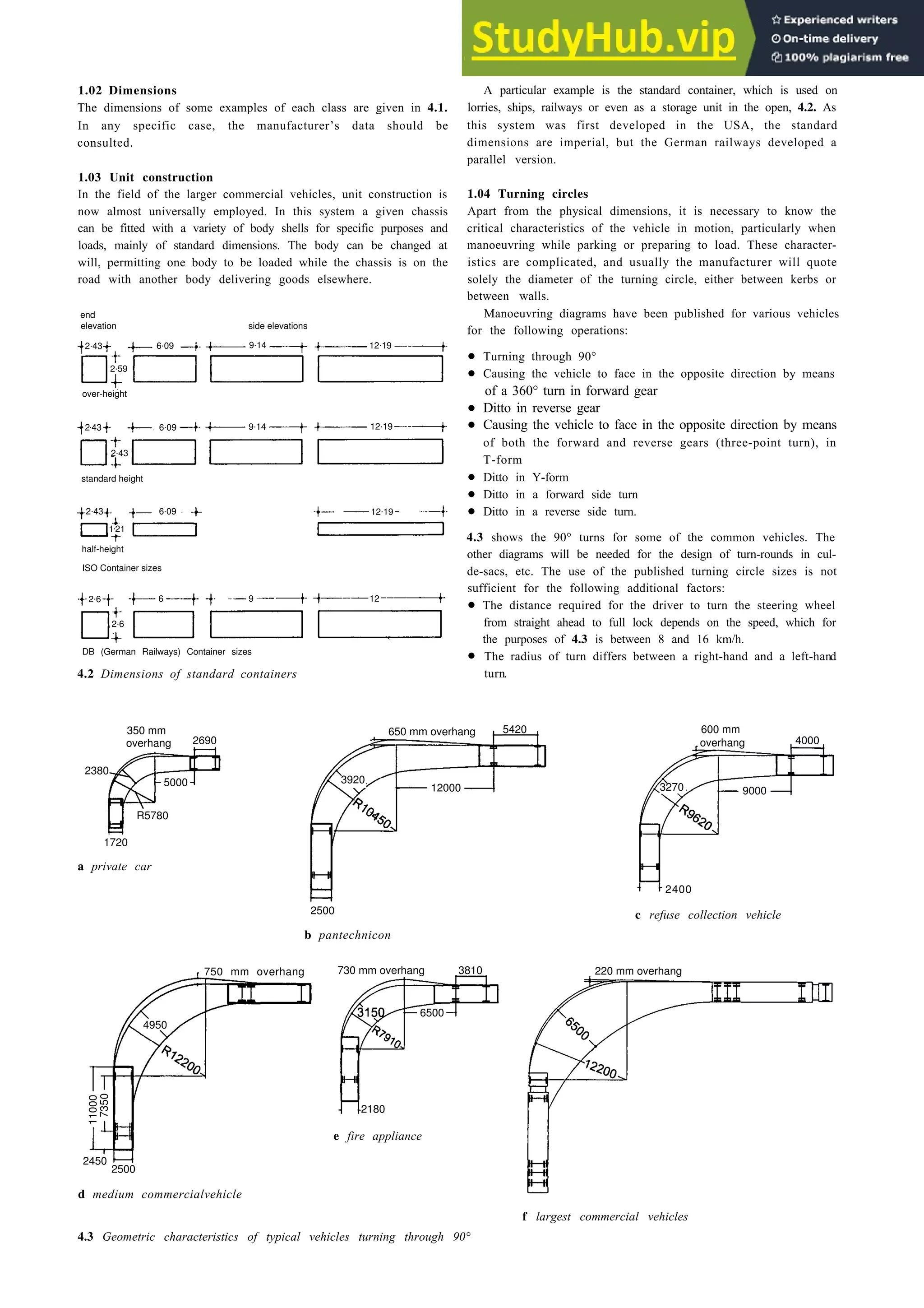

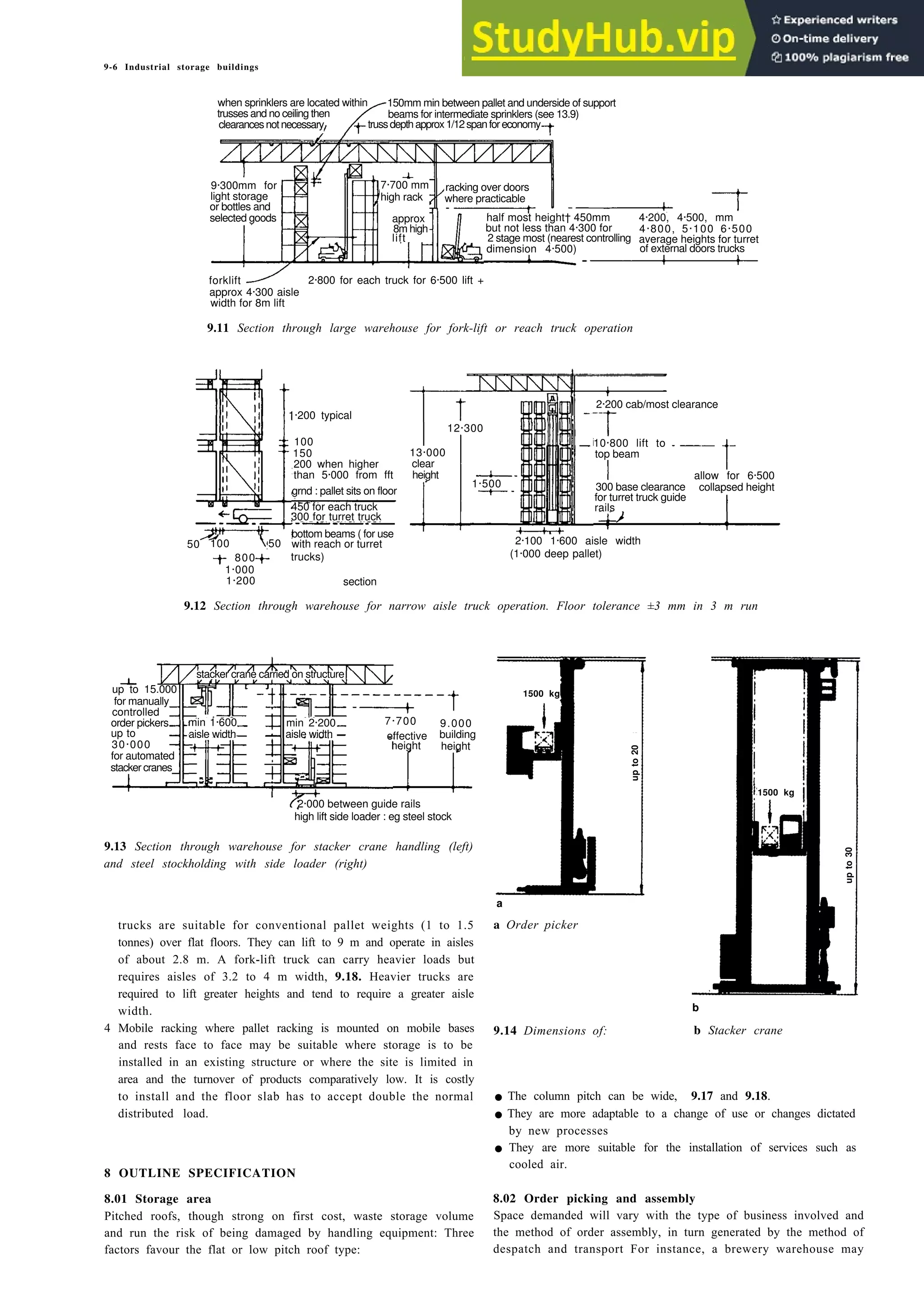

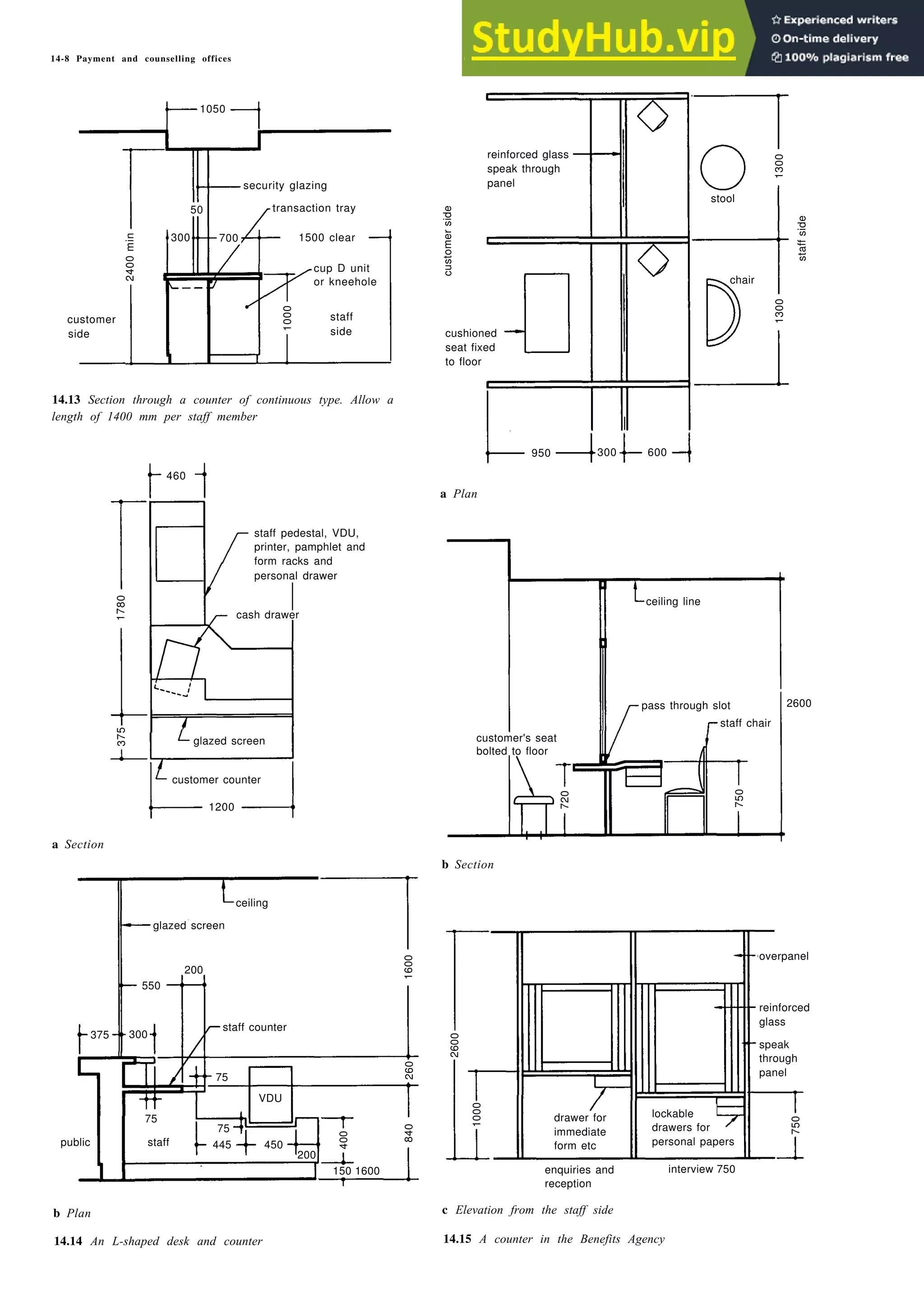

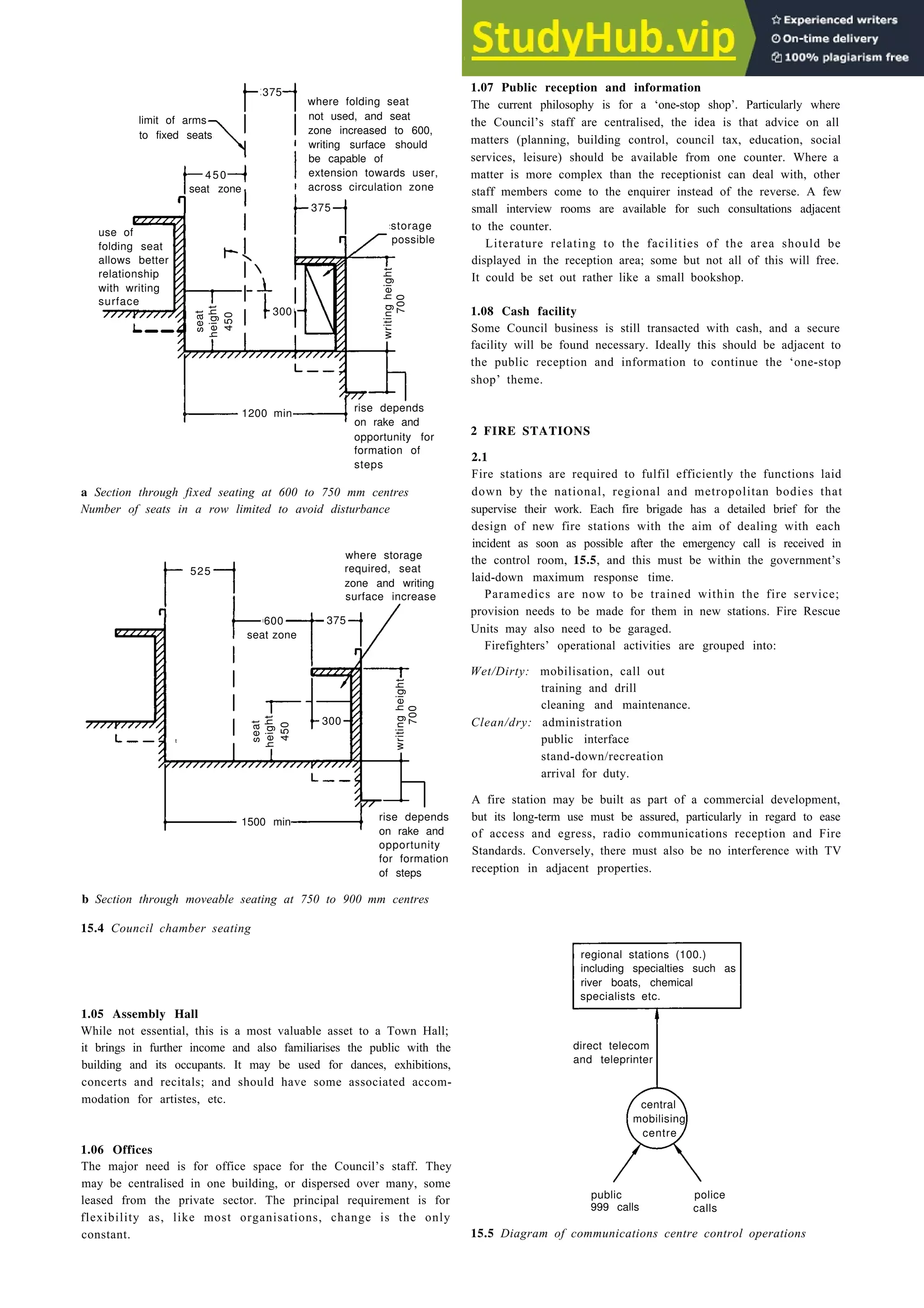

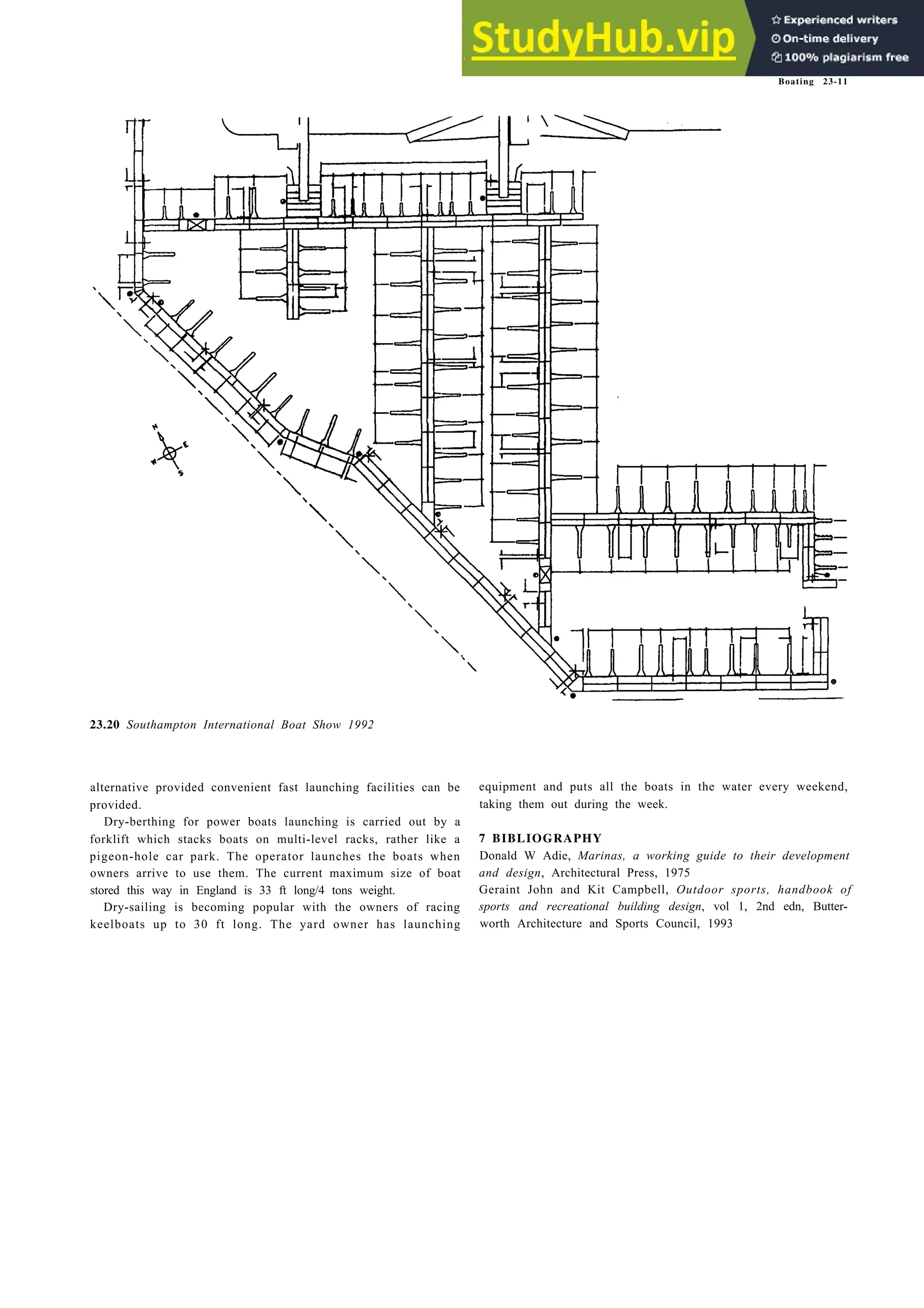

![23-8 Boating

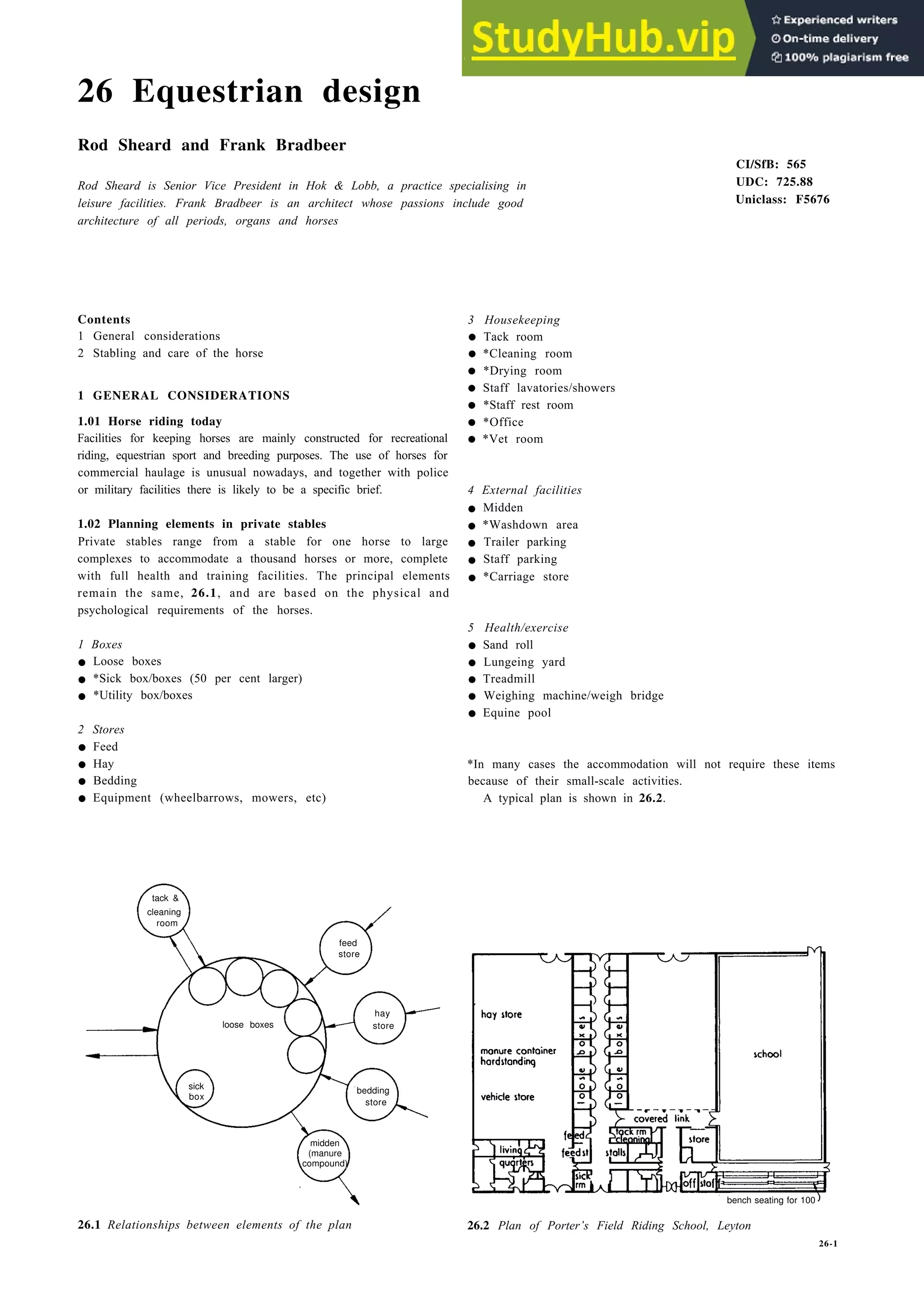

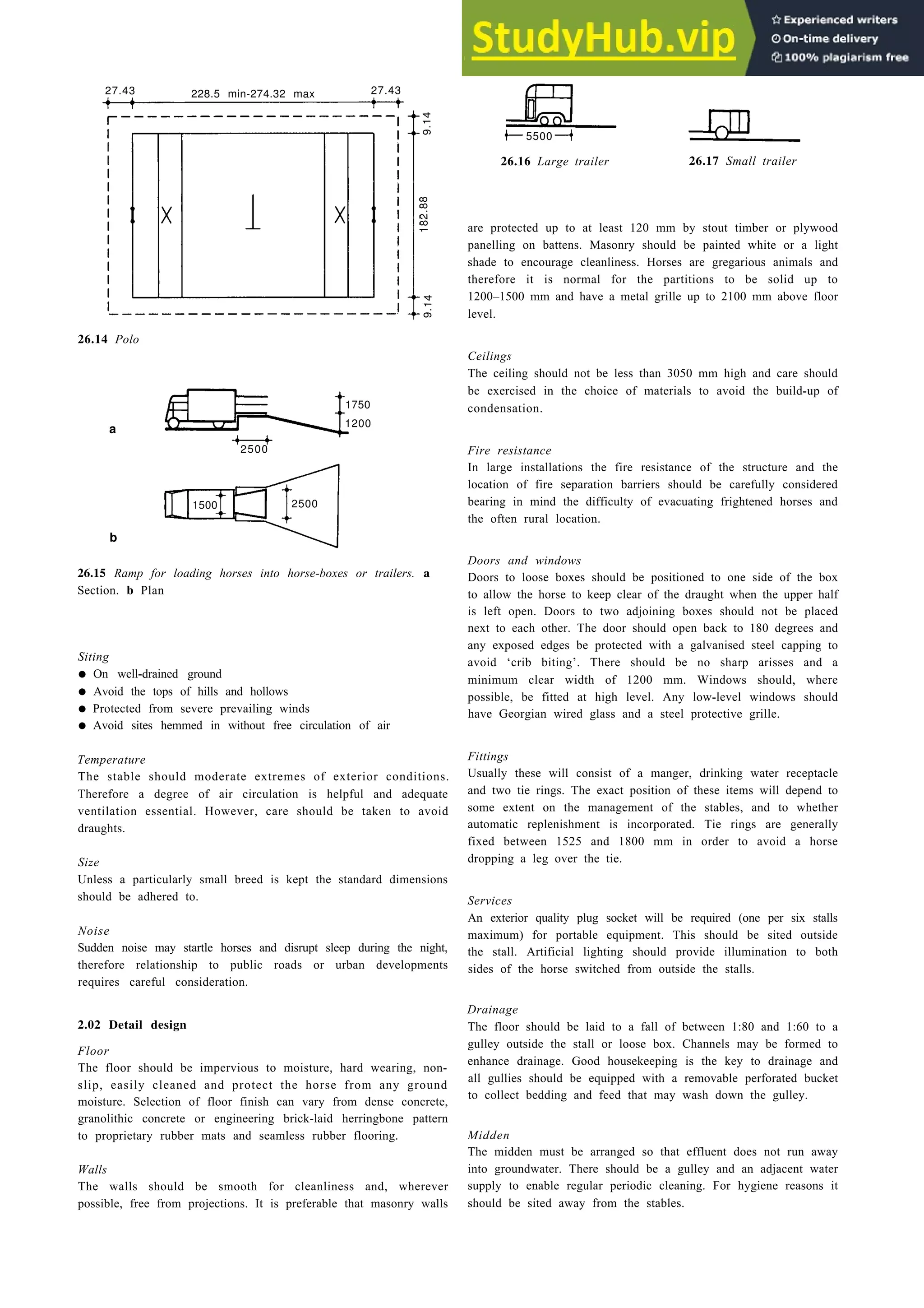

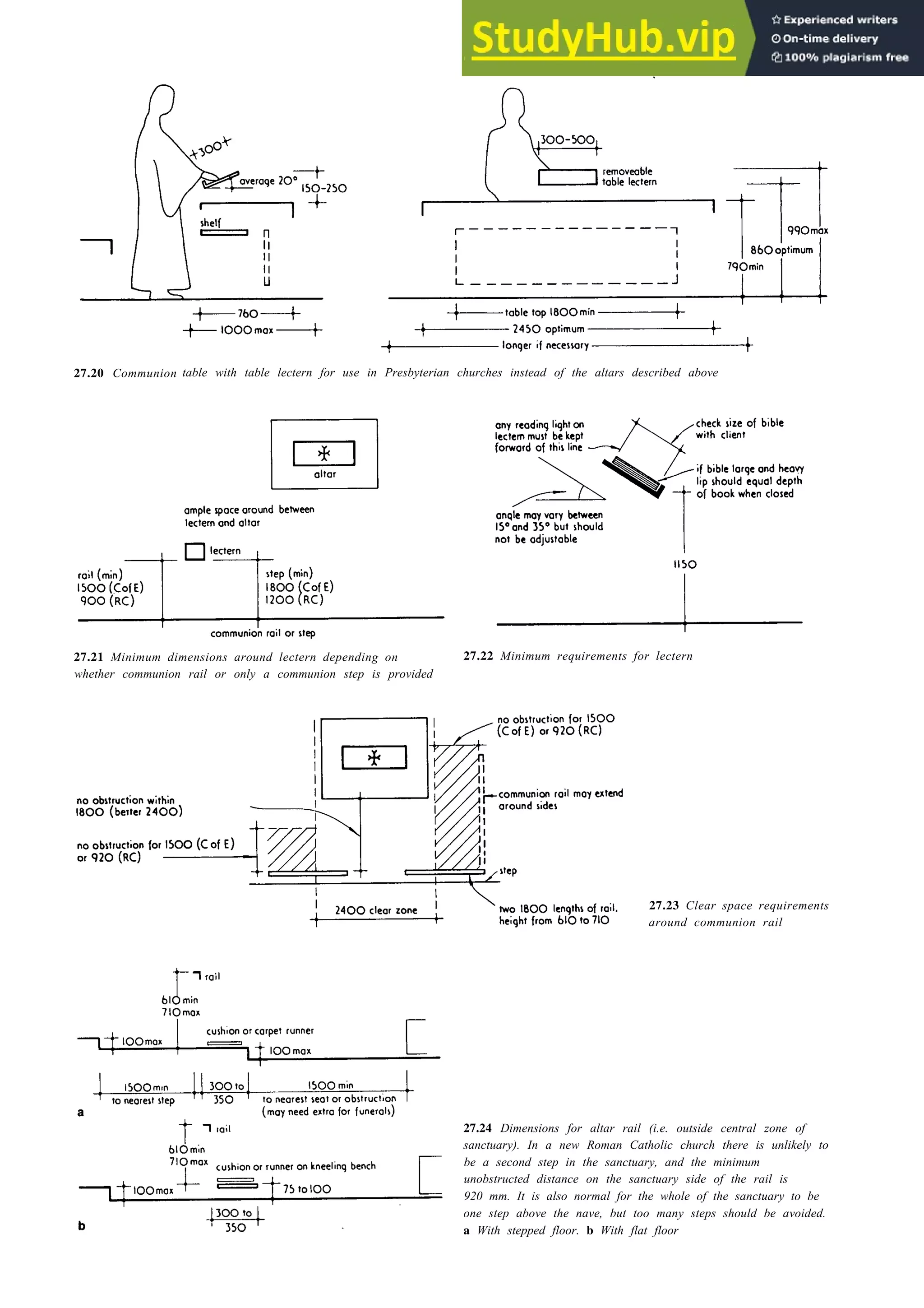

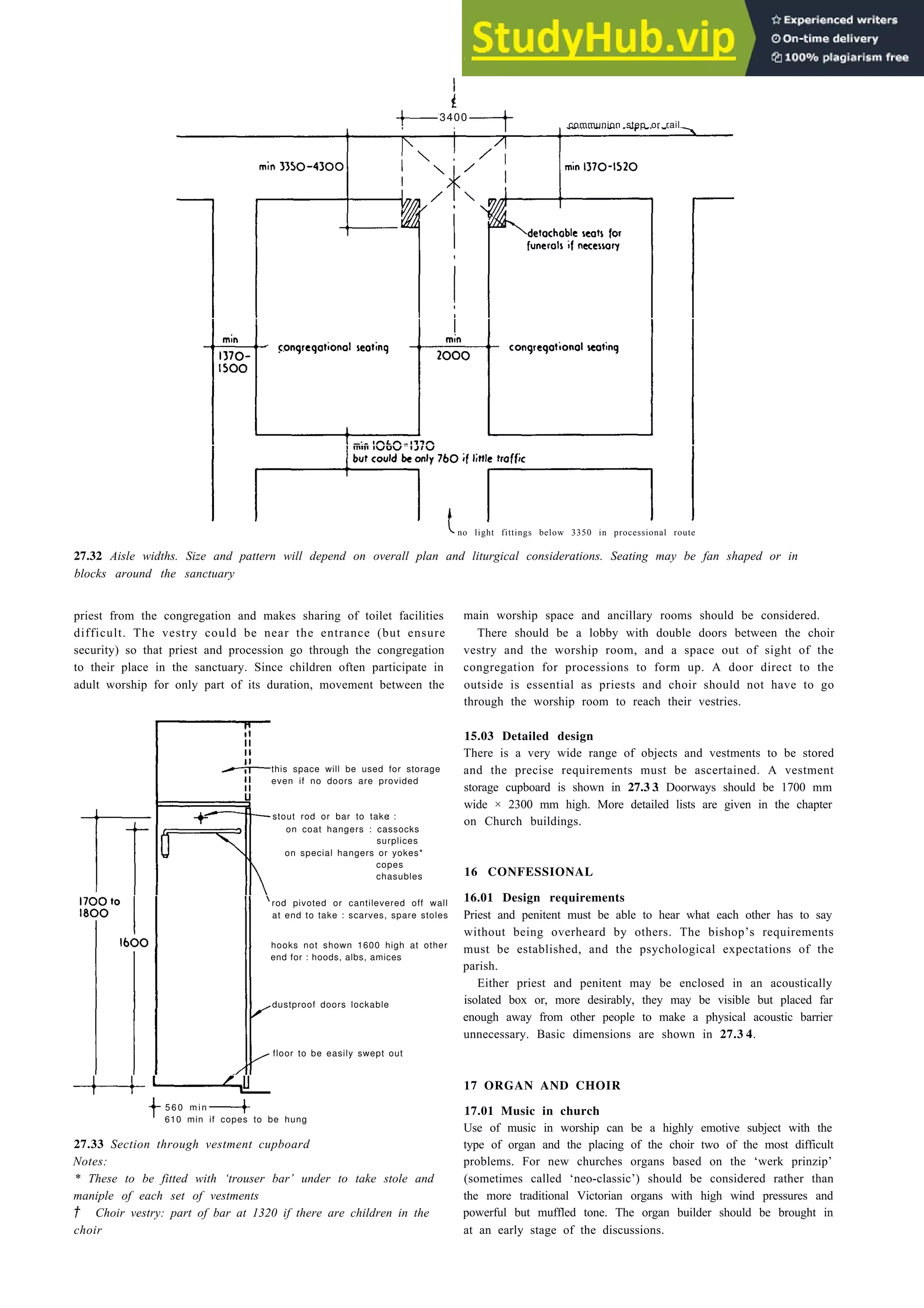

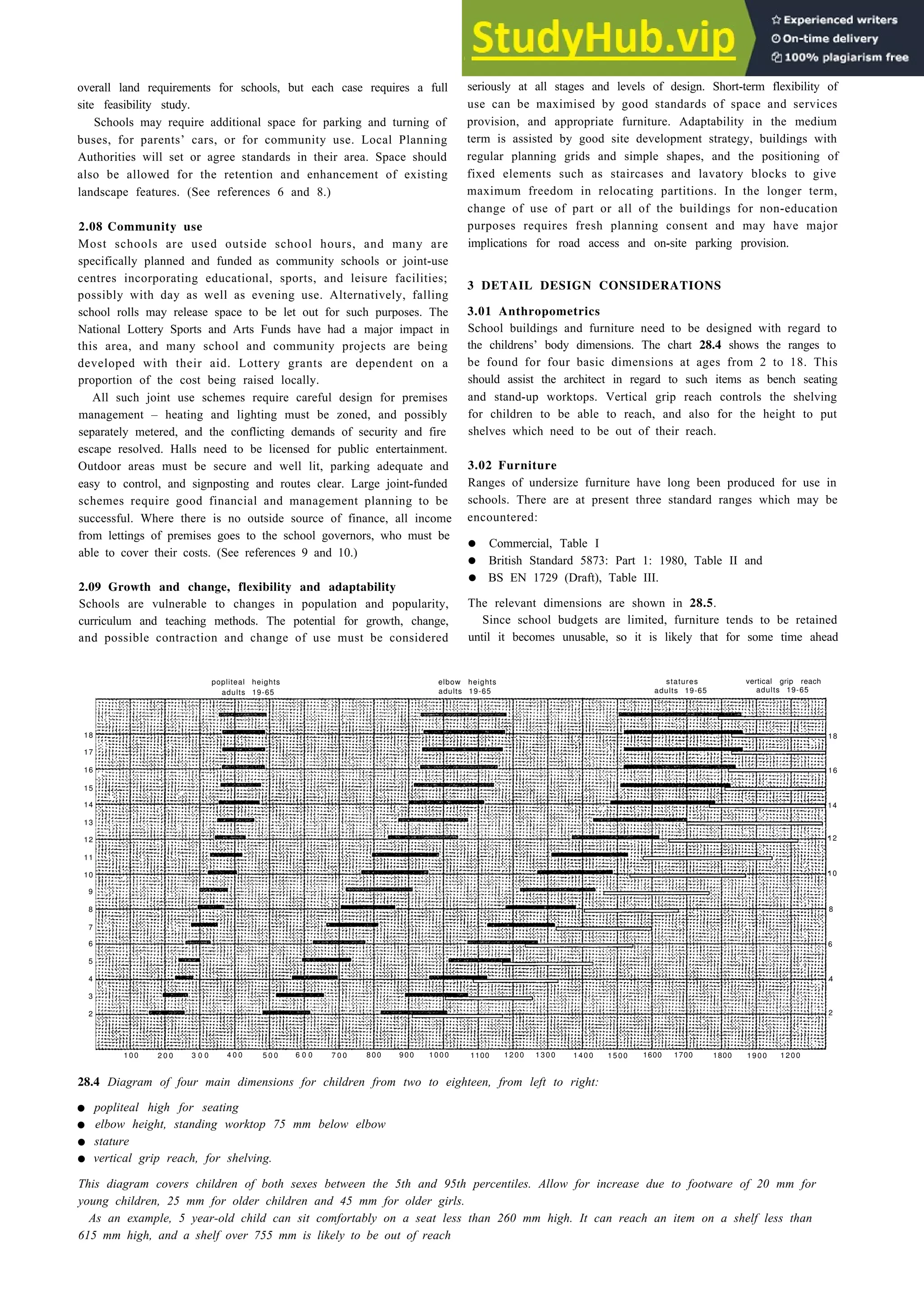

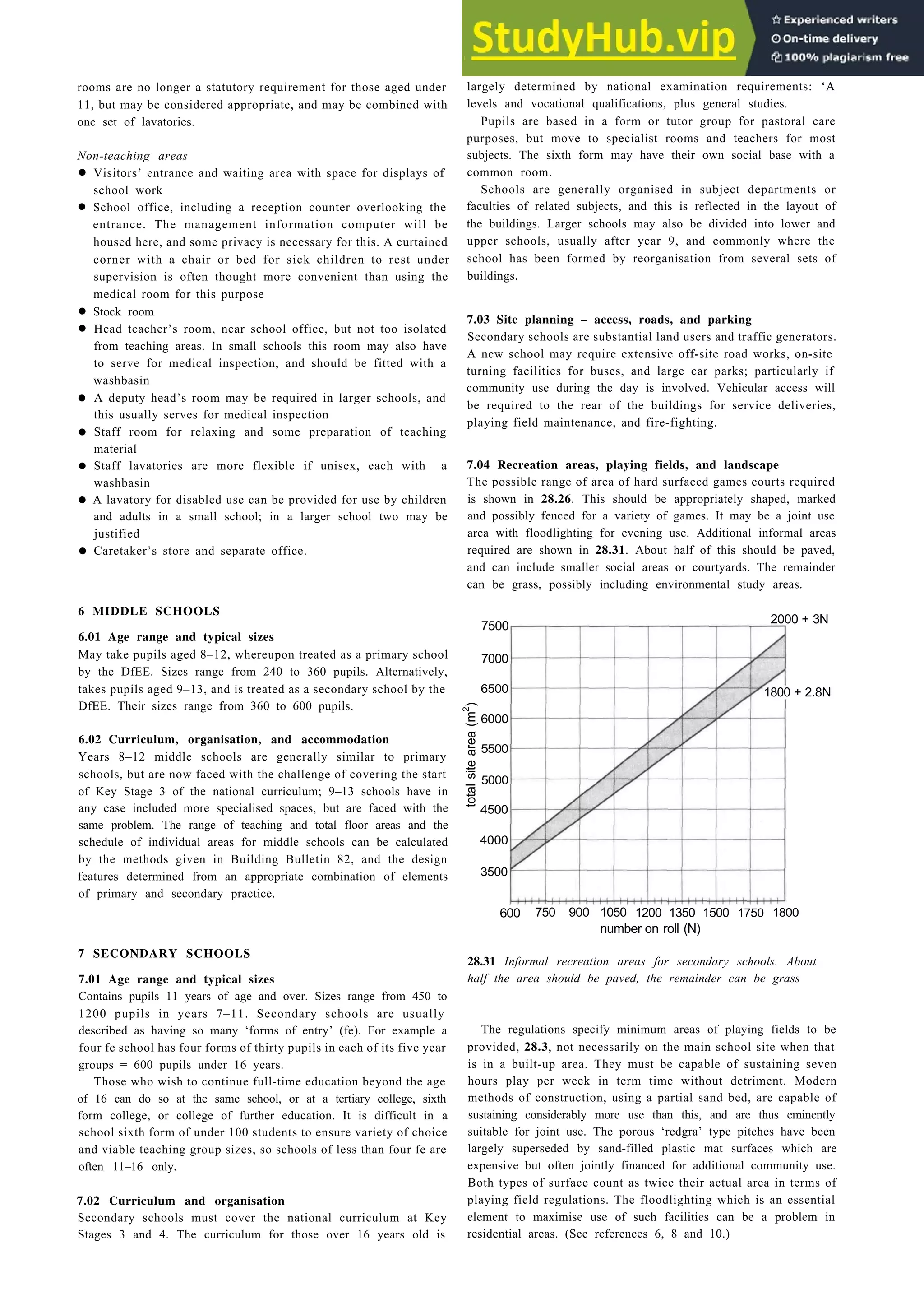

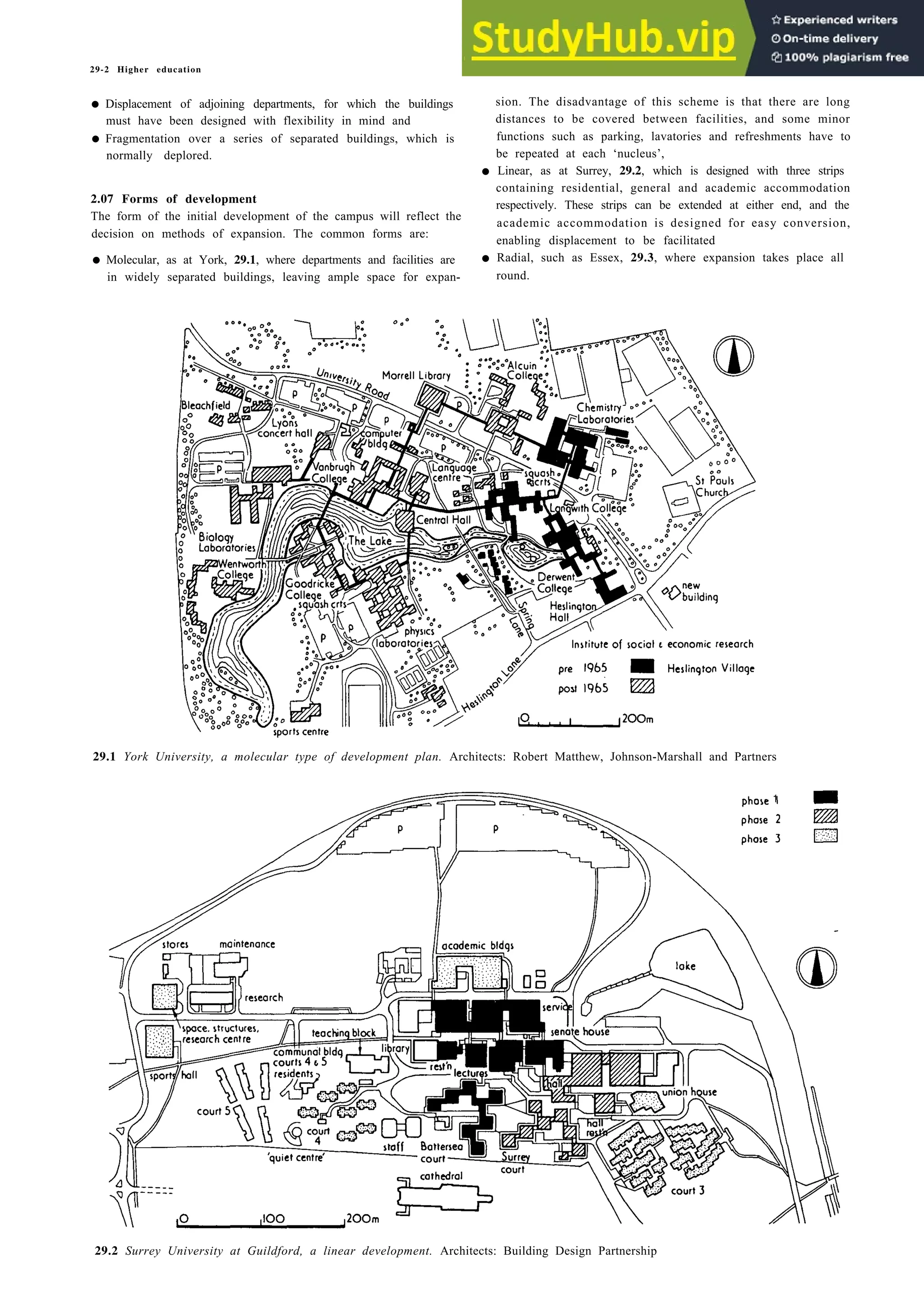

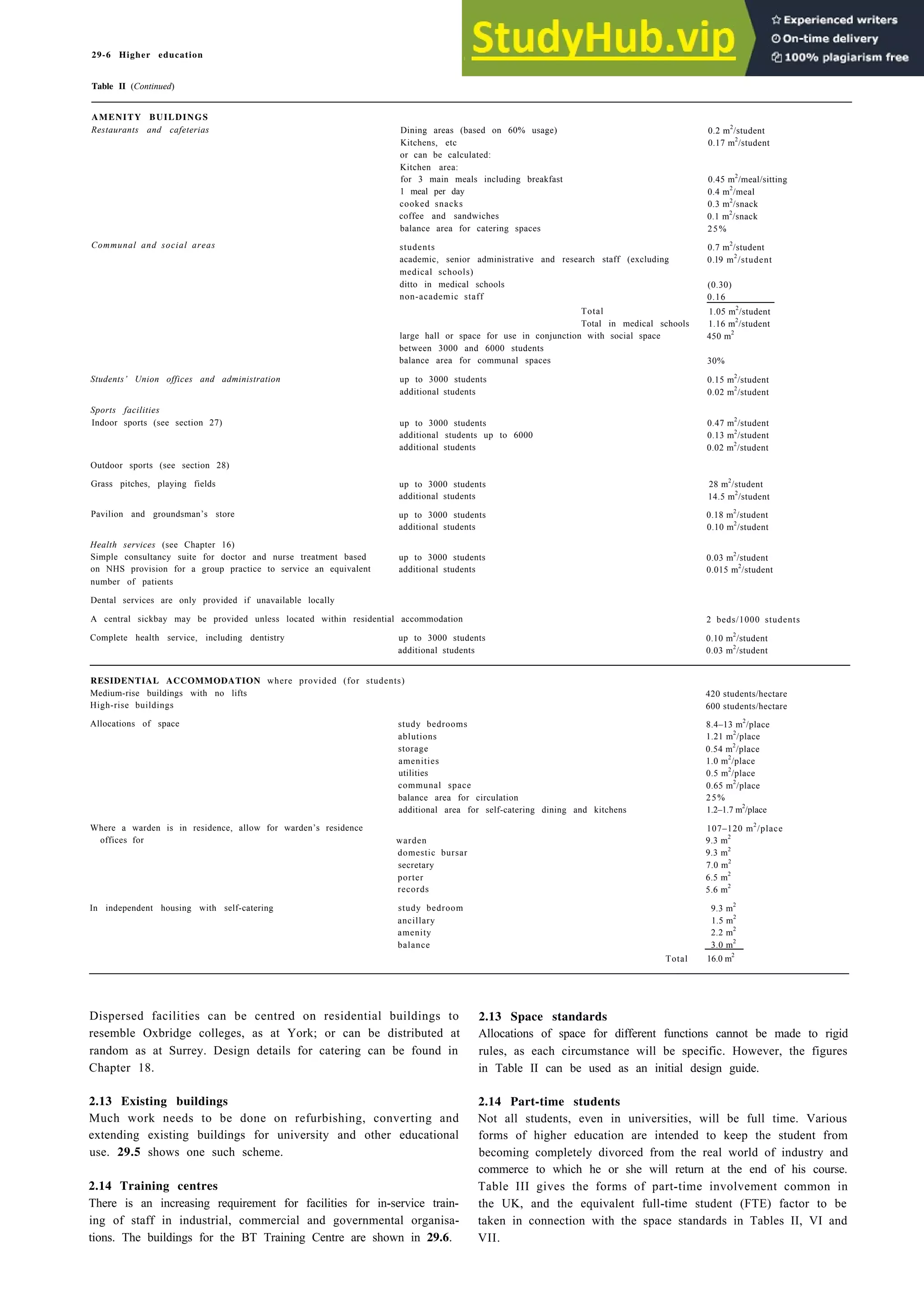

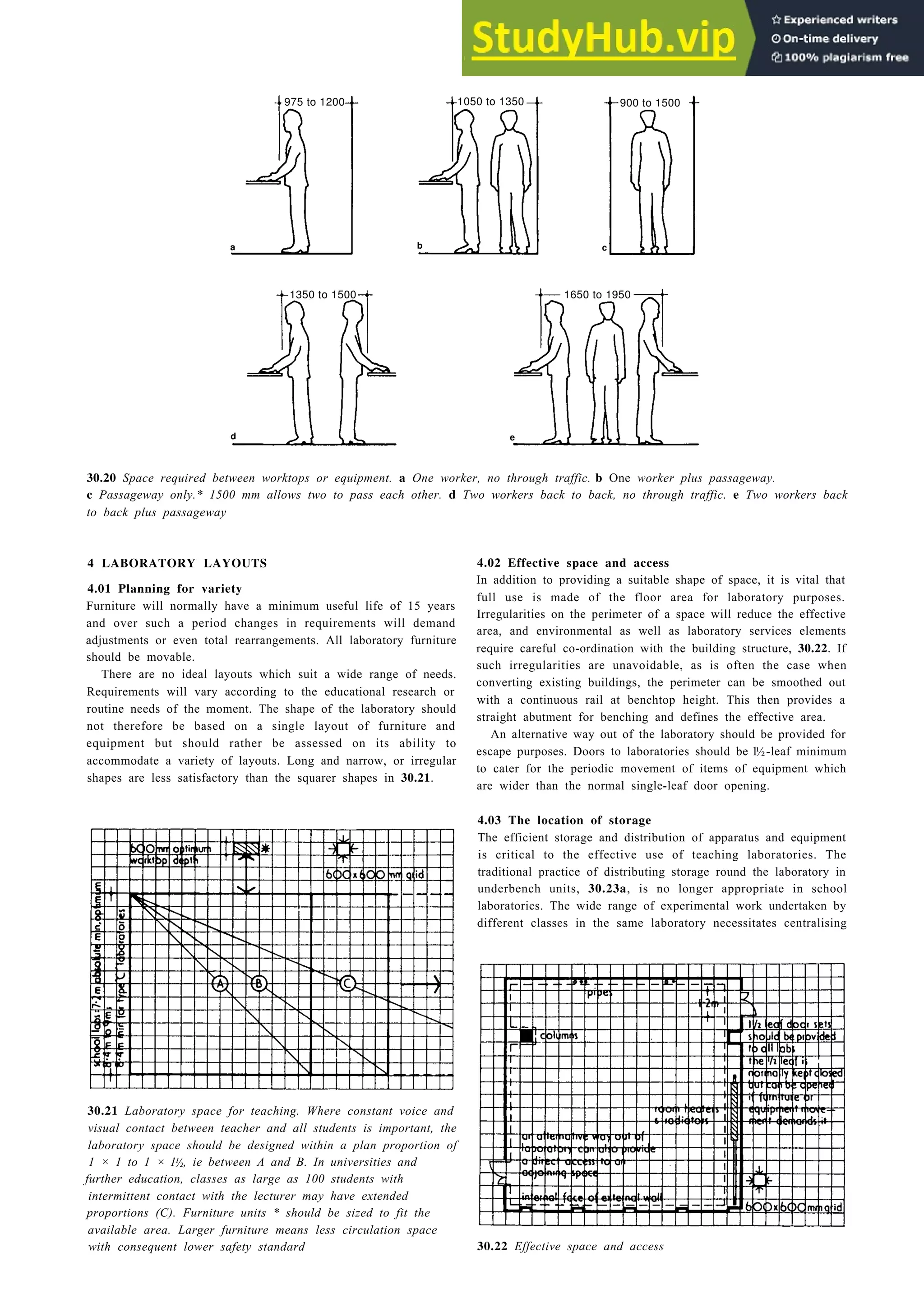

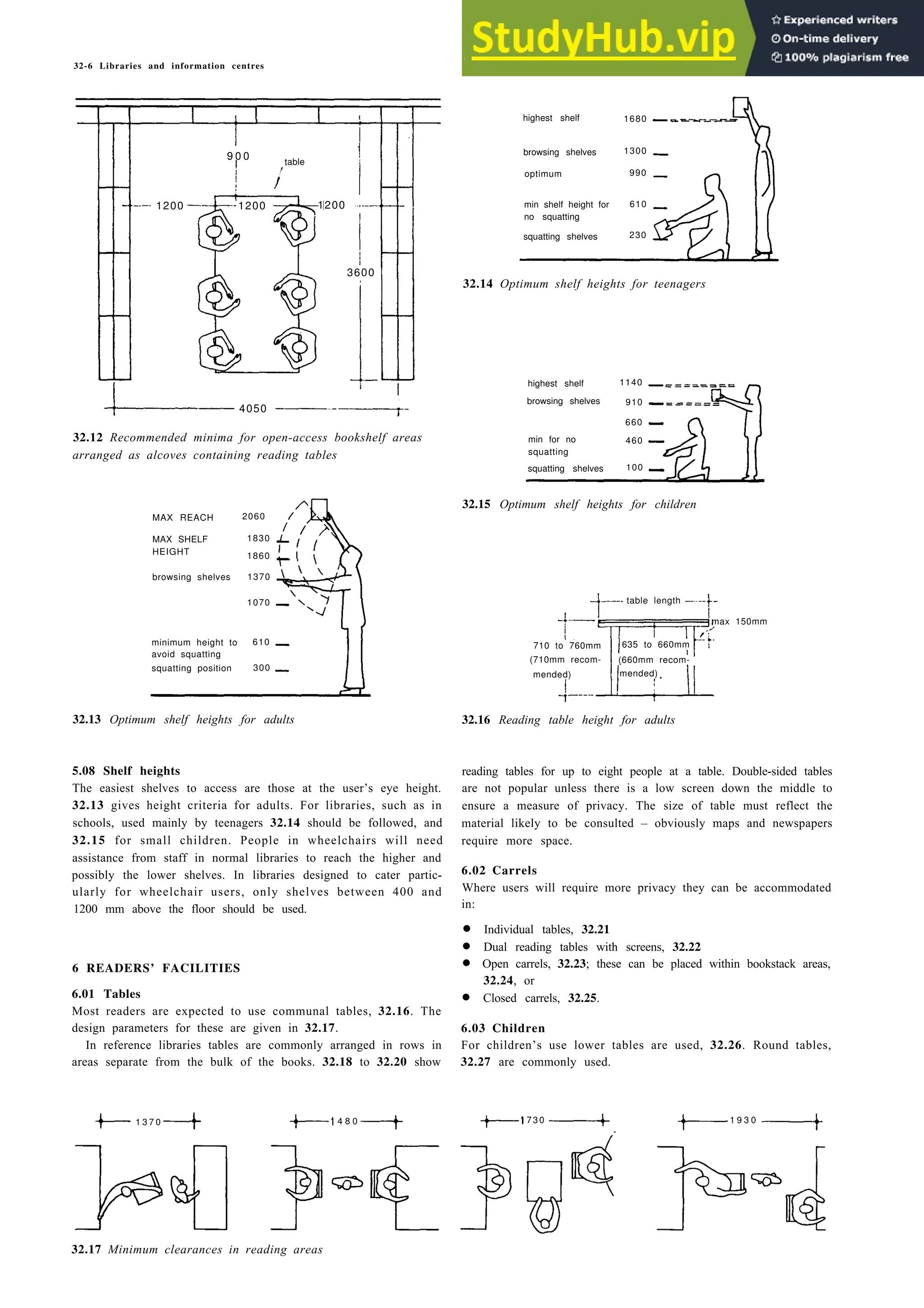

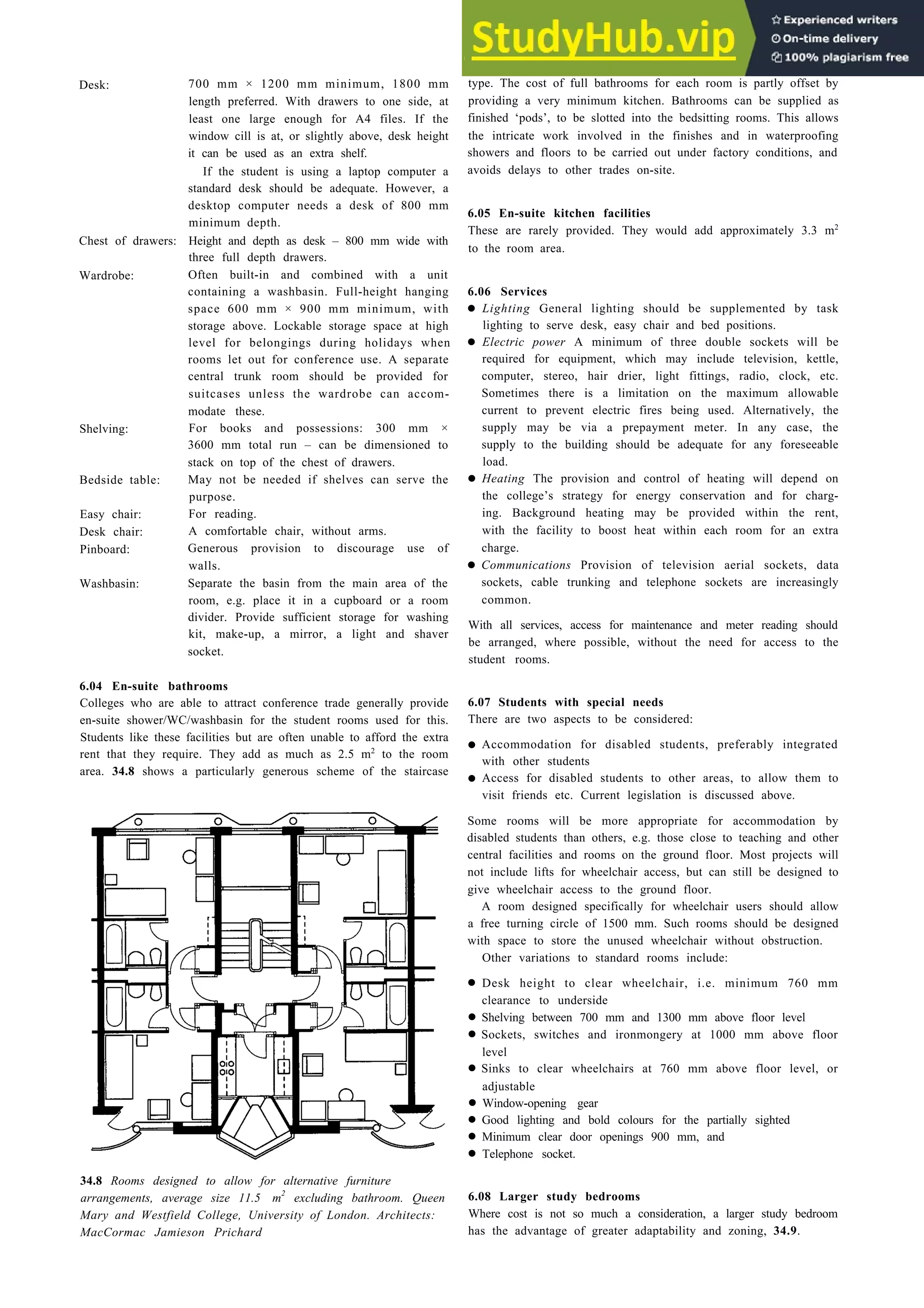

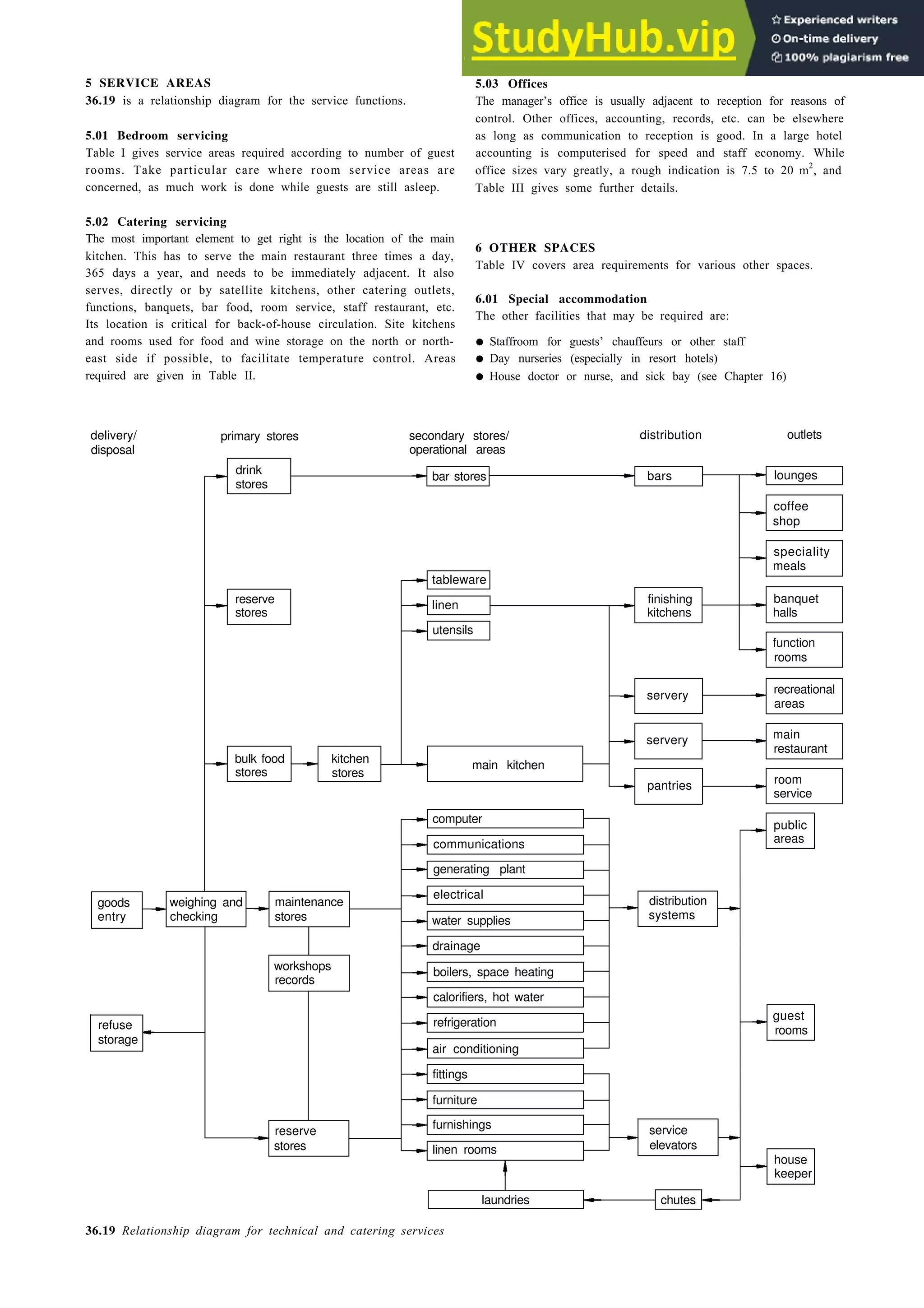

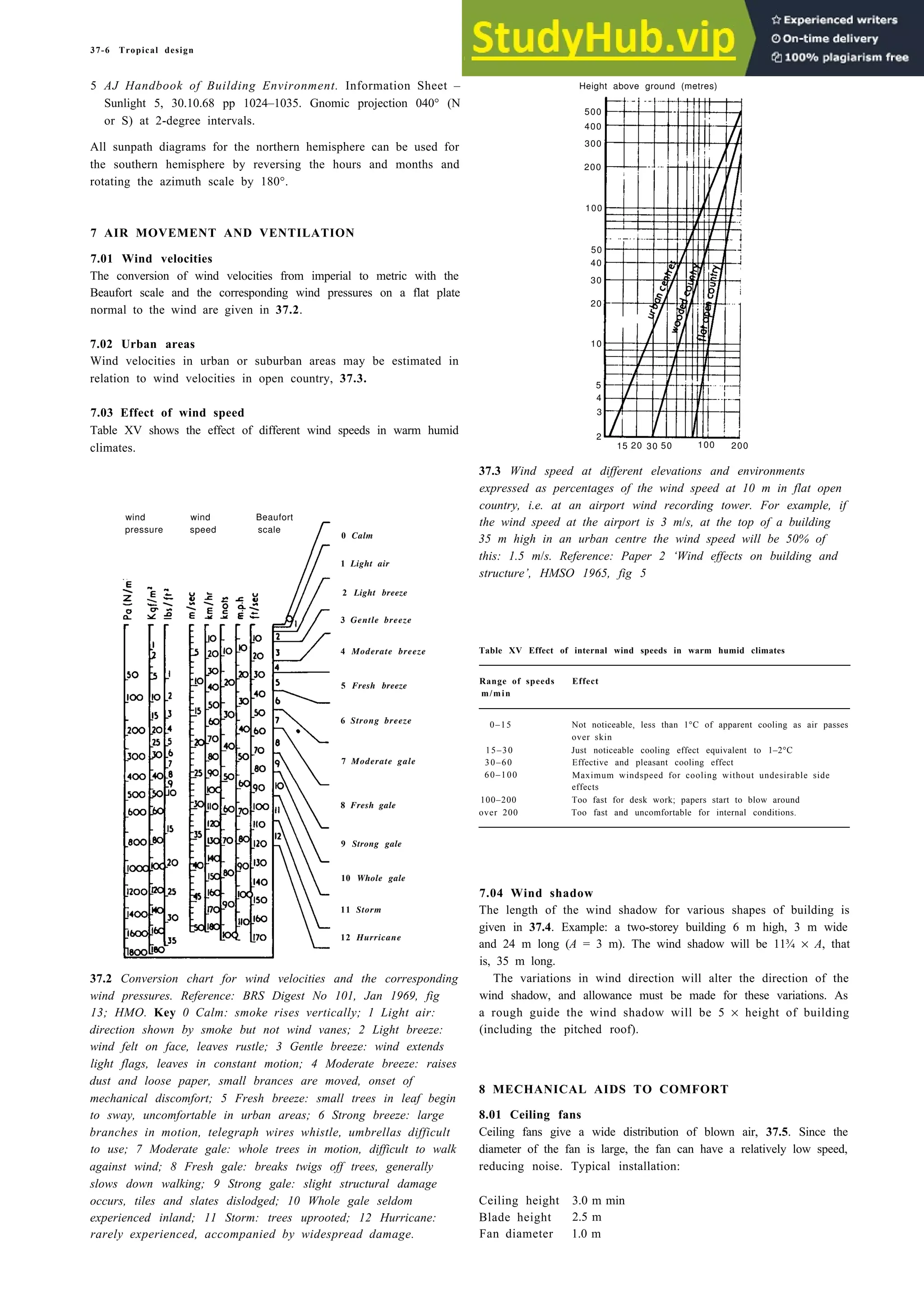

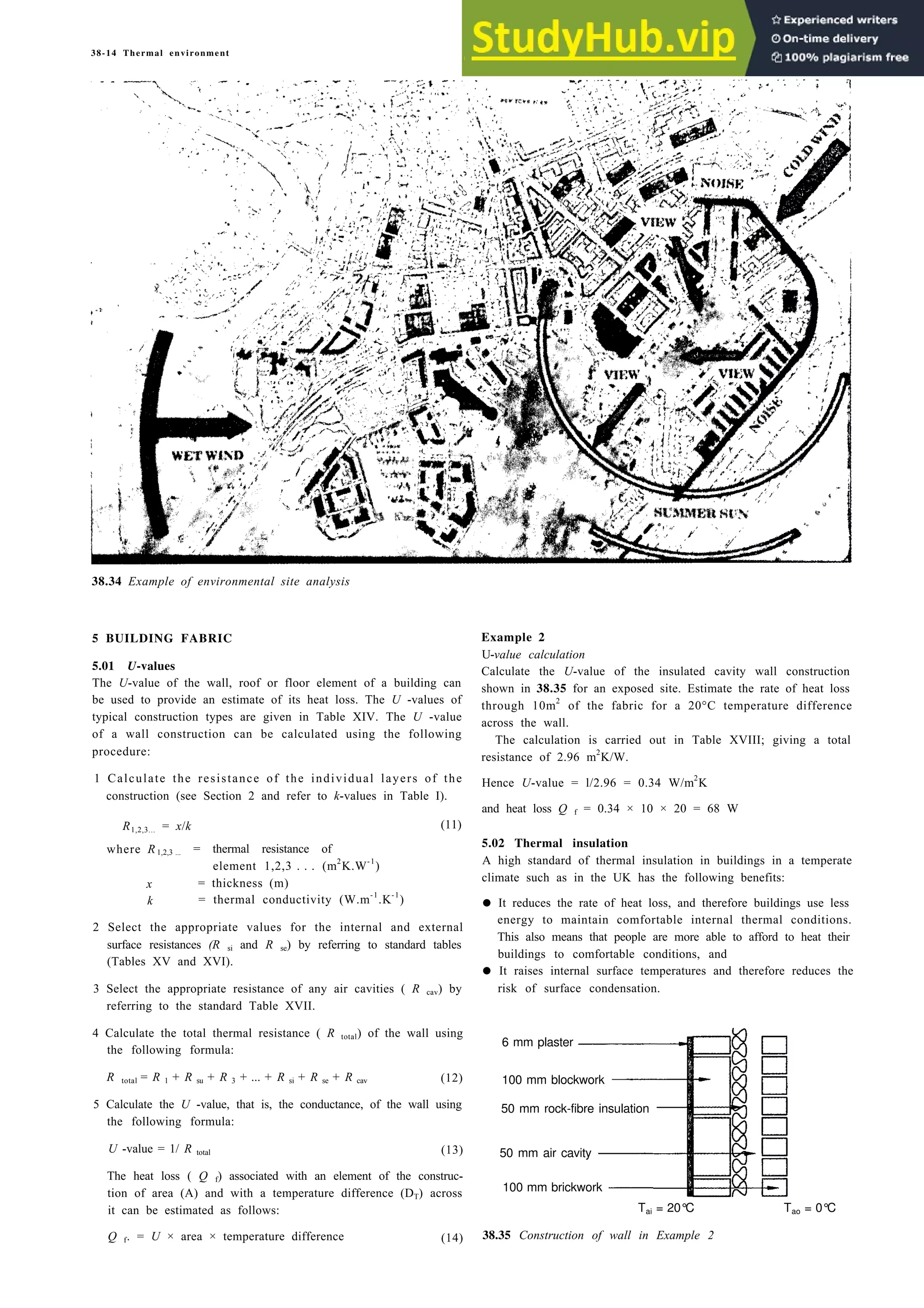

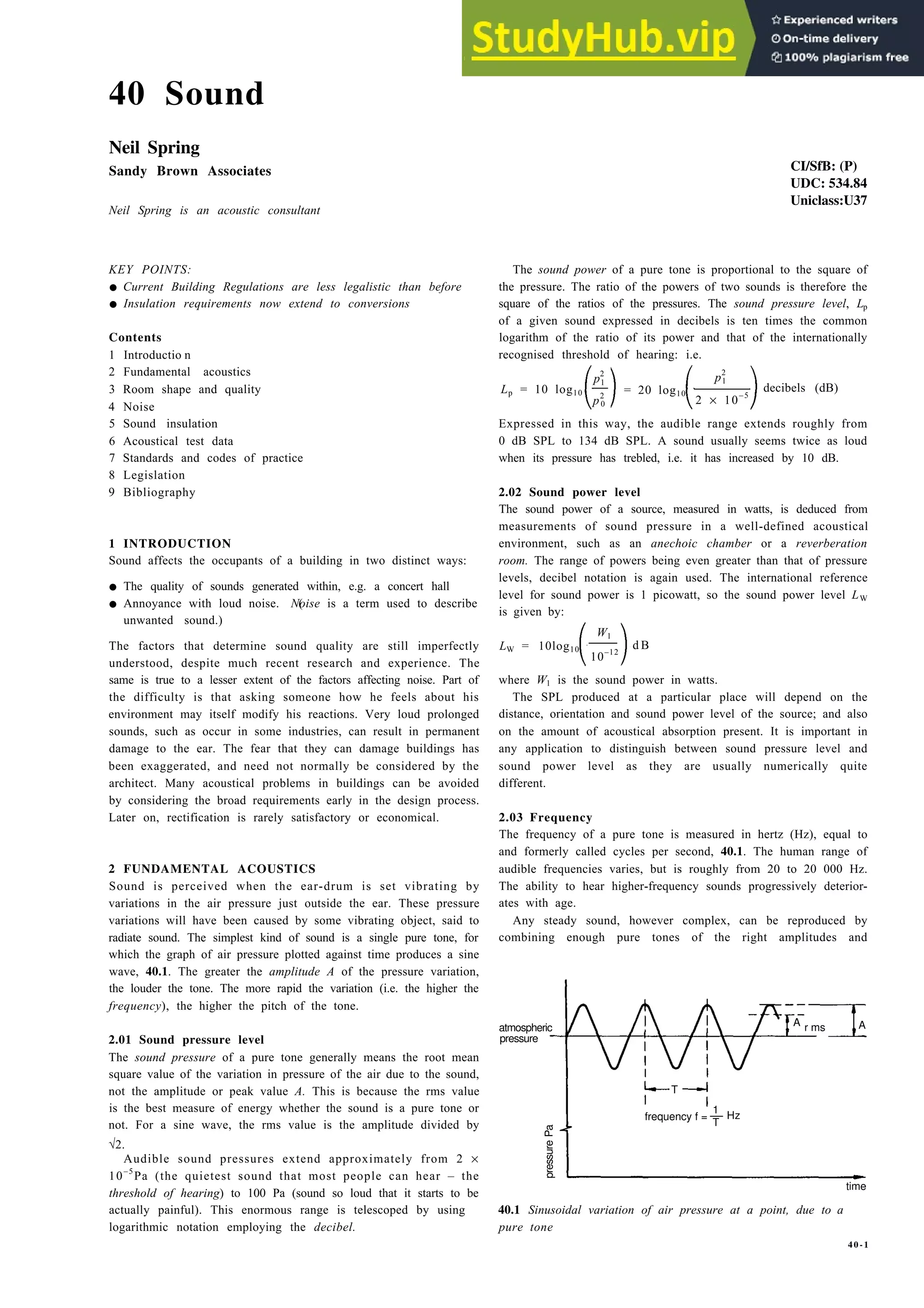

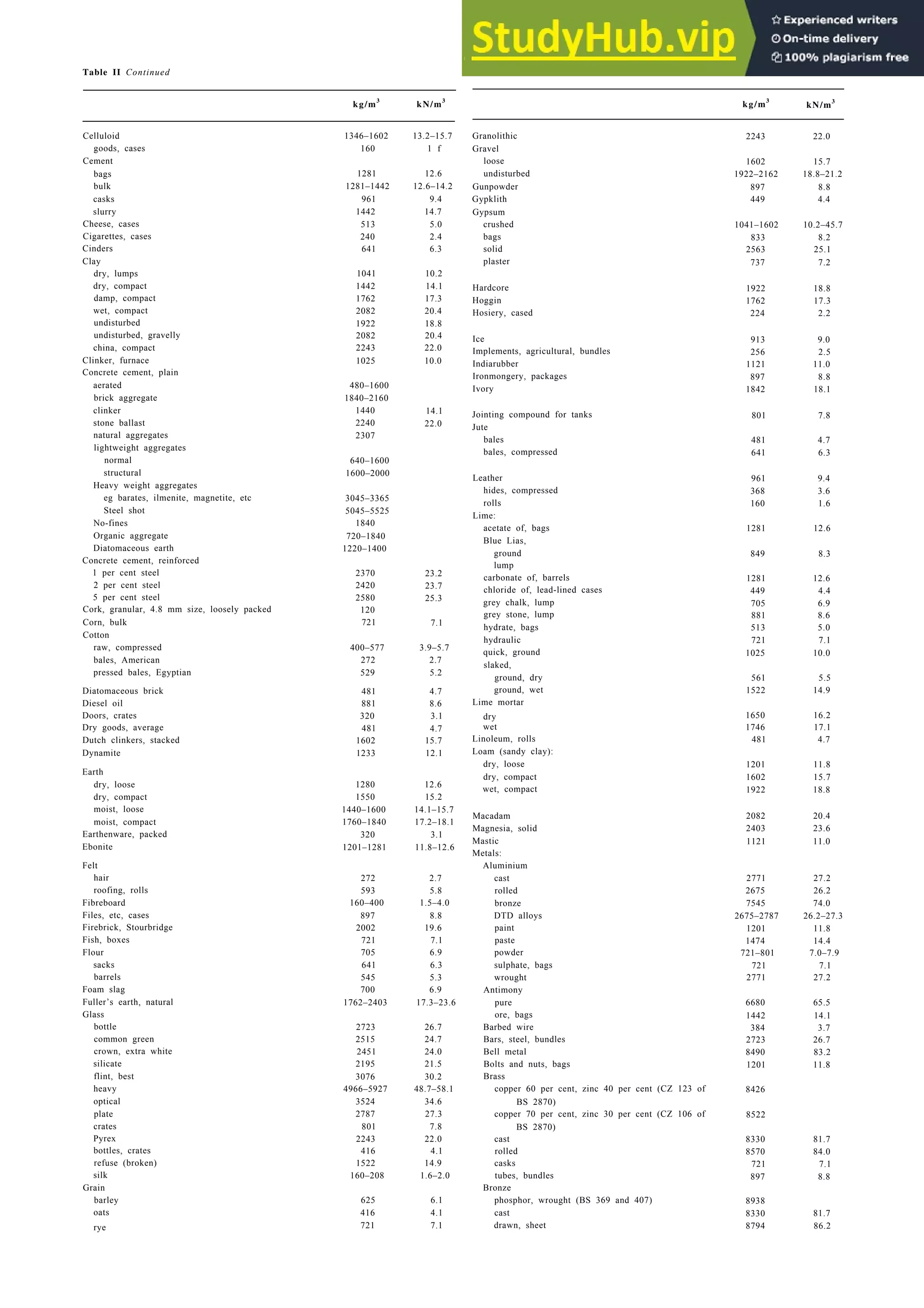

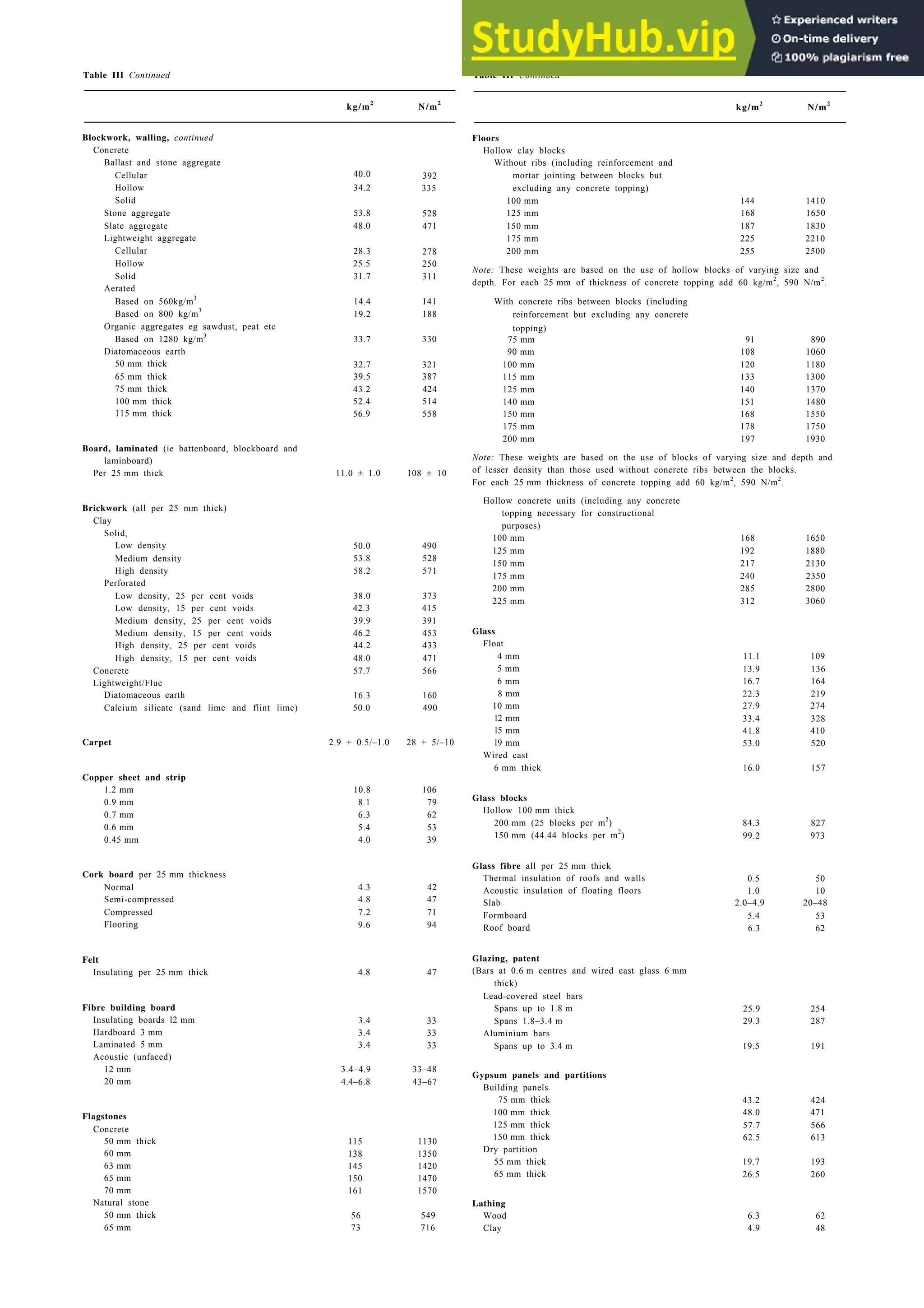

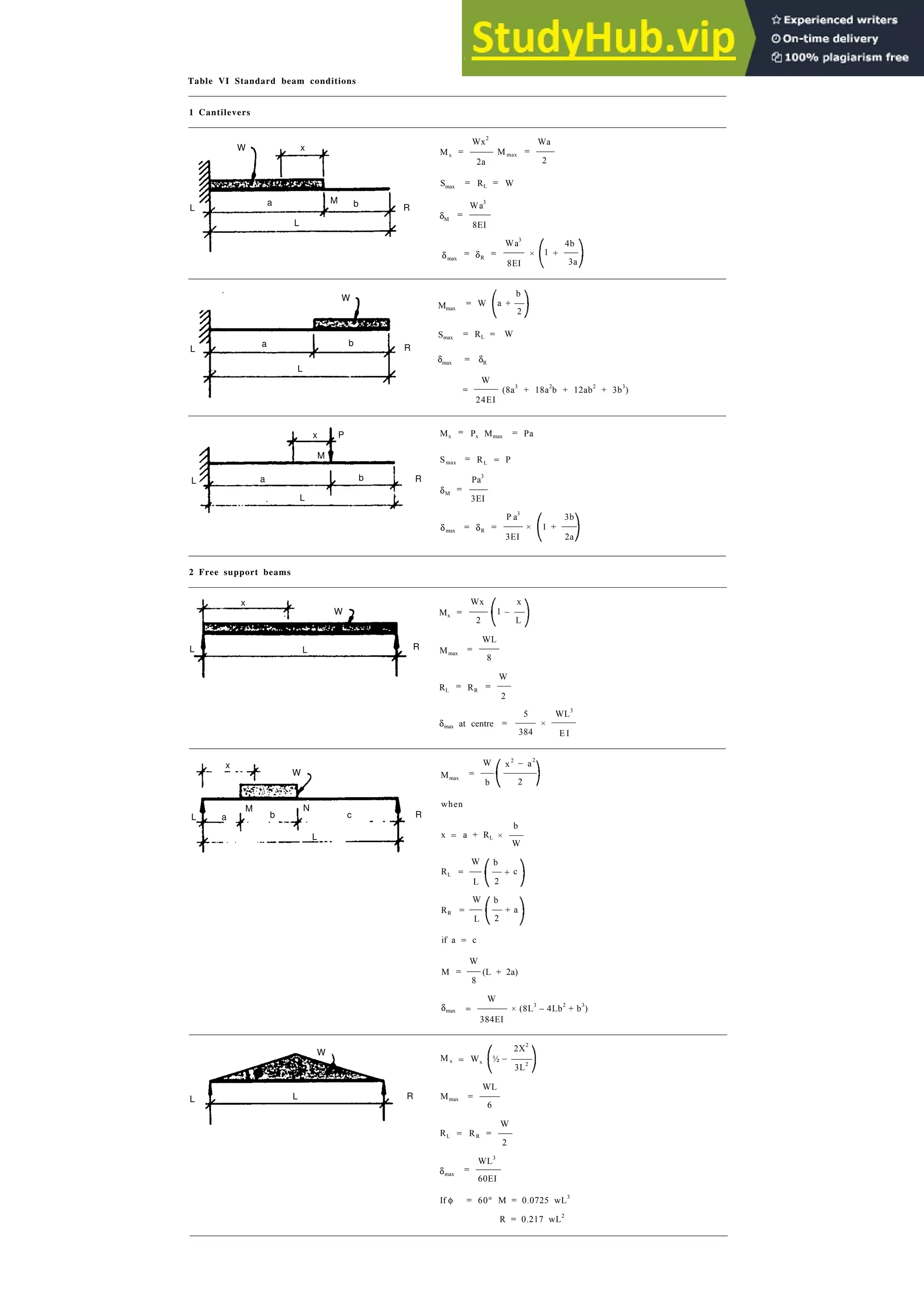

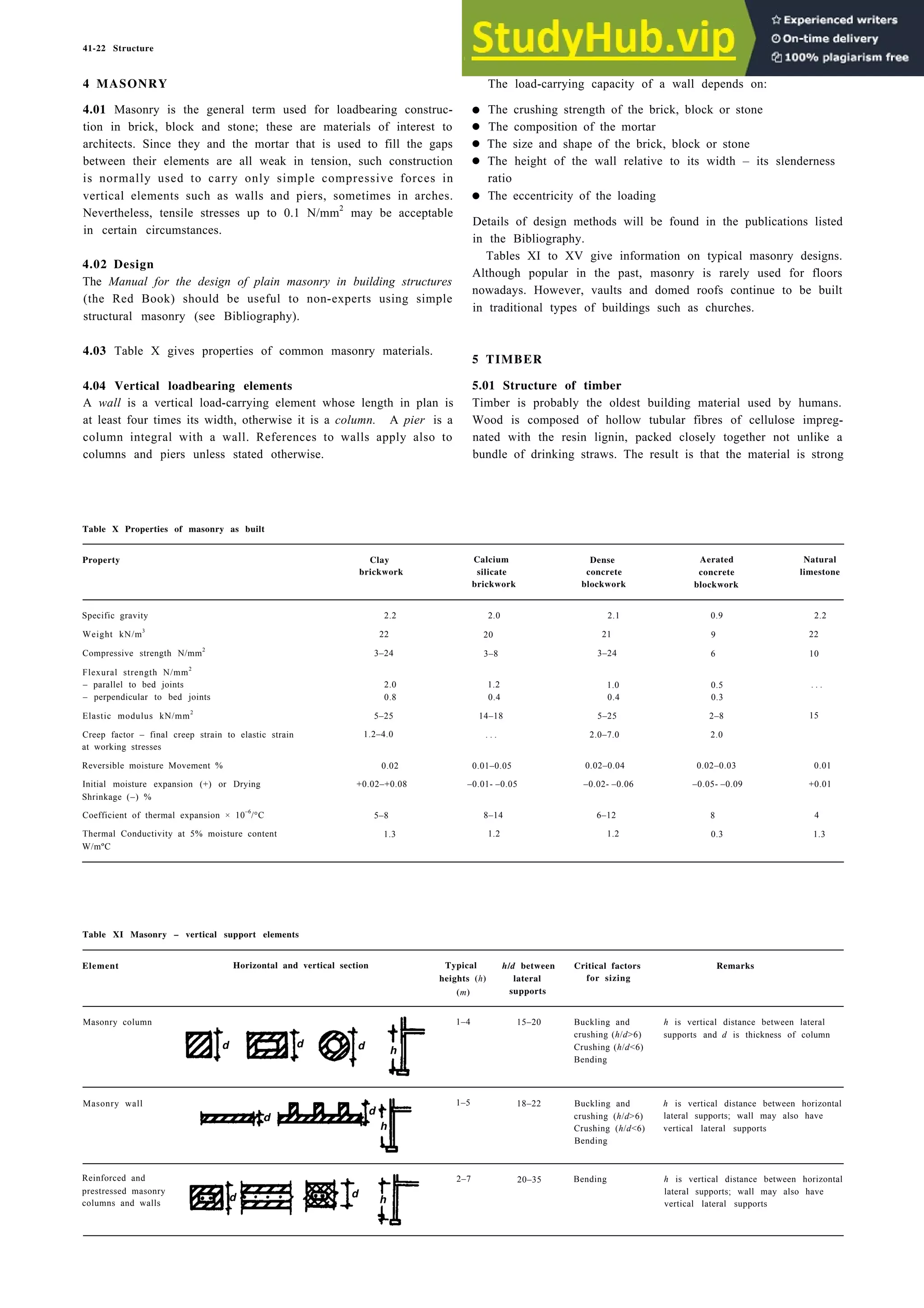

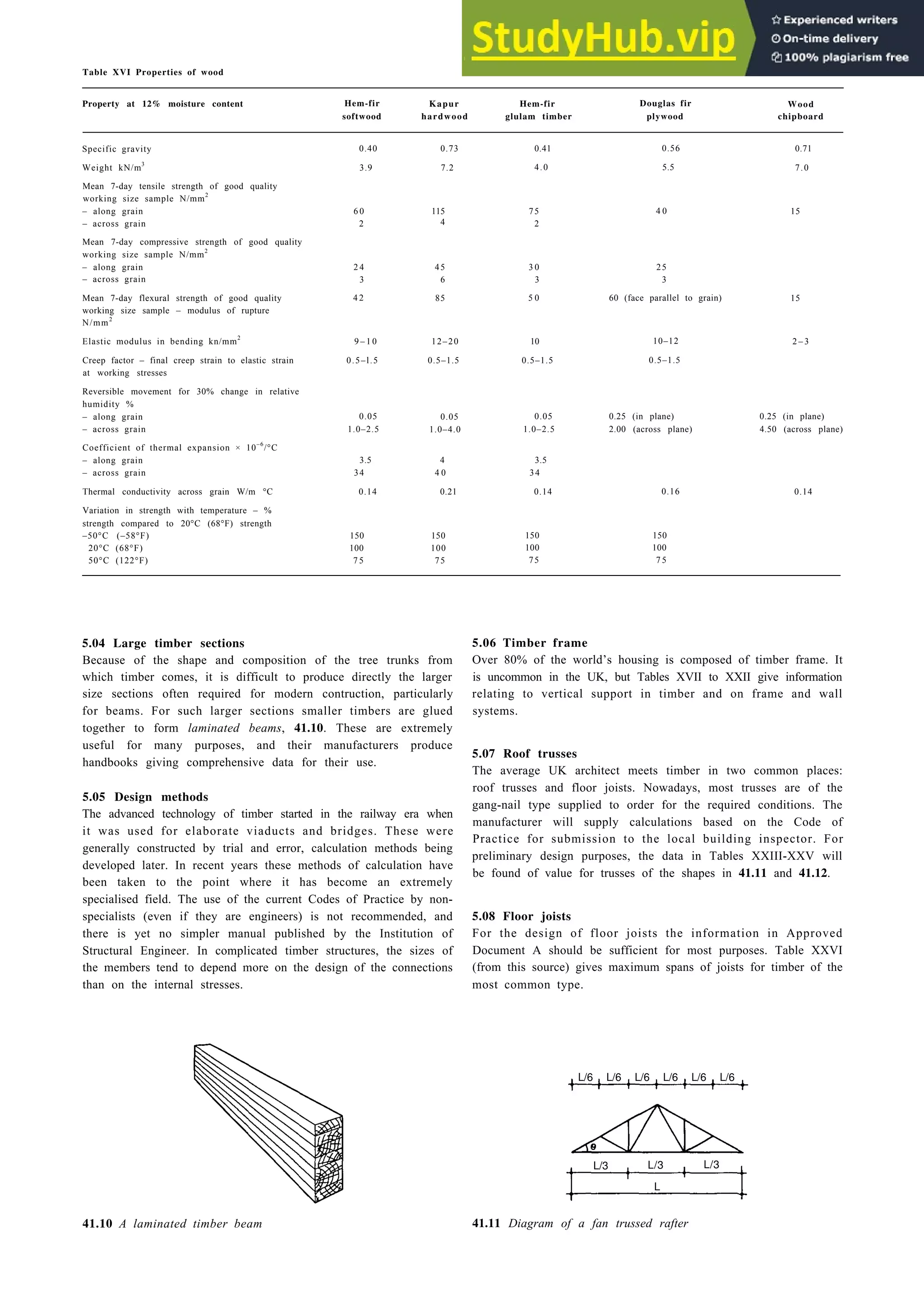

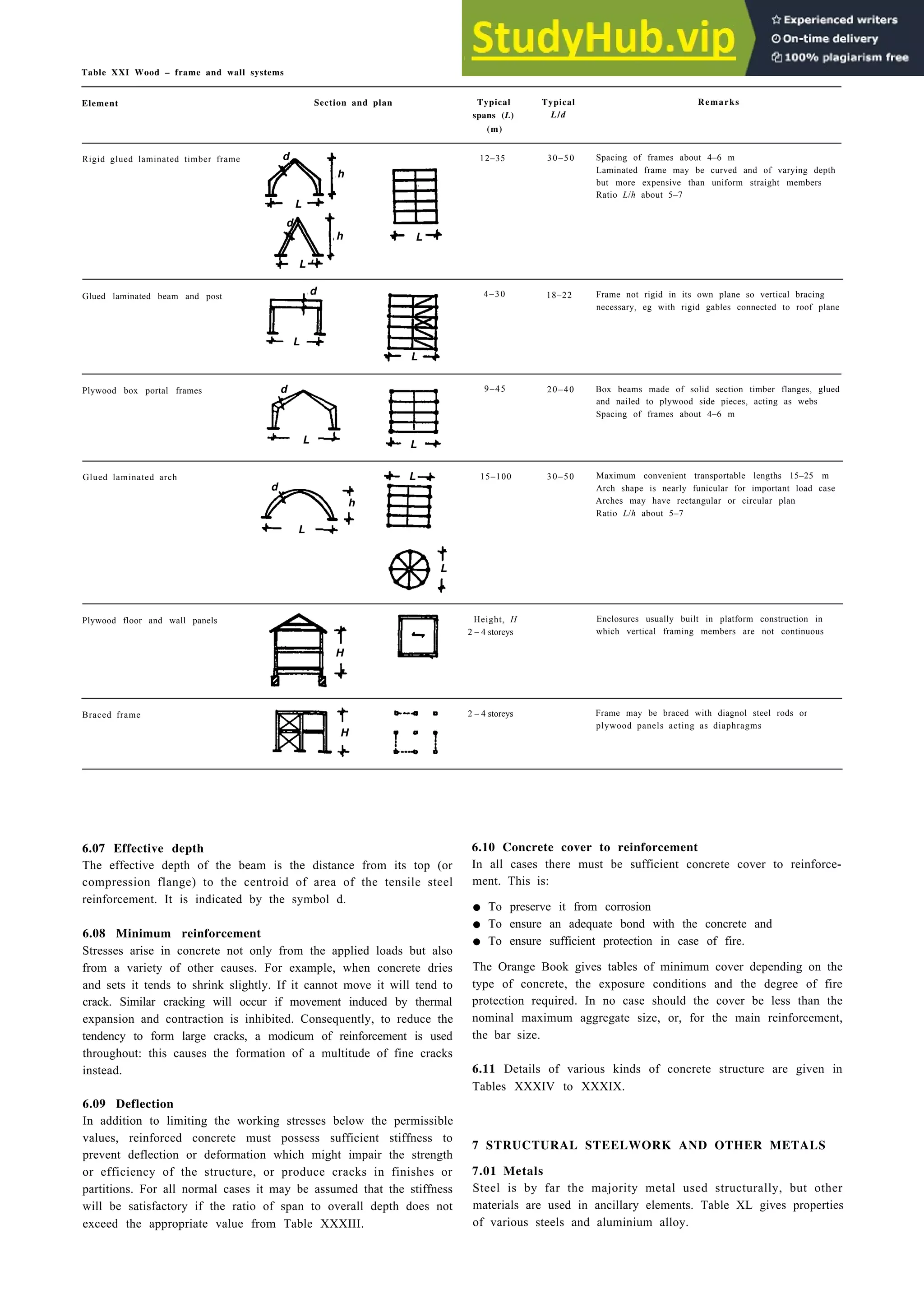

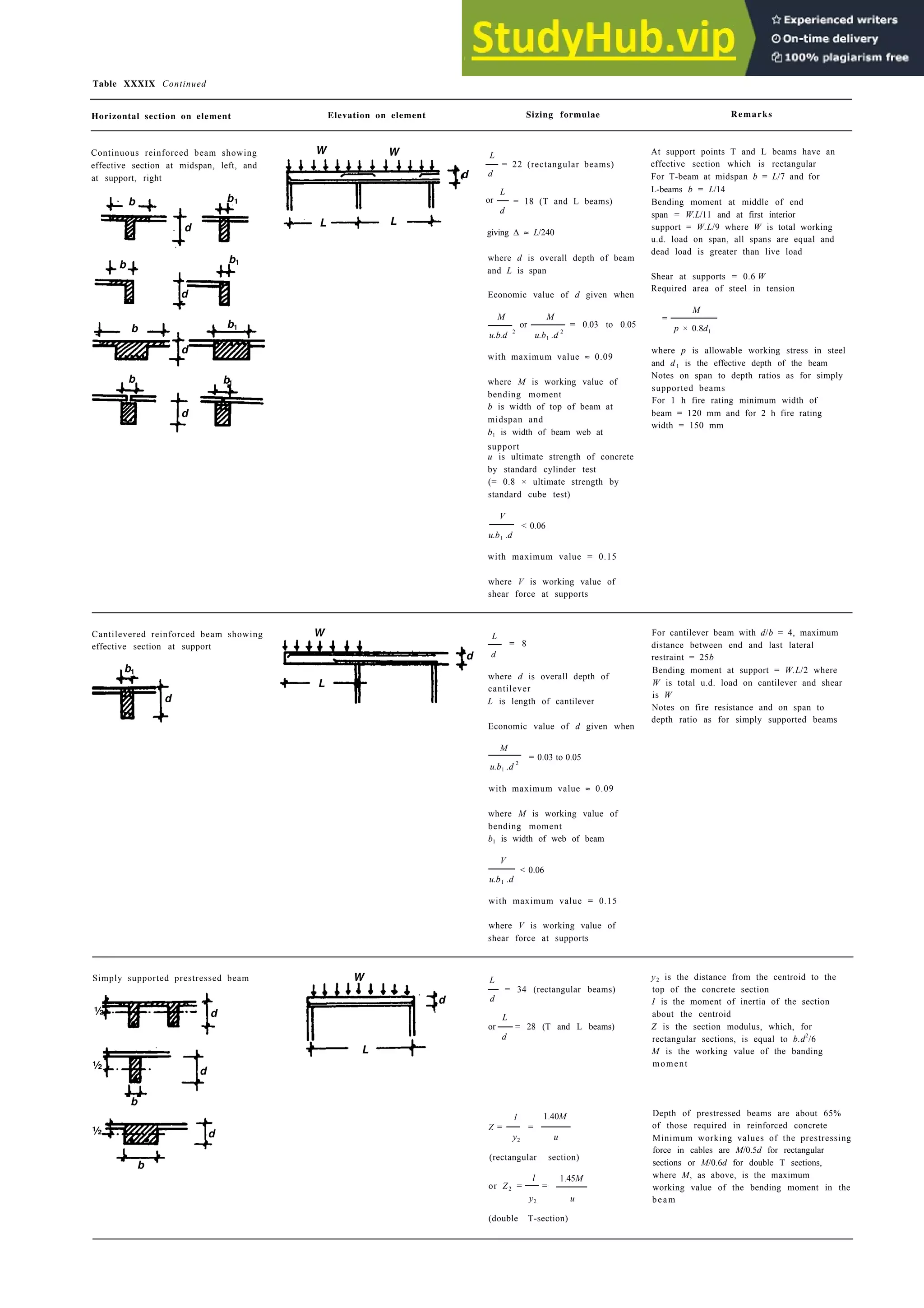

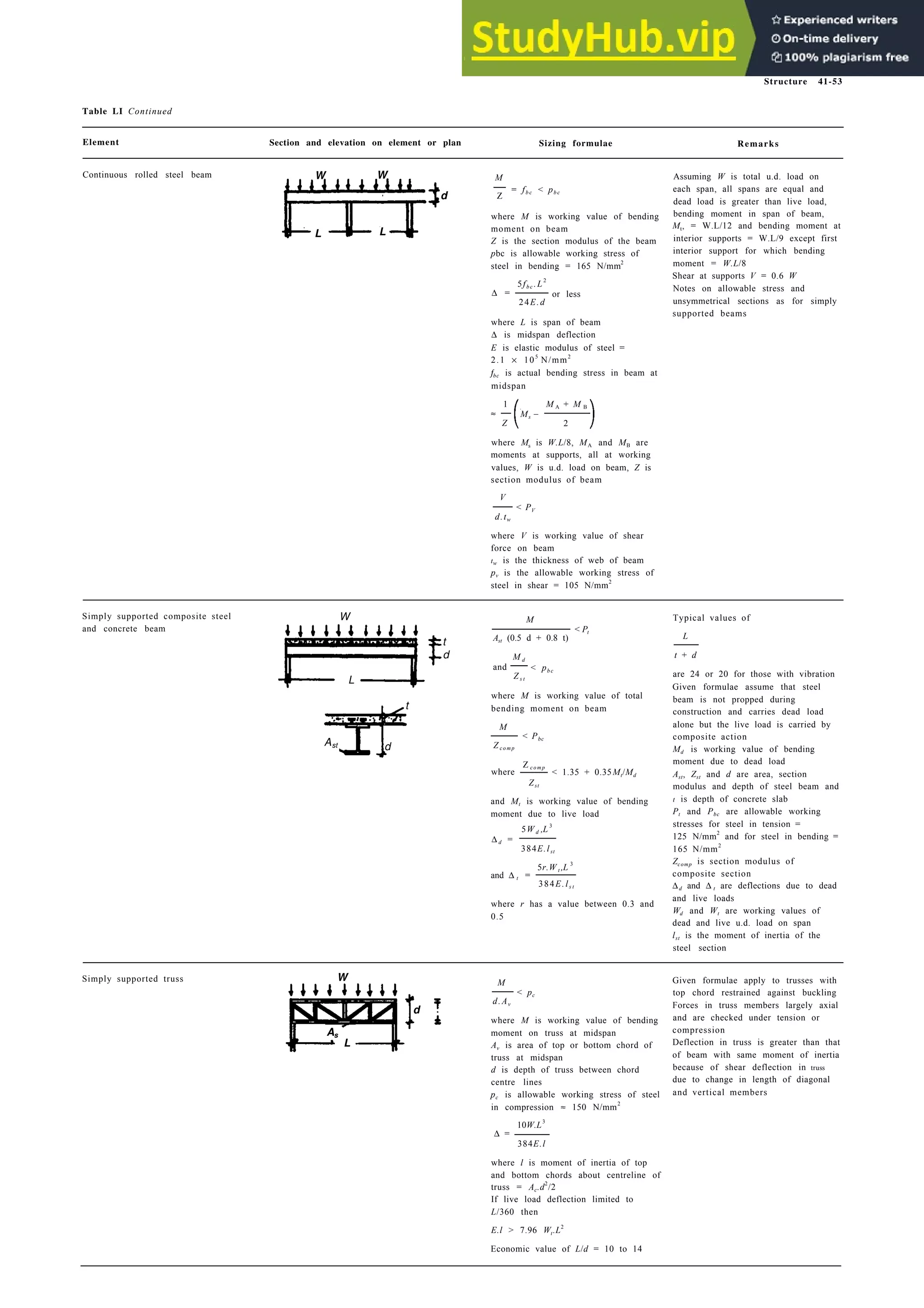

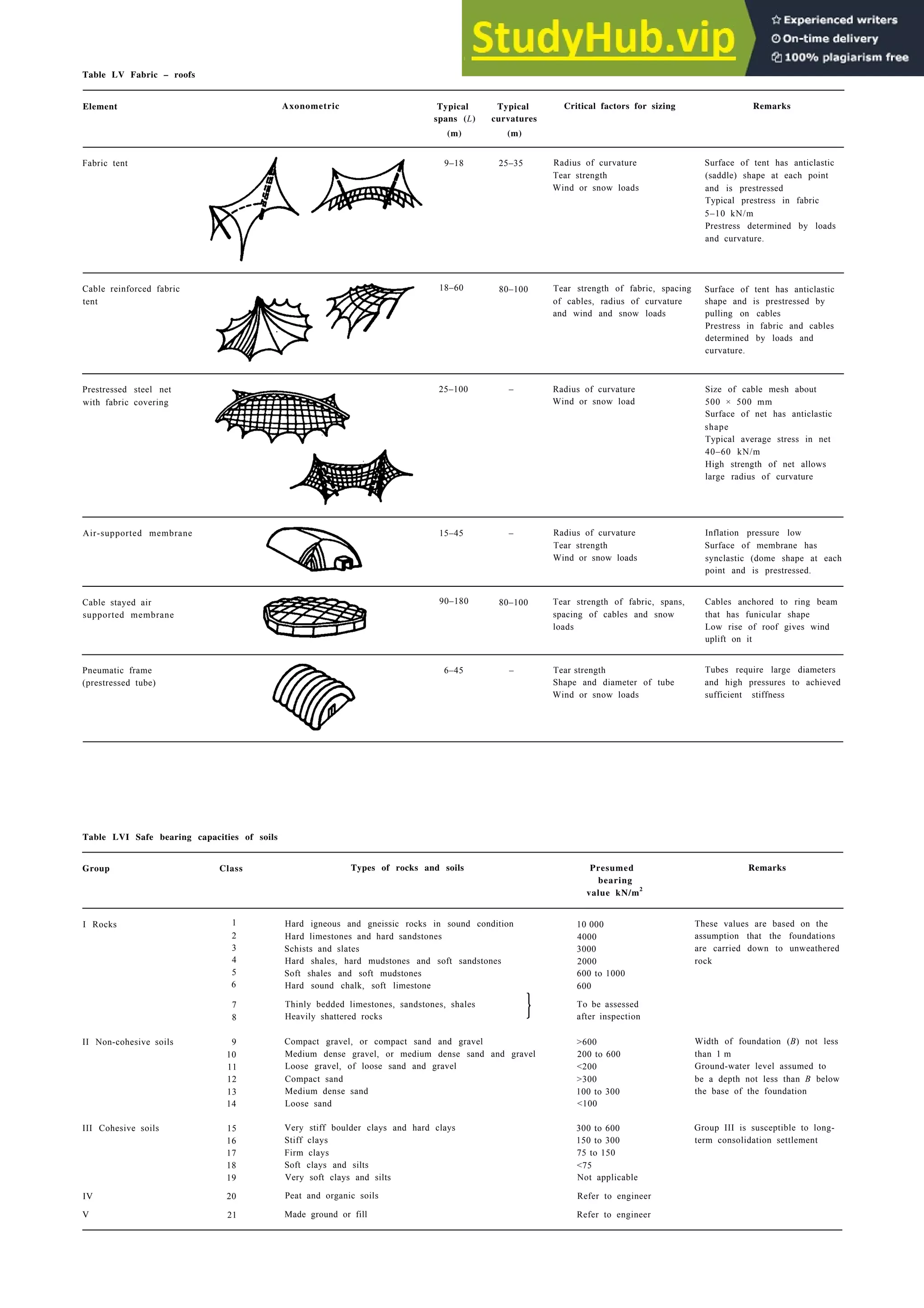

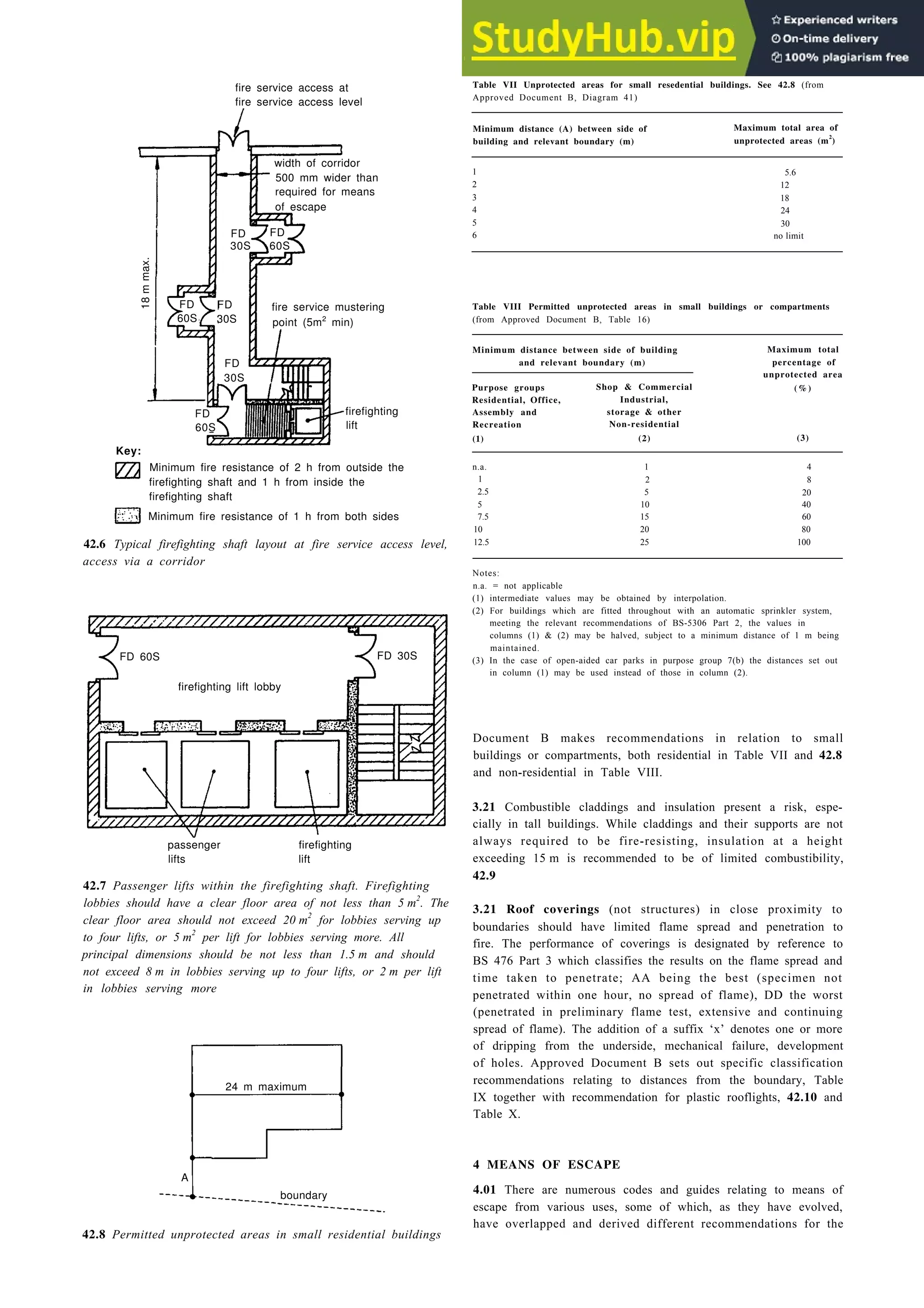

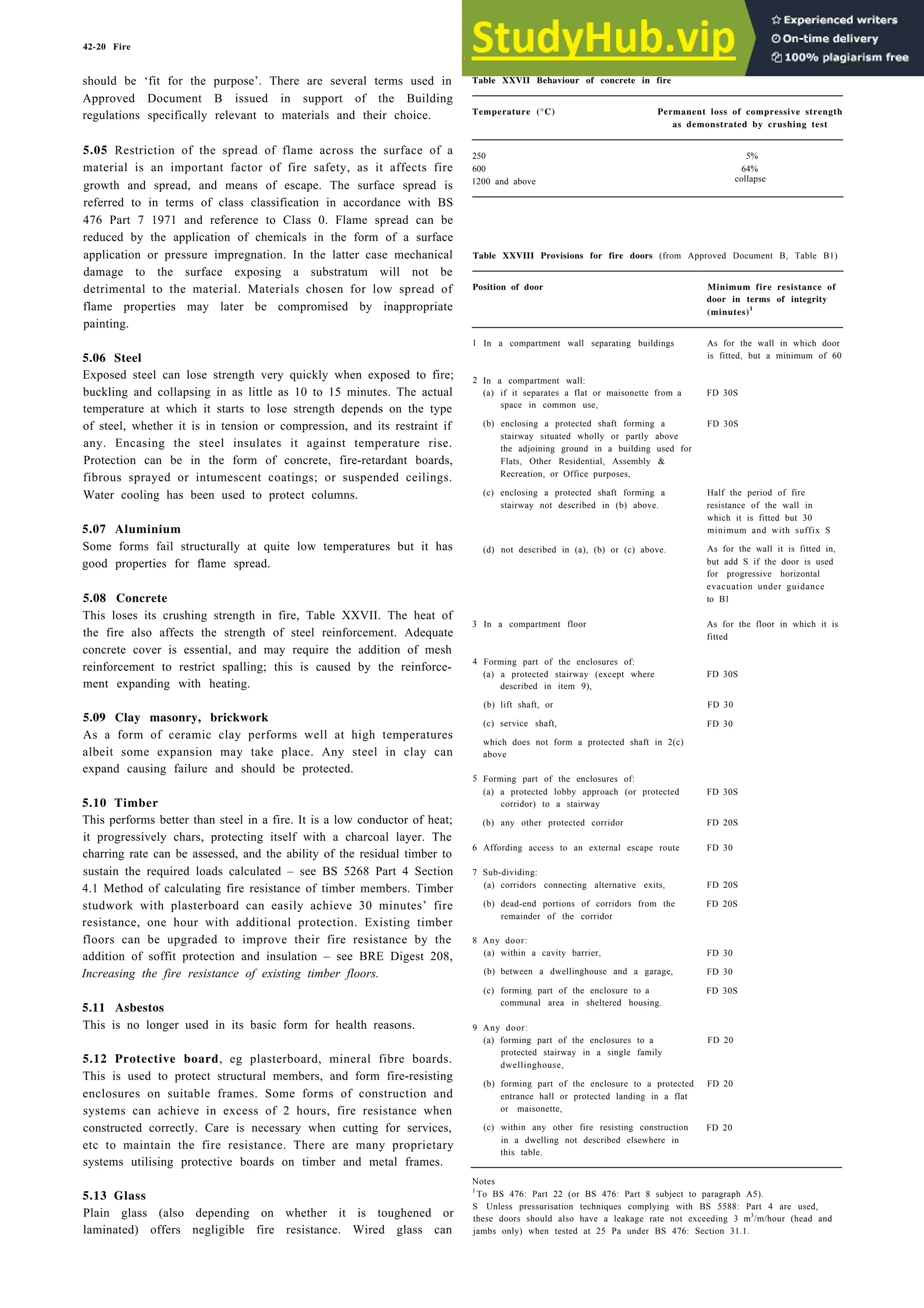

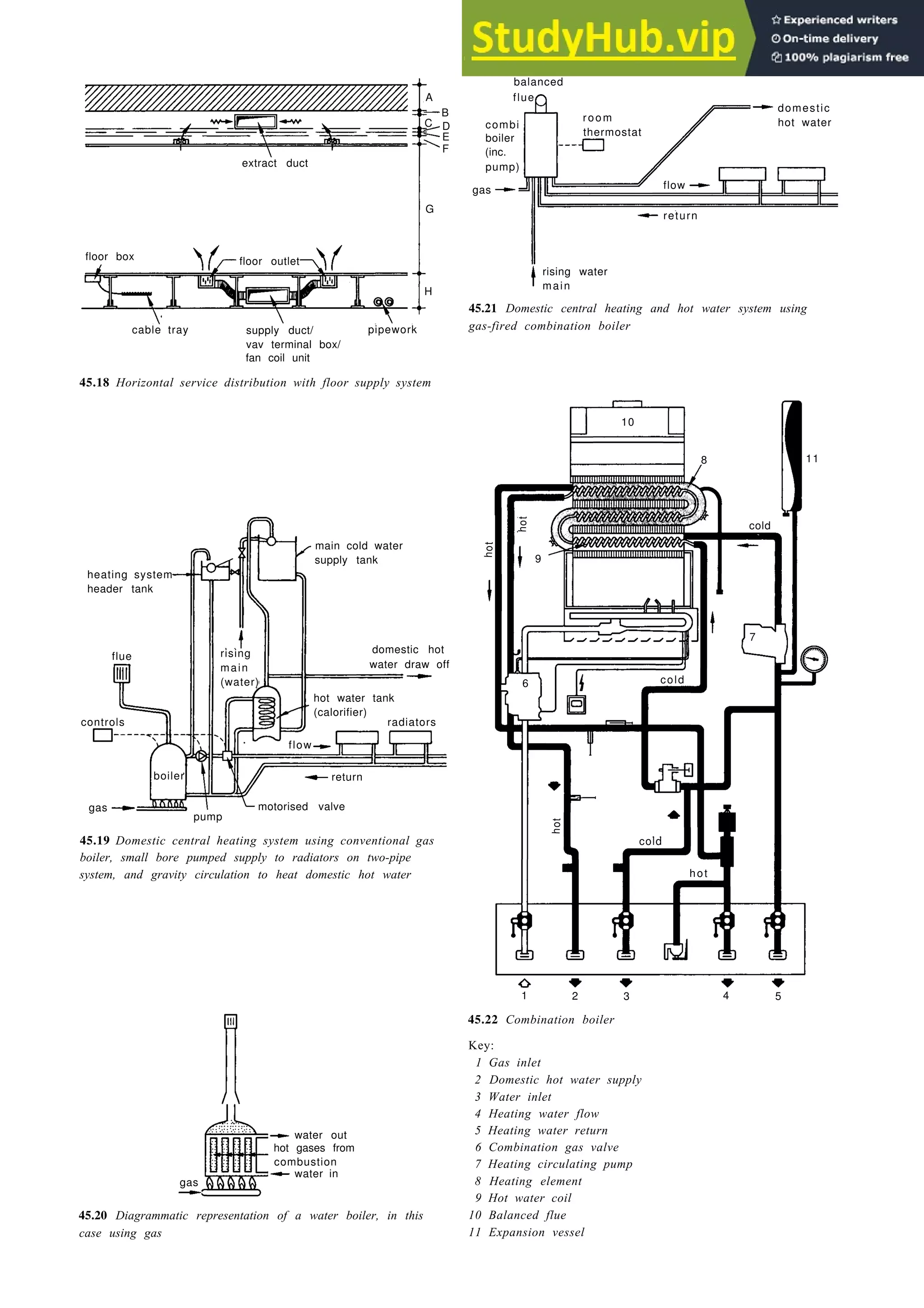

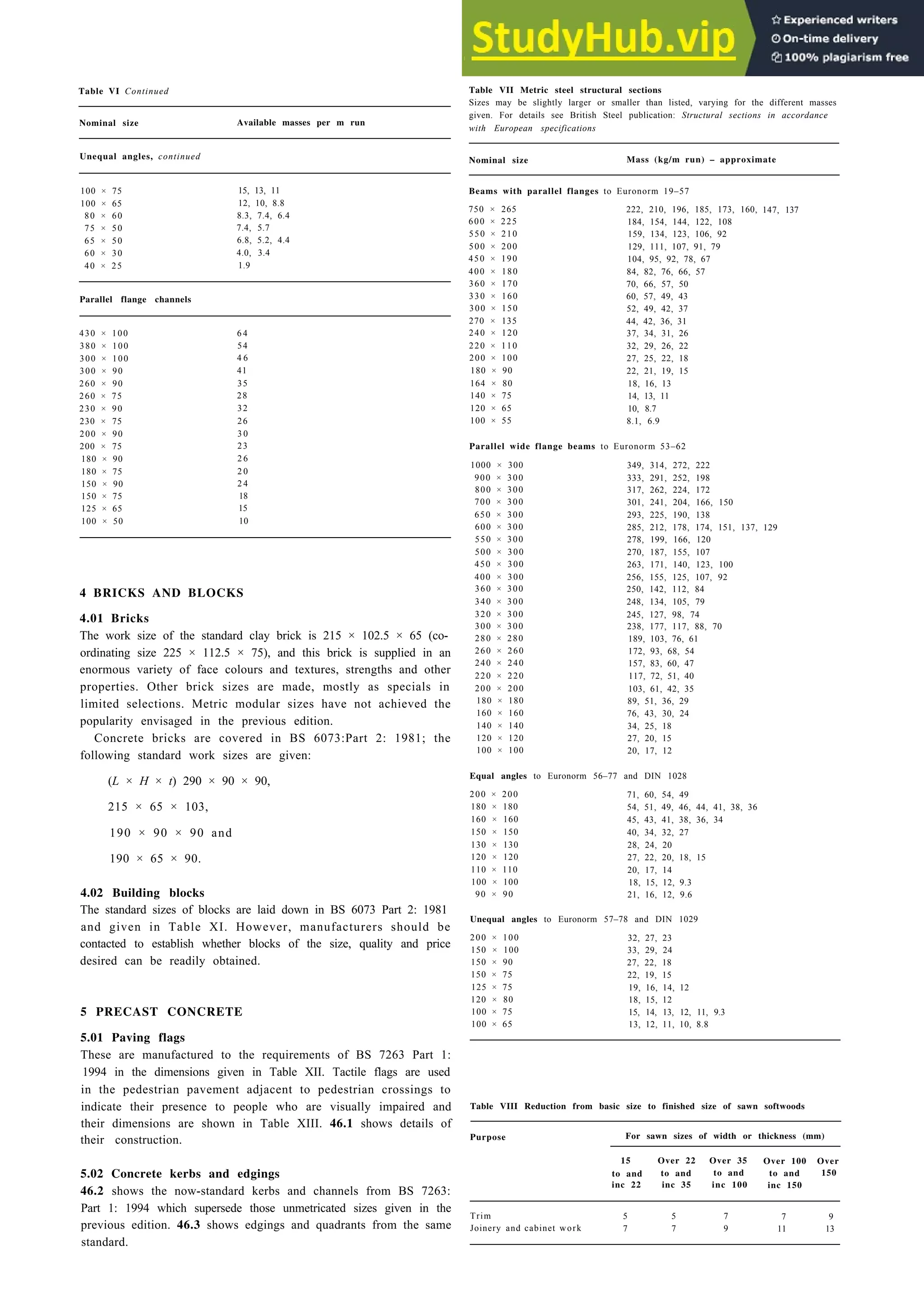

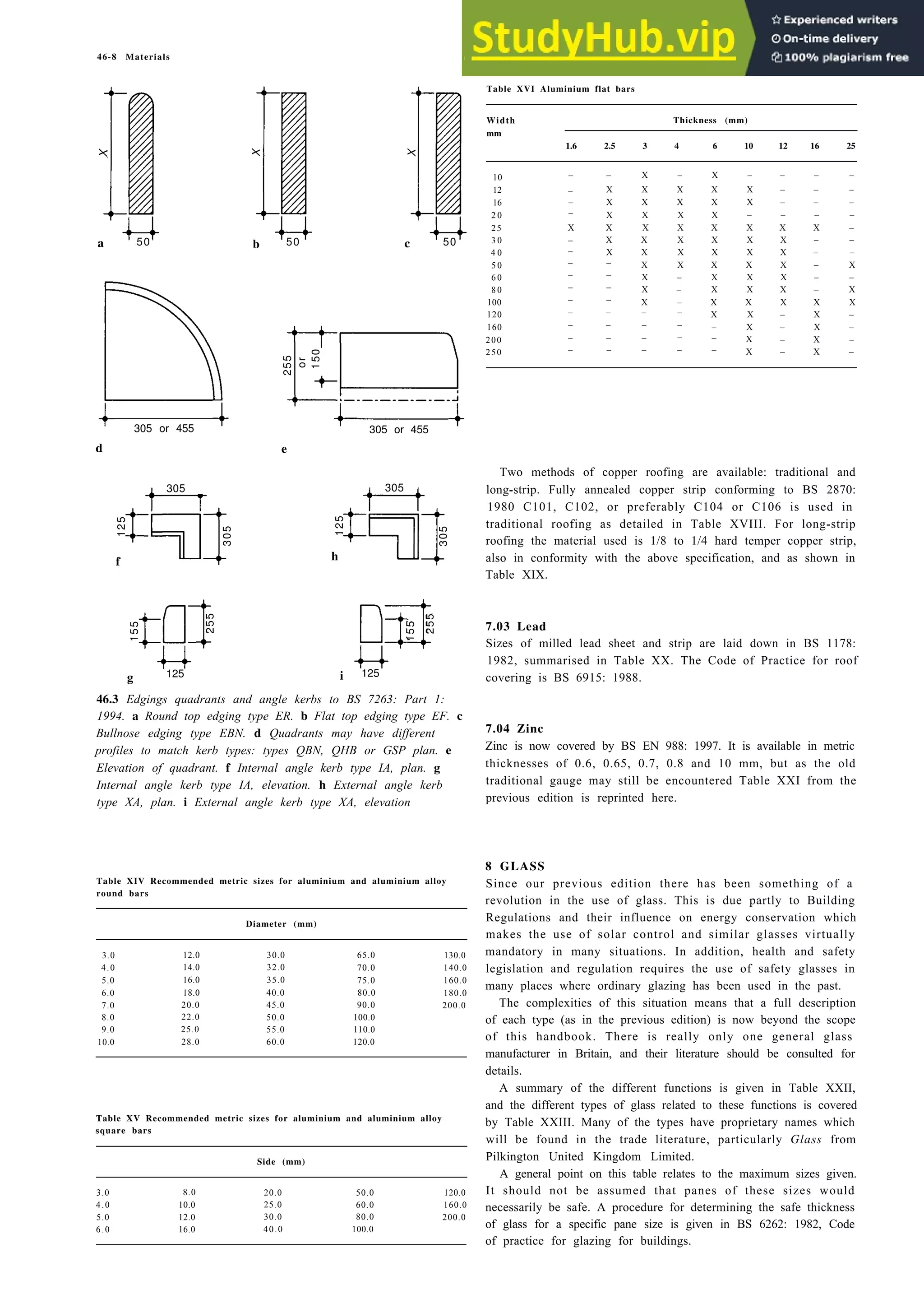

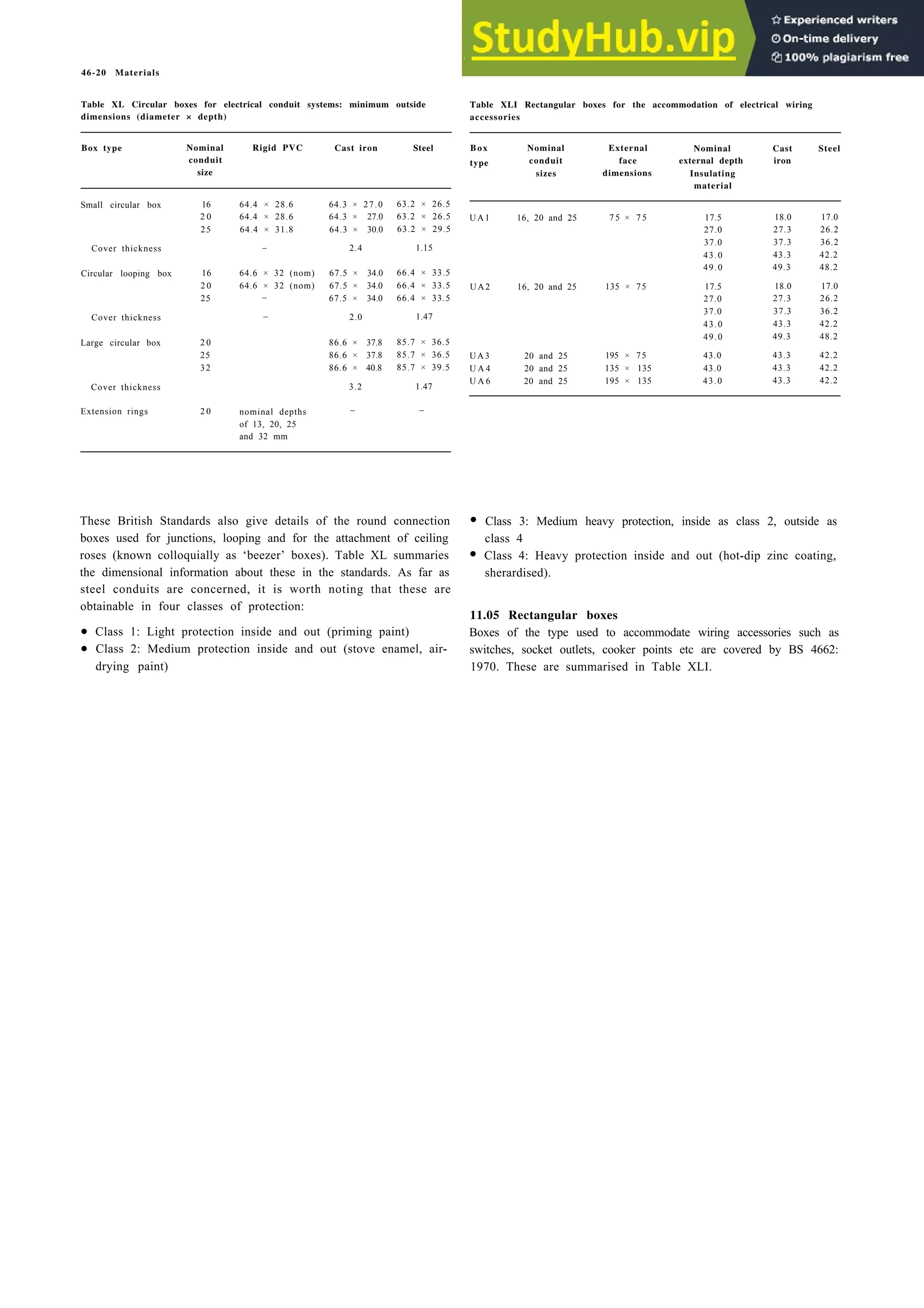

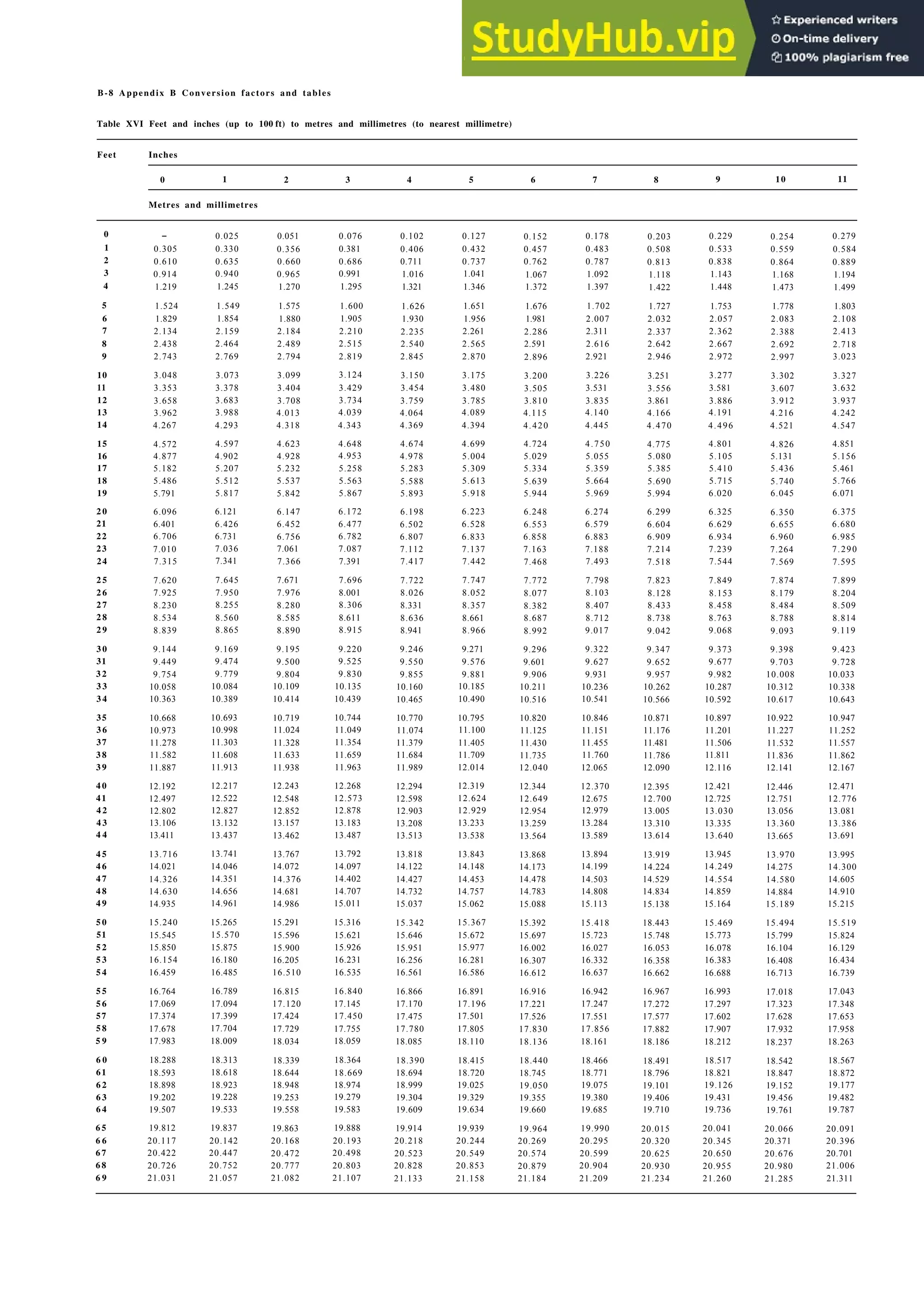

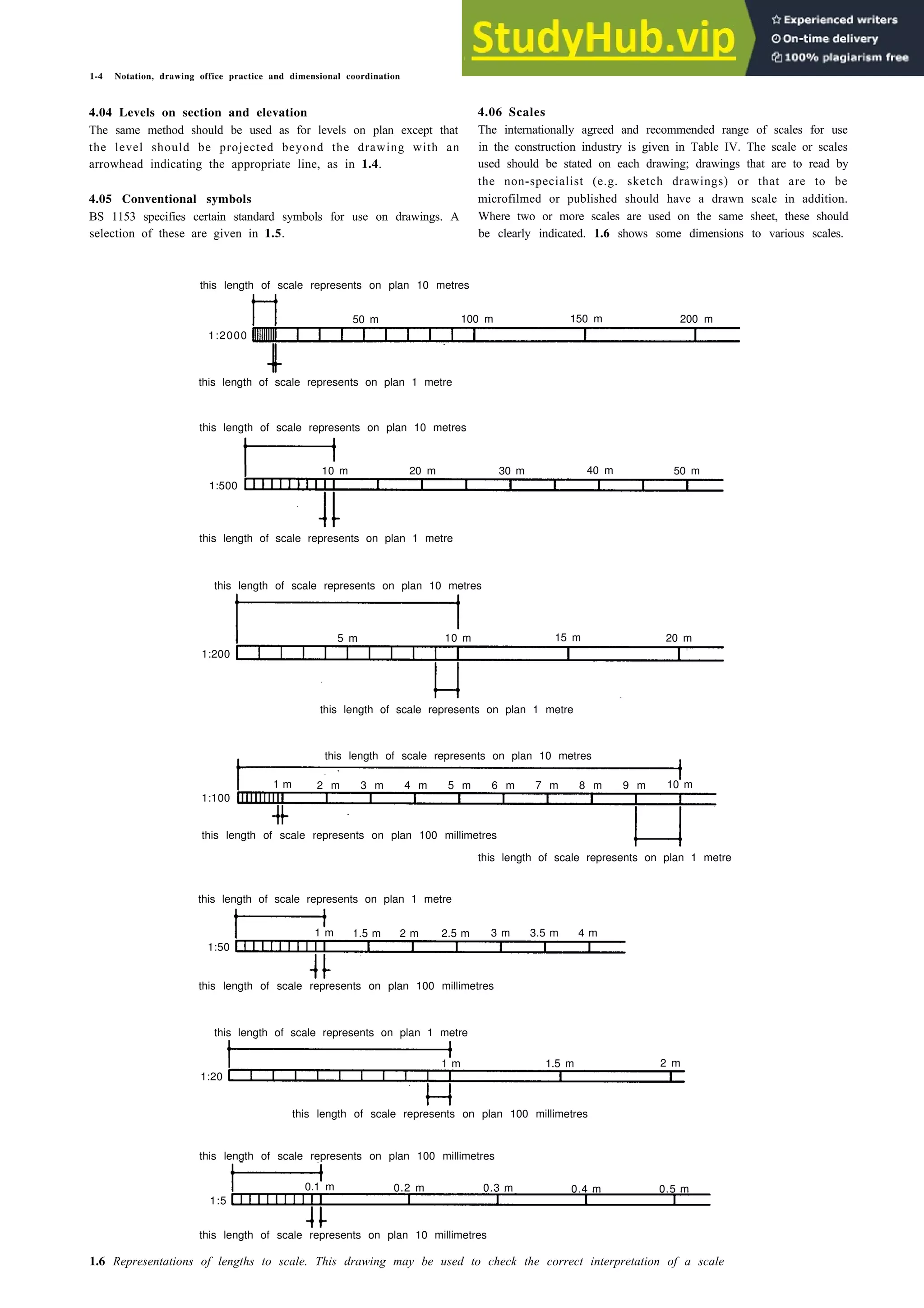

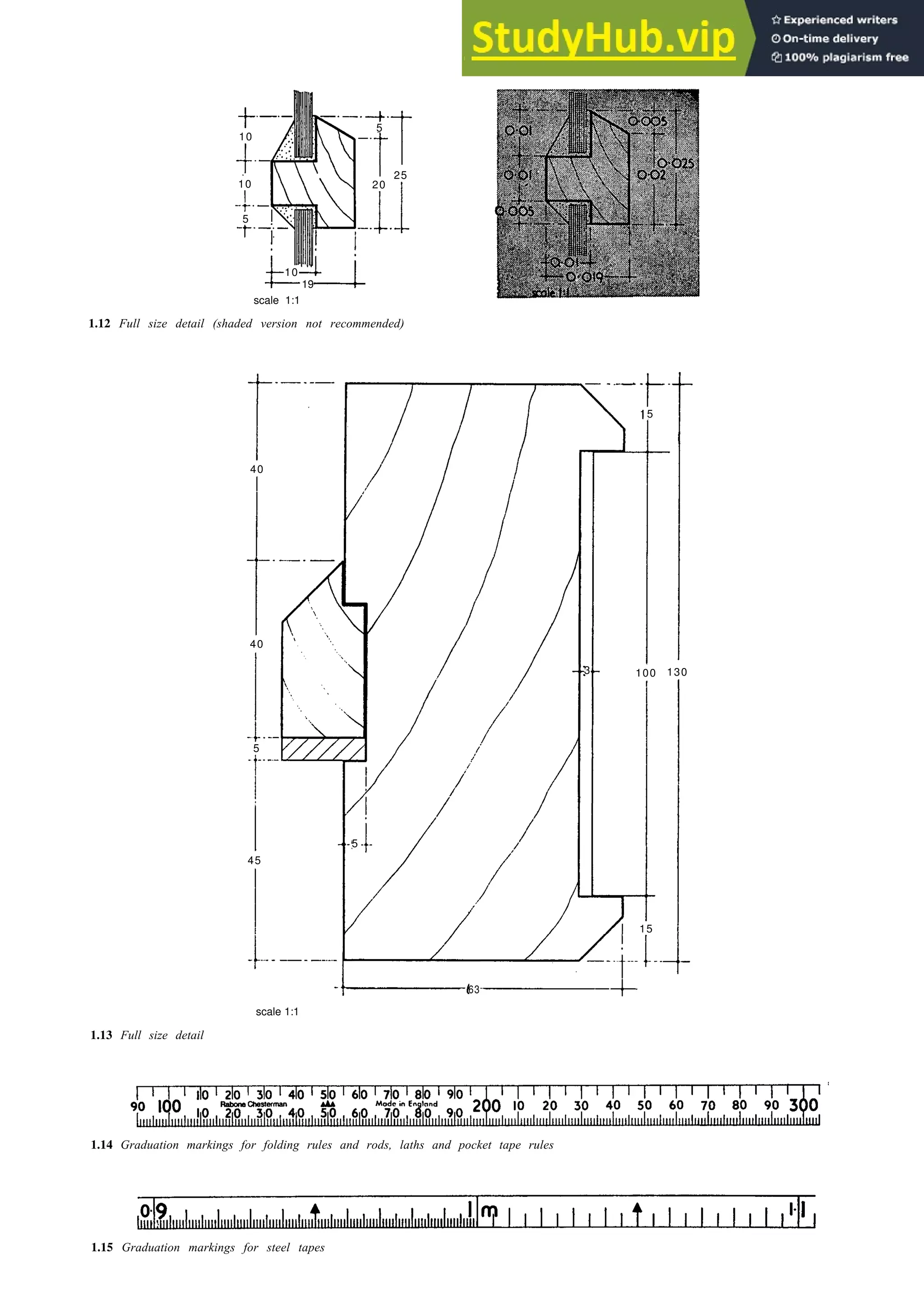

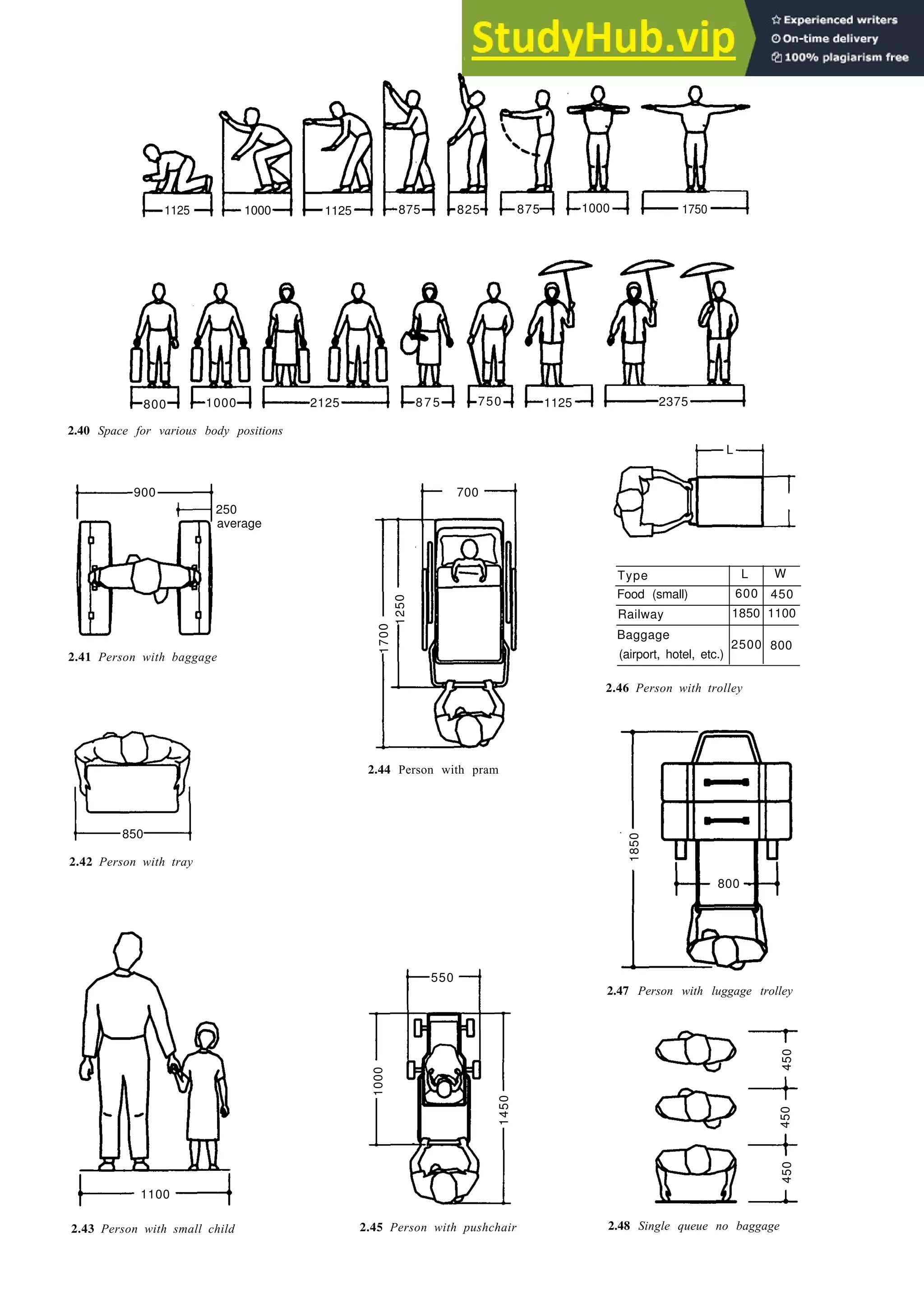

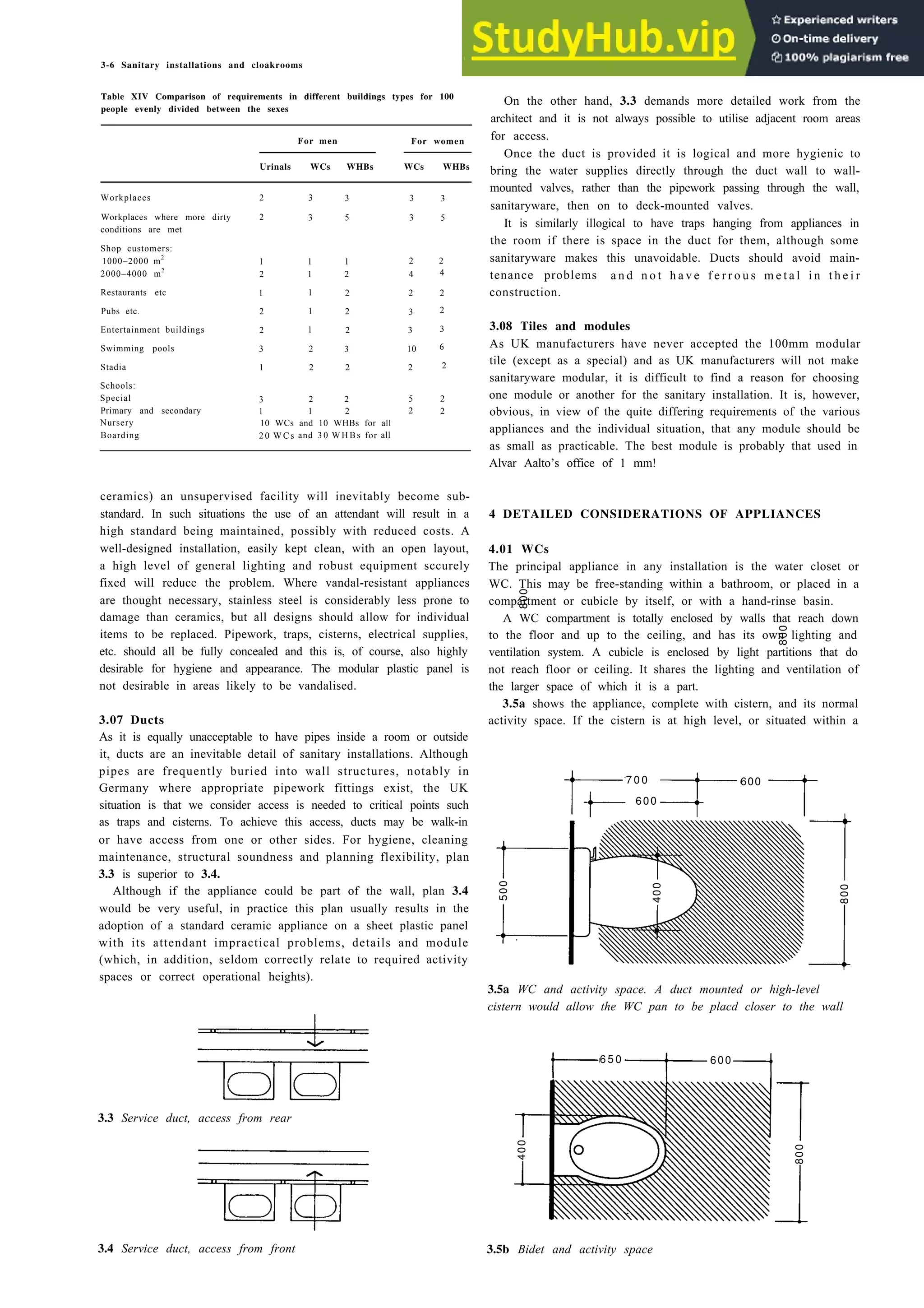

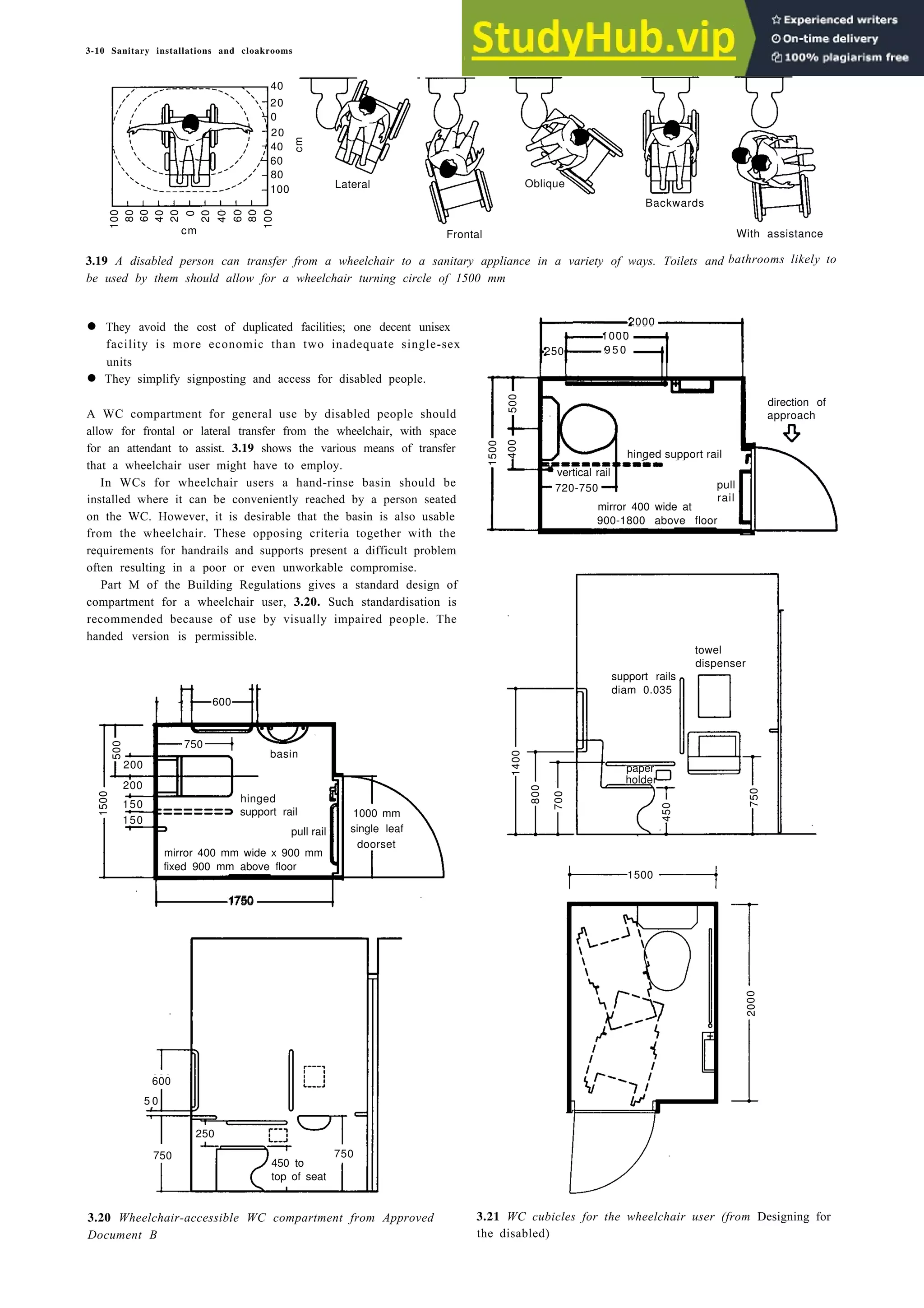

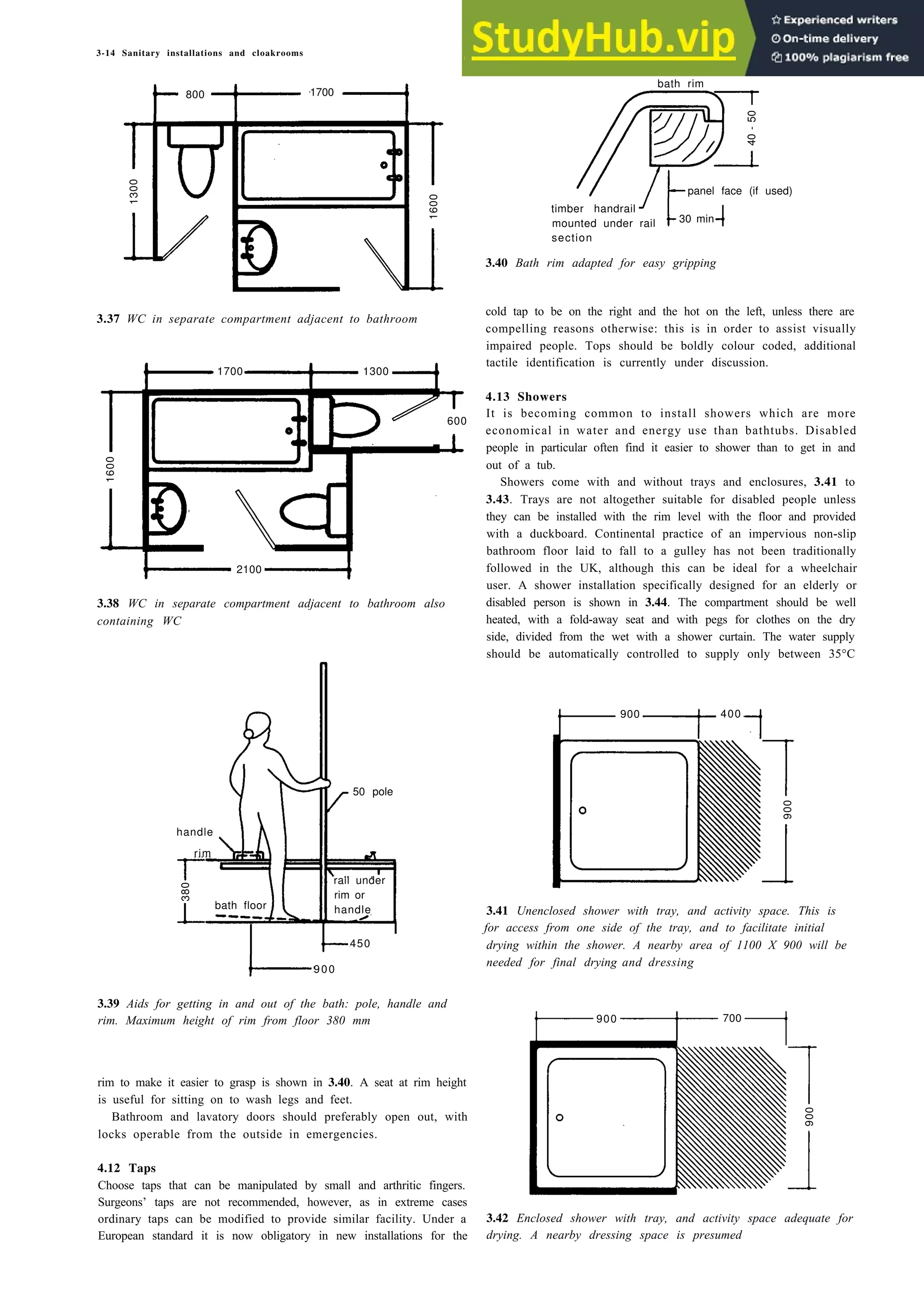

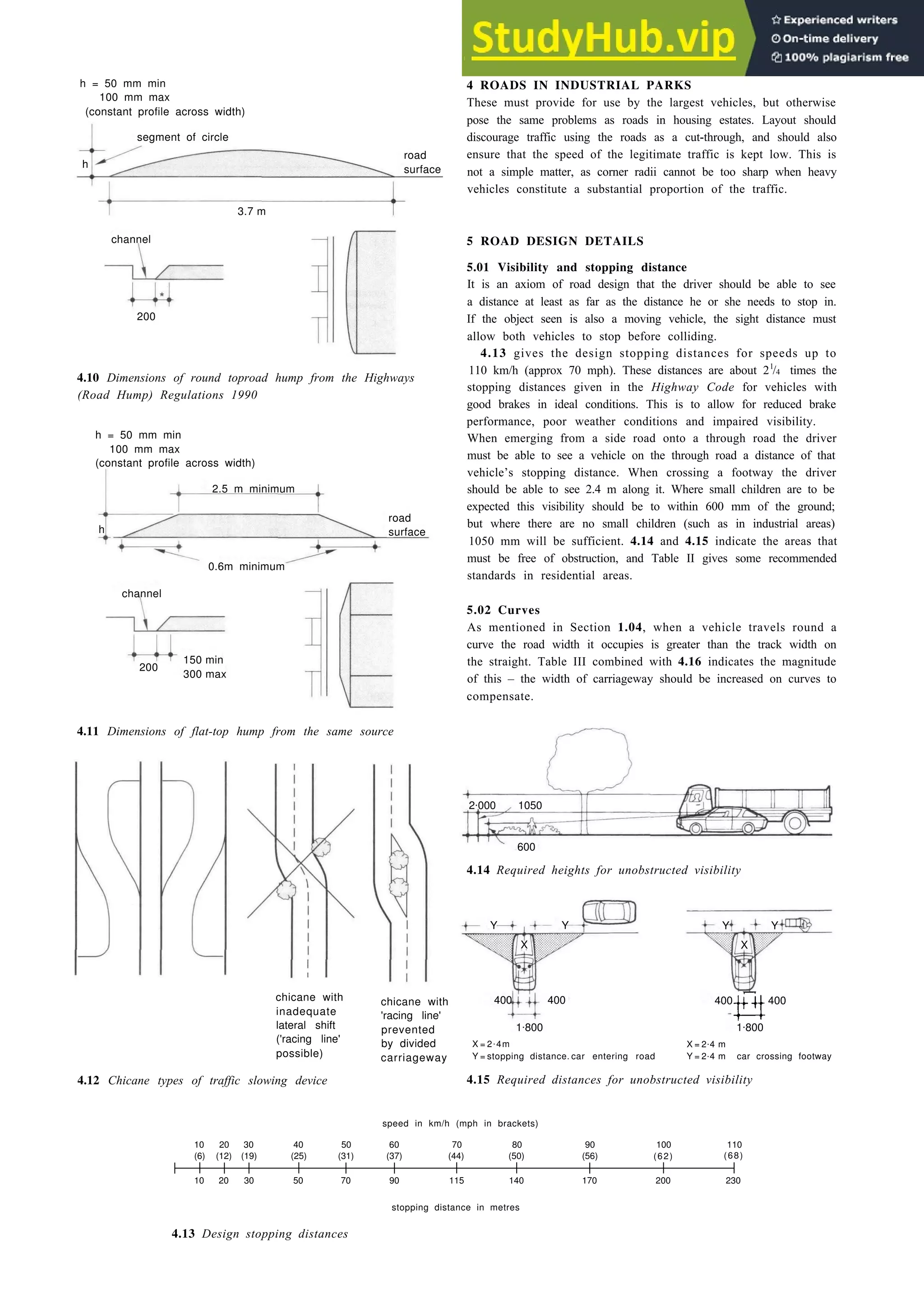

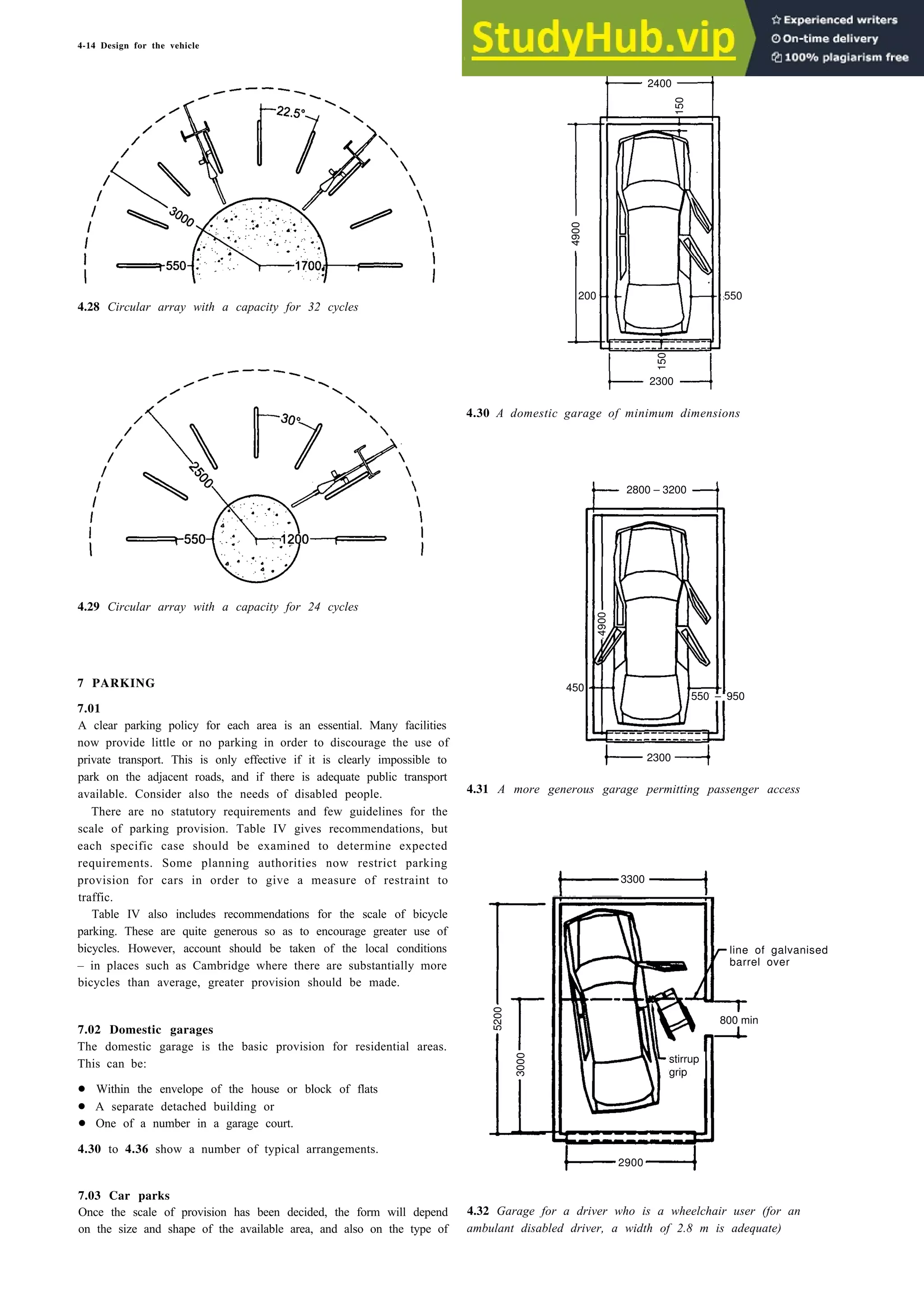

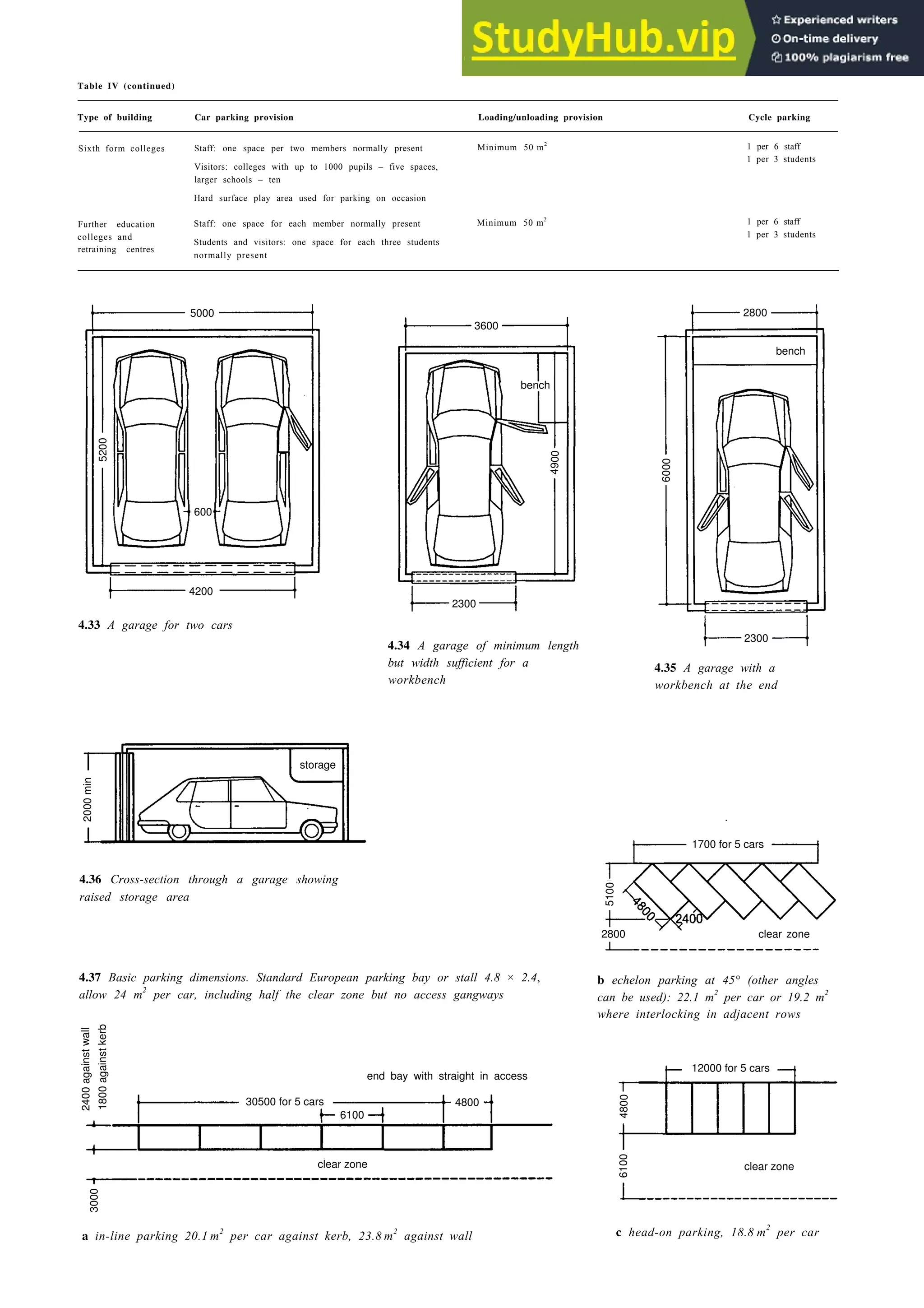

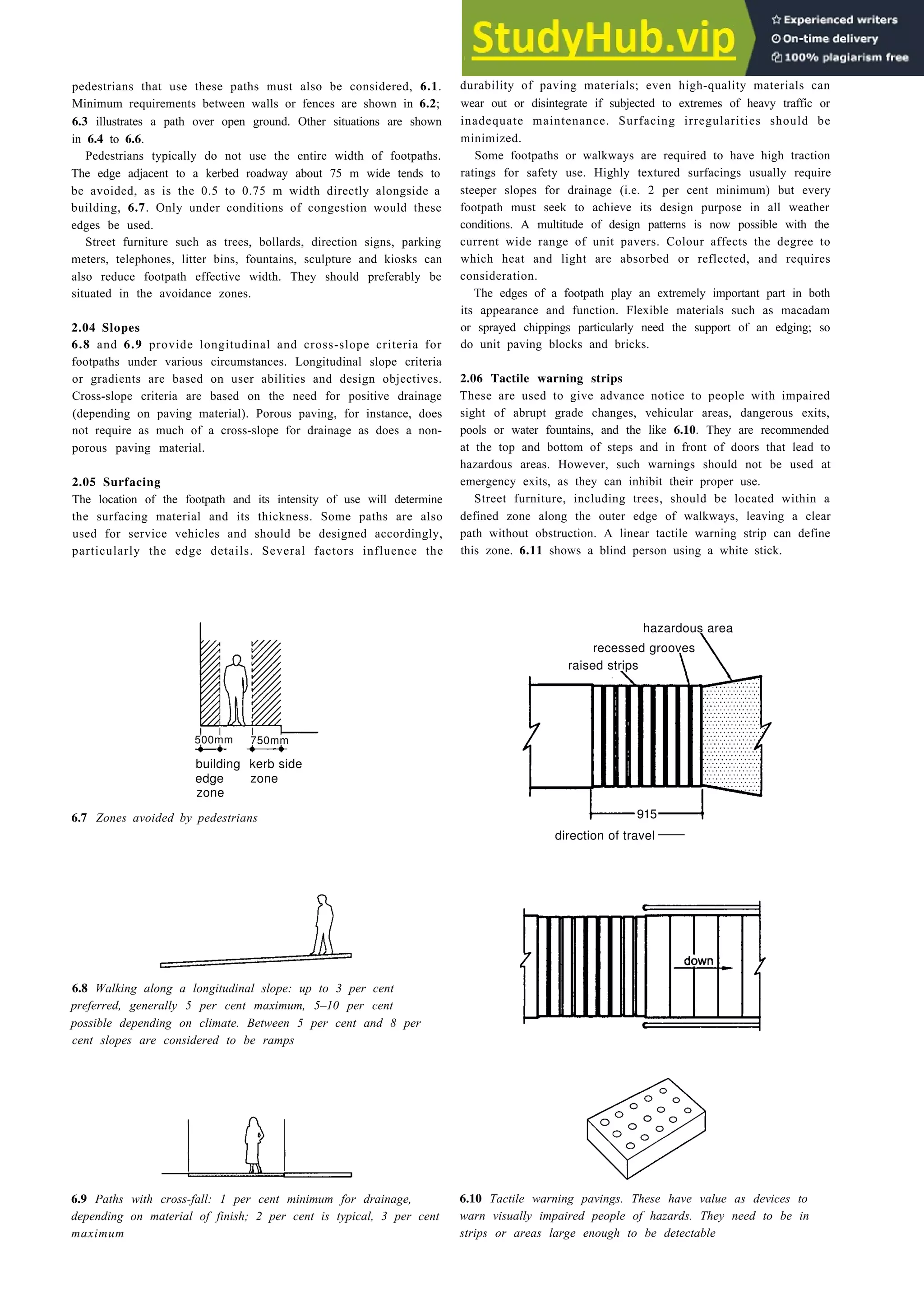

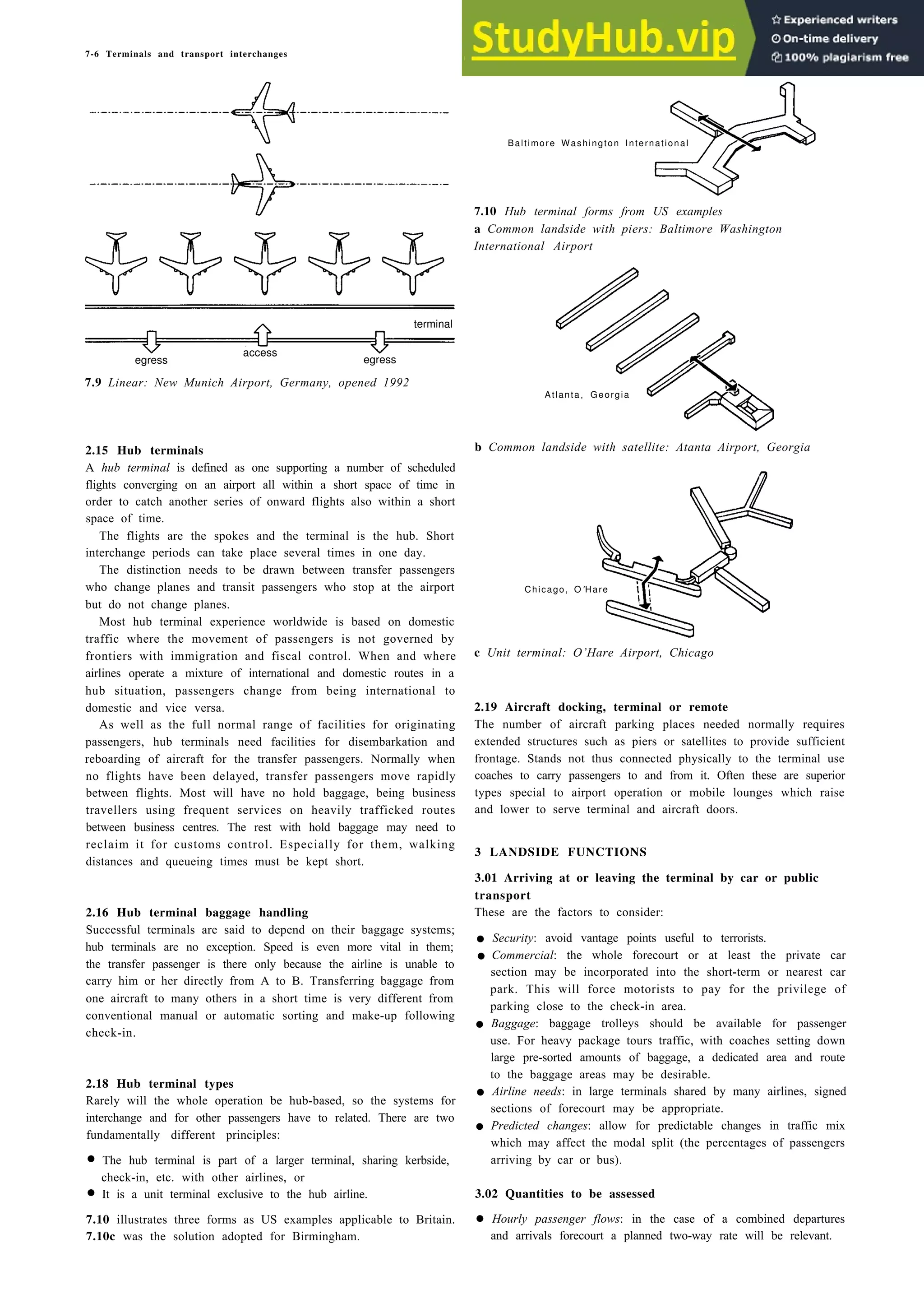

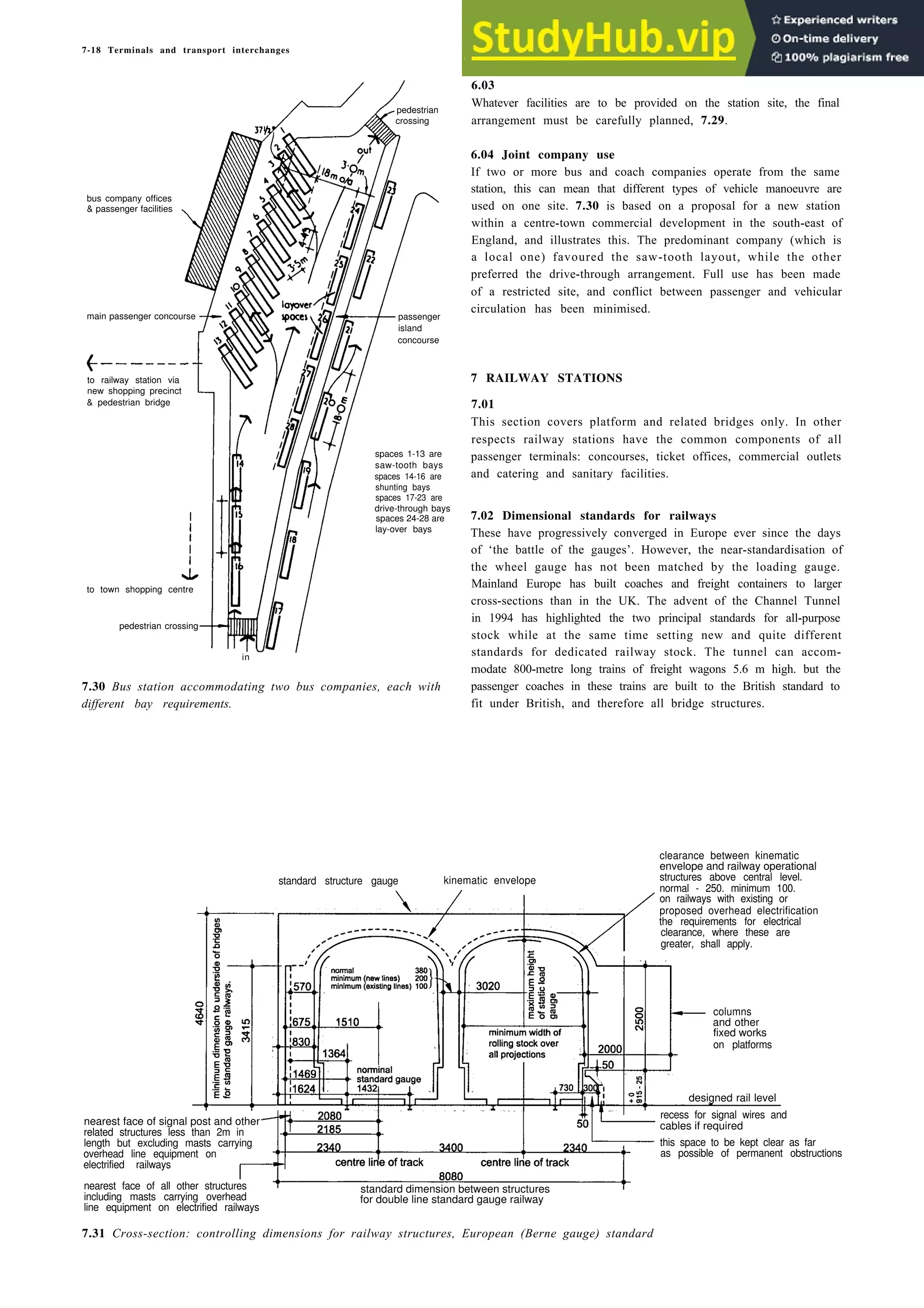

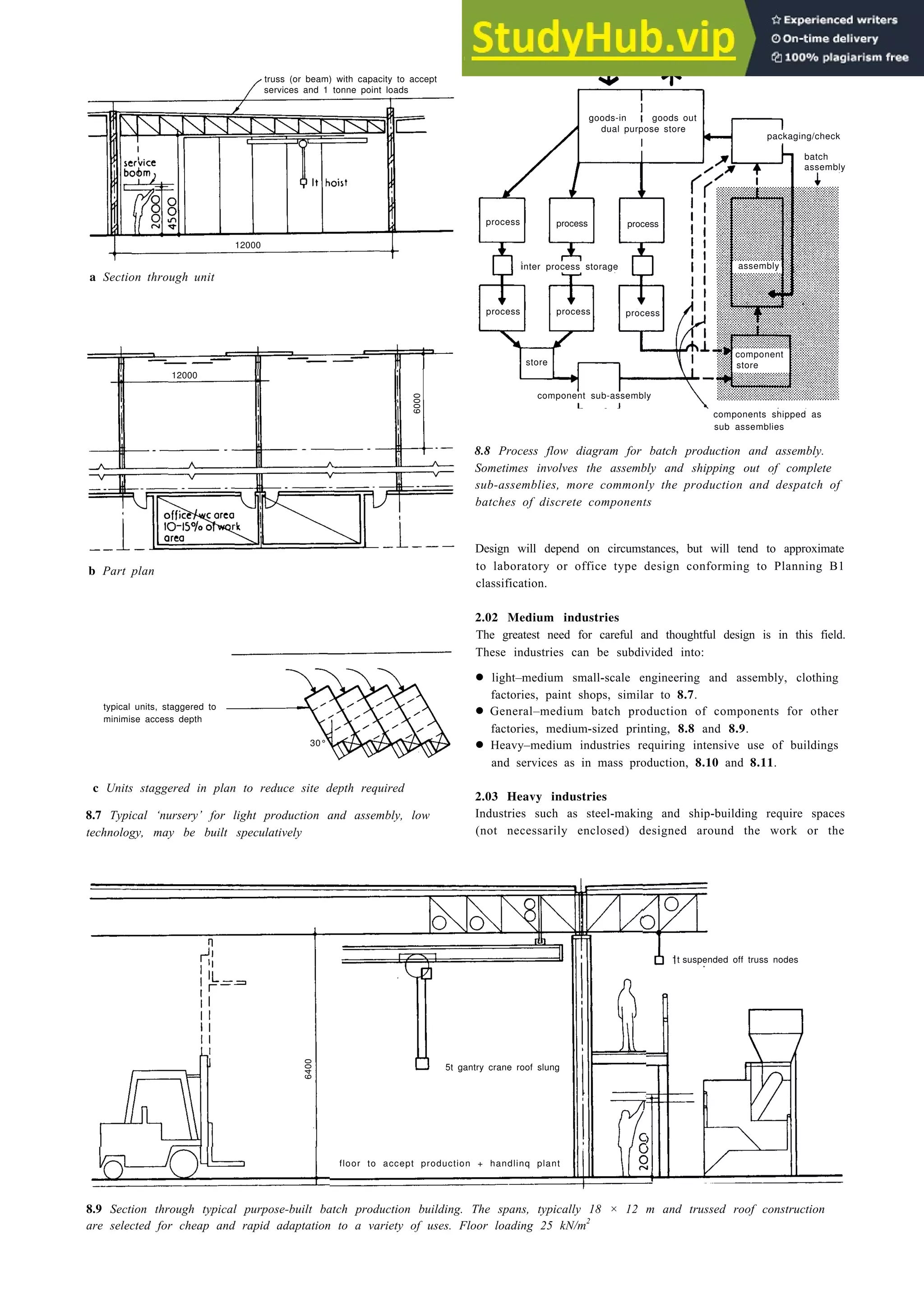

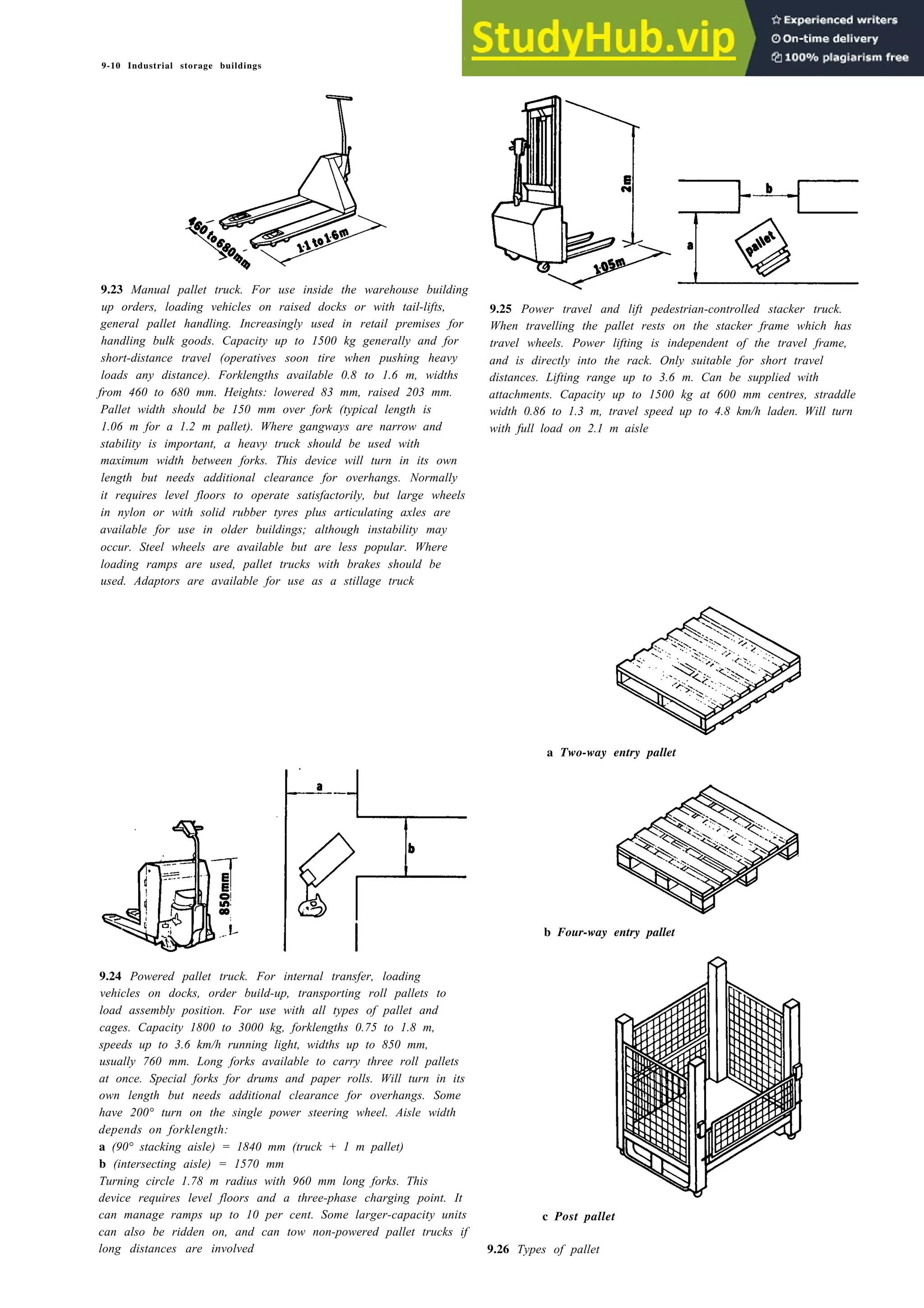

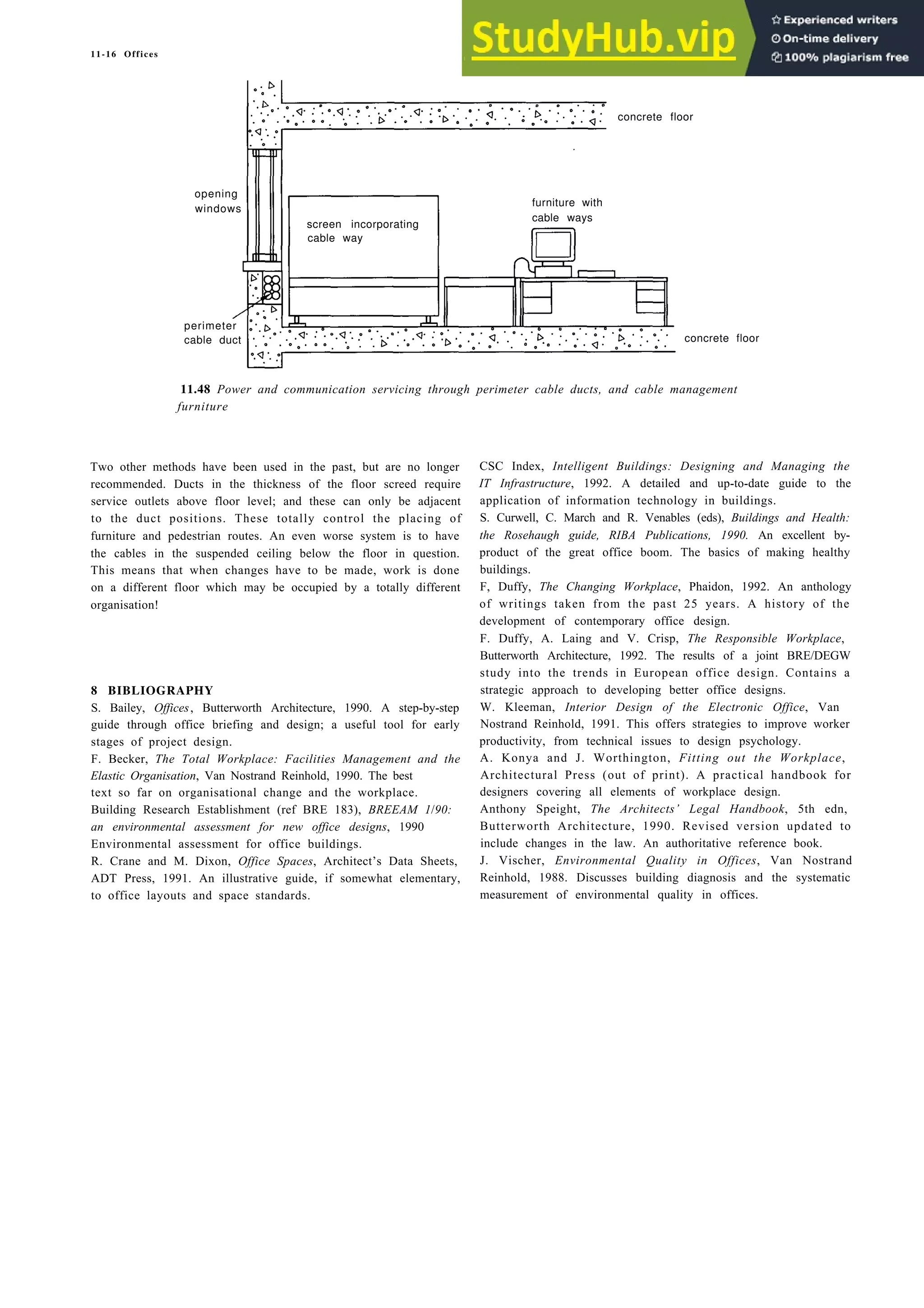

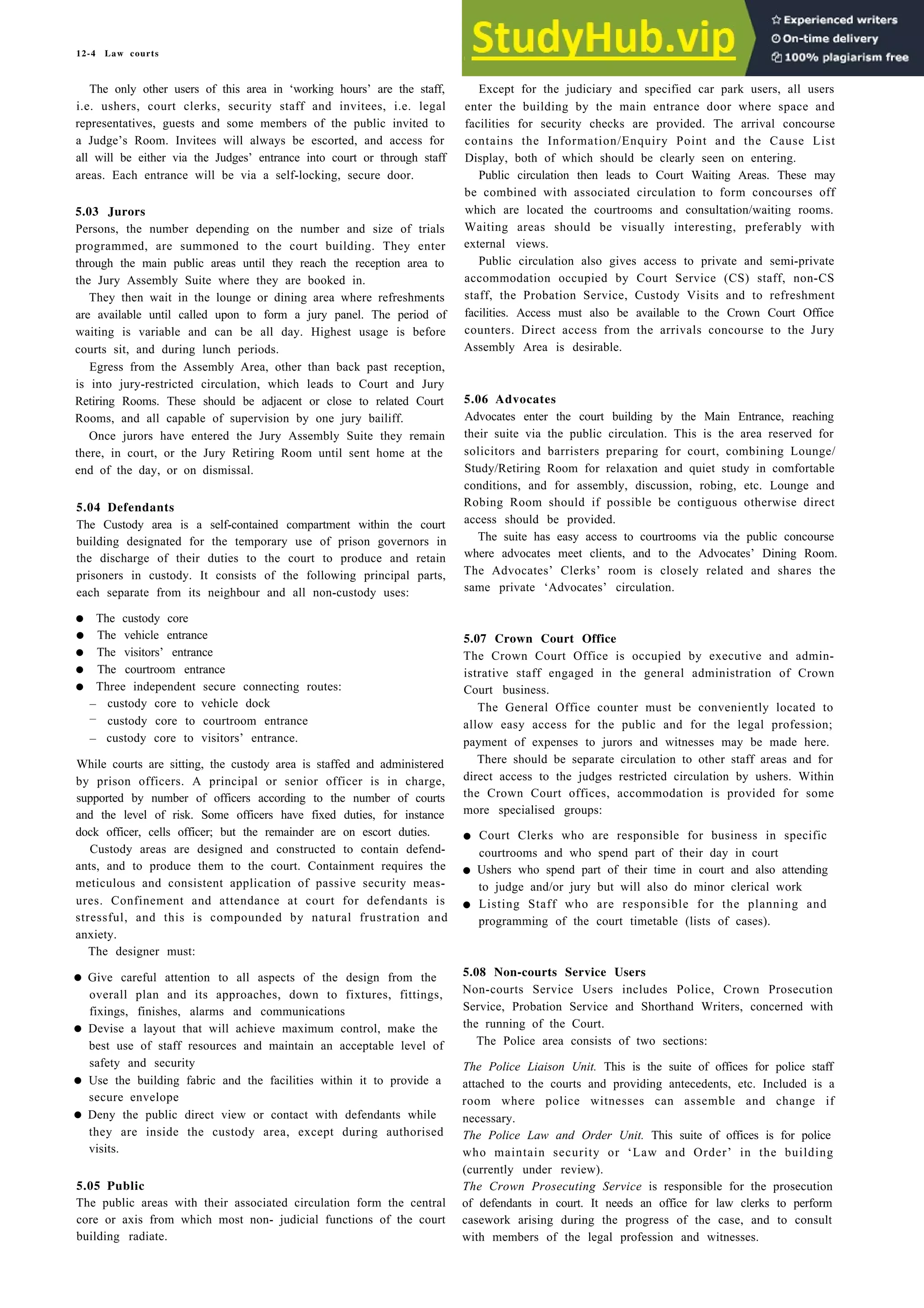

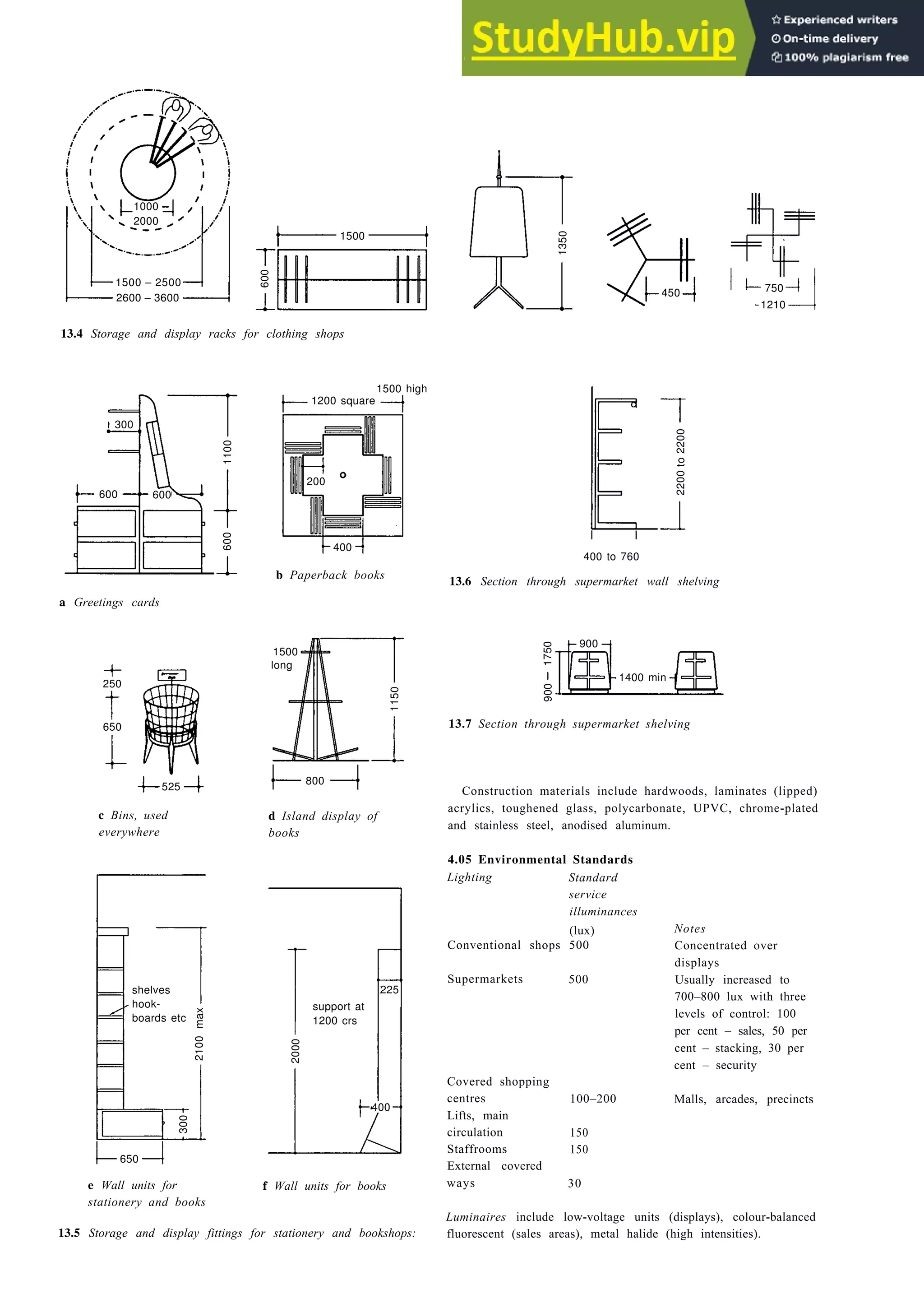

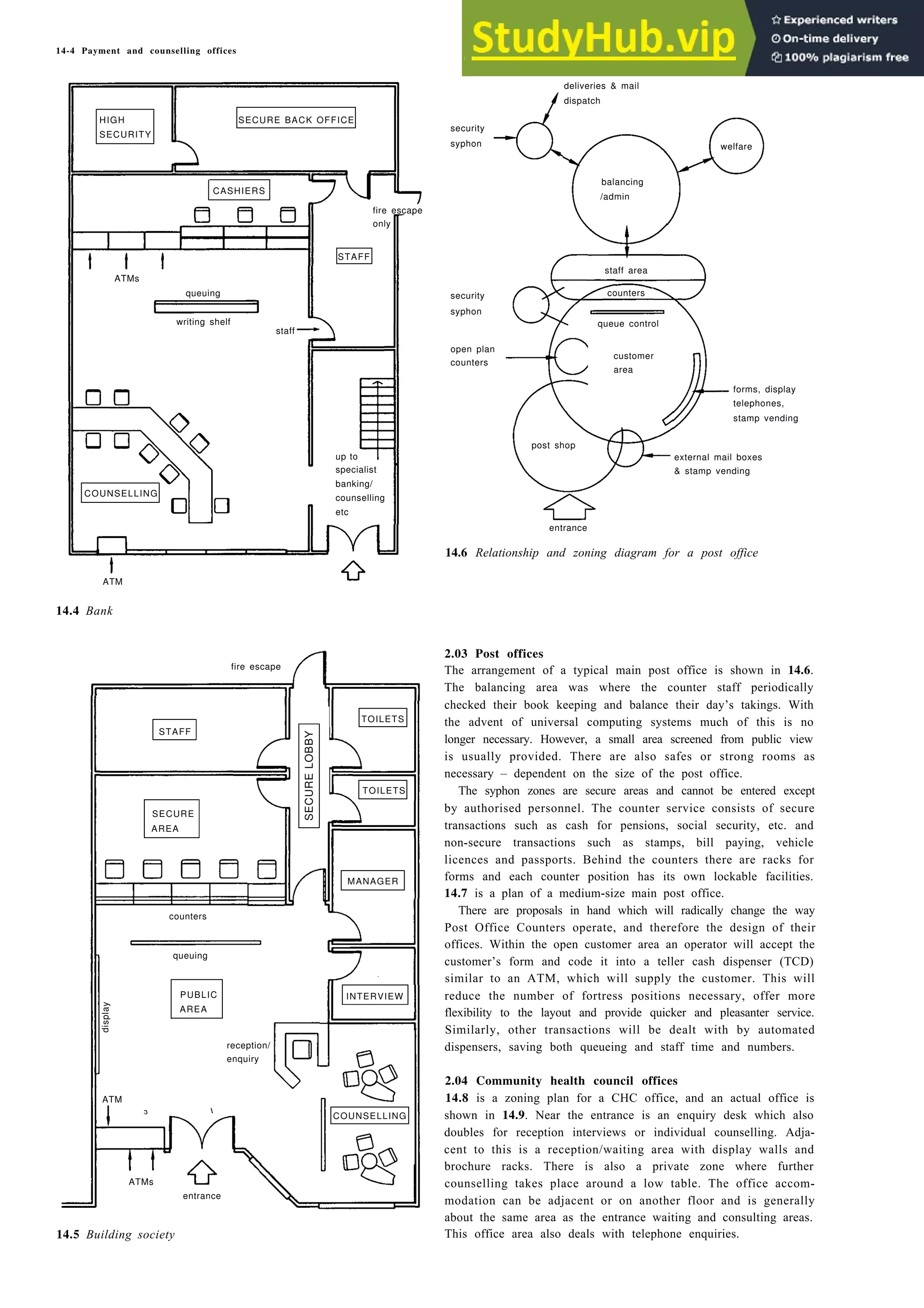

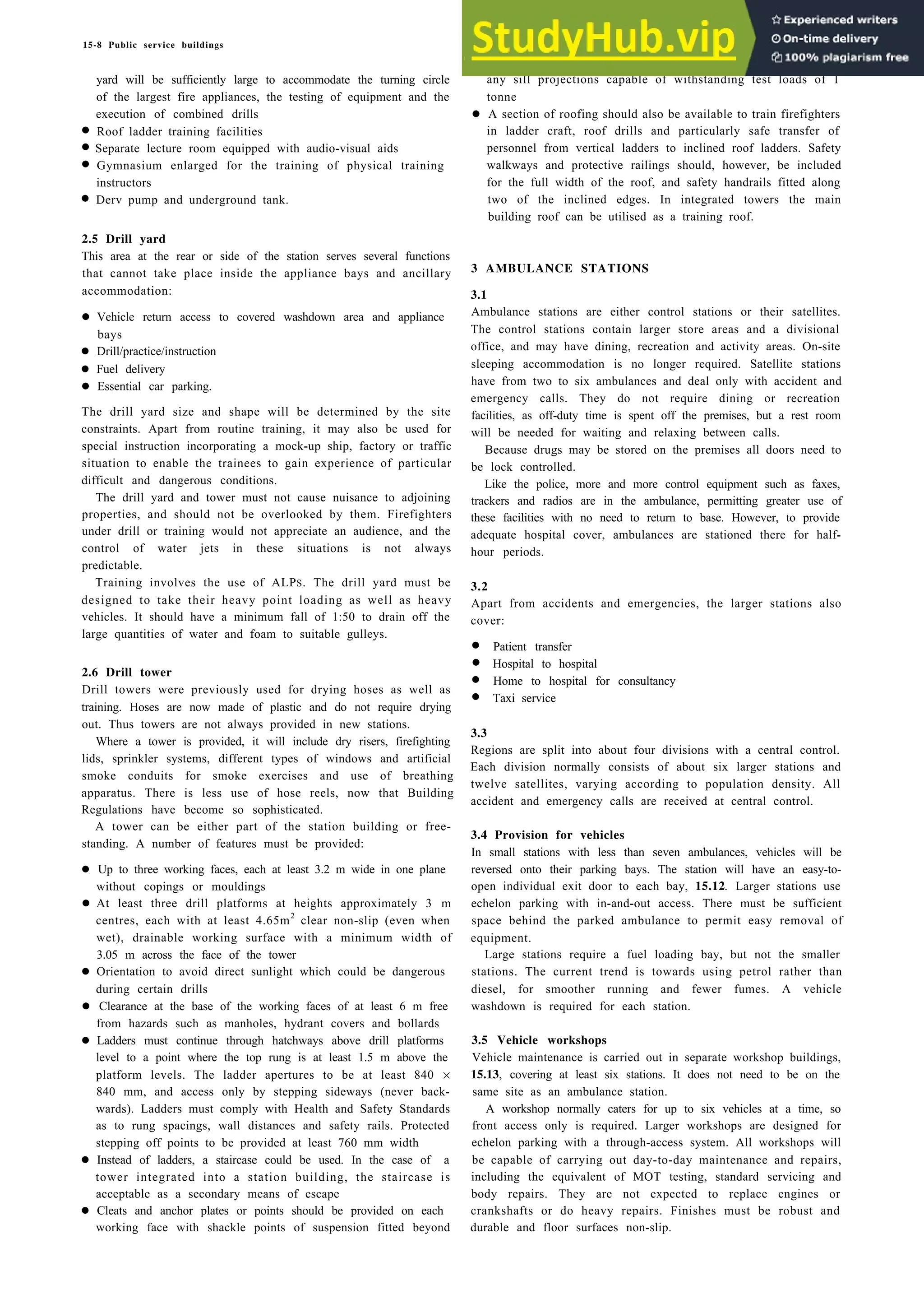

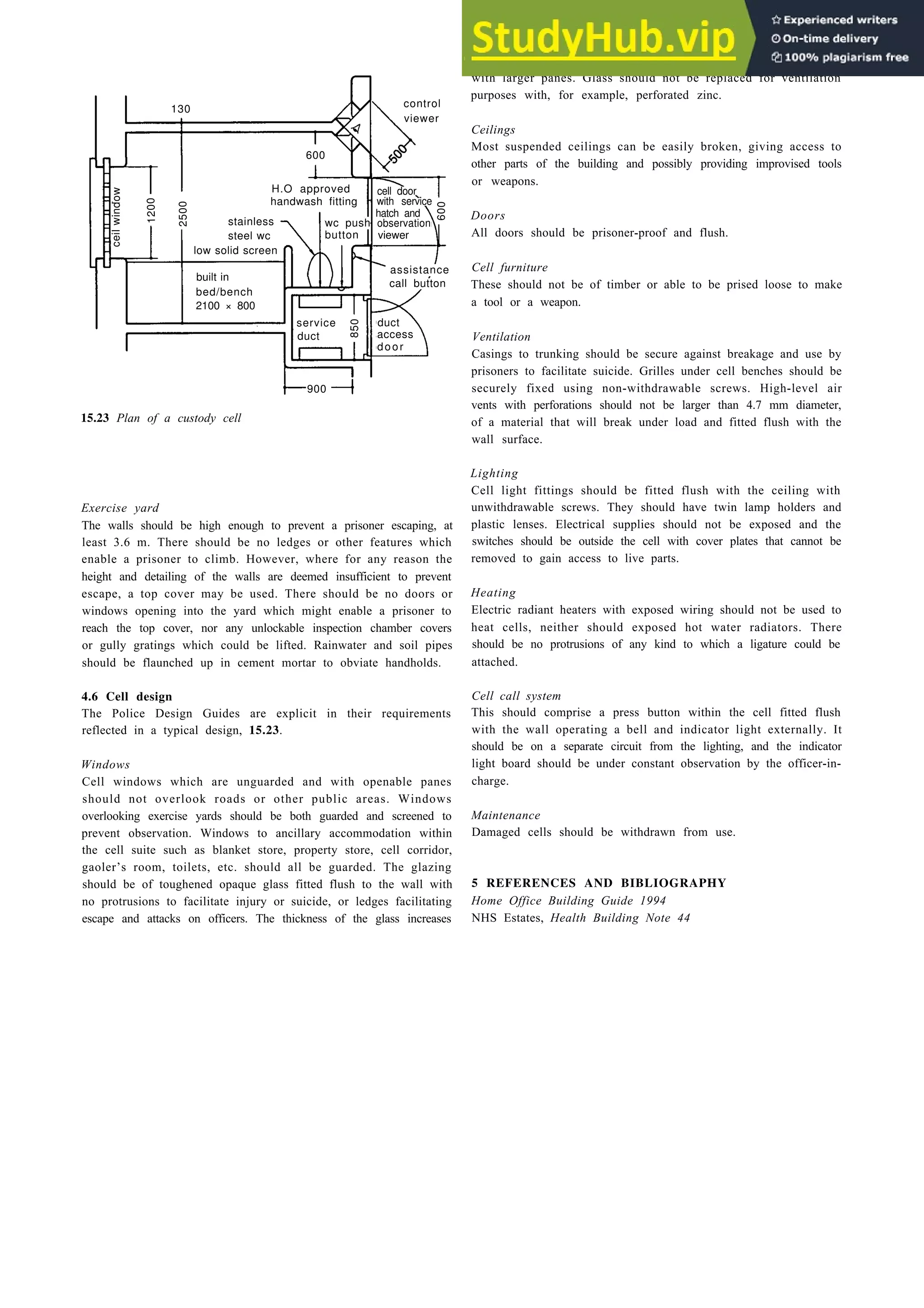

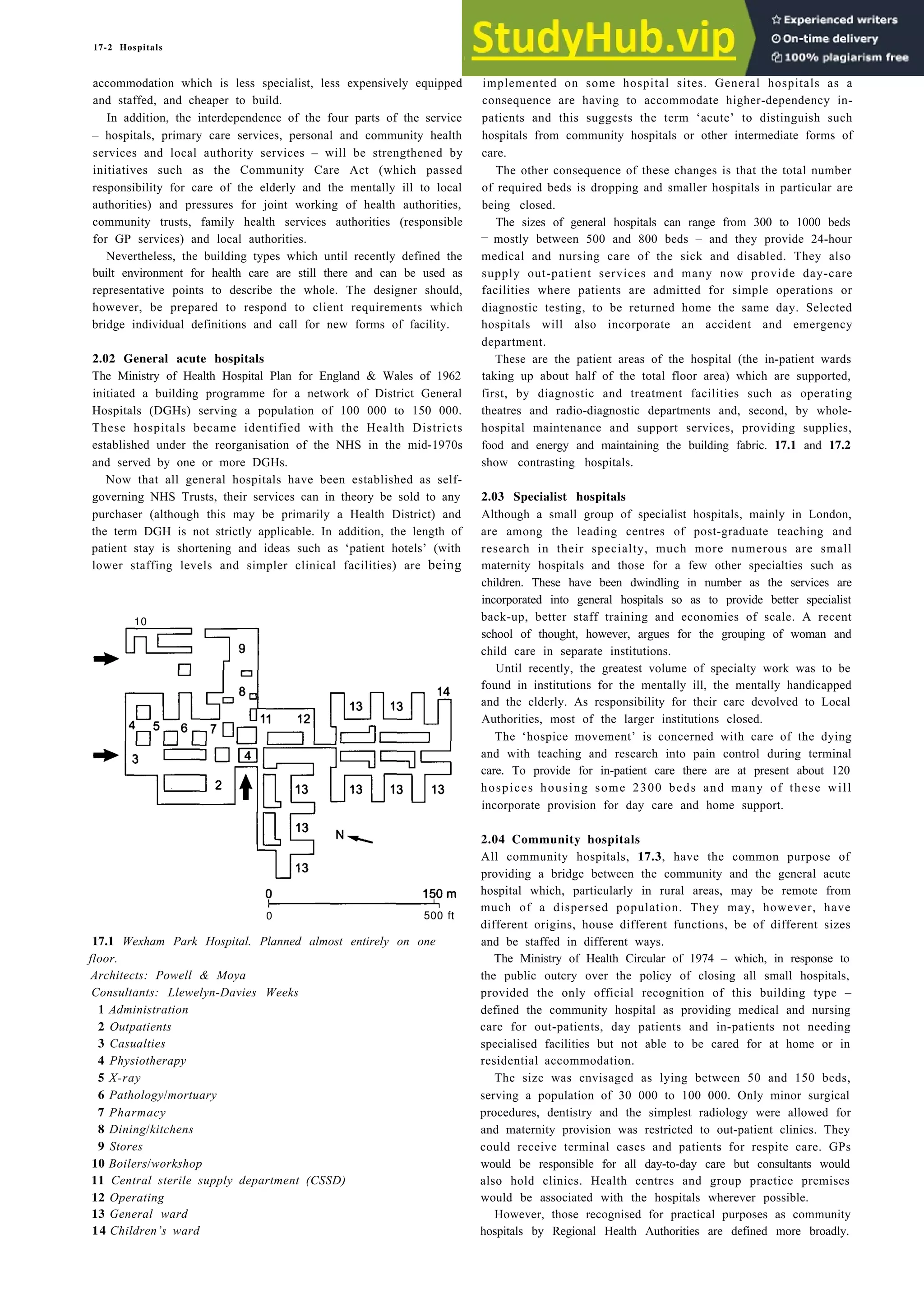

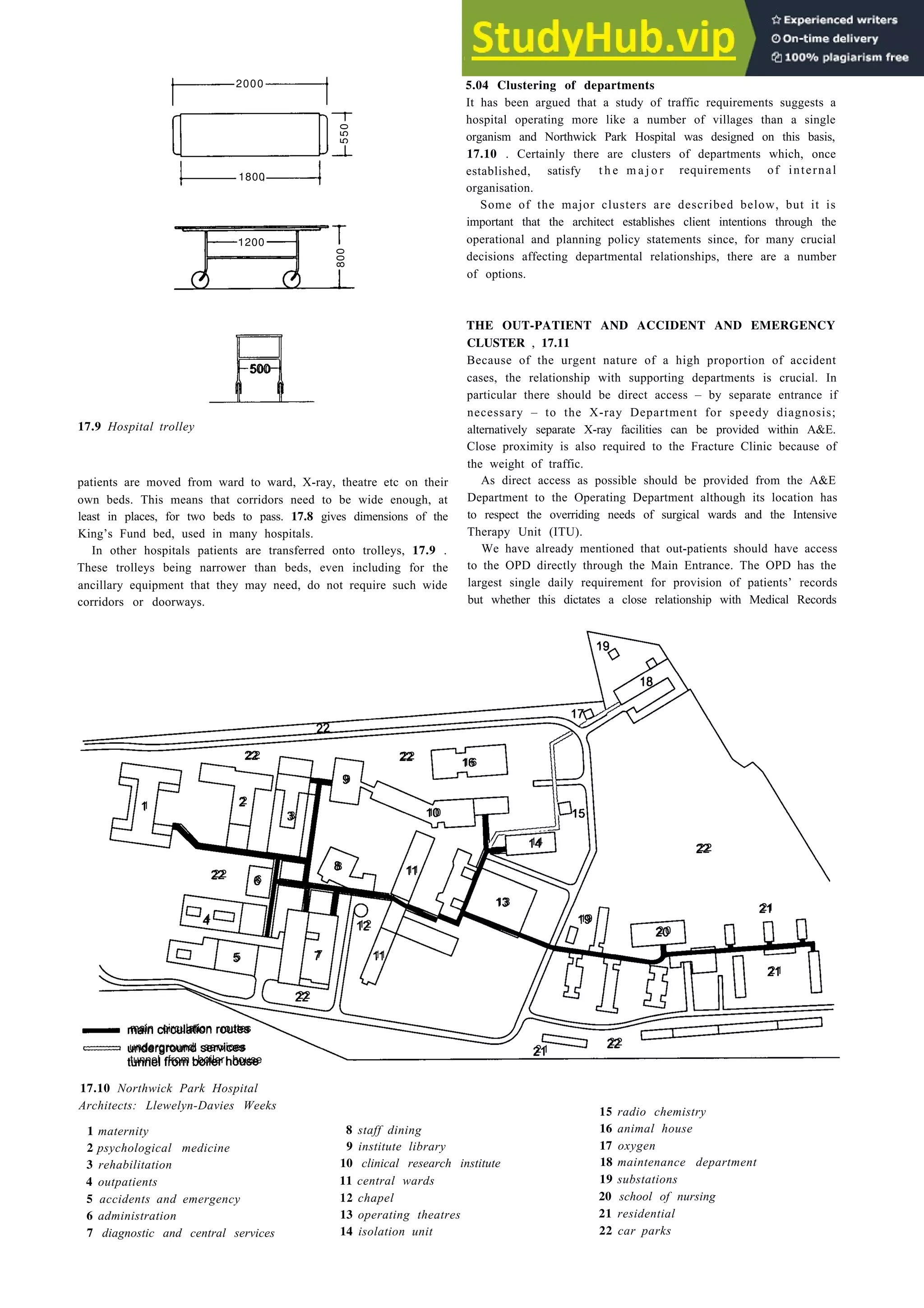

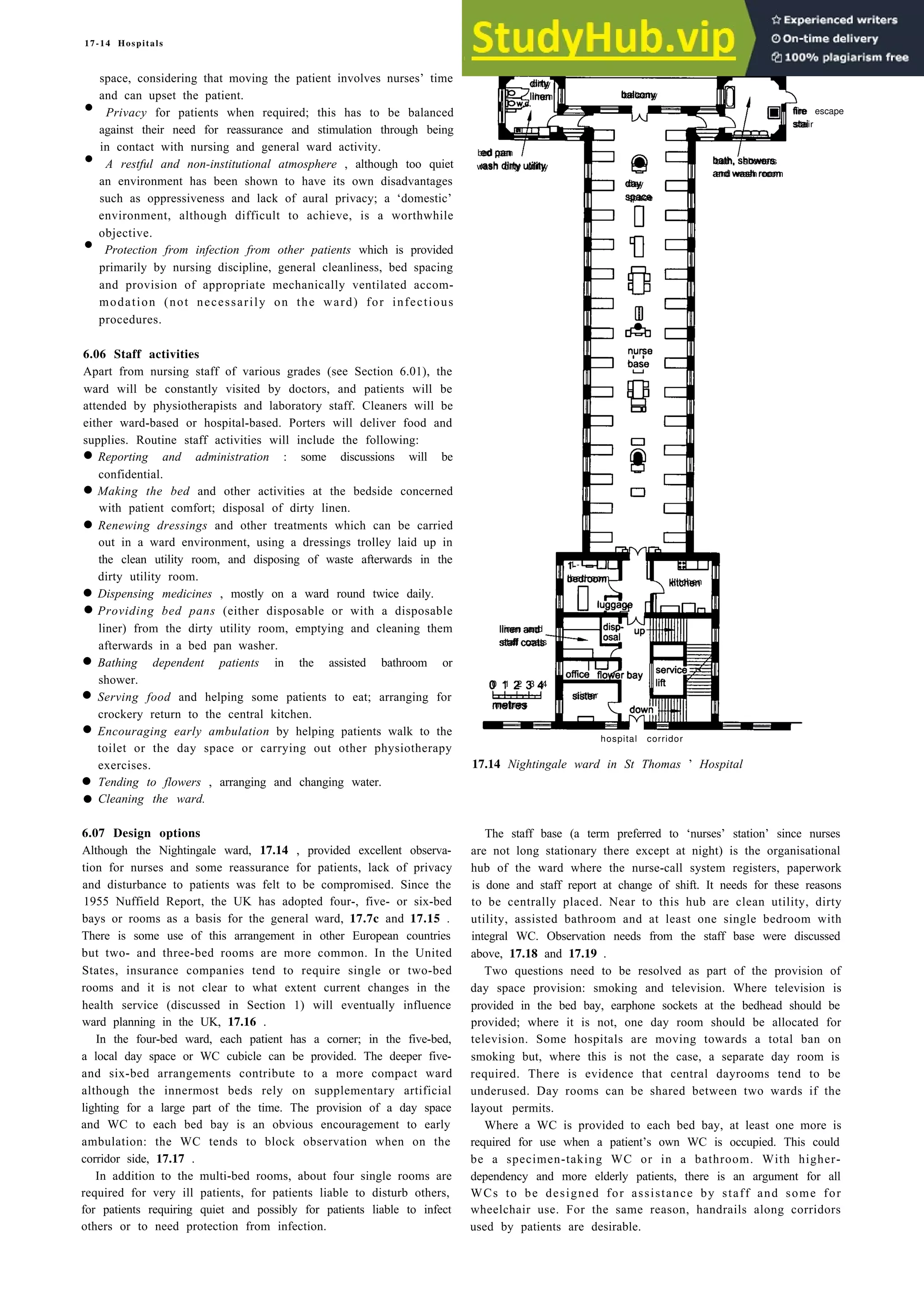

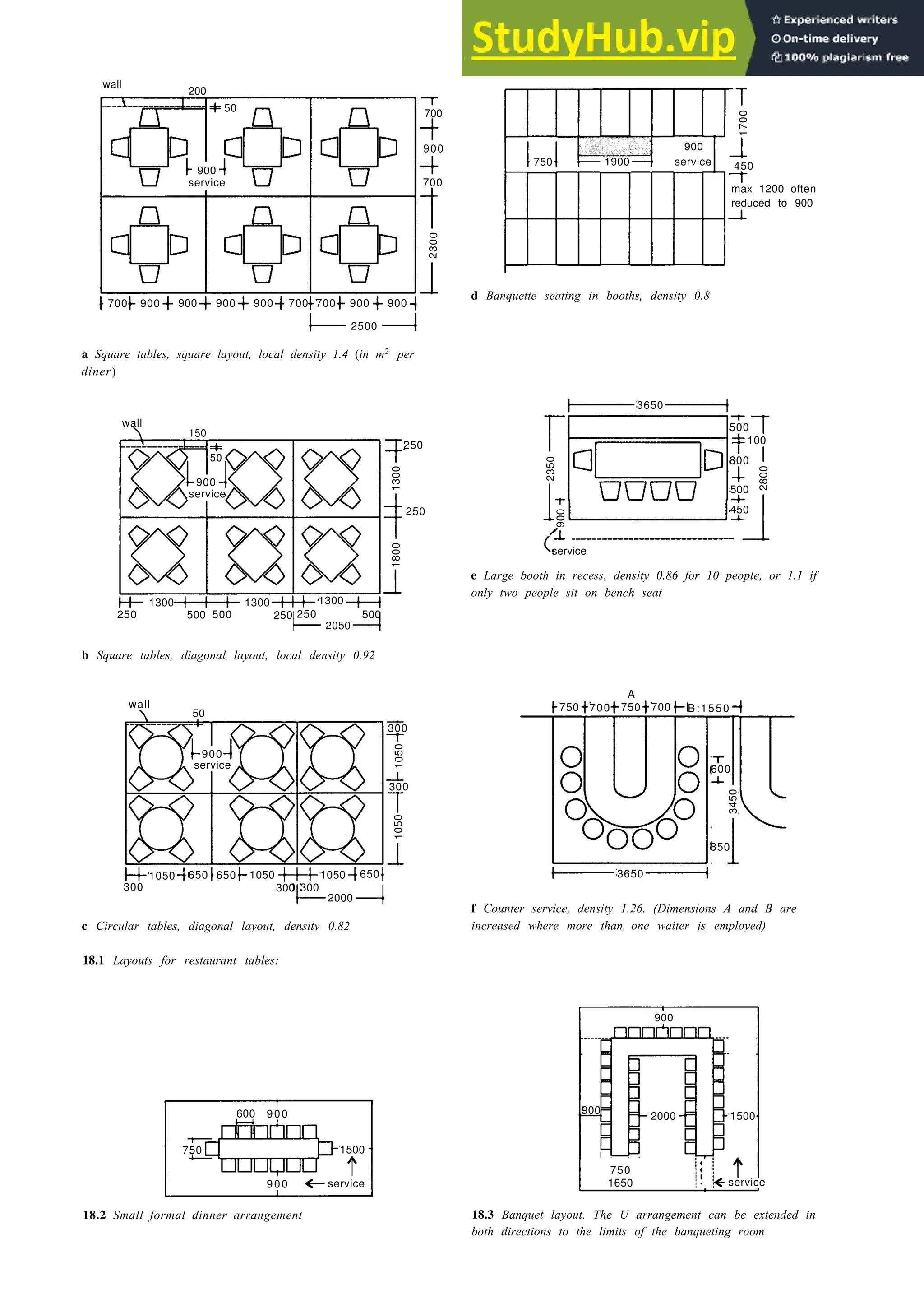

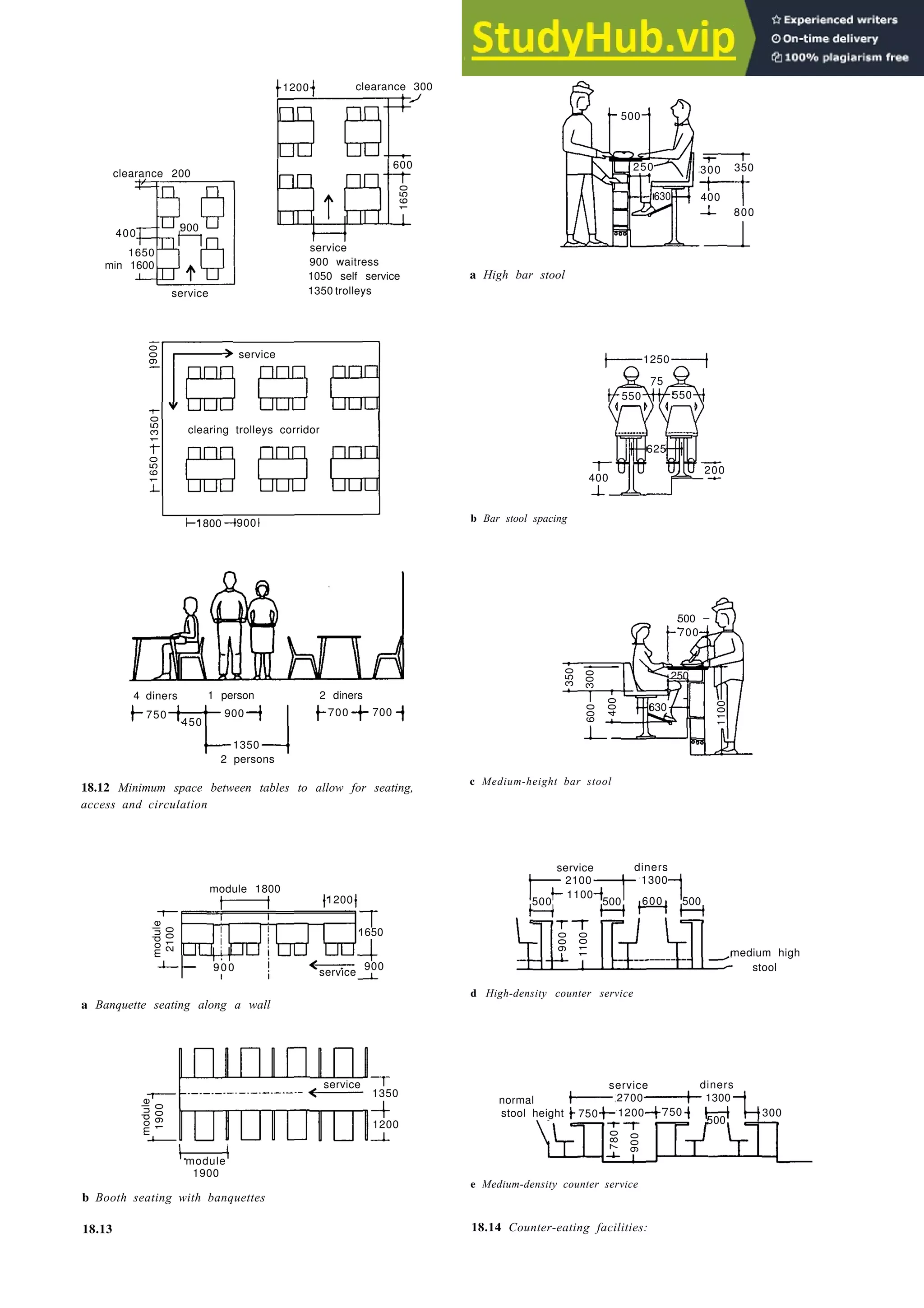

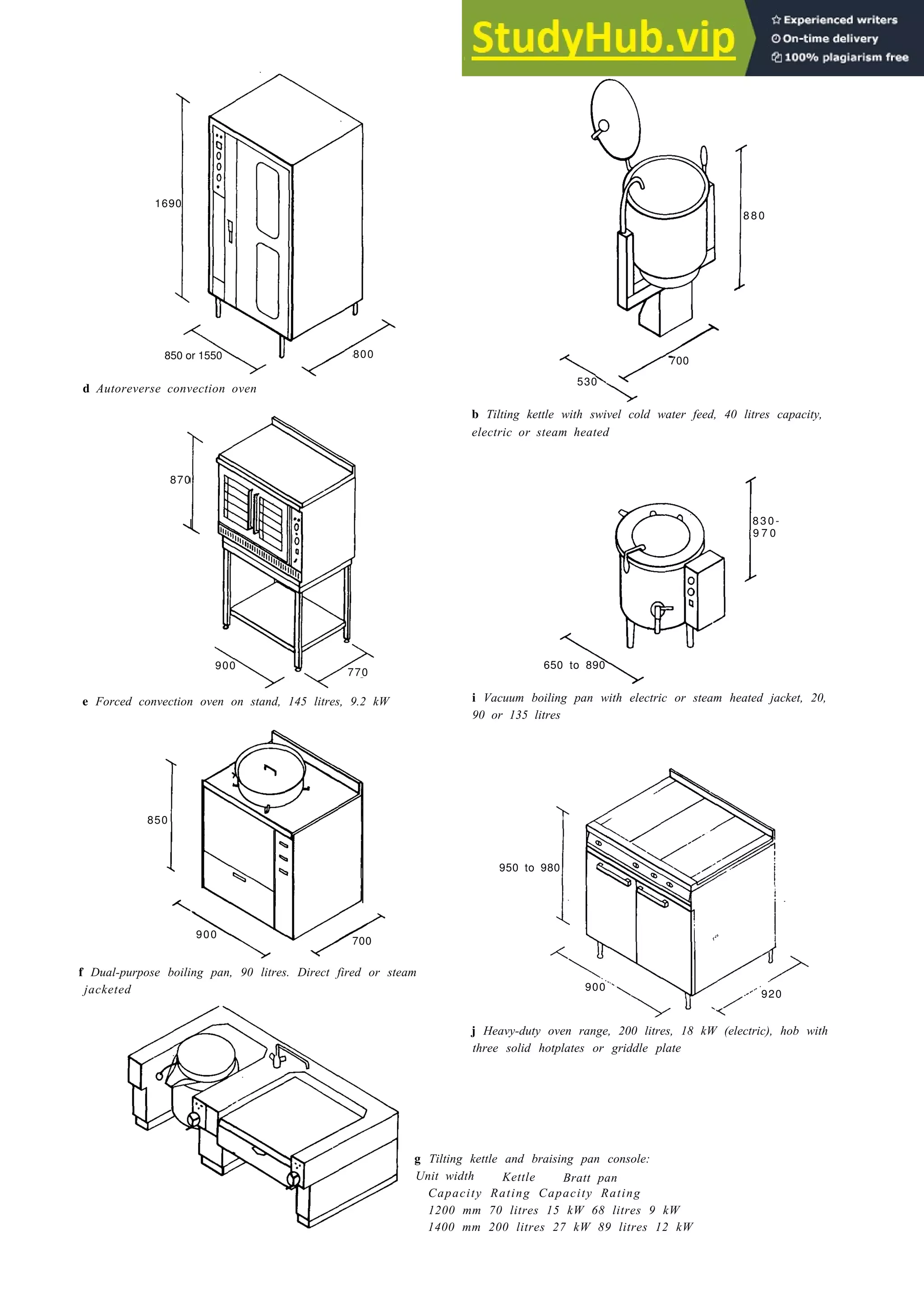

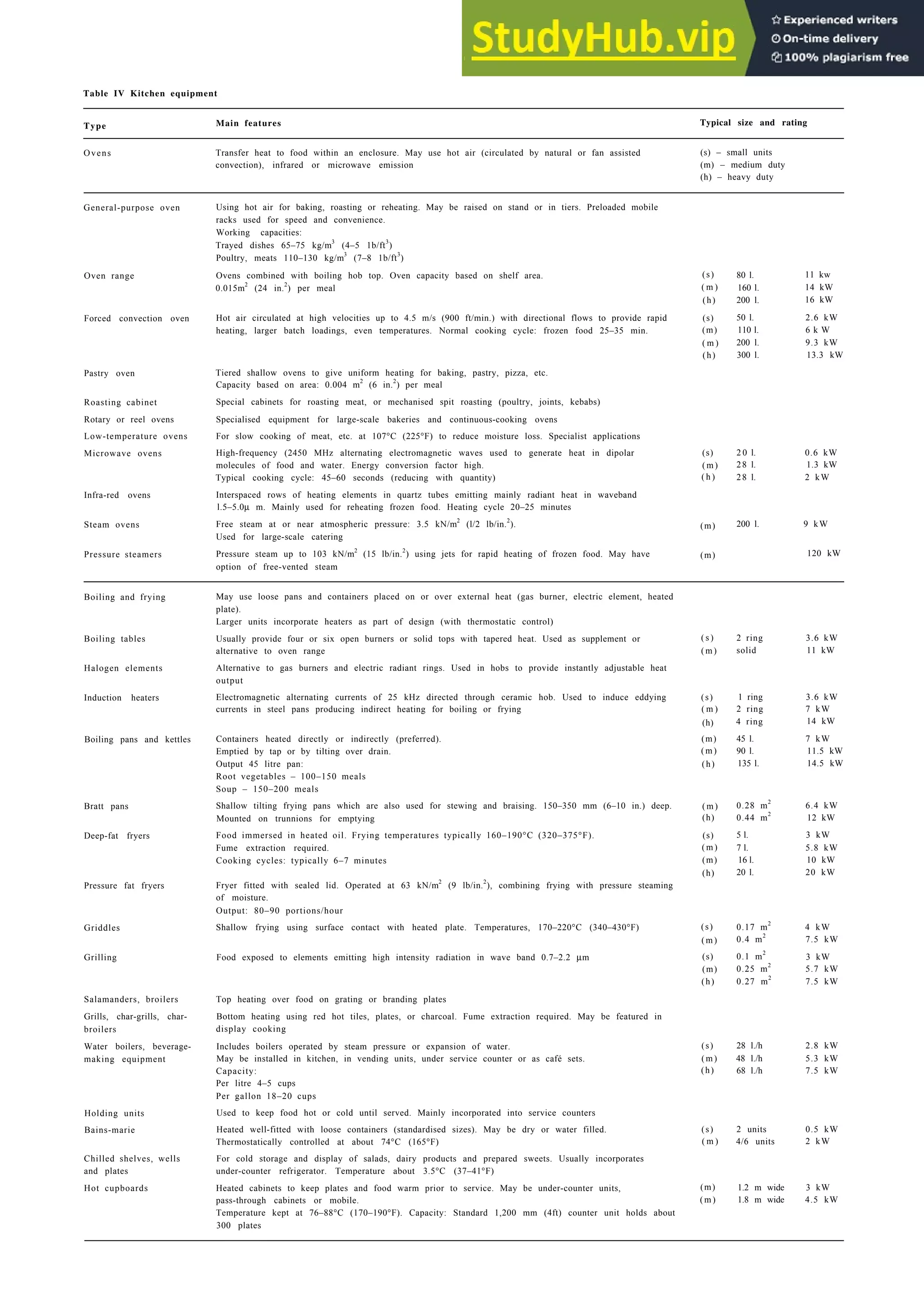

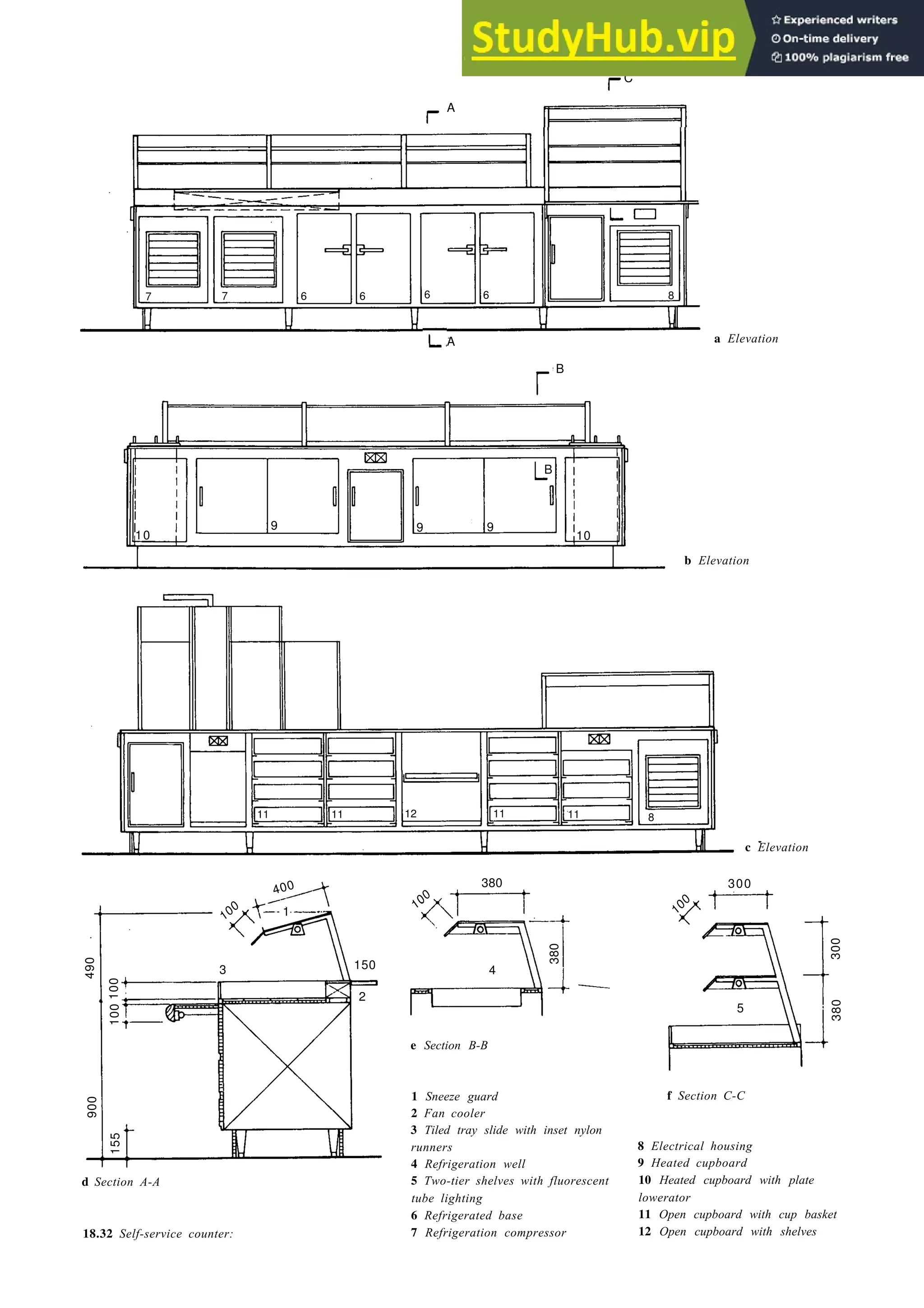

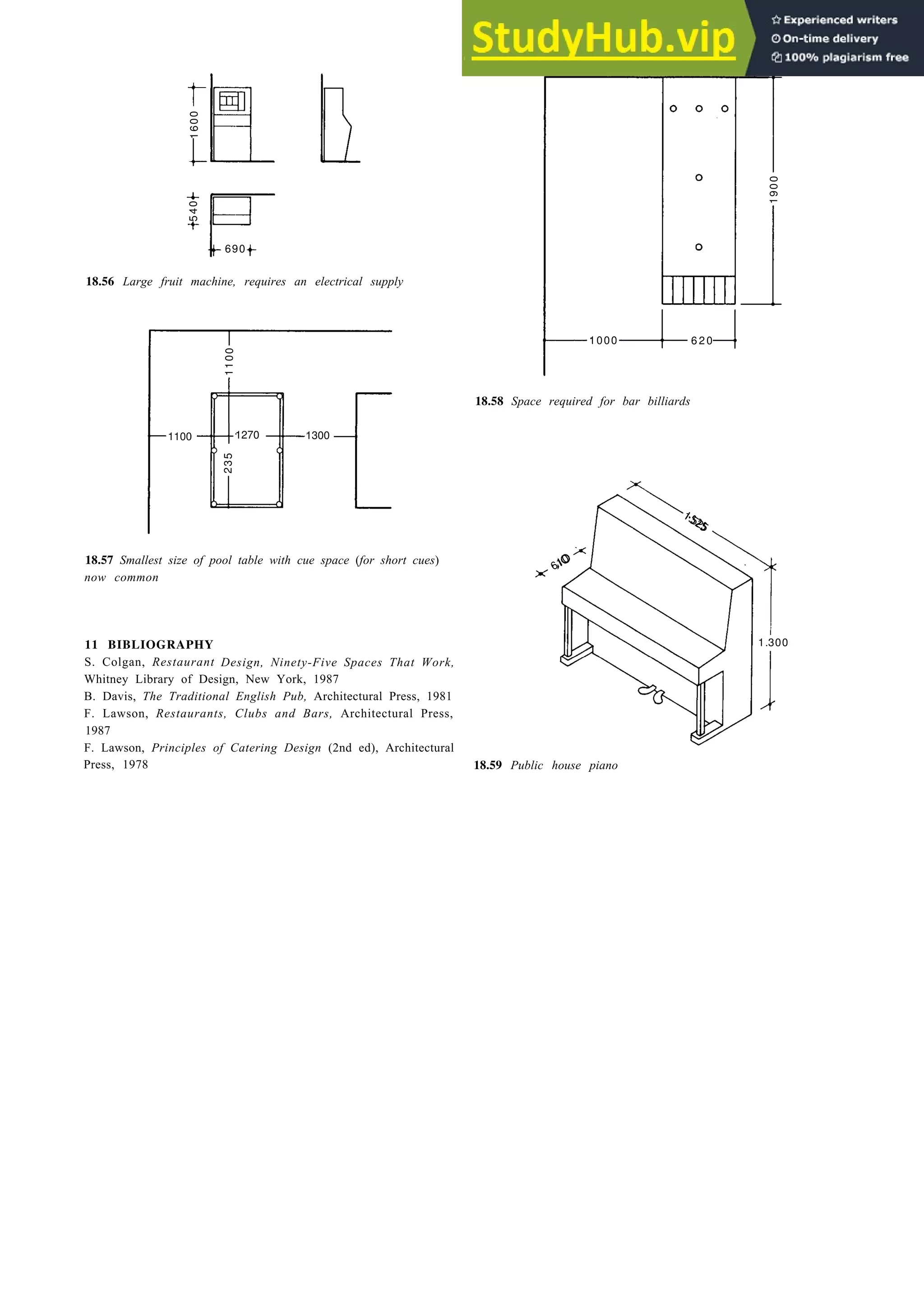

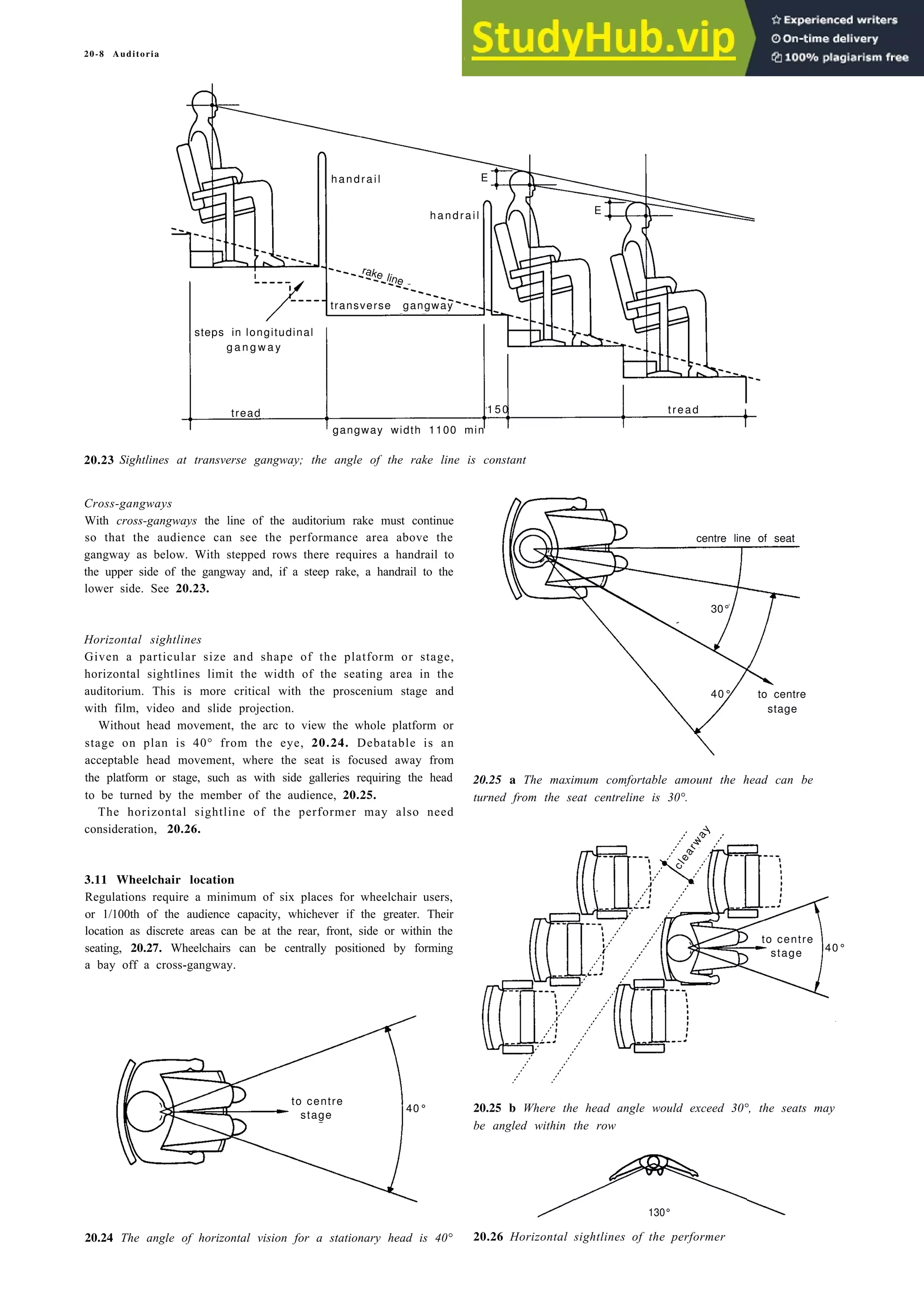

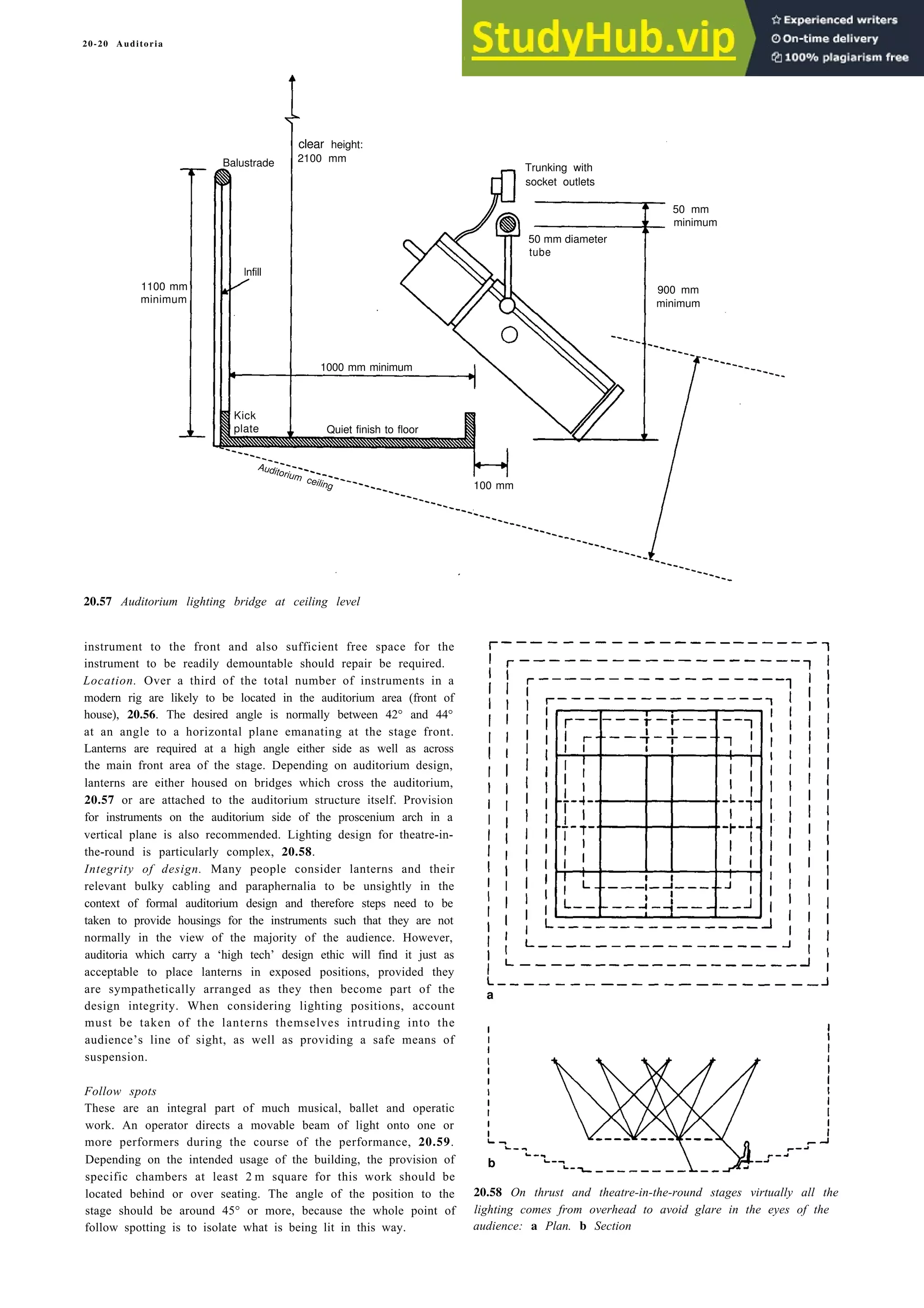

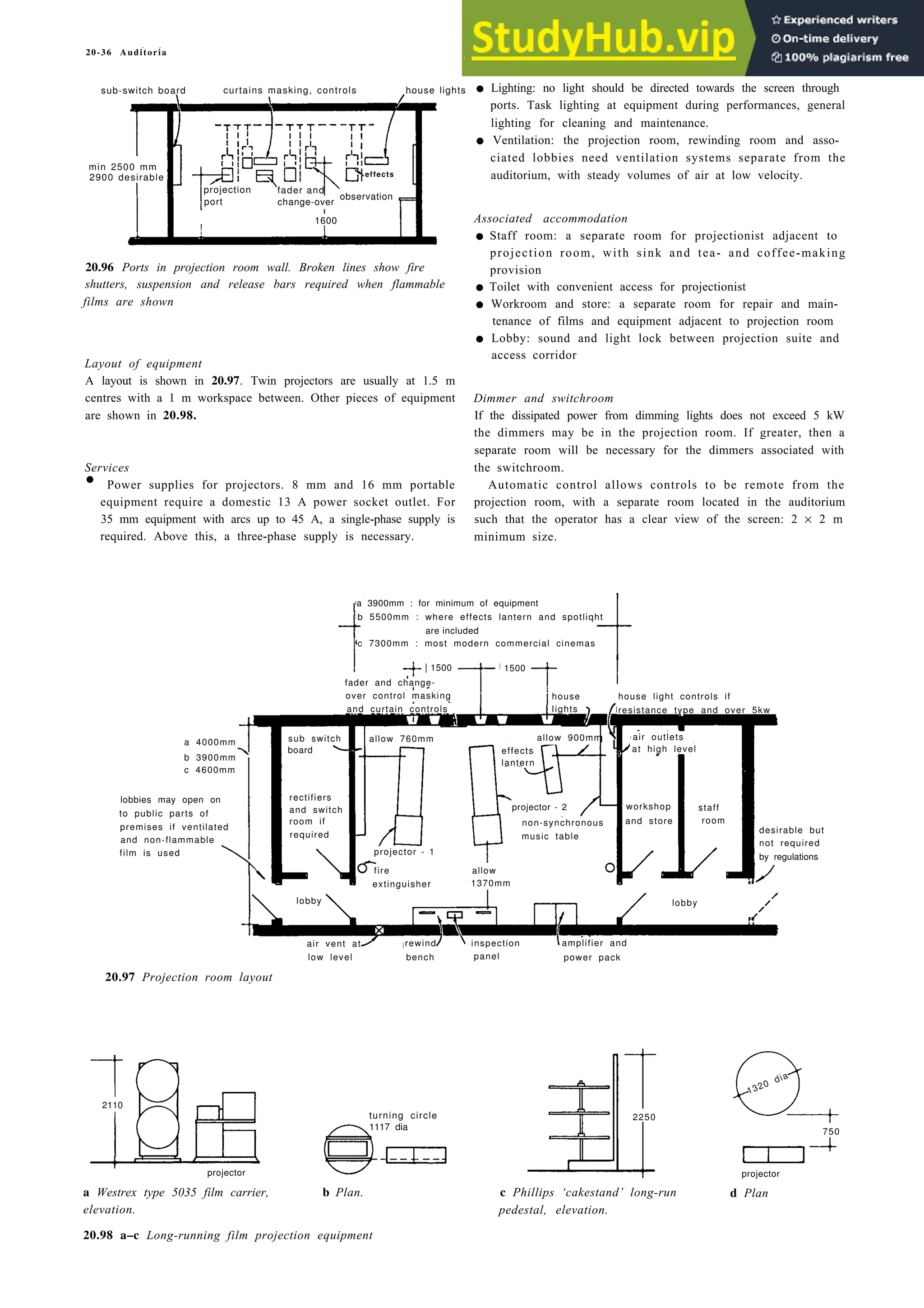

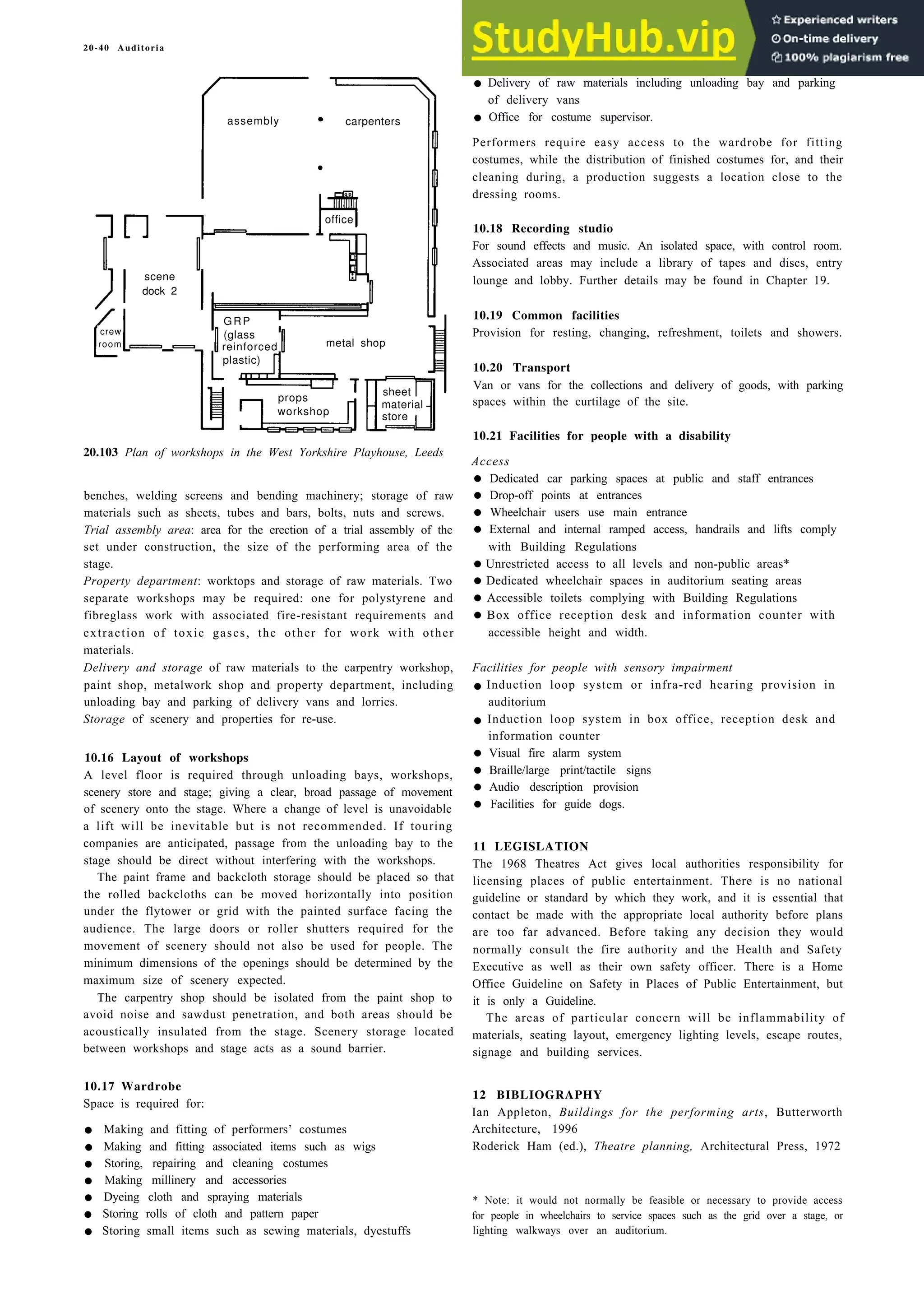

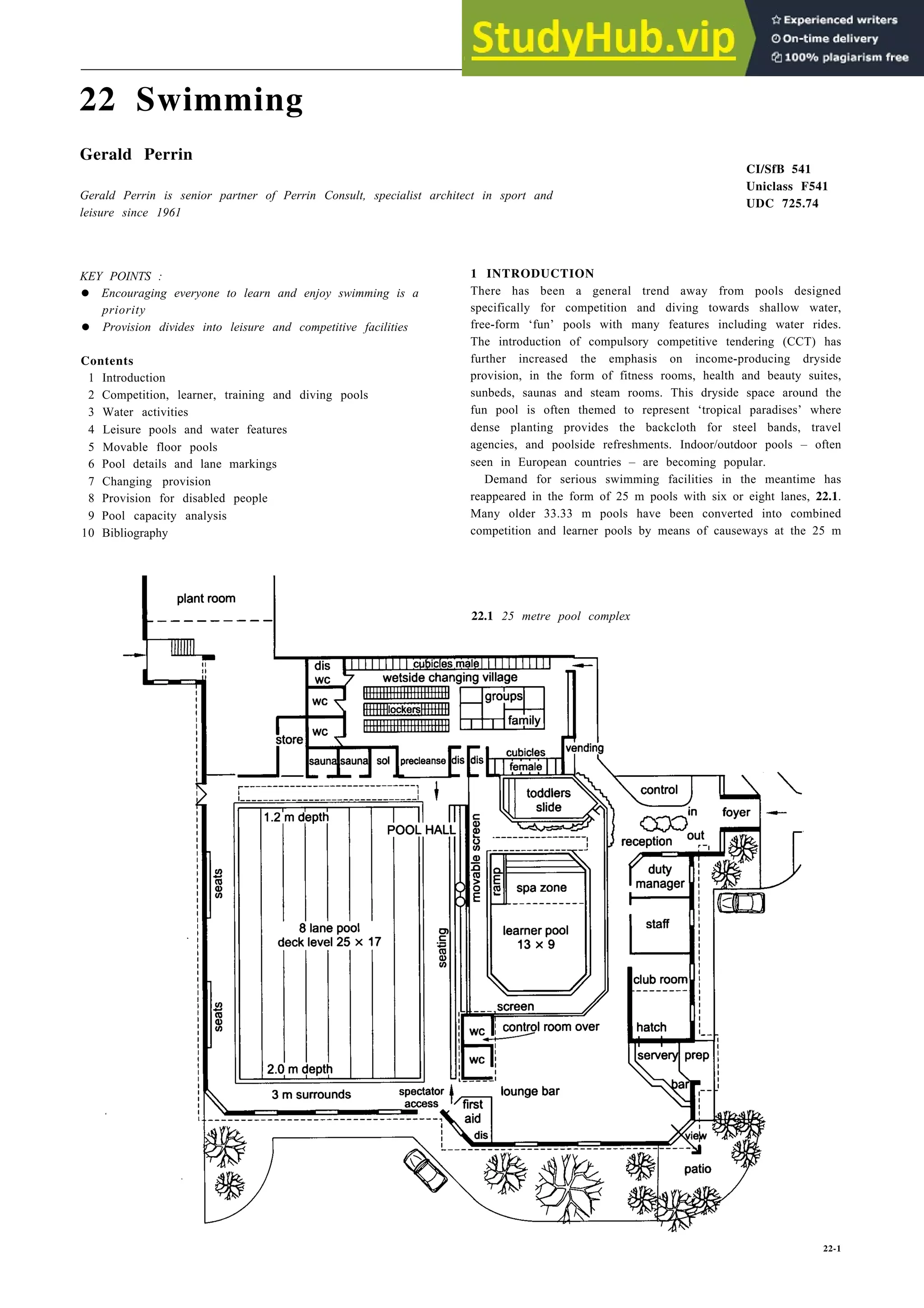

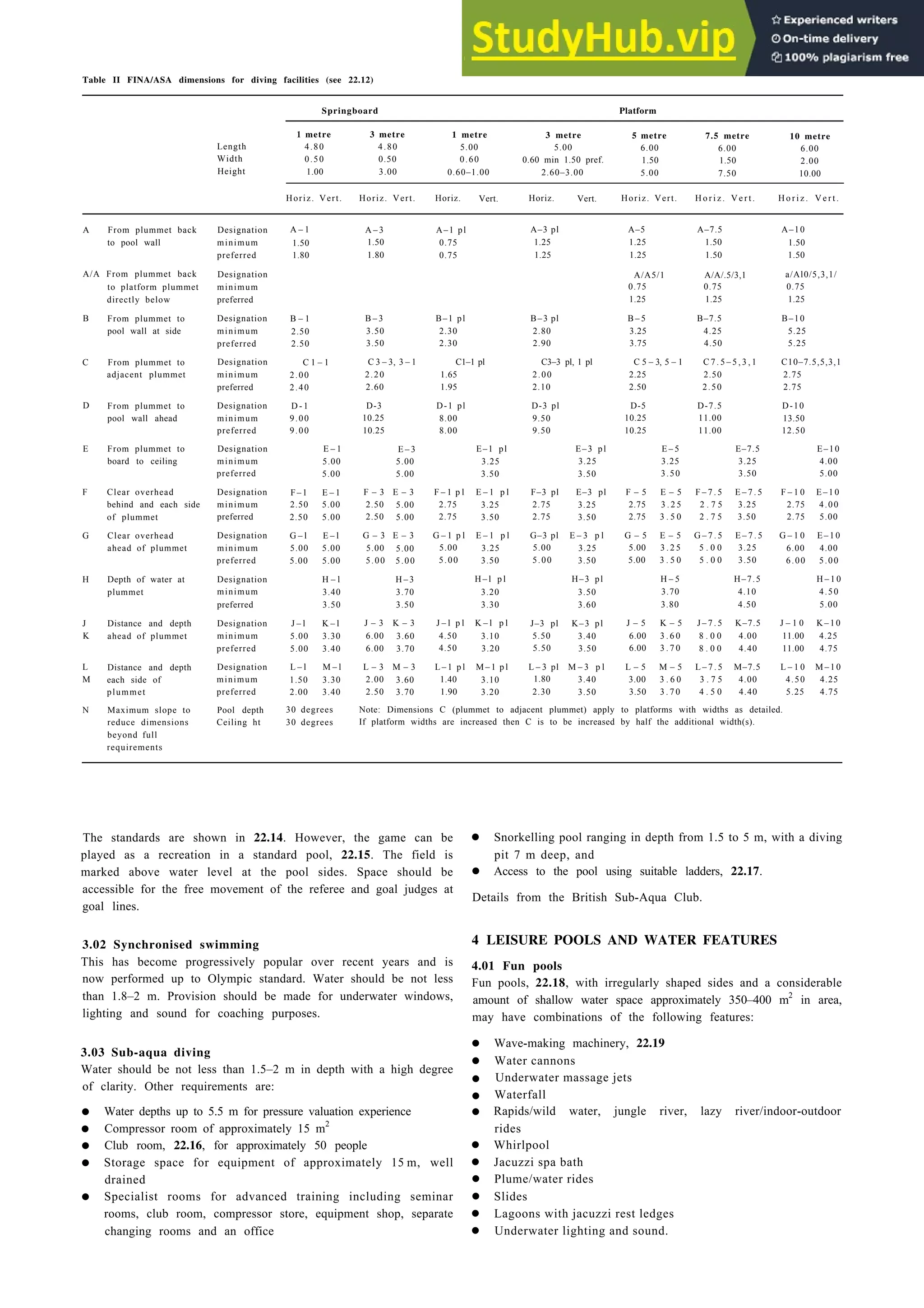

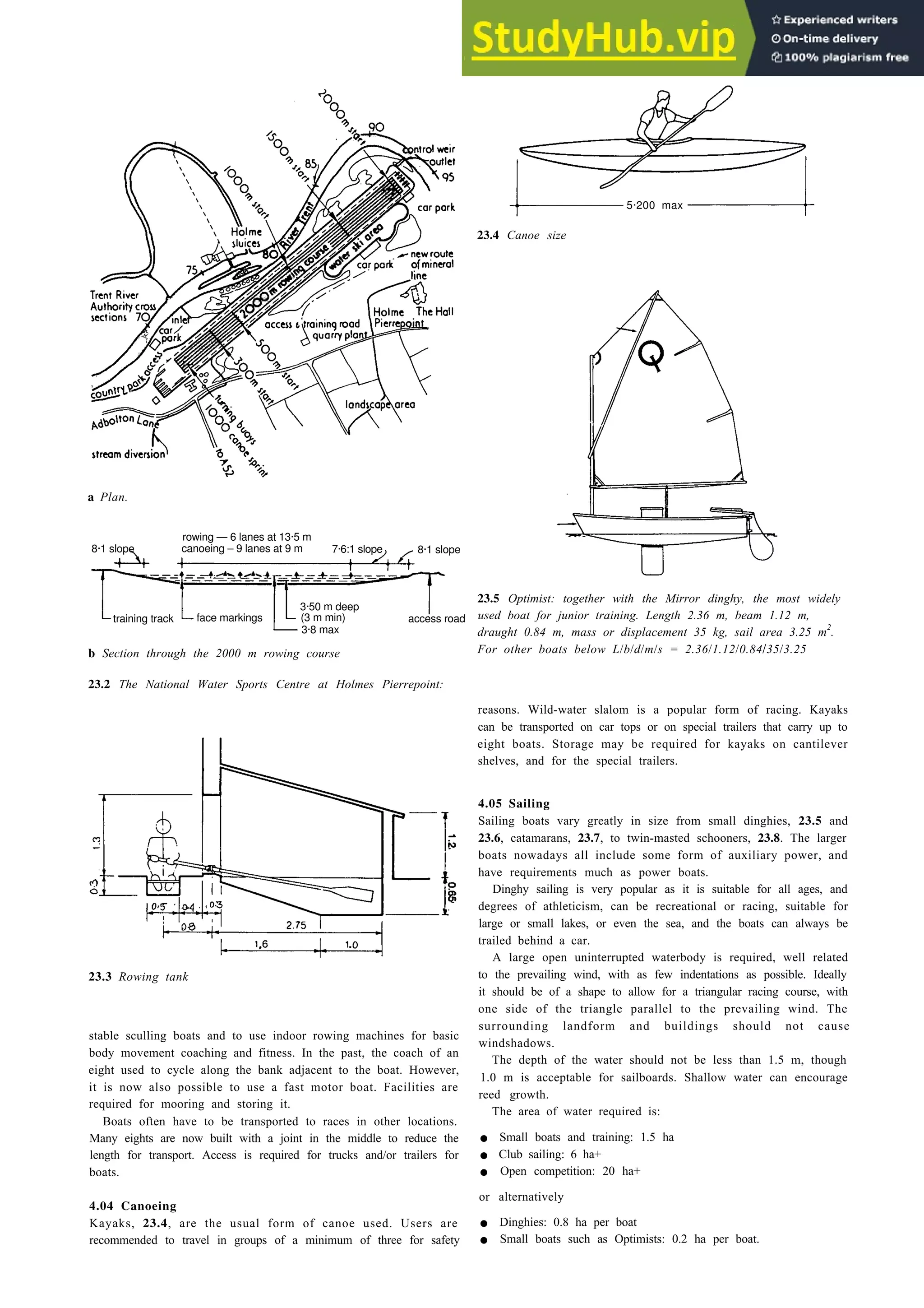

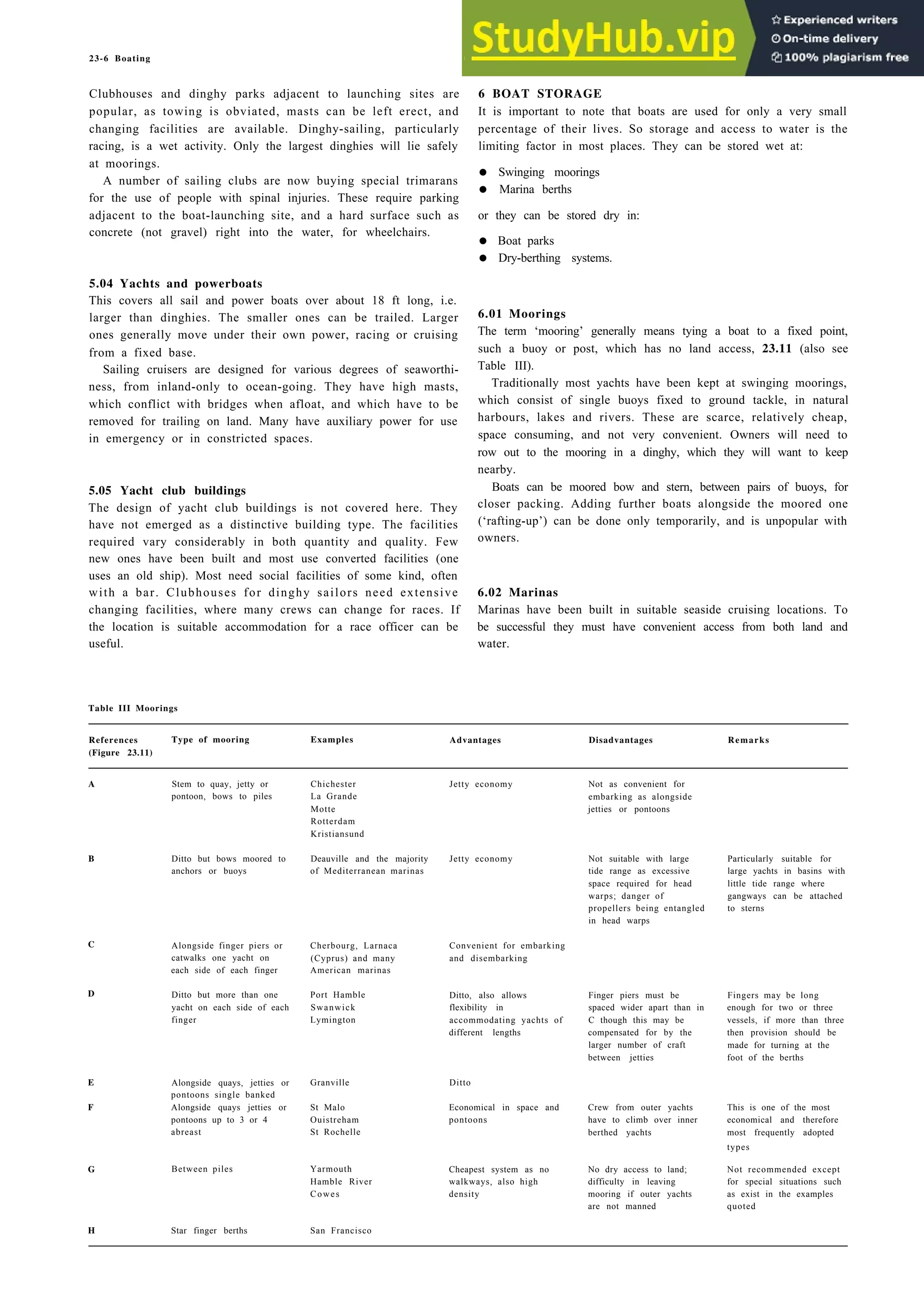

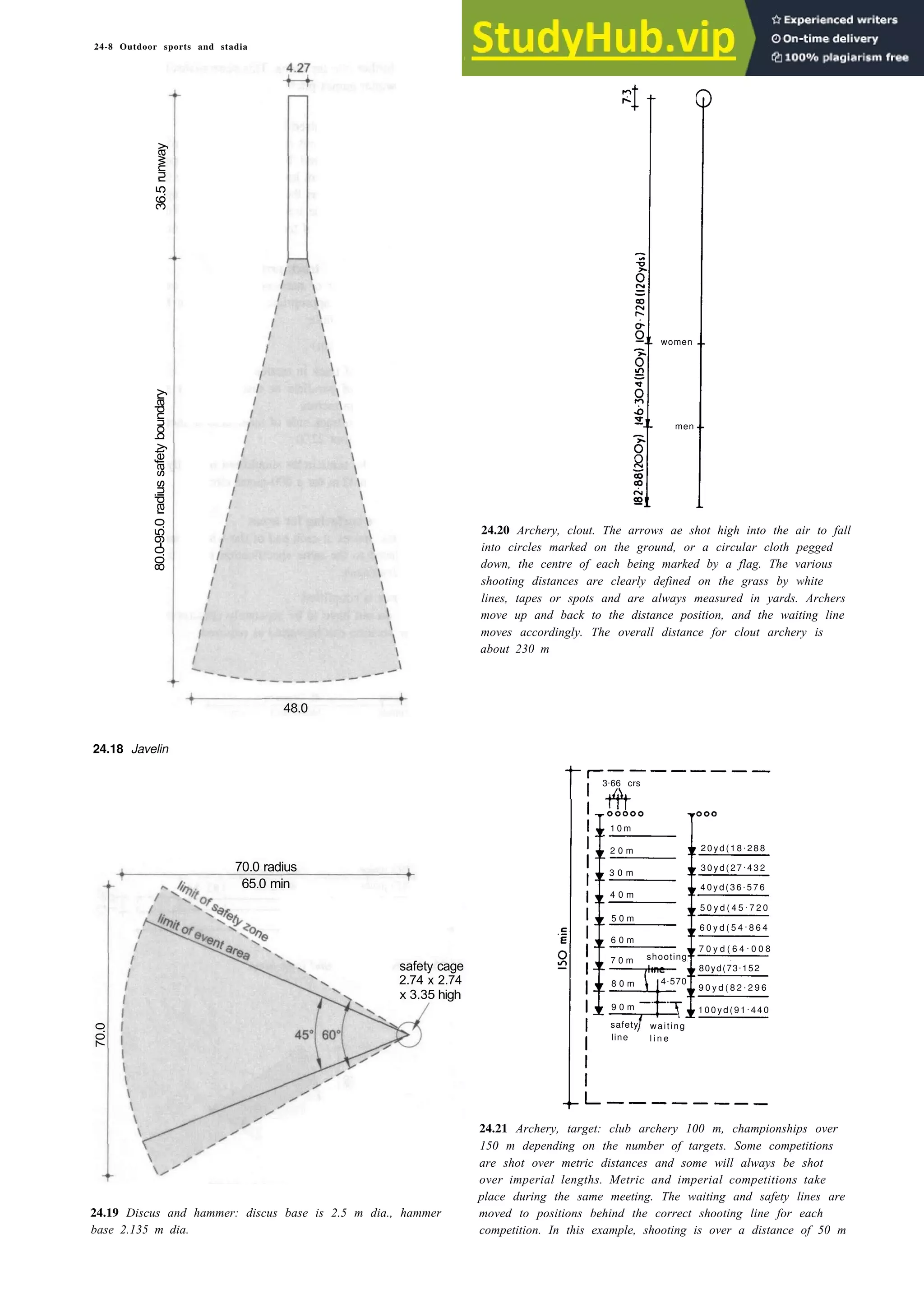

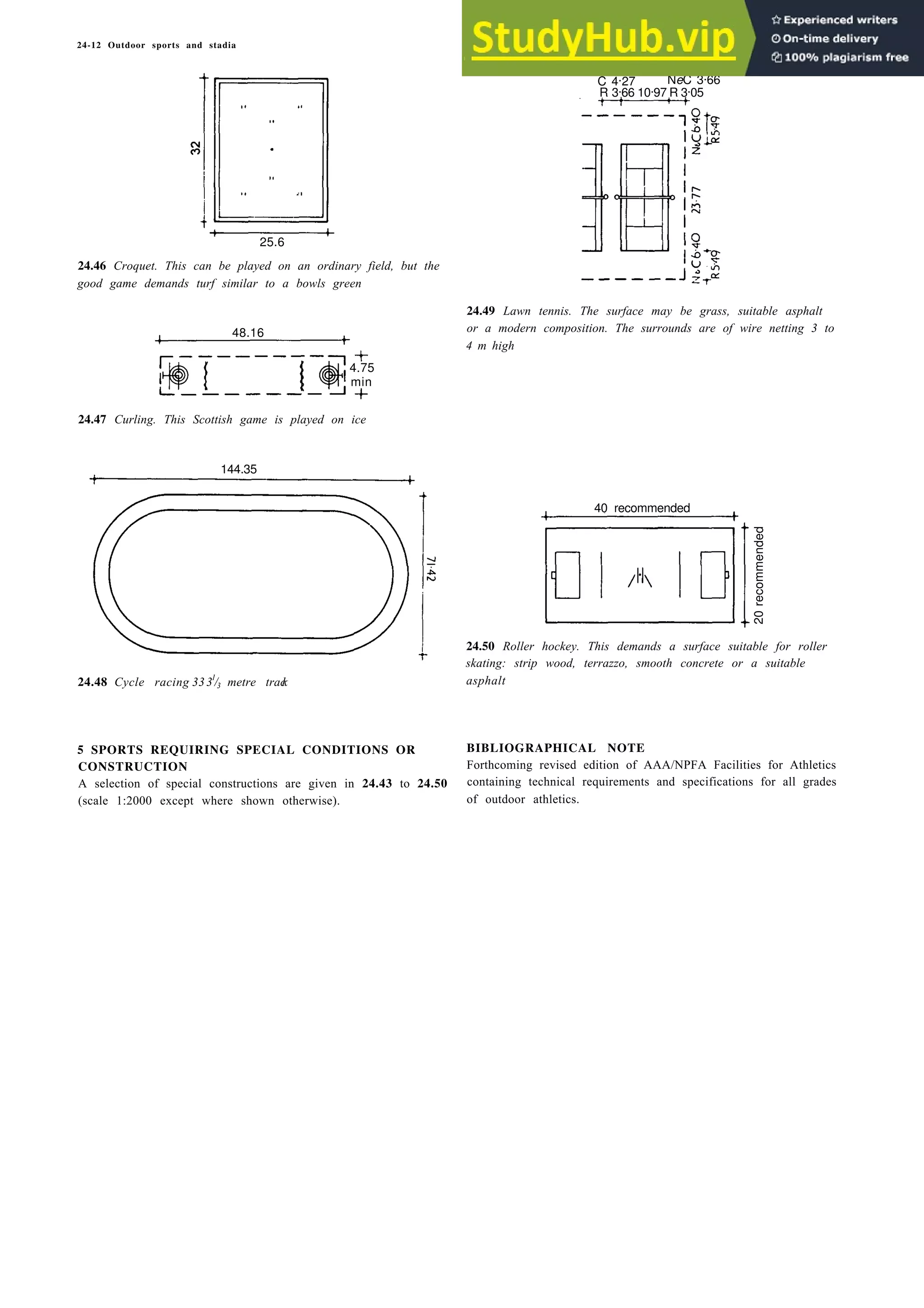

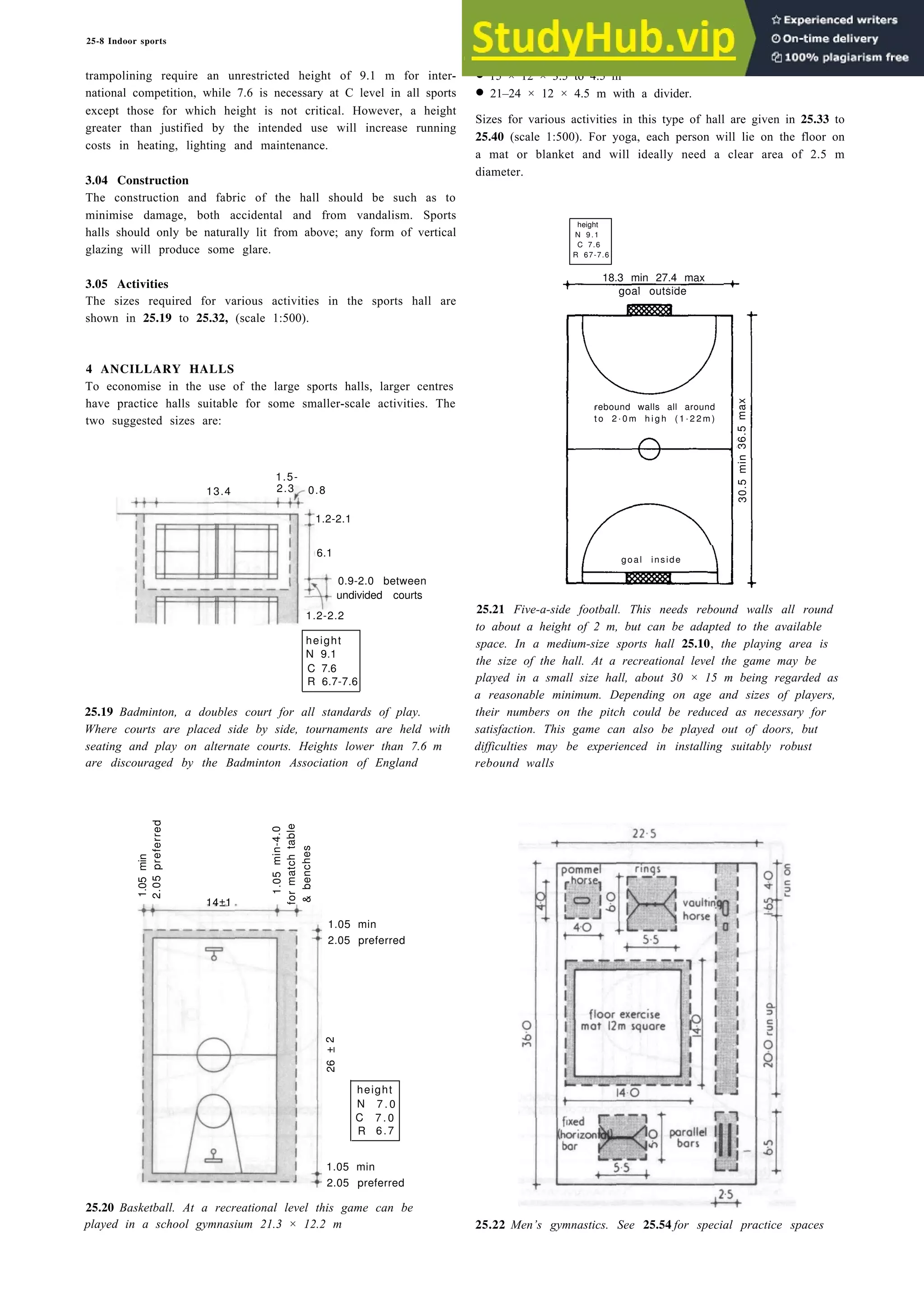

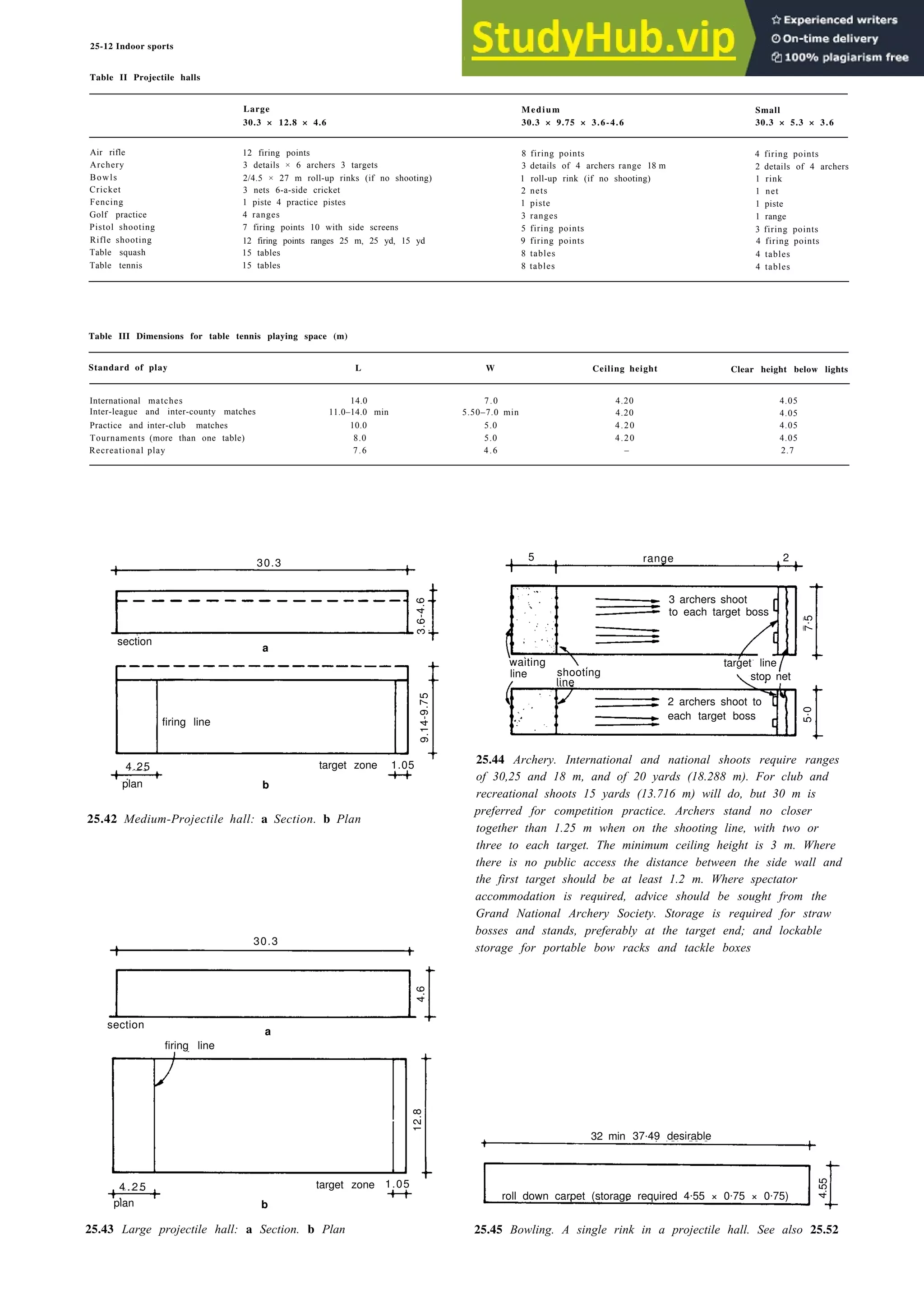

The interrelation between the amenities provided, 23.12, and the detailed breakdown of spaces and ratios is given in Table IV, and

main activities, 23.13, will control the basic layout. A marina may a checklist of accommodation and services in Table V.

be off-shore, landlocked or anything in between, 23.14 Marina pontoons are now standard items, 23.17. They are

There are many possible layouts, but generally, equal amounts arranged to rise and fall with changes in water level. Boats are

of space are allocated to land and water, 23.15 and 23.16. A usually moored stern to the pontoon, which often has access

water 50% land 50%

%

clearances 21·0

walkways

& piers 4·0

fuelling pier 2·0

lock 3·0

moorings 20·0

50%

5·0 shops

5·0 boatbuilding & repairs

2·5 slipway / haulout

2·5 harbourmaster / customs

2·5 boat storage *

0·5 hoistwell & travelator

4·0 allied sports

0·5 bulkhead walls

2·5 leisure area

1·0 club building

2·5 service loading bay

1·0 information centre / offices

2·0 landscaping

1·0 footpaths

1·0 staff parking

2·5 workshops stores

14·0 car / trailer parking †

50·0 %

not including dual use of car parking area

† assumes 4·7 m × 2·43 m (16' × 18') bays

23.15 One allocation of on- and off-shore space assuming a 50:50 land/water split. This is

appropriate to European standards

27% 28%

50%

moorings remainder

50%

clearances parking

23% 22%

water land

23.16 Principal space allocations based on the average of ten

American marinas. The difference between these figures and

those in [23.15] are mainly due to the use of a 2.7 × 5.8 m

parking bay

Table IV Spatial requirements and likely size ranges

Min. Max.

Land-to-water ratio 1:1 2:1

Density of boats/hectare (wet moorings) 62 162

Density of boats/hectare on hardstanding 25 75

Car-to-boat ratio 1:1 1:5:1

Density of cars/hectare (2.4 × 5.0 bays) 350 520

Ranges of boat length 4.8–13.7 m 4.3–21.3 m

Ranges of boat beam 1.8–4.3 m 1.5–6.0 m

Ranges of boat draught: inboard 0.64–1.27 m 0.48–1.65 m

outboard 0.30–0.56 m 0.20–0.64 m

sailing boats 1.14–1.77 m 1.00–2.16 m

Average boat length 5.5 m 9 m

Percentage total parking area to total water area 20% 50%

People-to-boats ratio 1.5:1 3:1

People-to-cars ratio 1:1 4.5:1

Cars-to-boats ratio 1:2 2:1

3050

walkway 2440 detachable

removable

services

deck sections

continuous

100 × 150 fender

protection skirt

through

rigid foam flotation bolts anchor

billets

diagonal bracing

foam frame

pile

23.17a Construction detail of floating pier, section A–A

23.17b Detail of anchor pile

top 3280

location of

mooring

3050 hardware

2440 2300

1830

1220

1370

610

0.0

finger pier

1830

securing

610 guide

0.0

1220

hinge

2440](https://image.slidesharecdn.com/architectureebookmetrichandbookplanninganddesigndata-230807180049-33007df6/75/Architecture-Ebook-Metric-Handbook-Planning-and-Design-Data-pdf-388-2048.jpg)

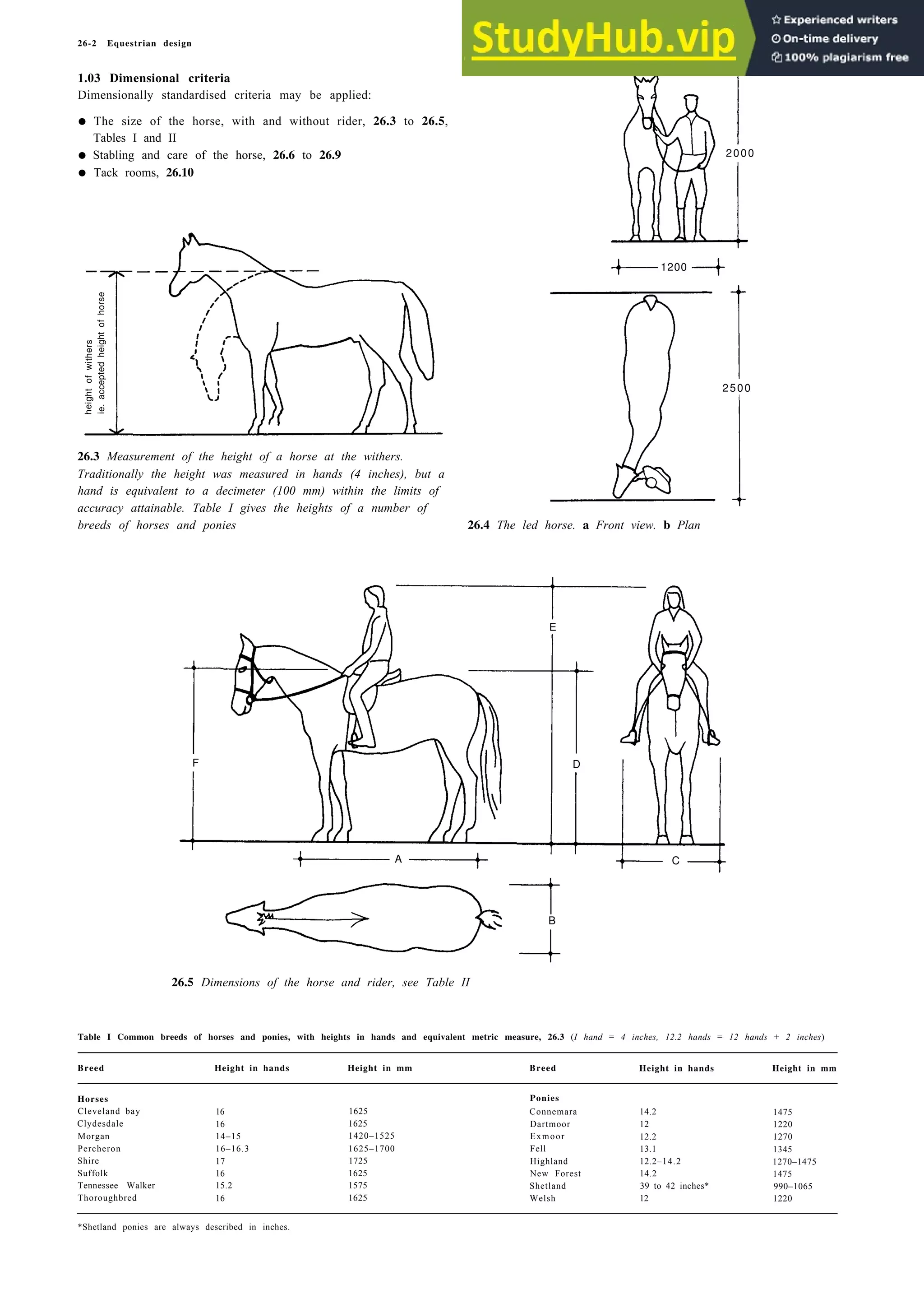

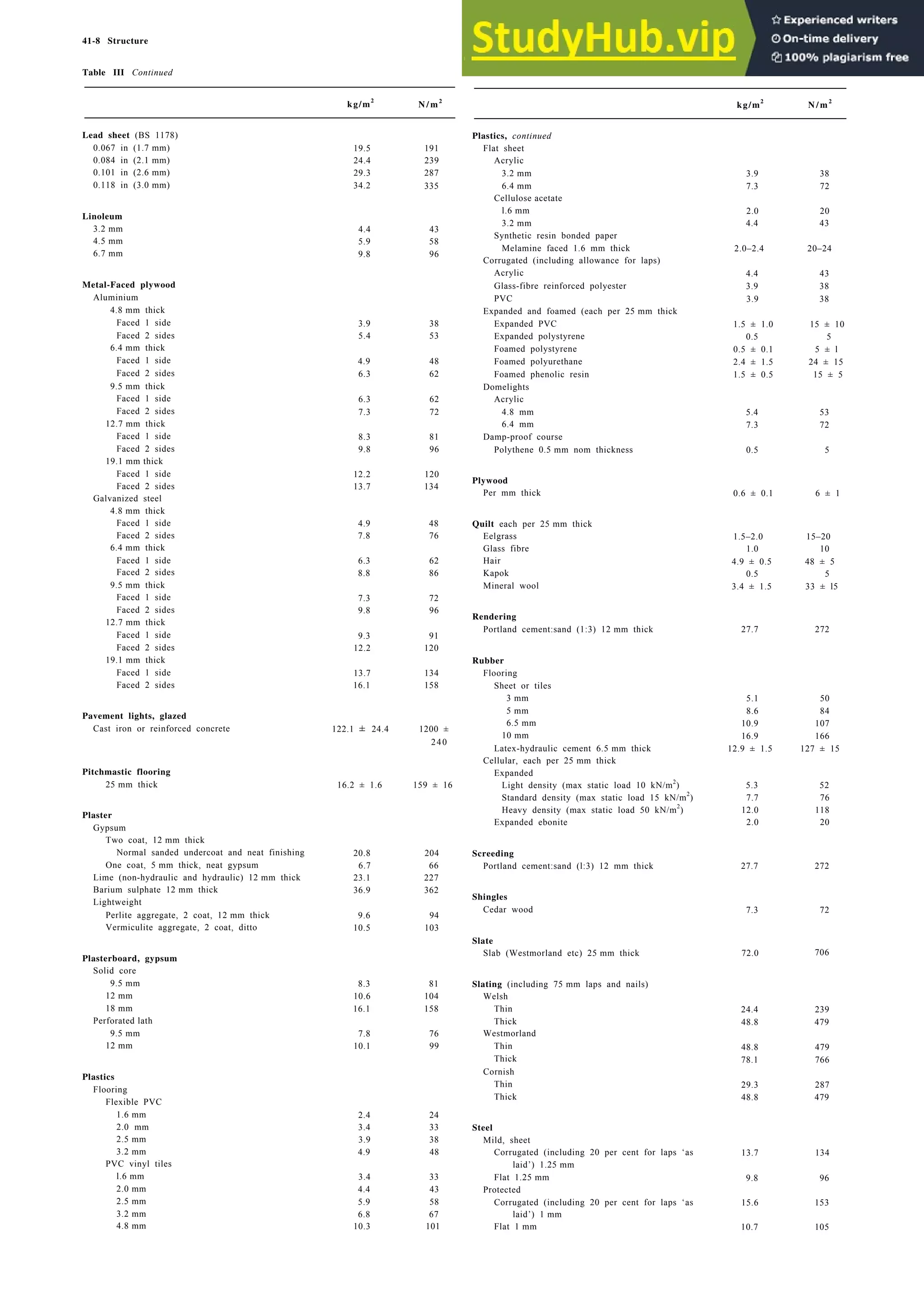

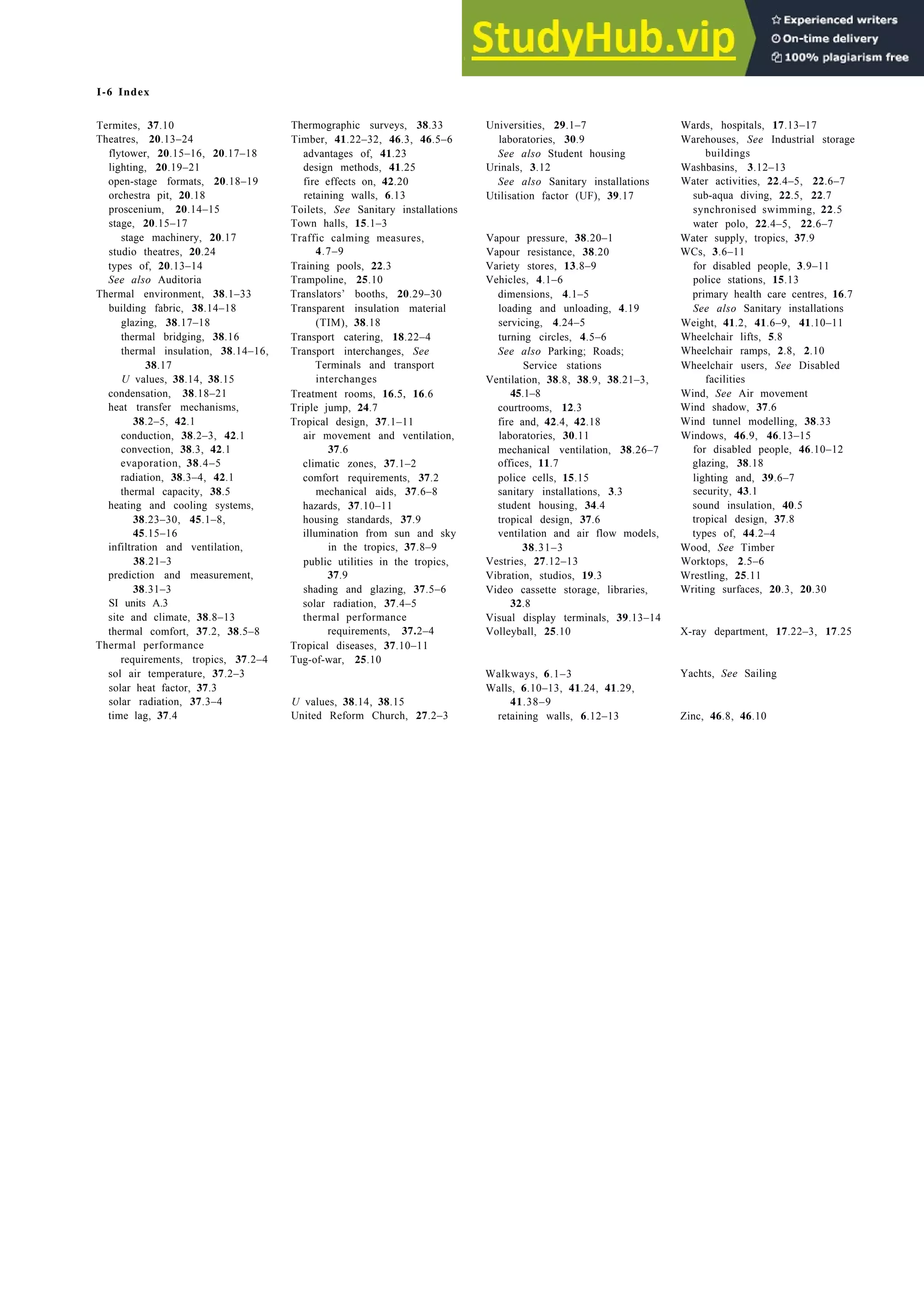

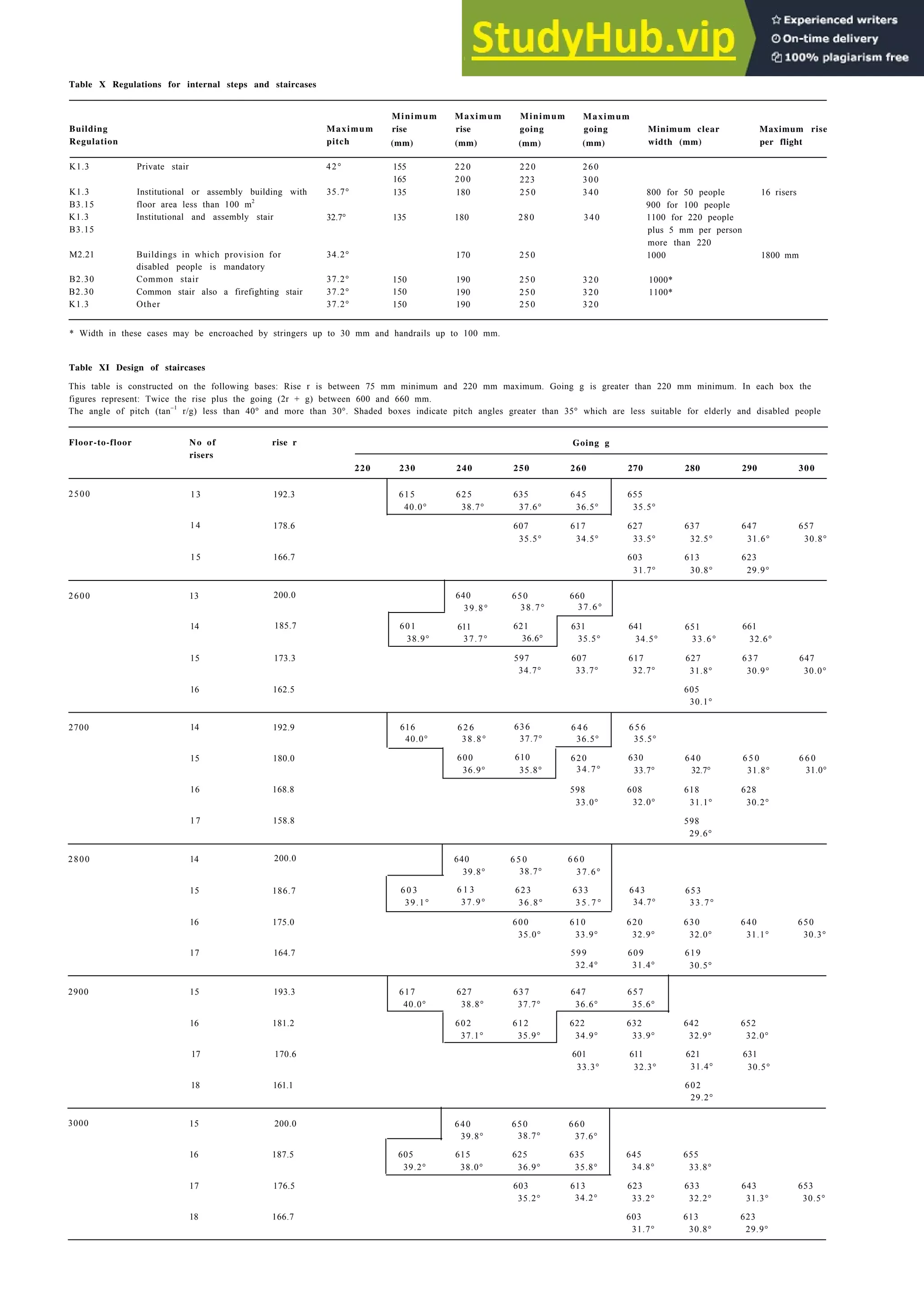

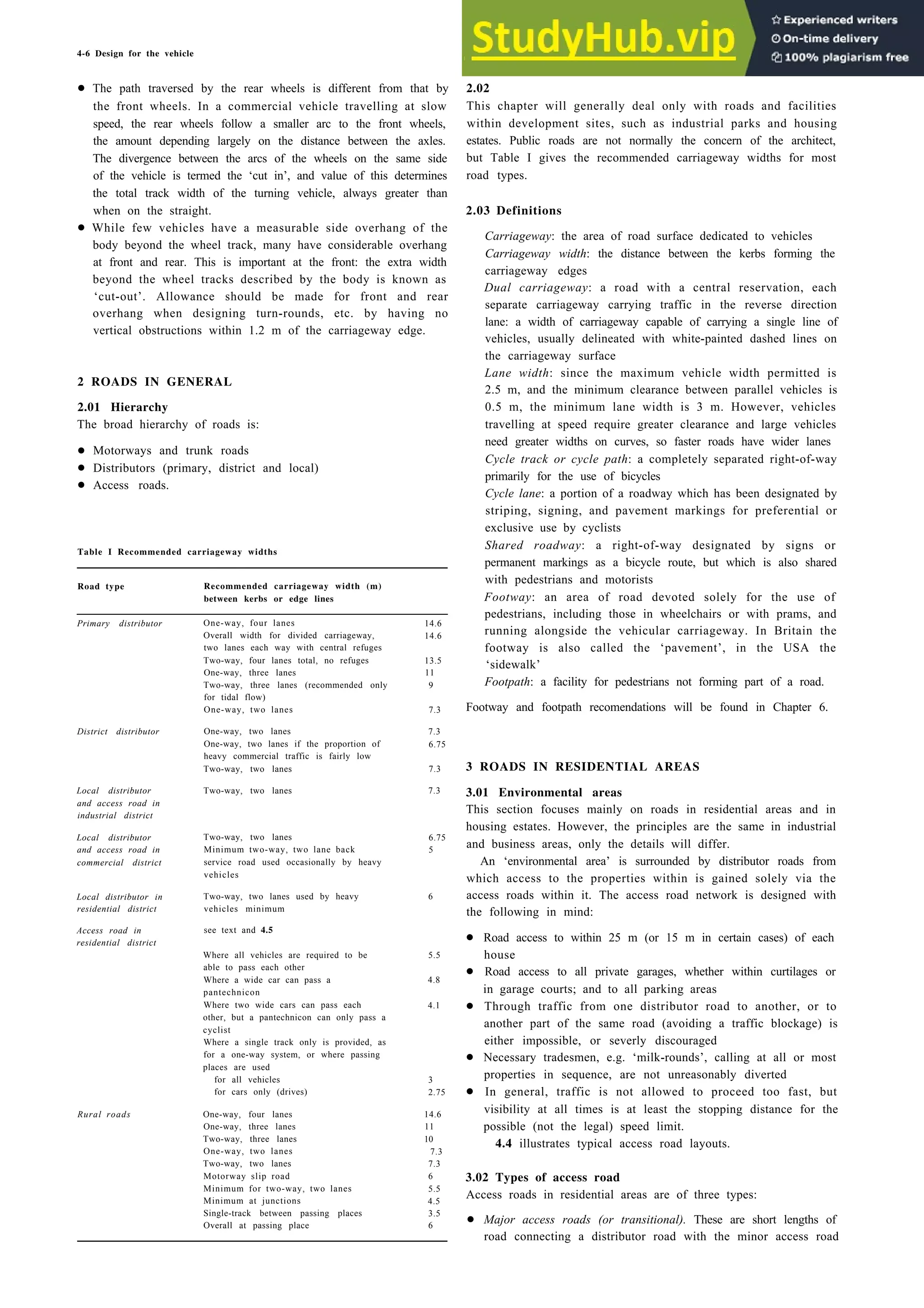

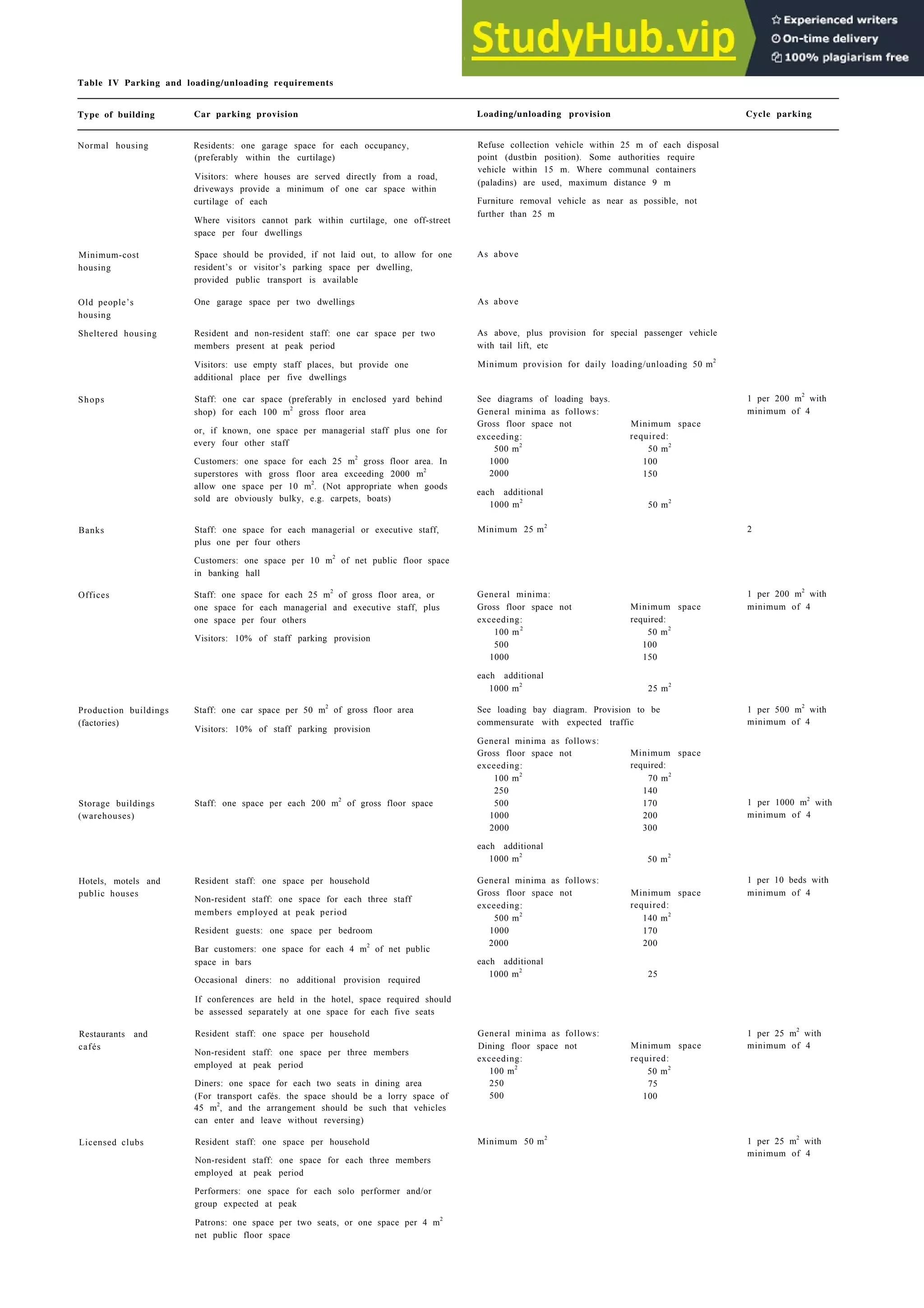

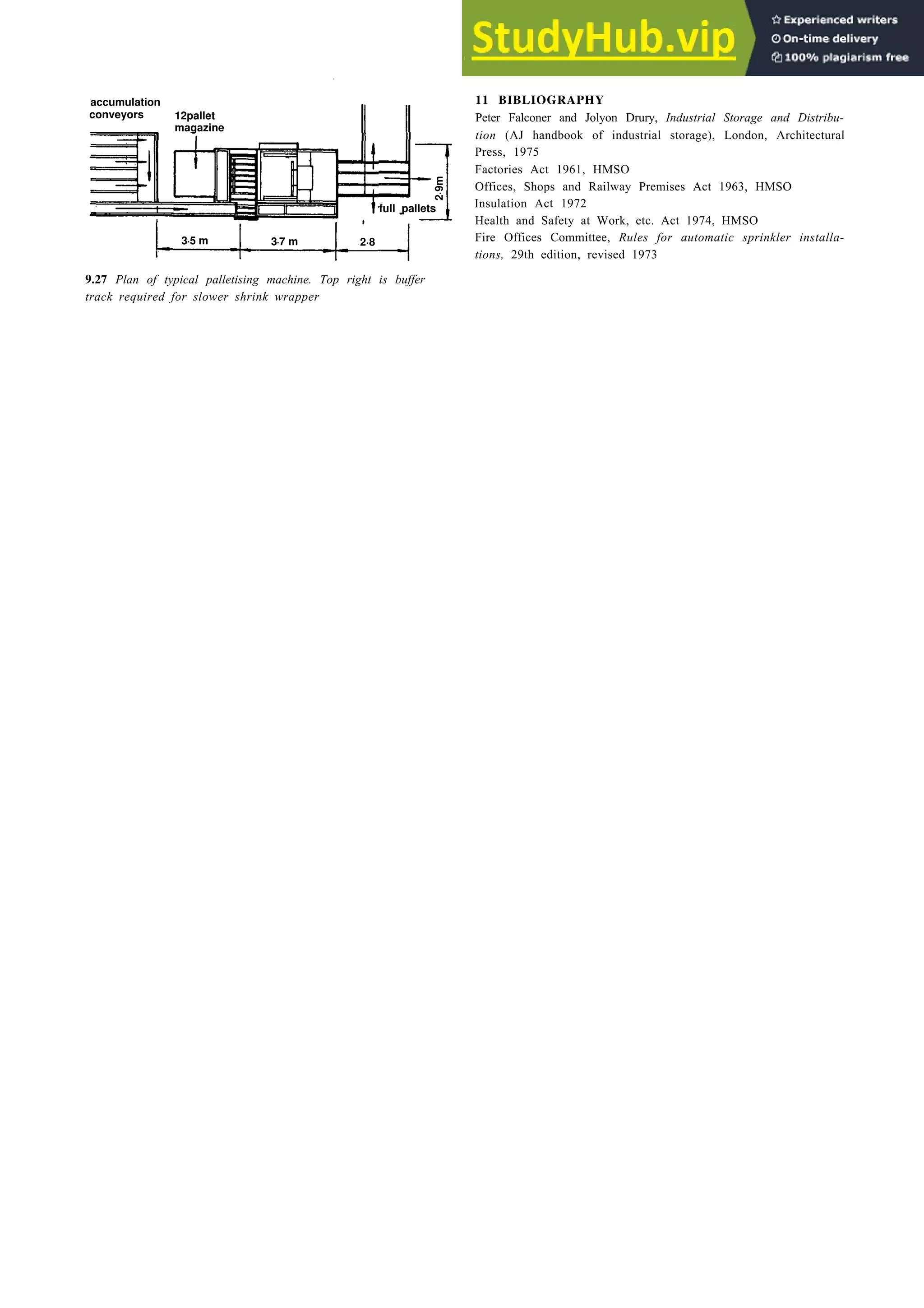

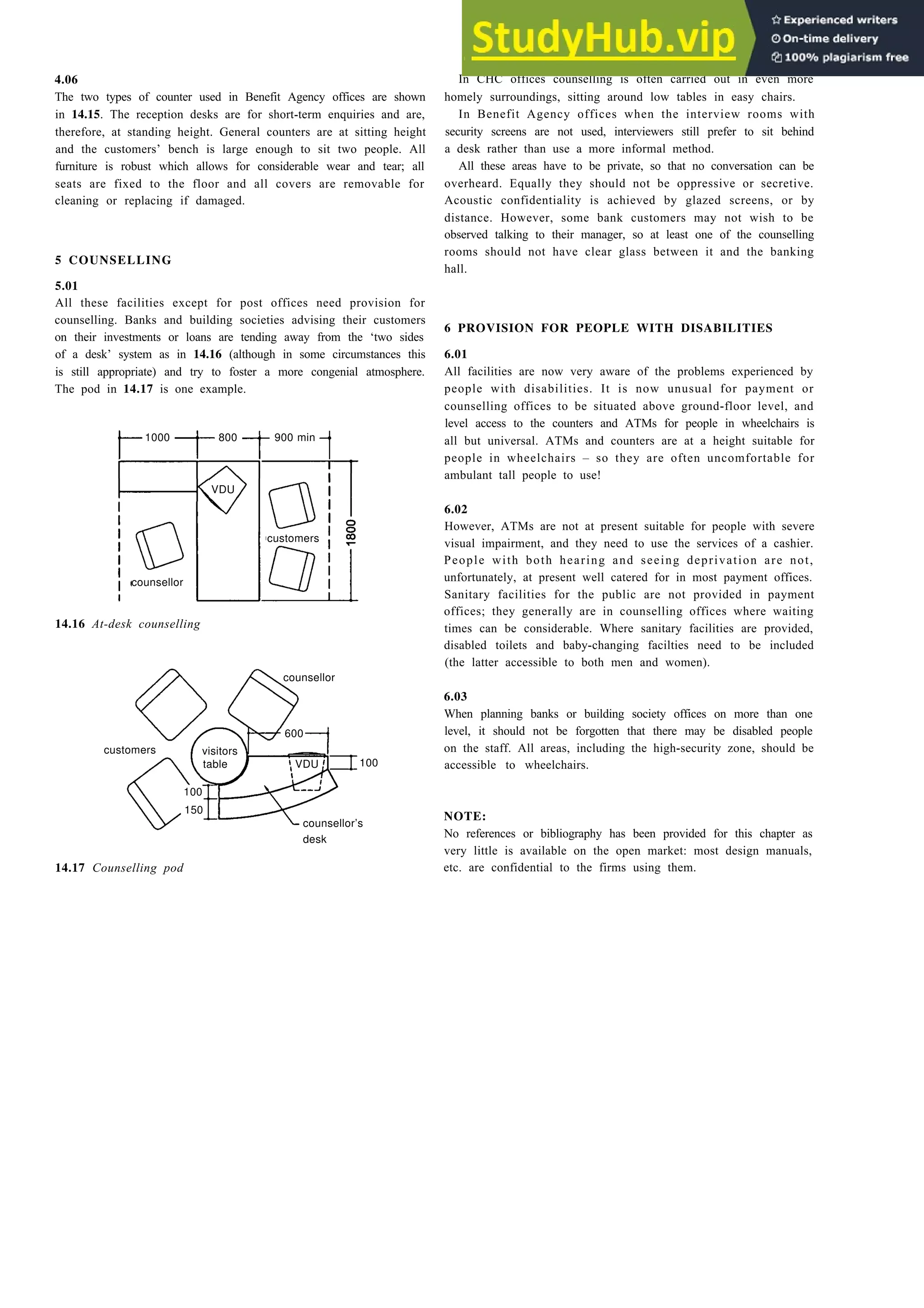

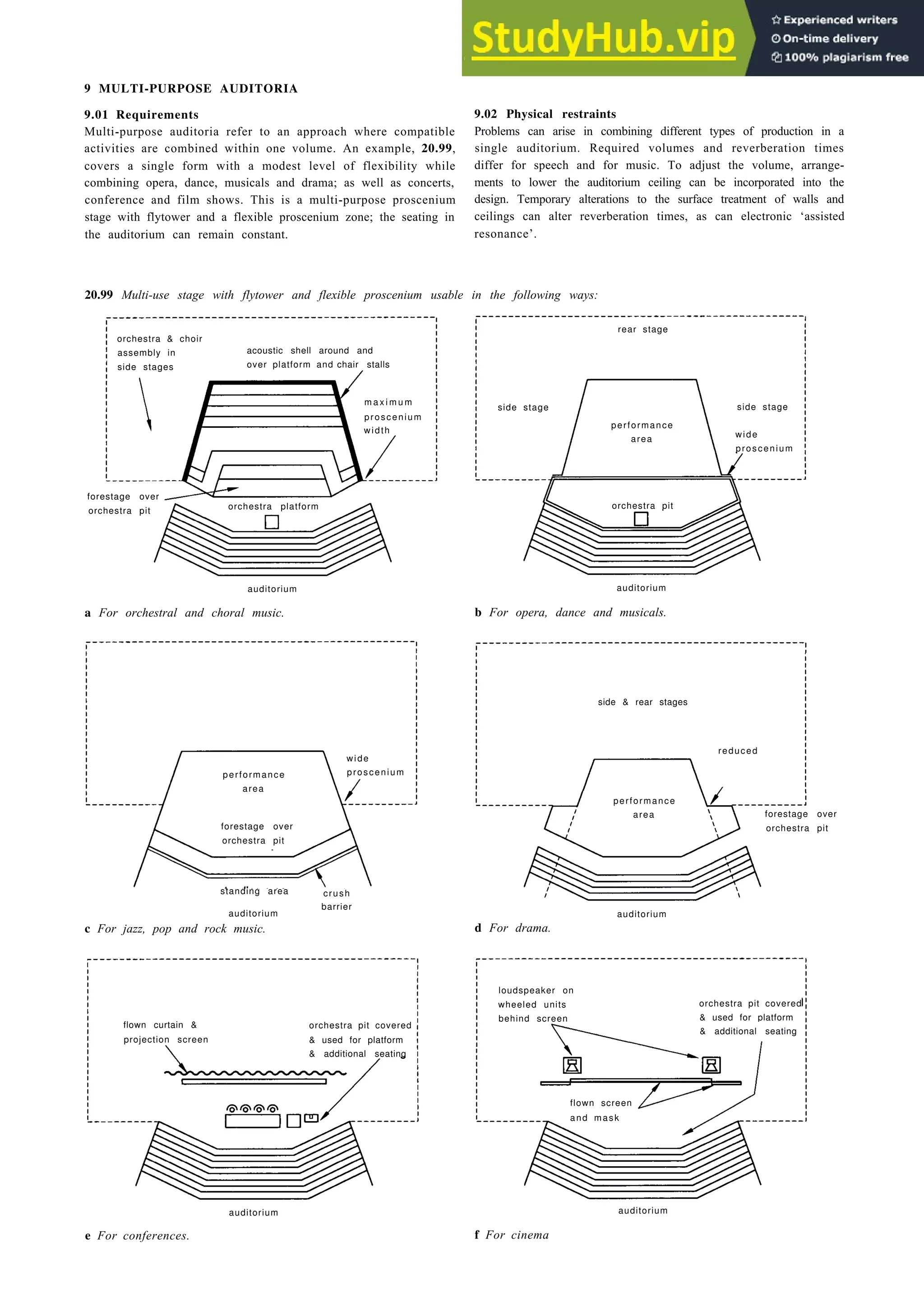

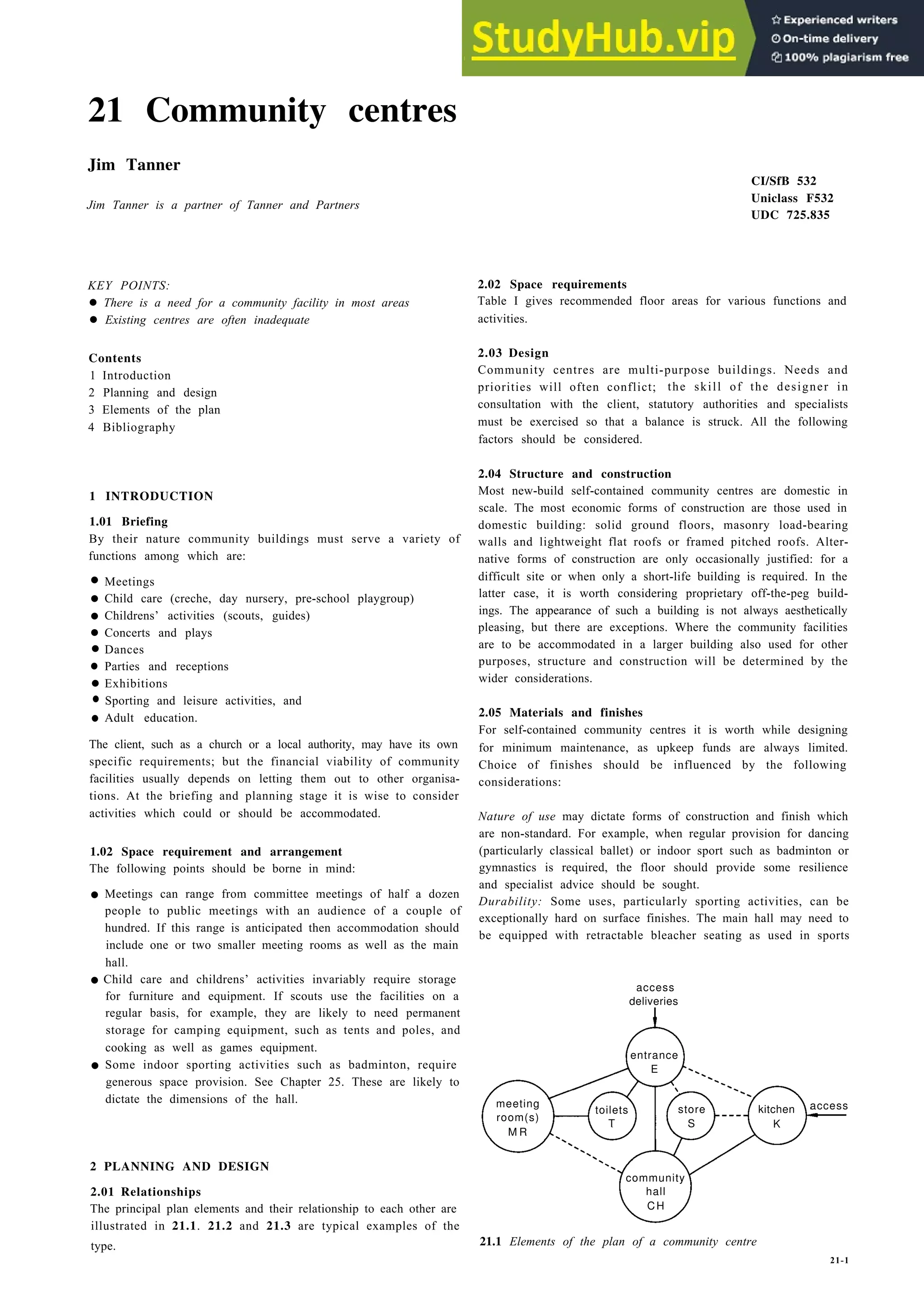

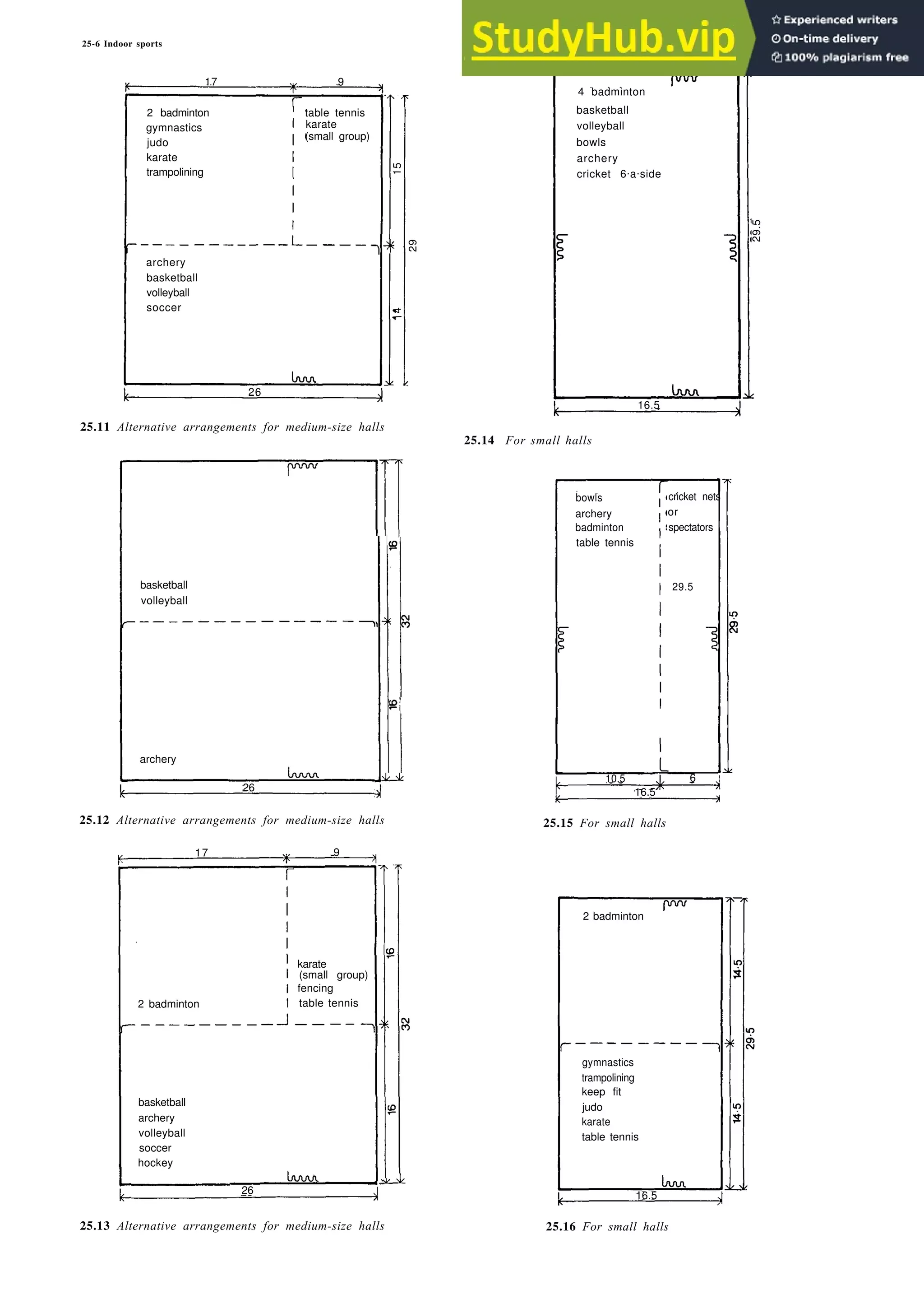

![25-14 Indoor sports

bend

length

B

(may

be

banked)

overall

width

W

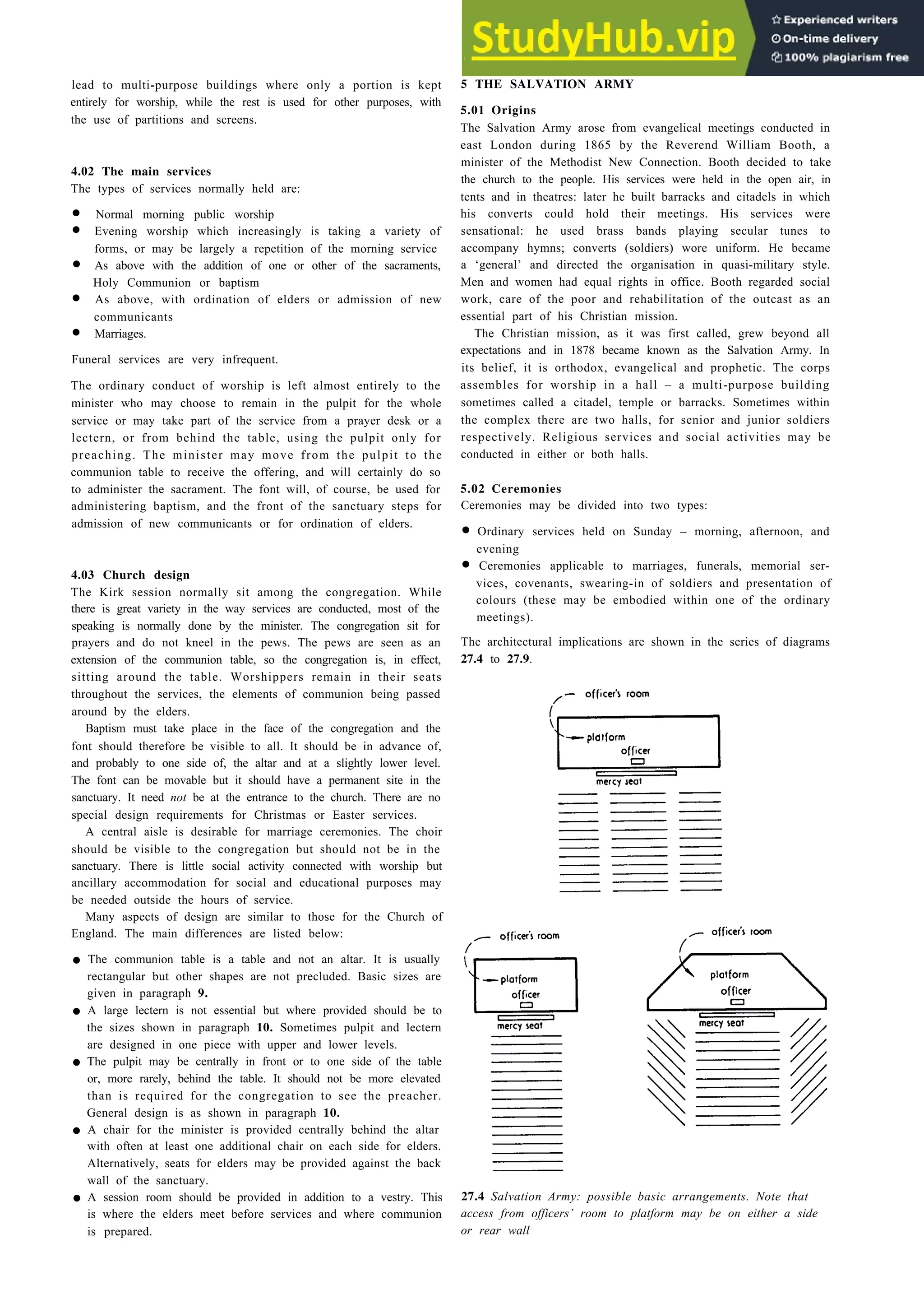

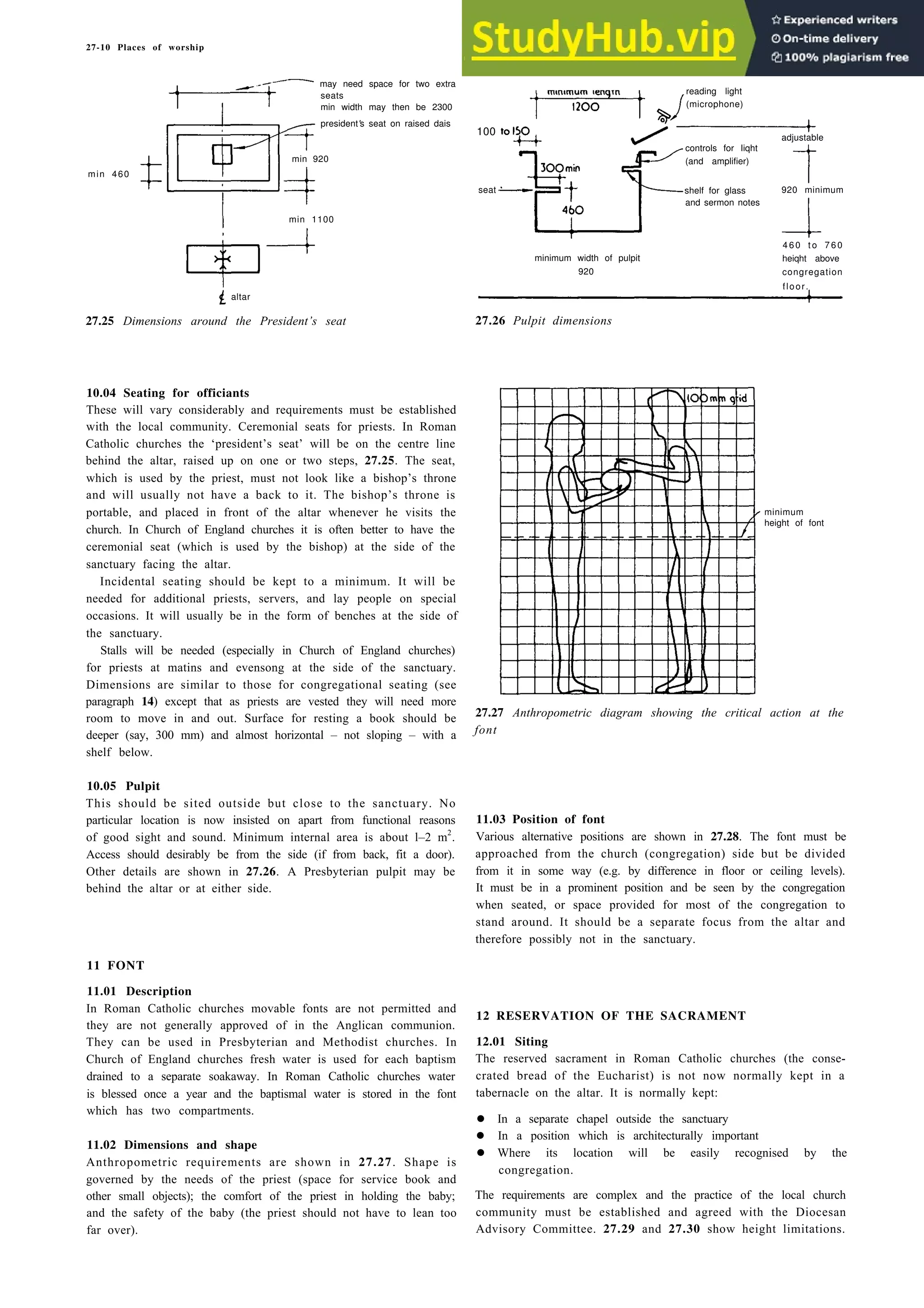

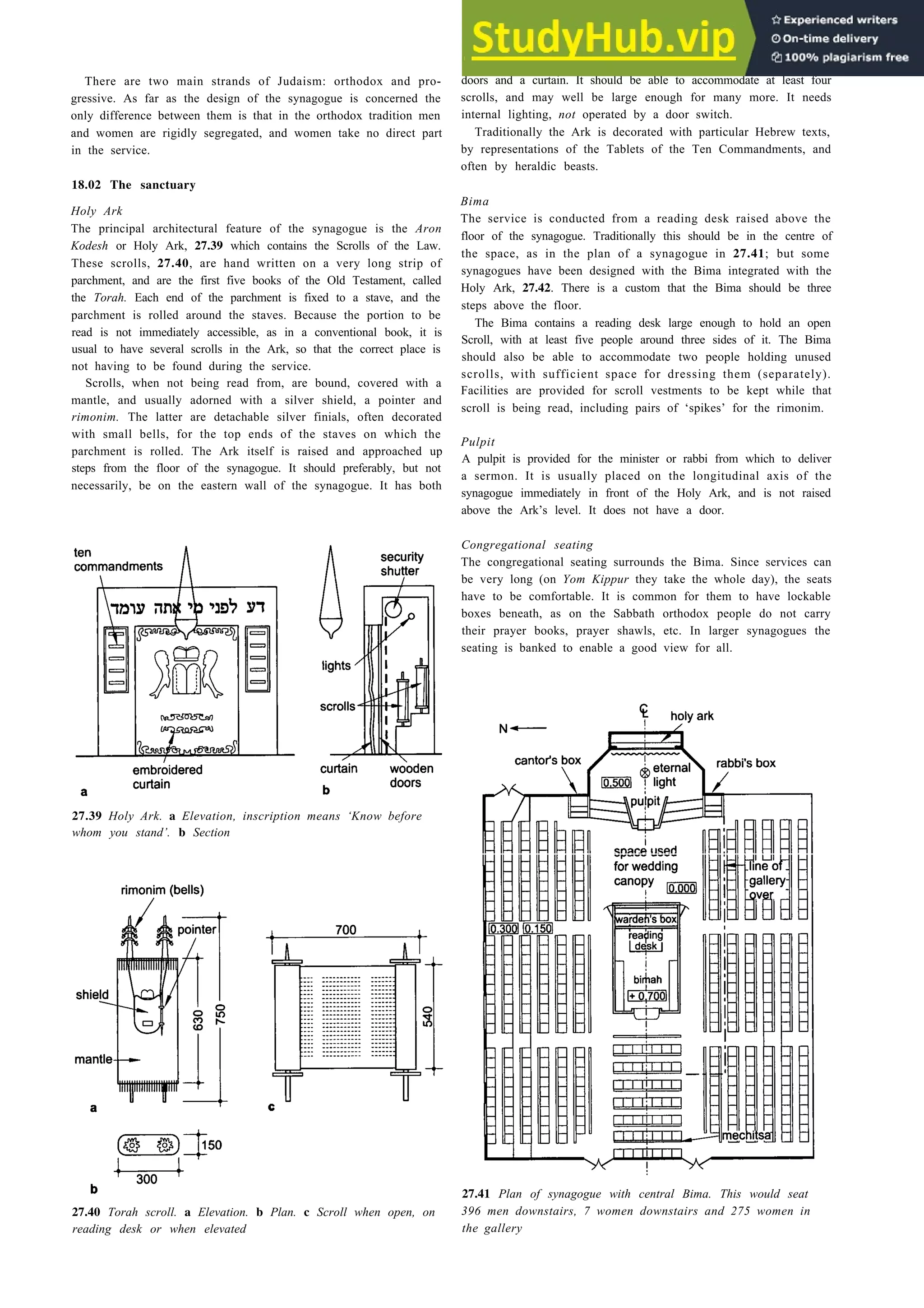

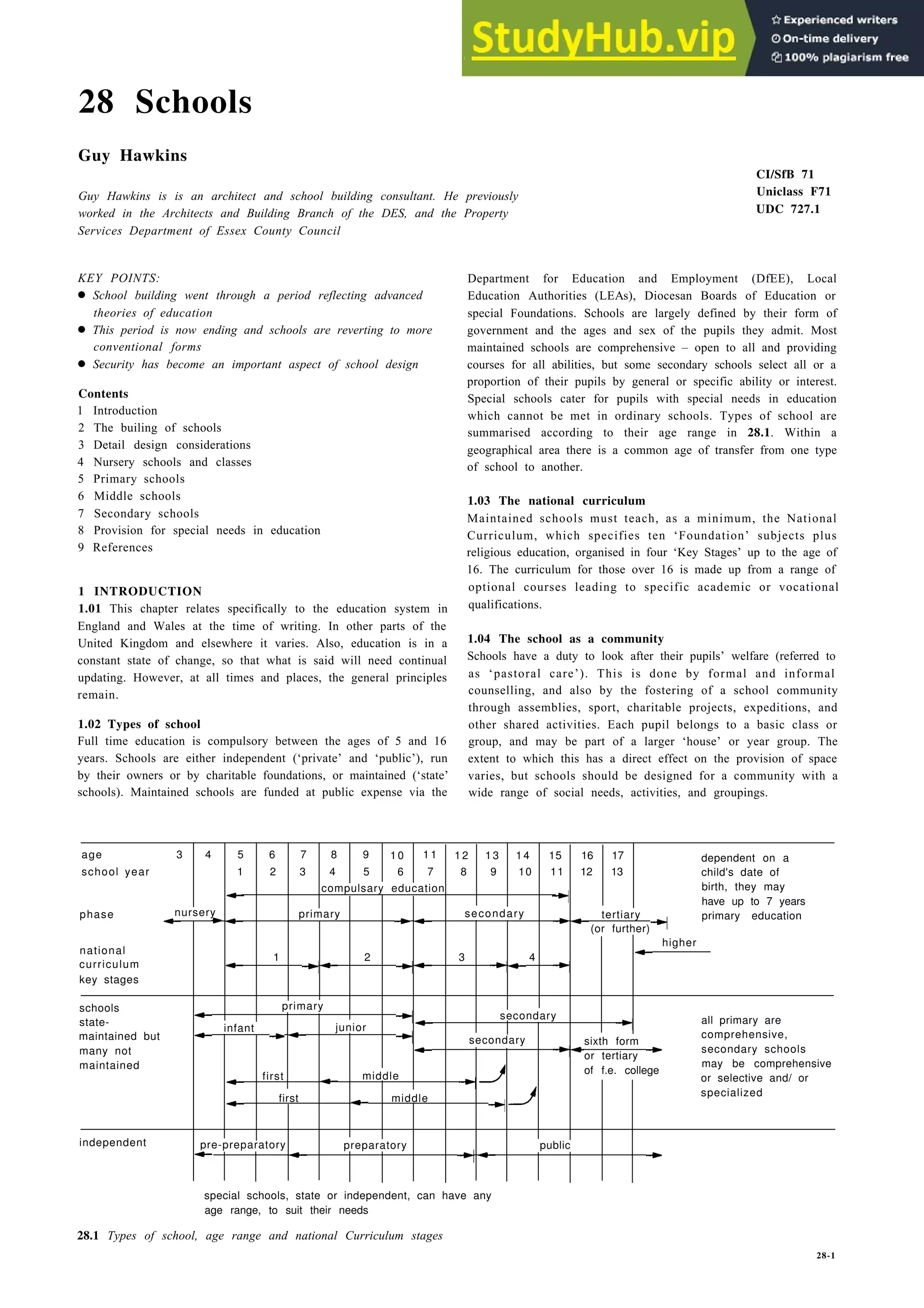

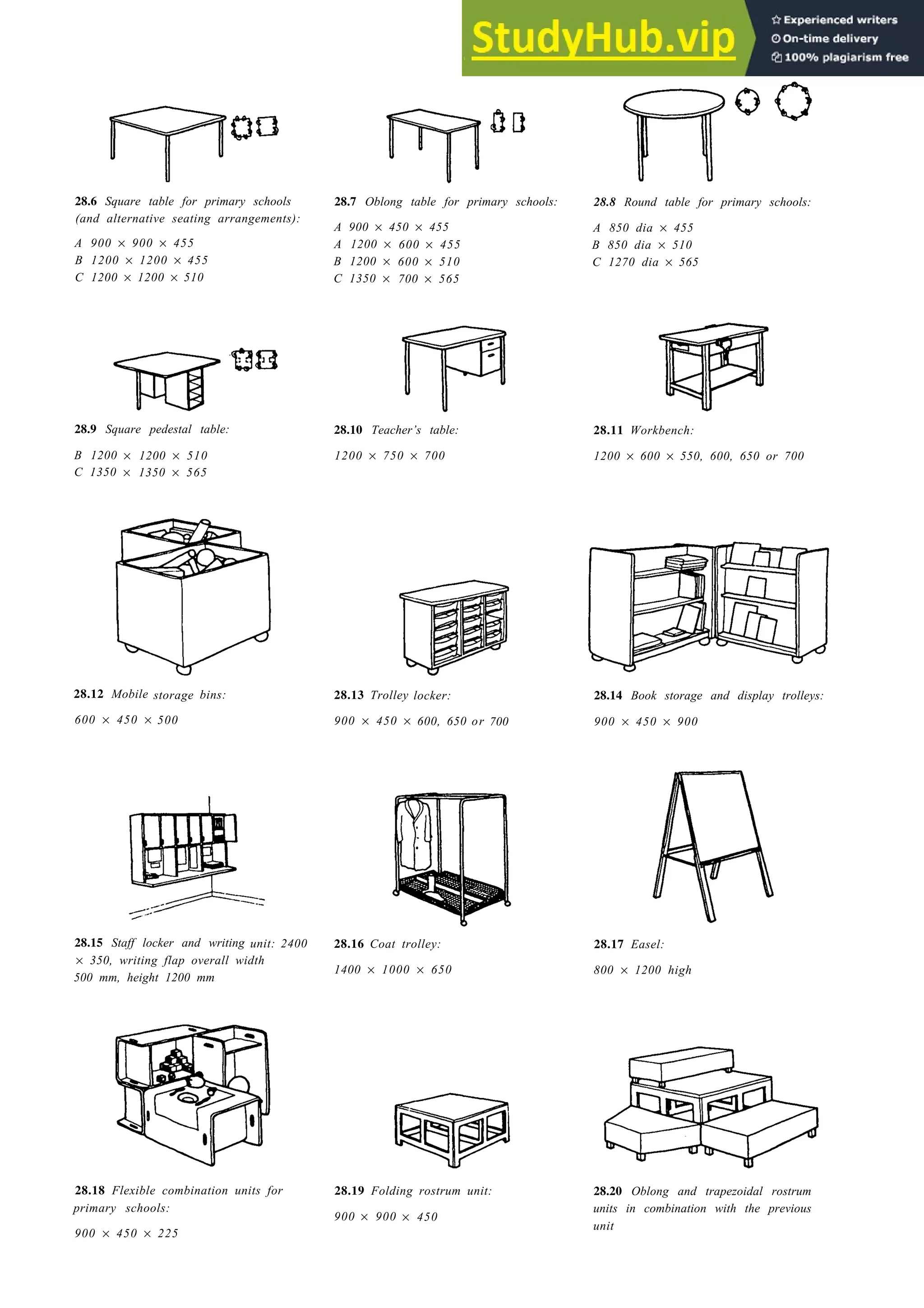

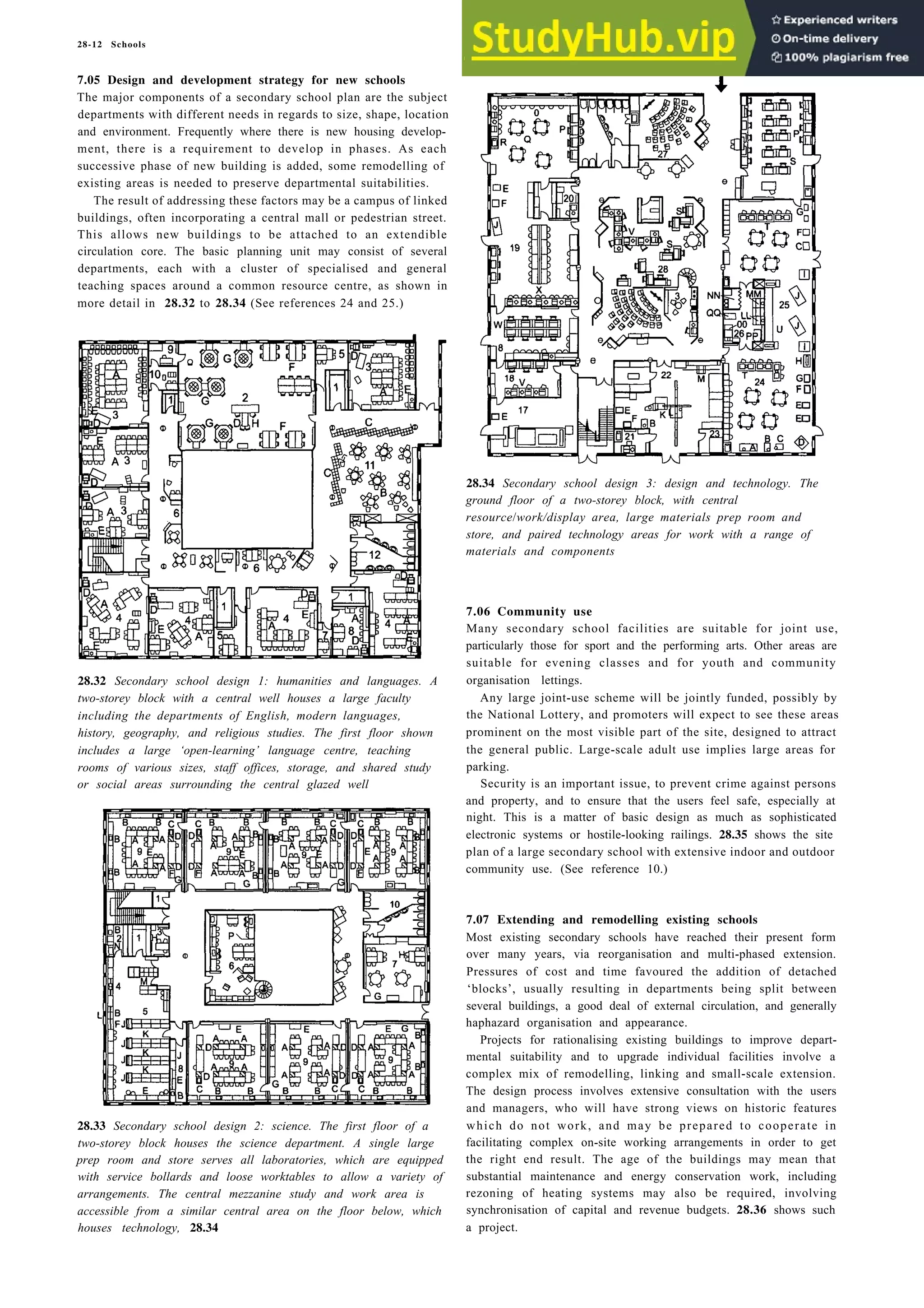

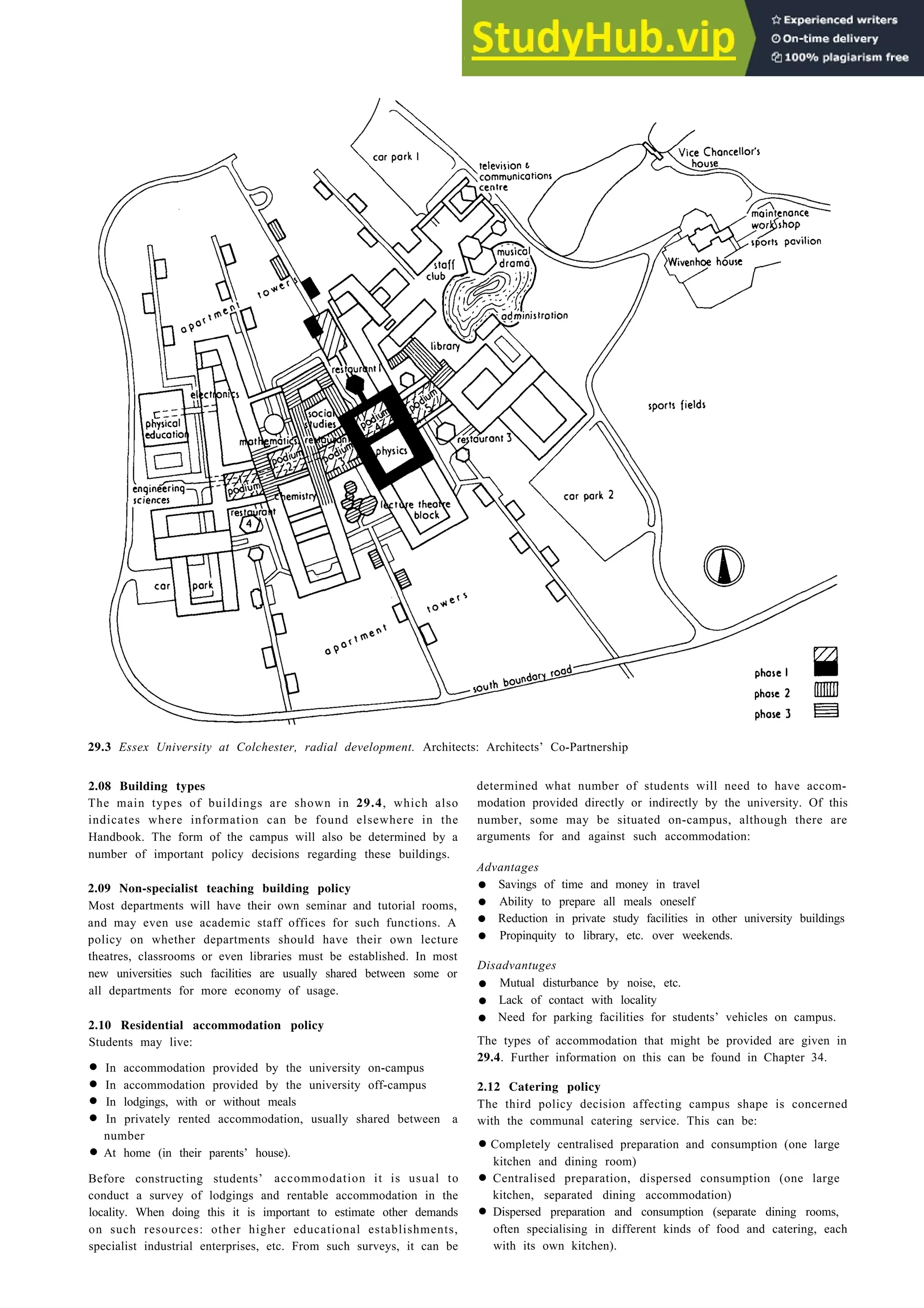

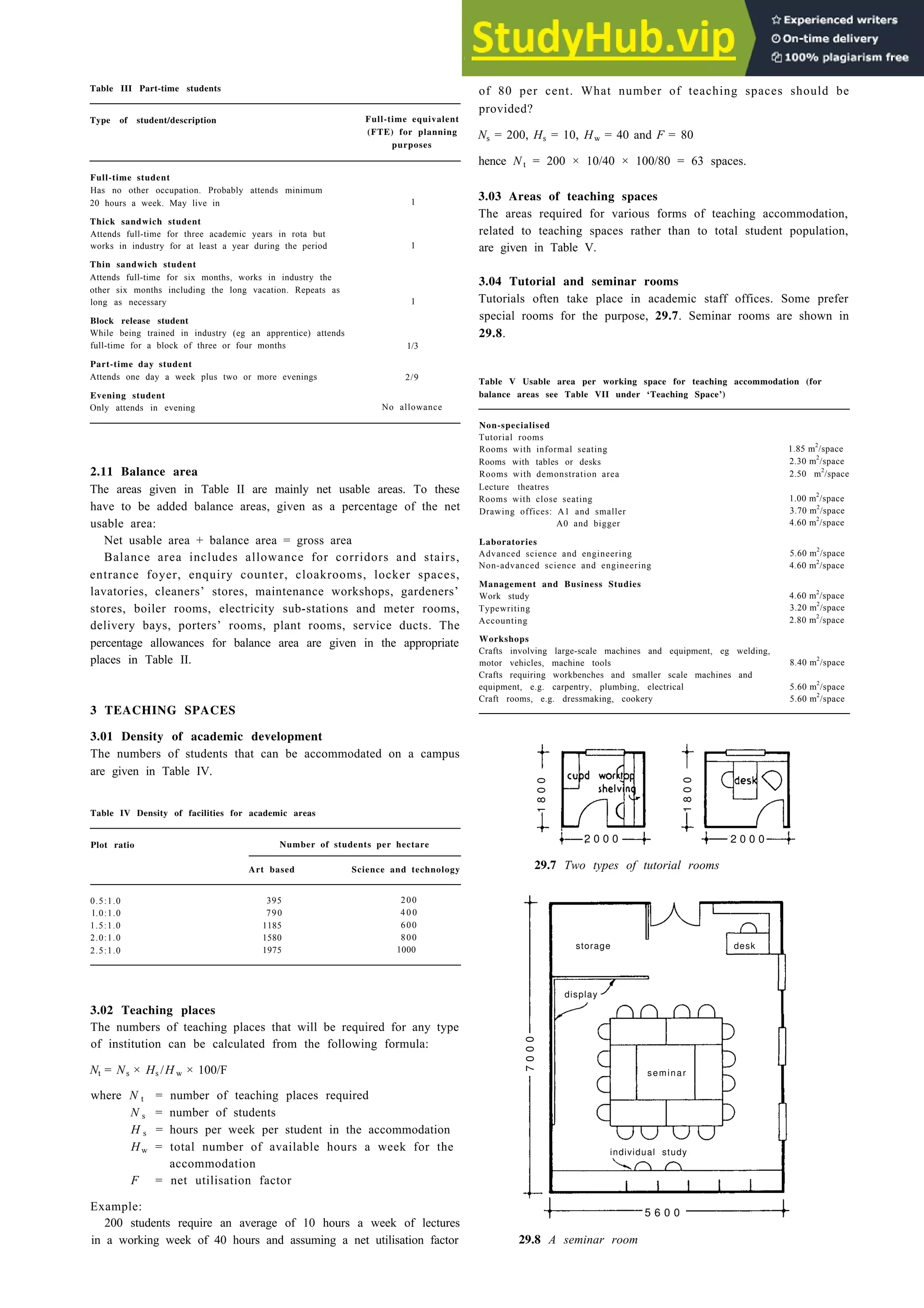

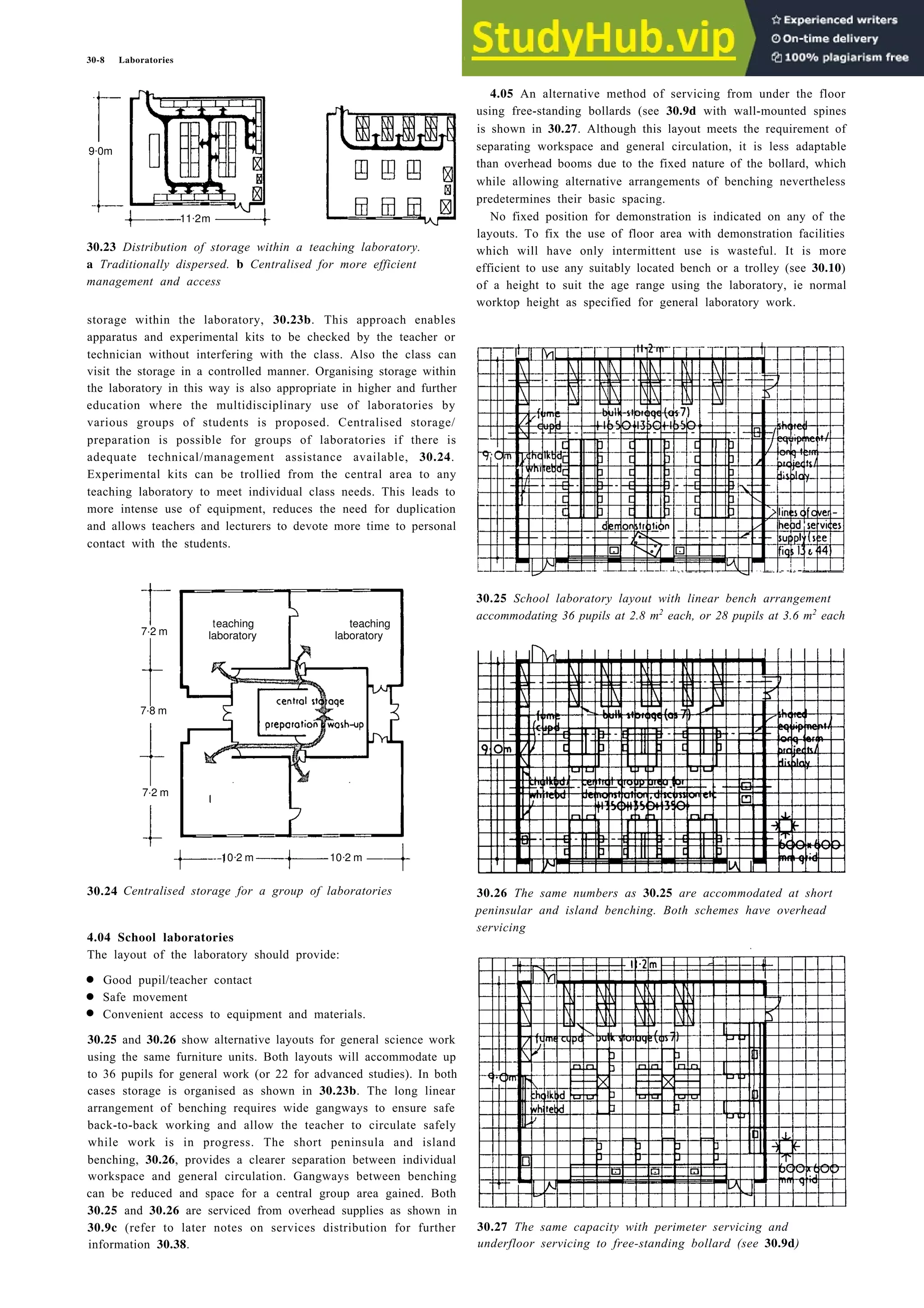

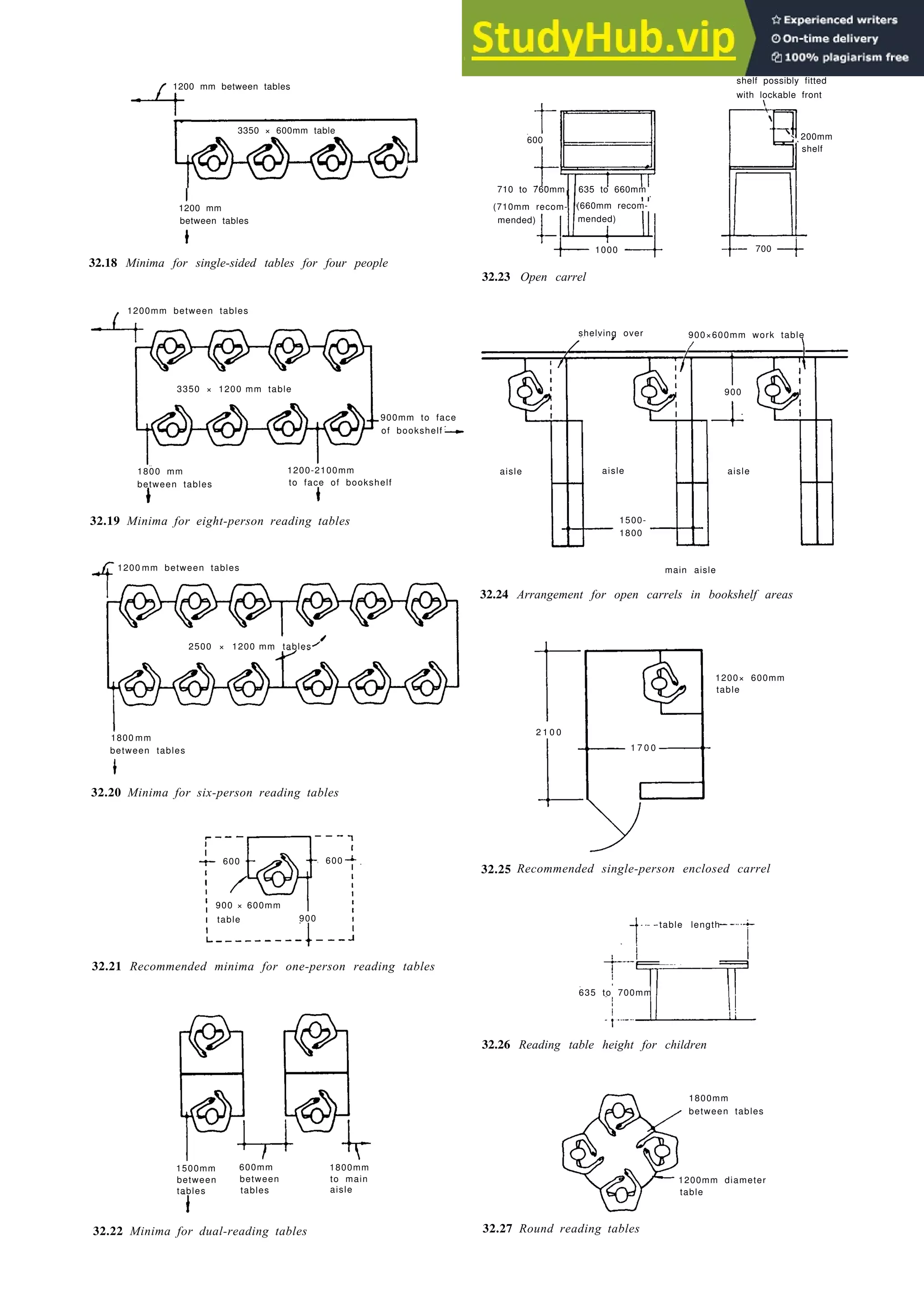

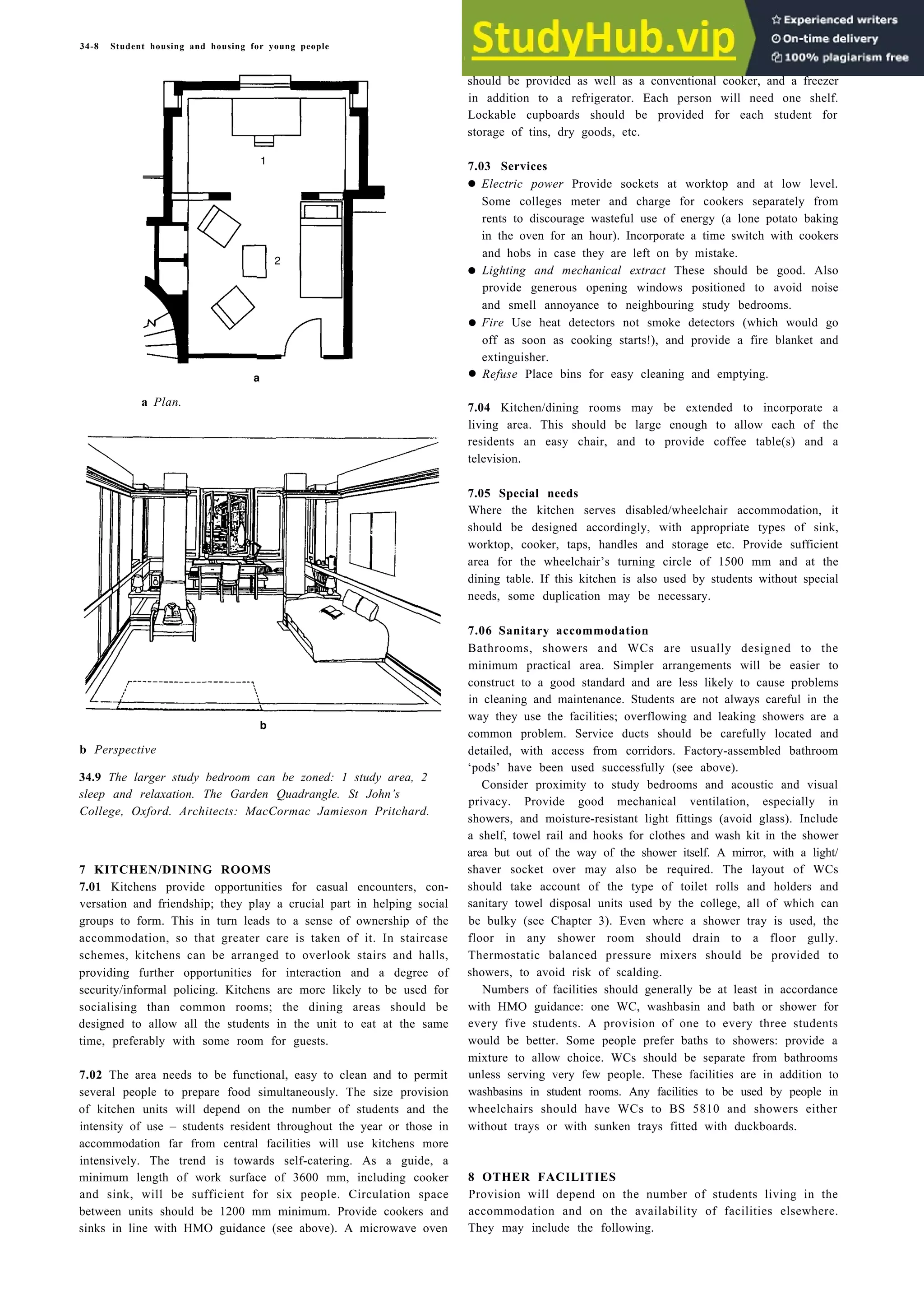

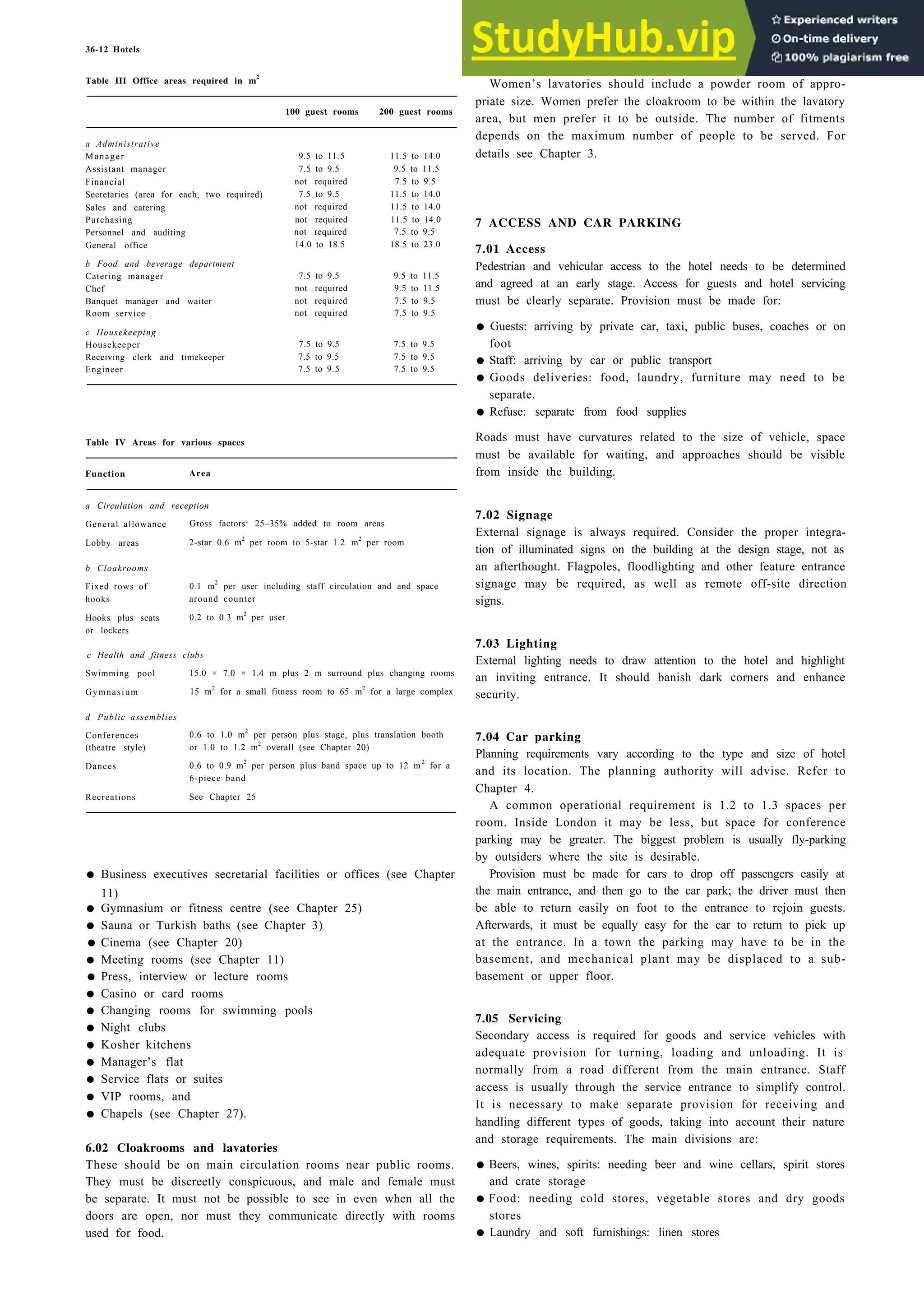

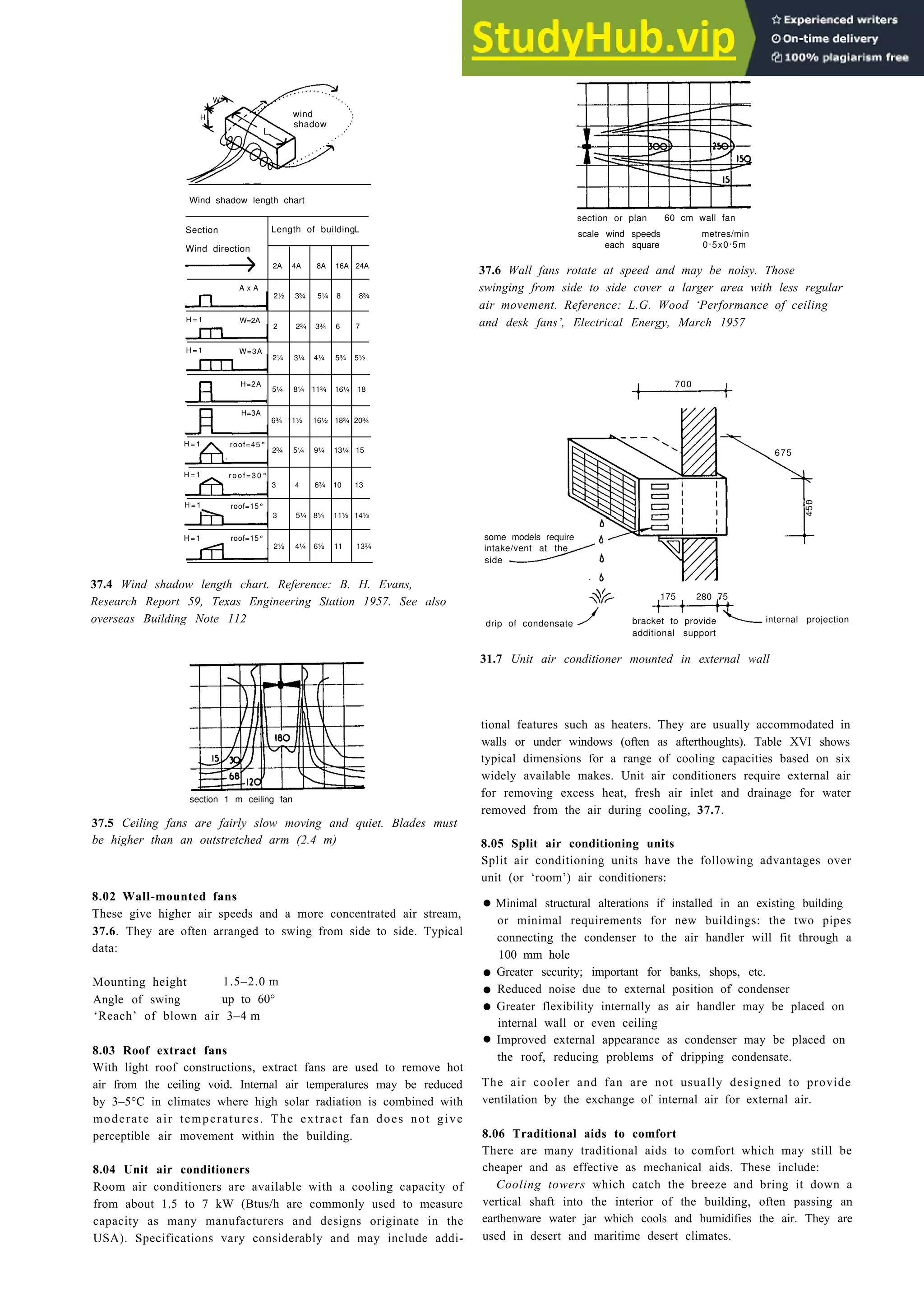

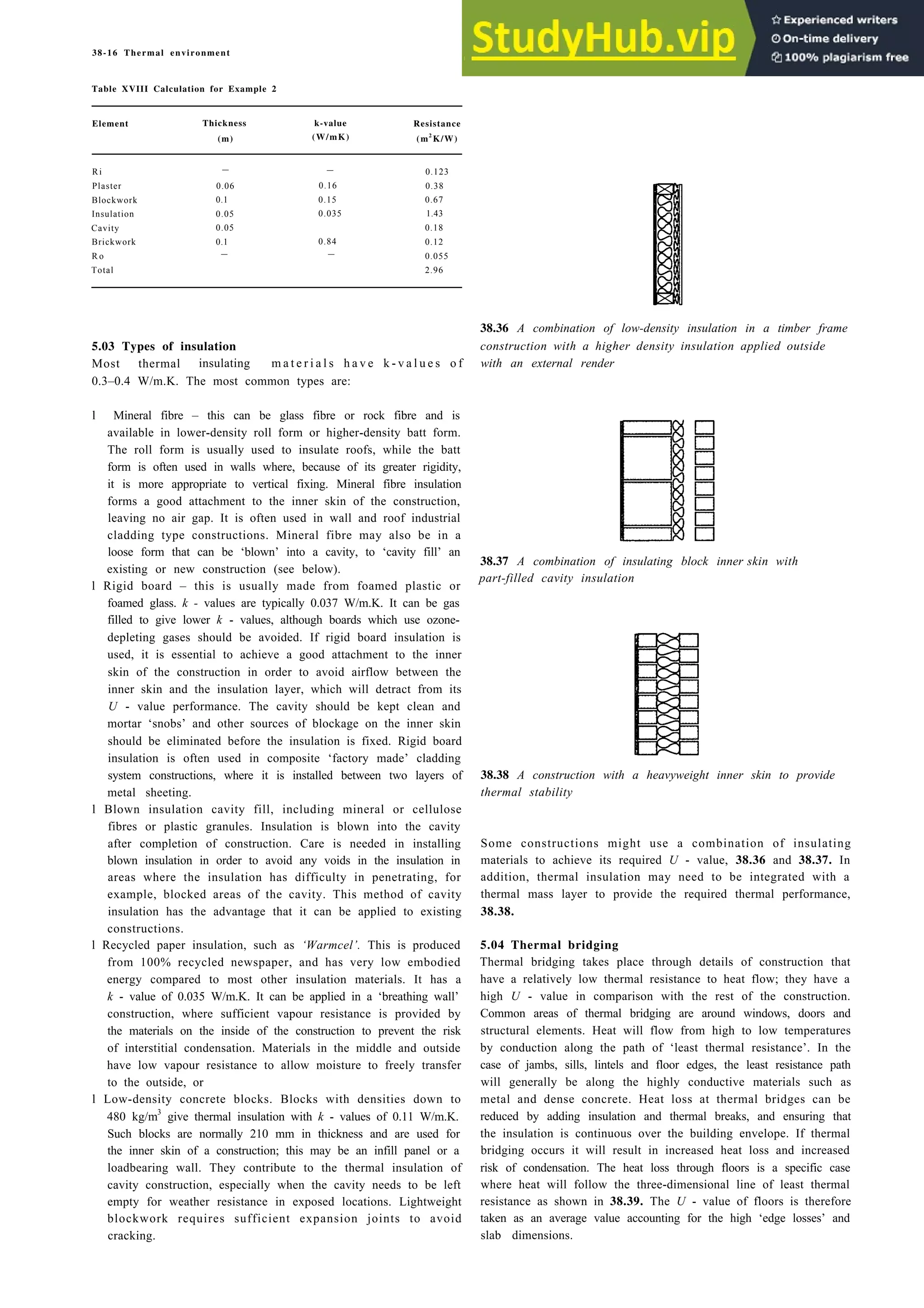

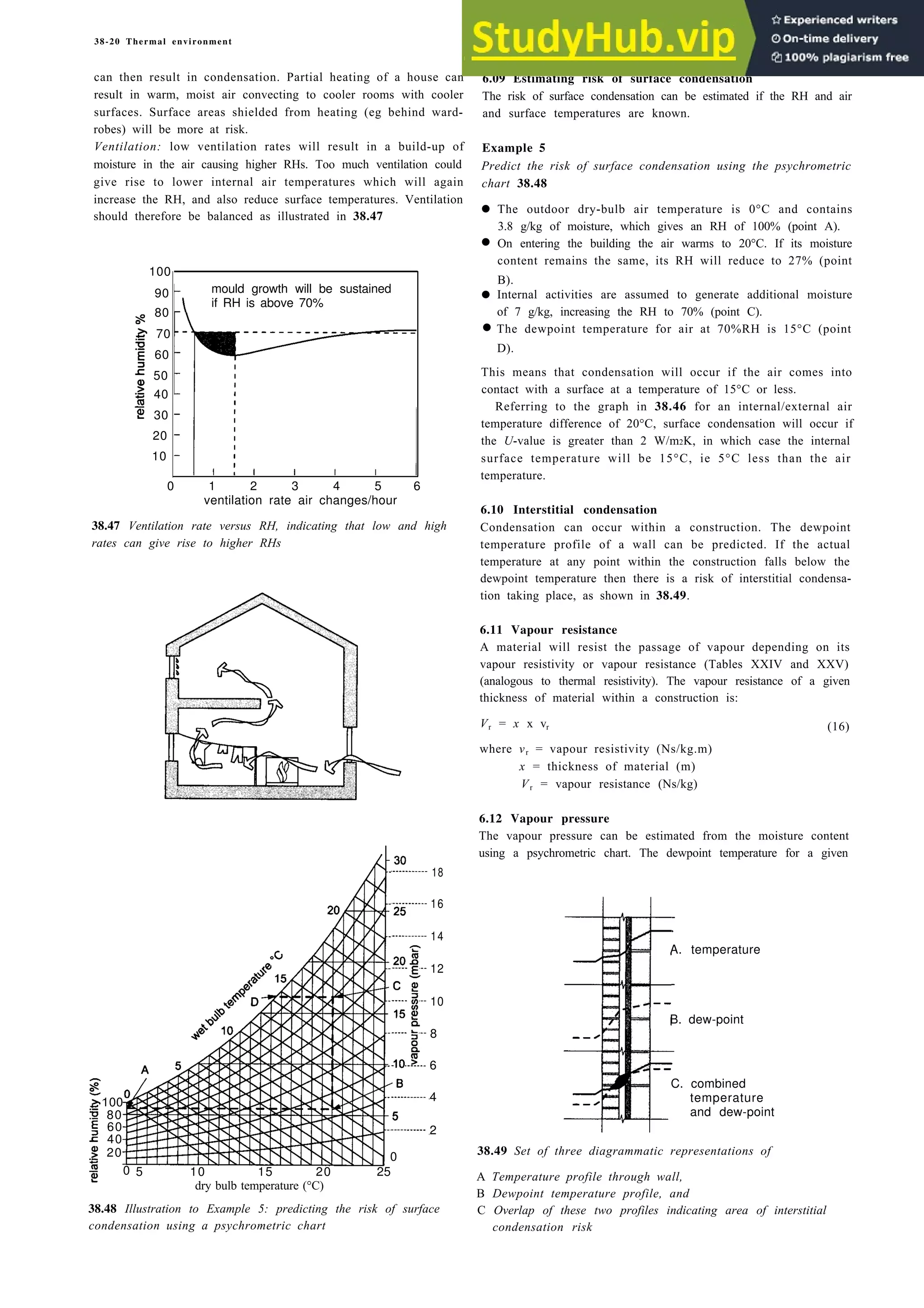

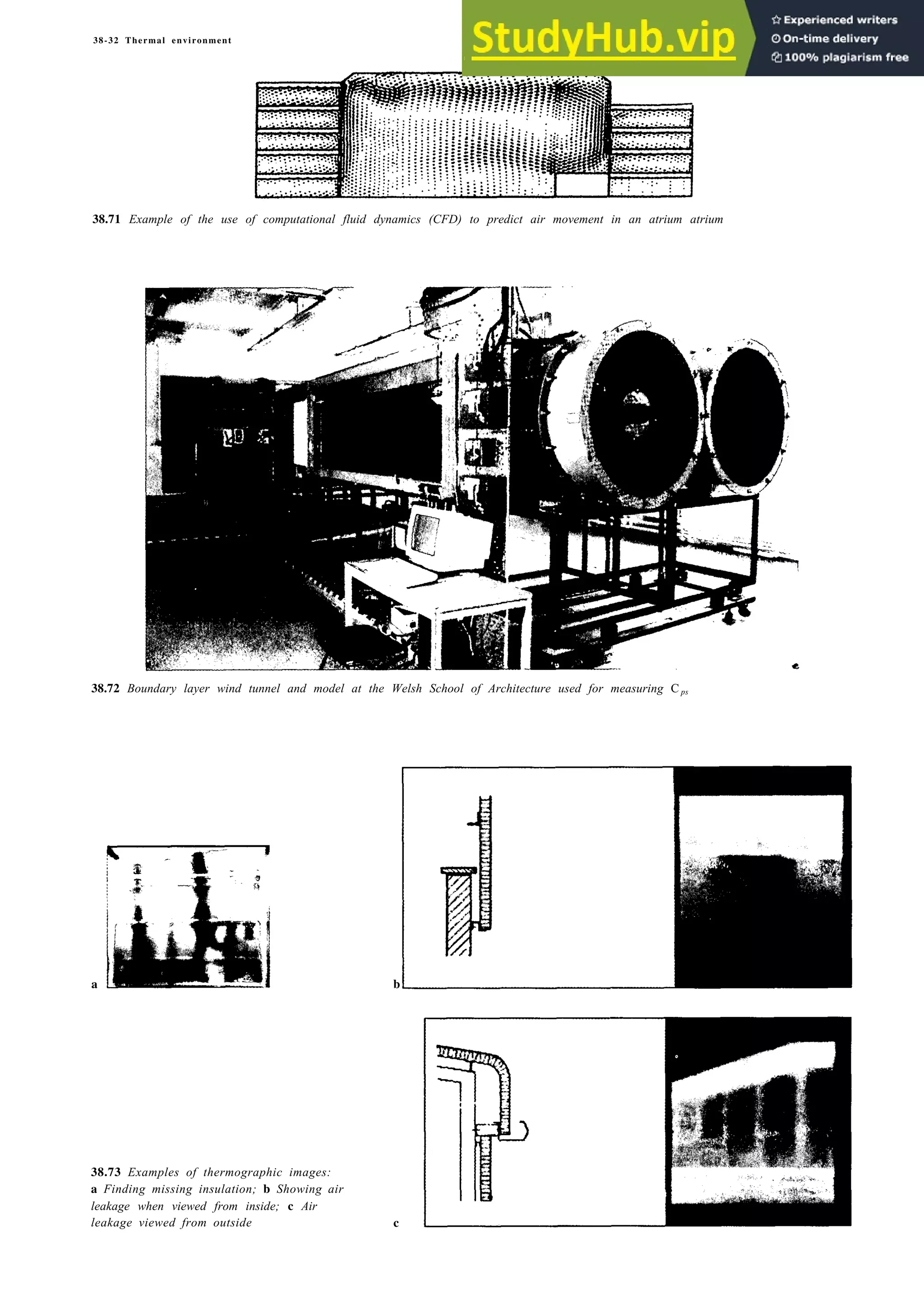

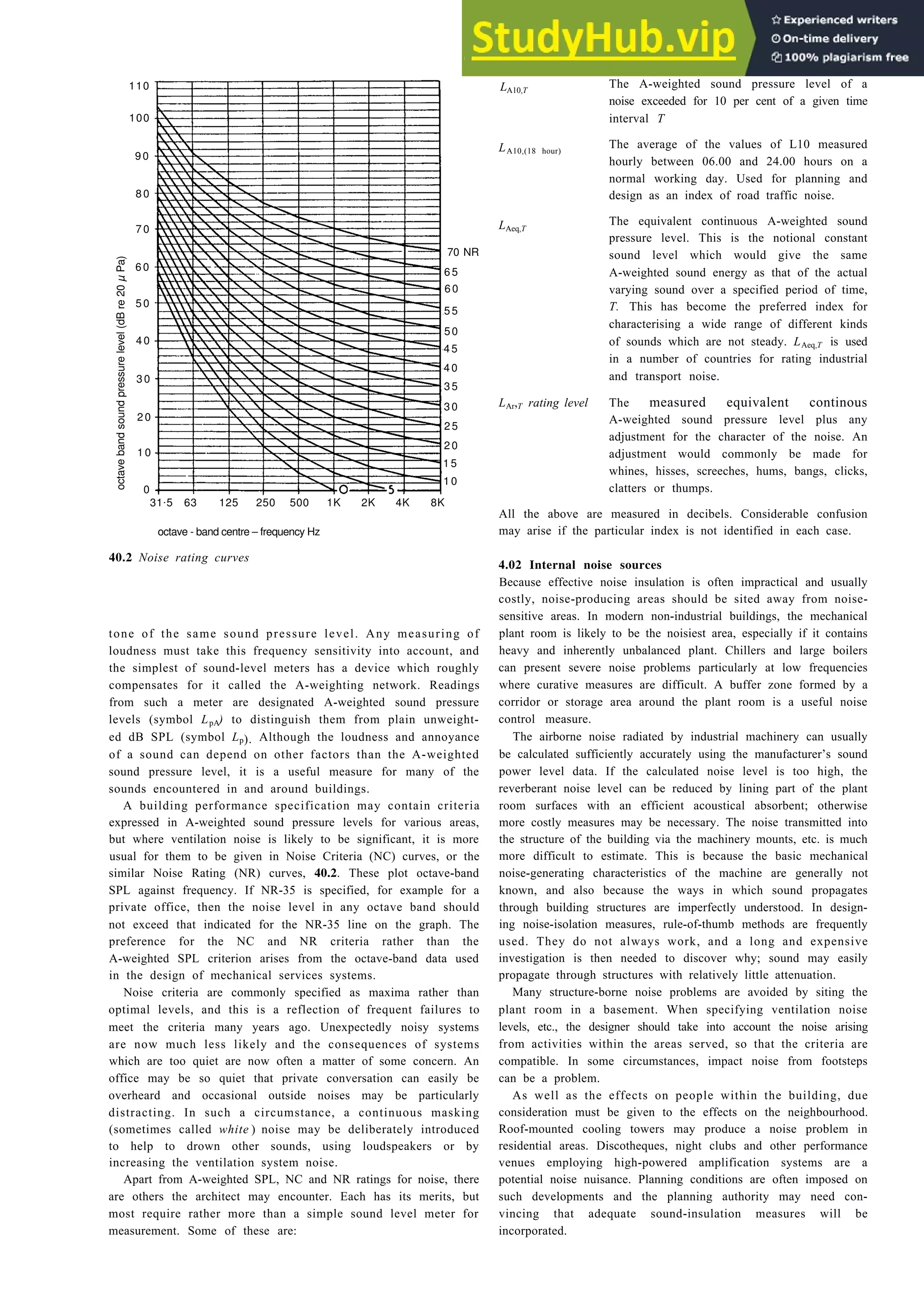

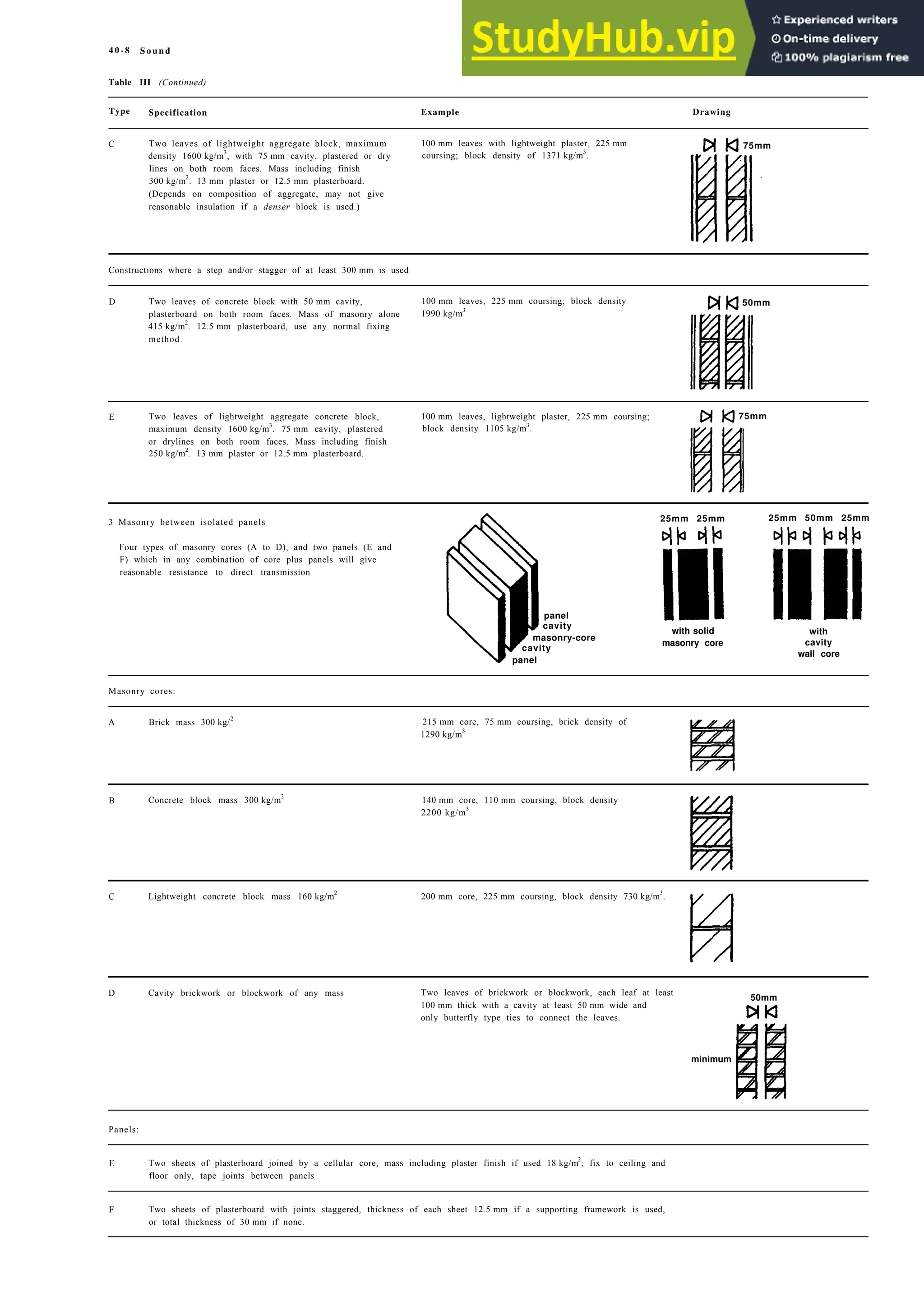

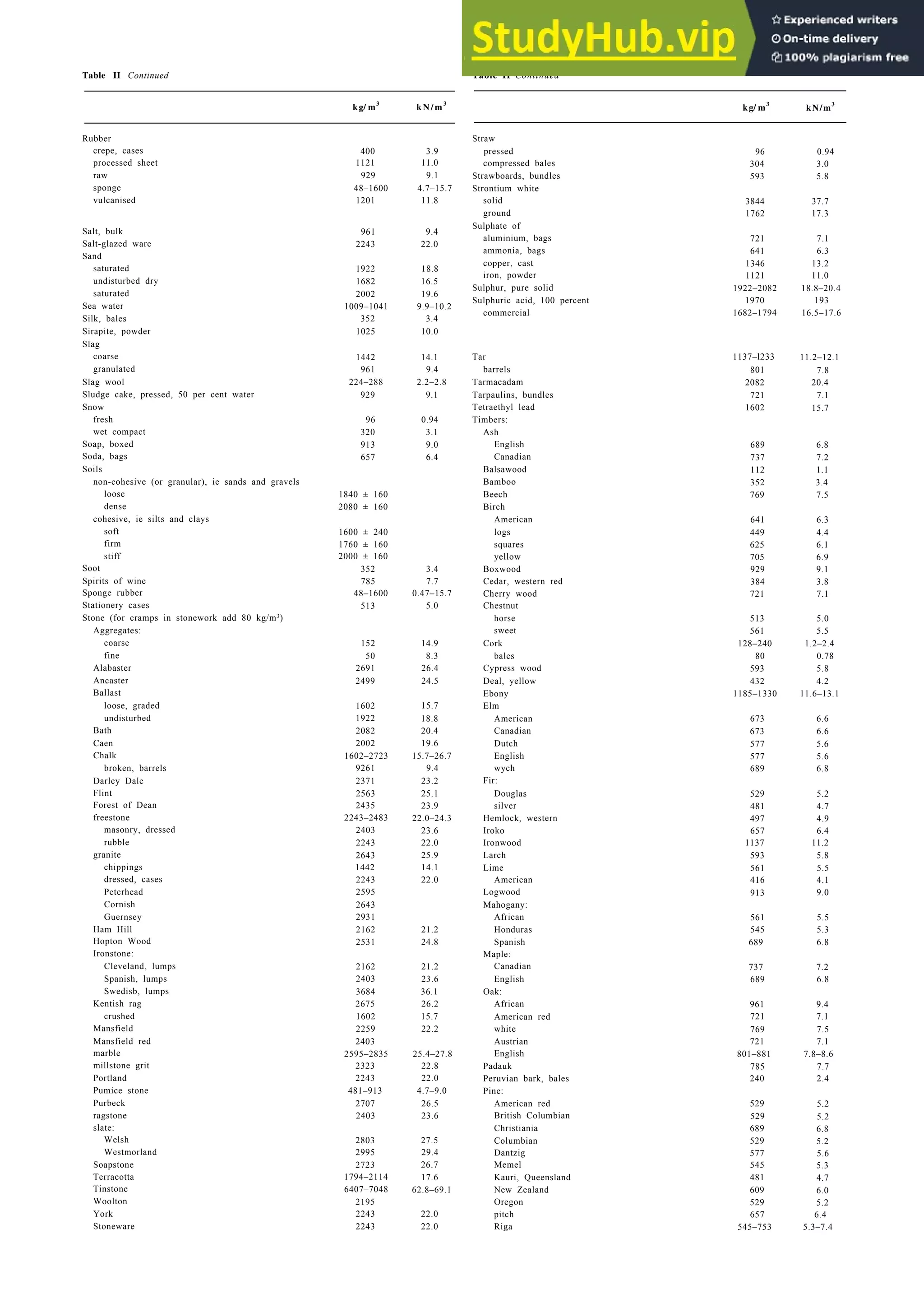

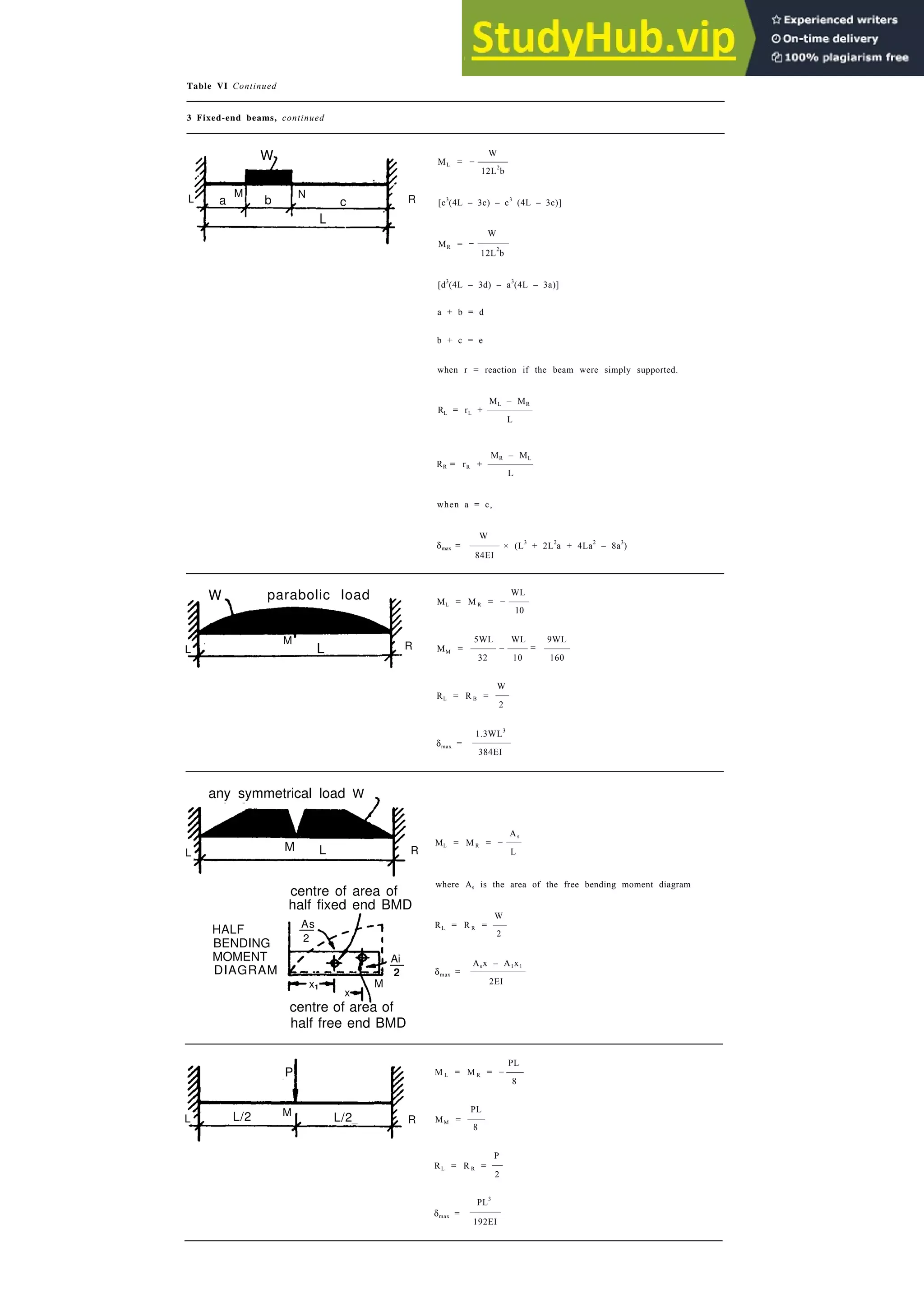

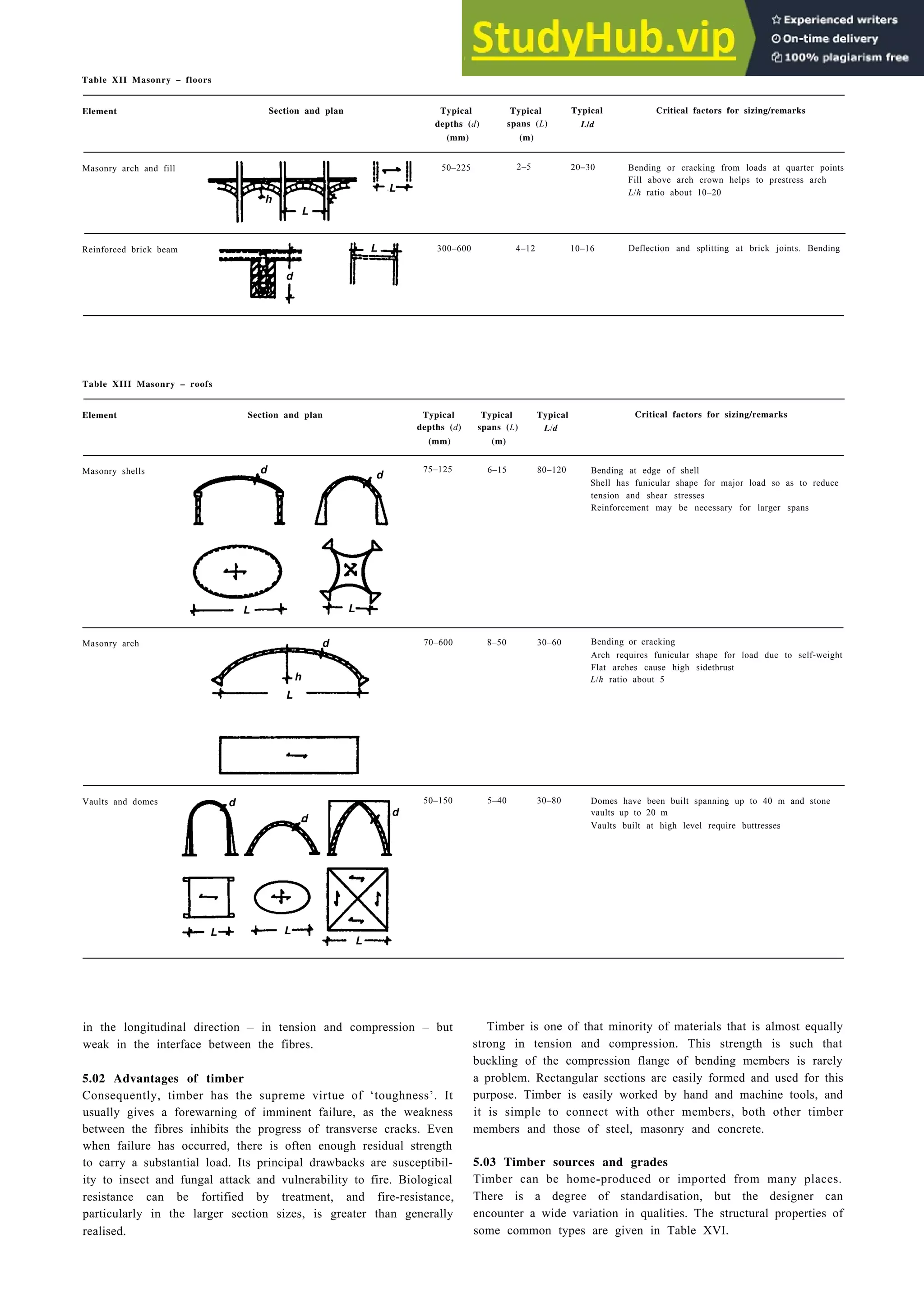

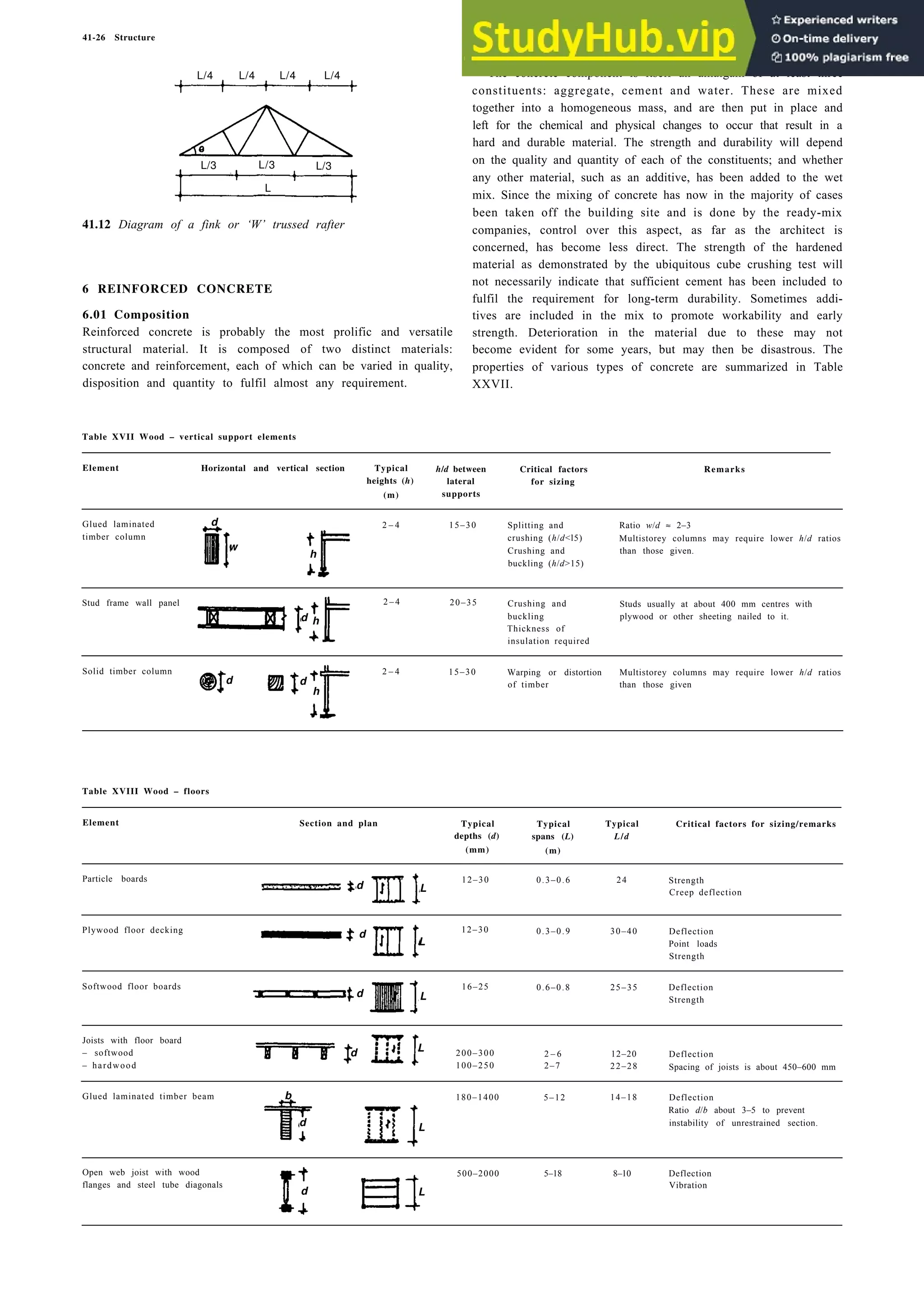

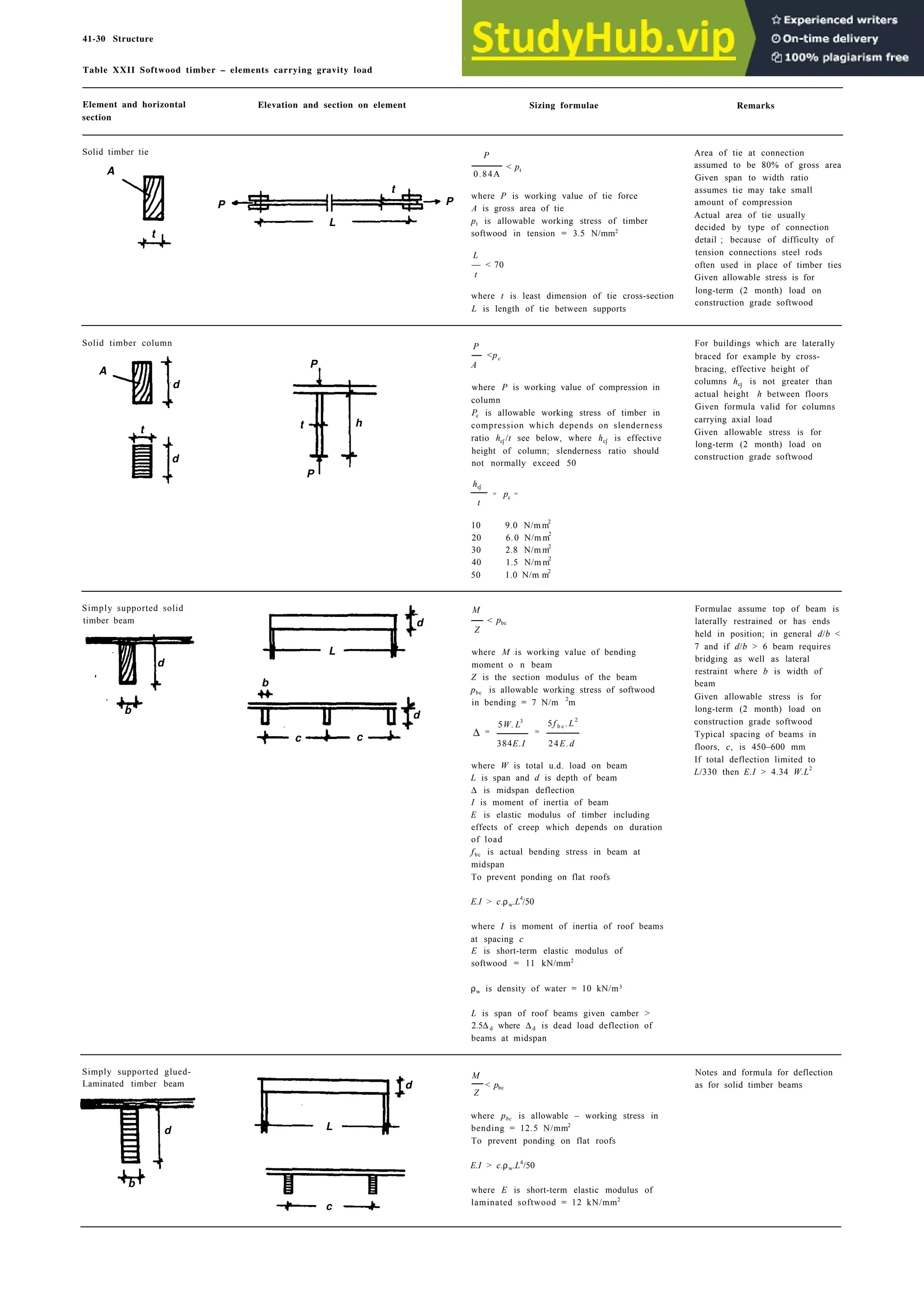

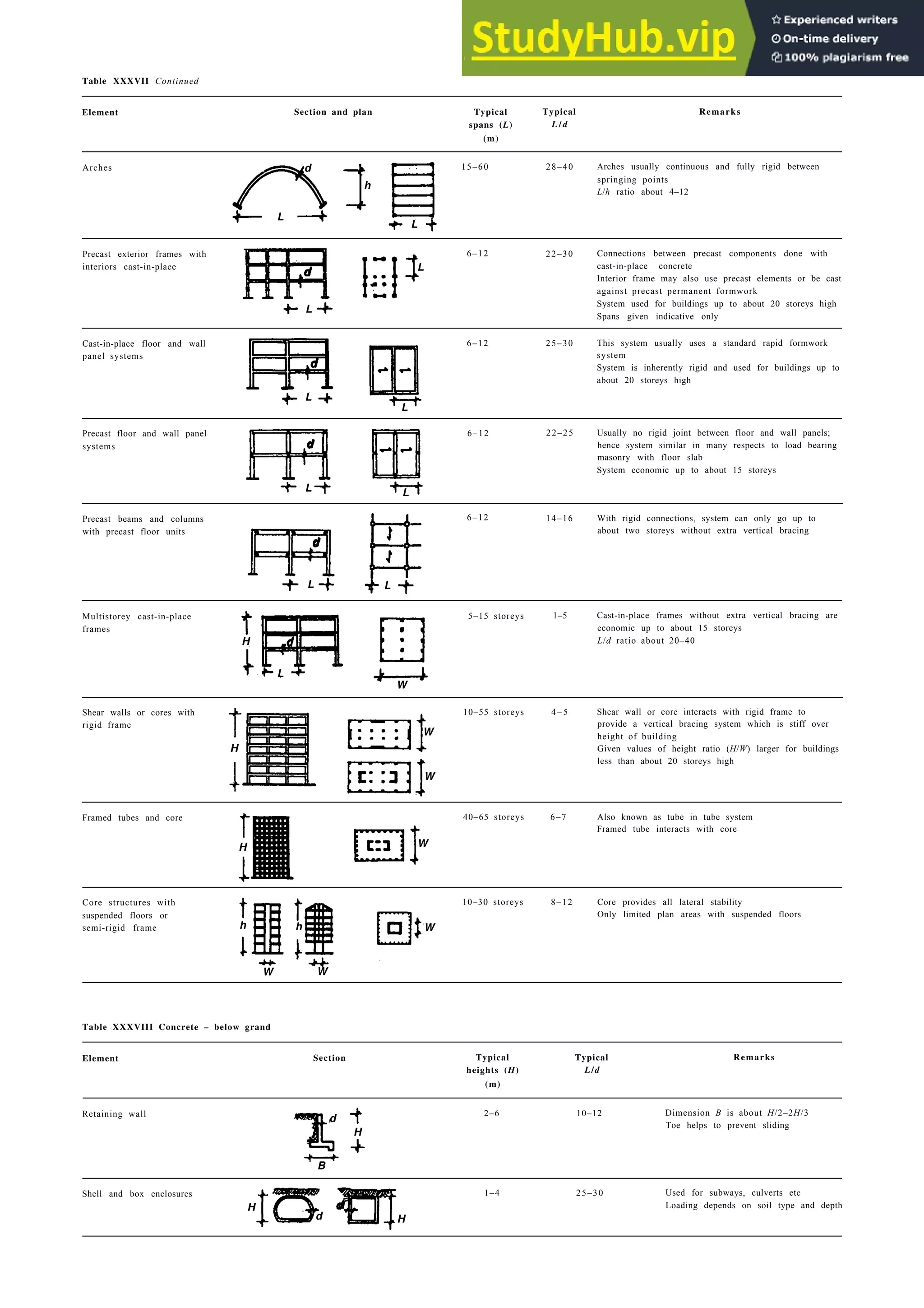

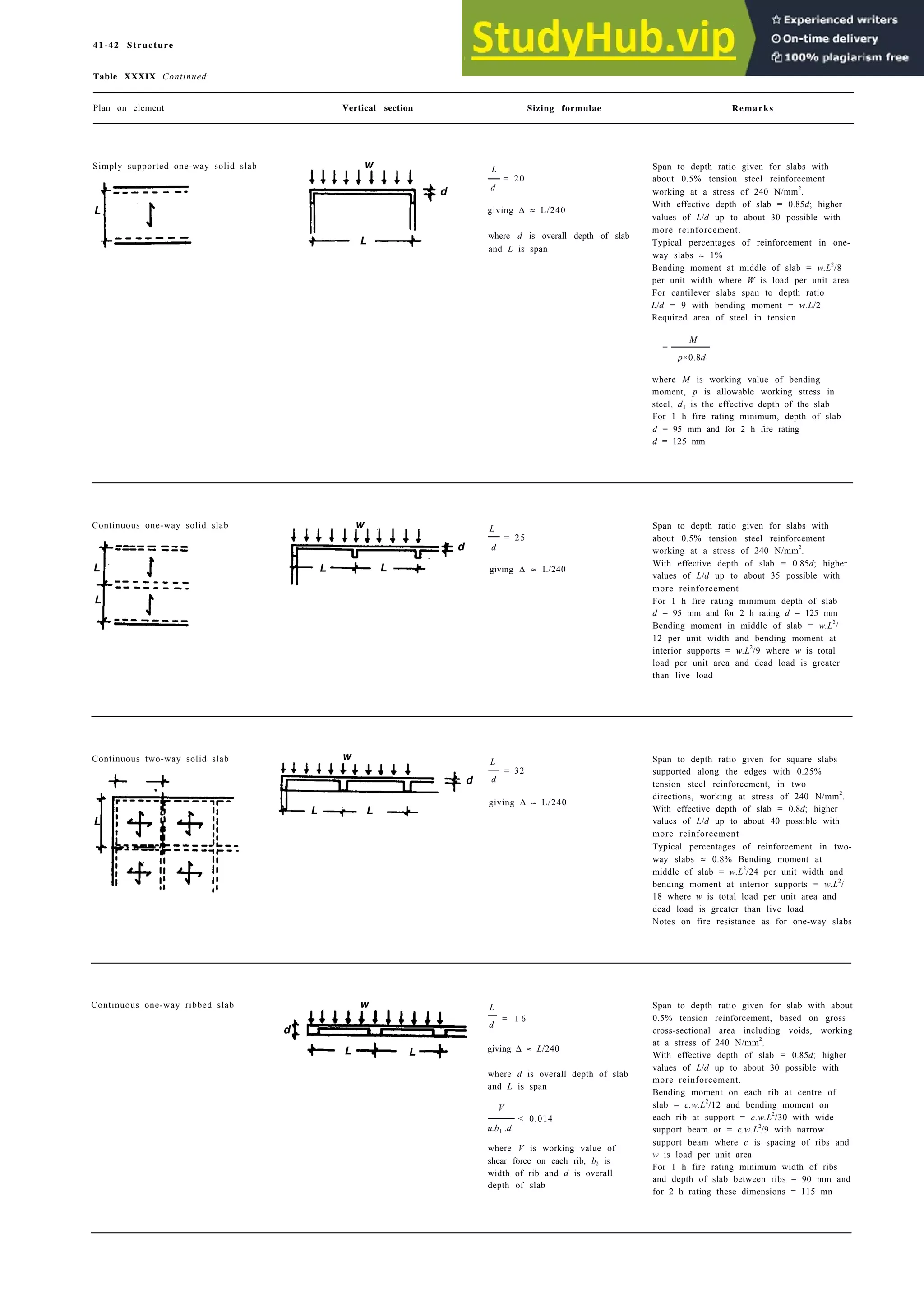

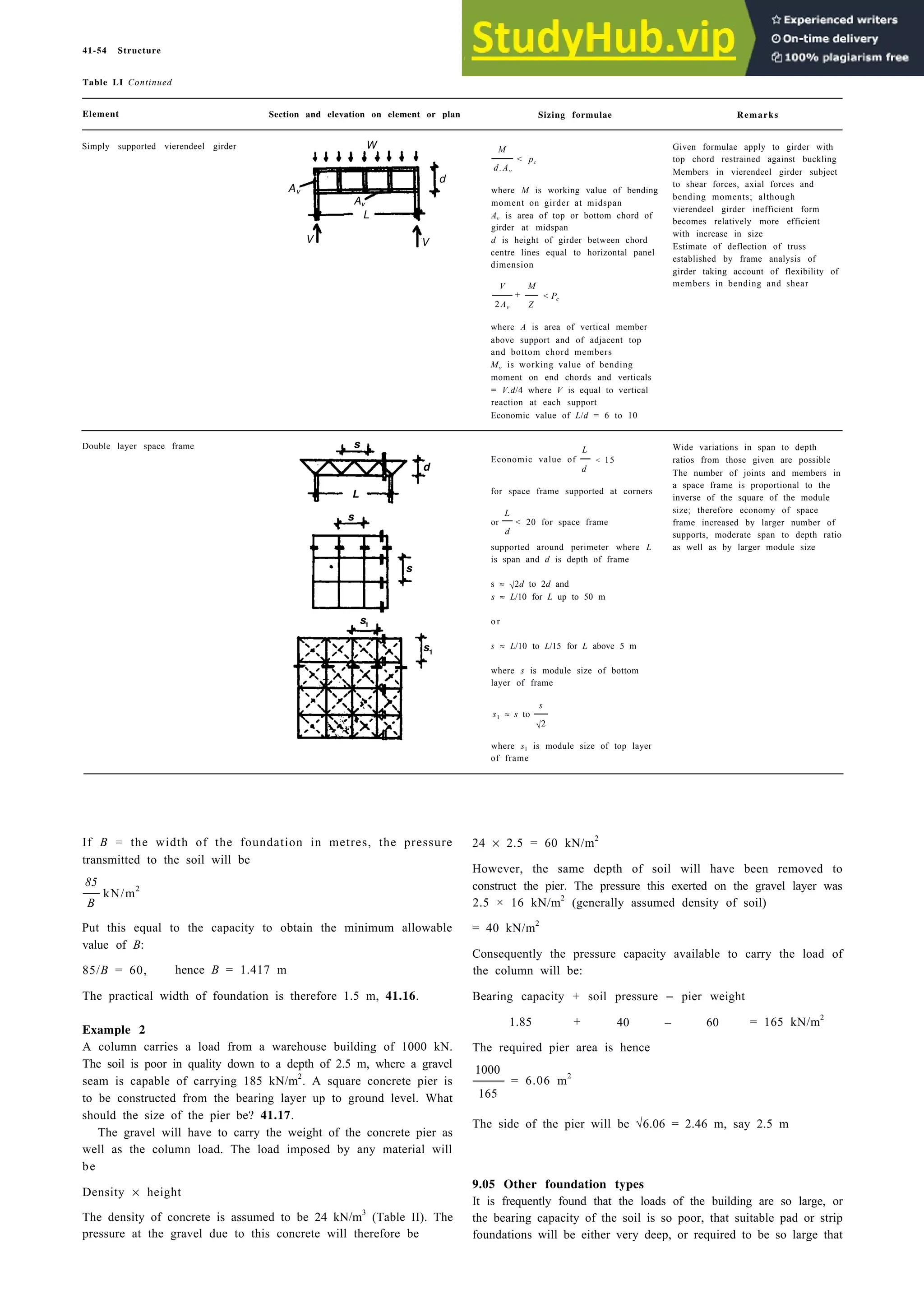

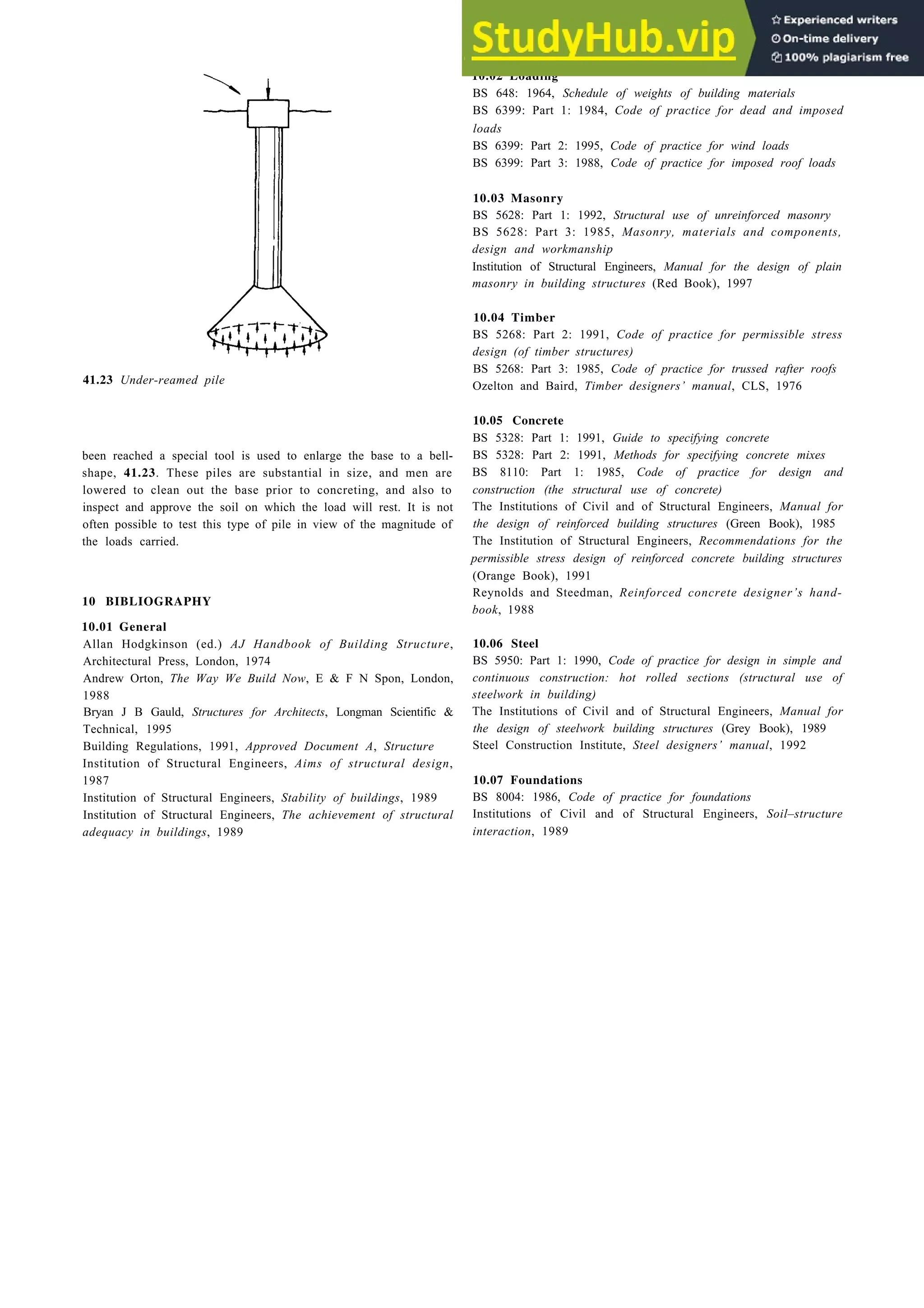

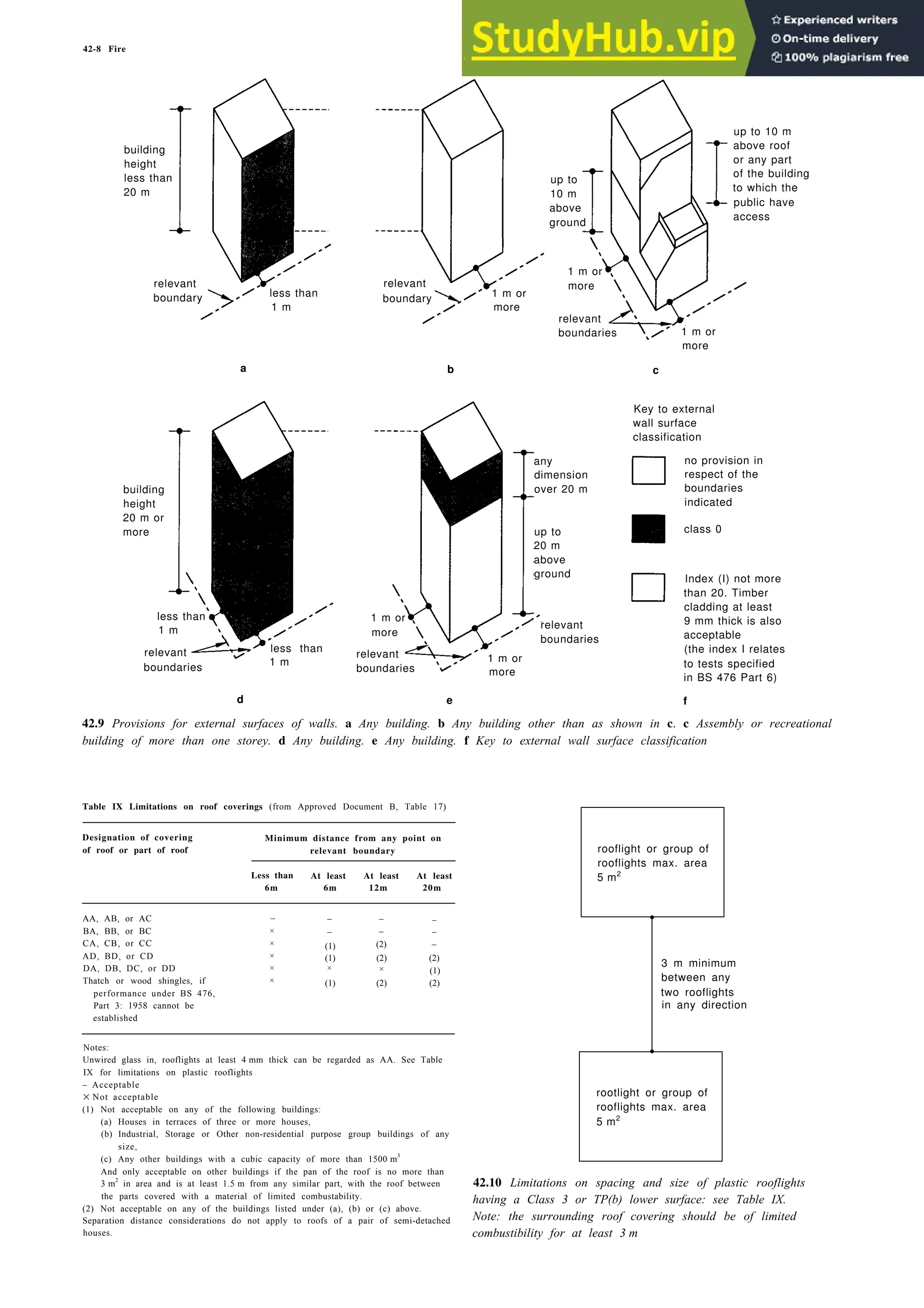

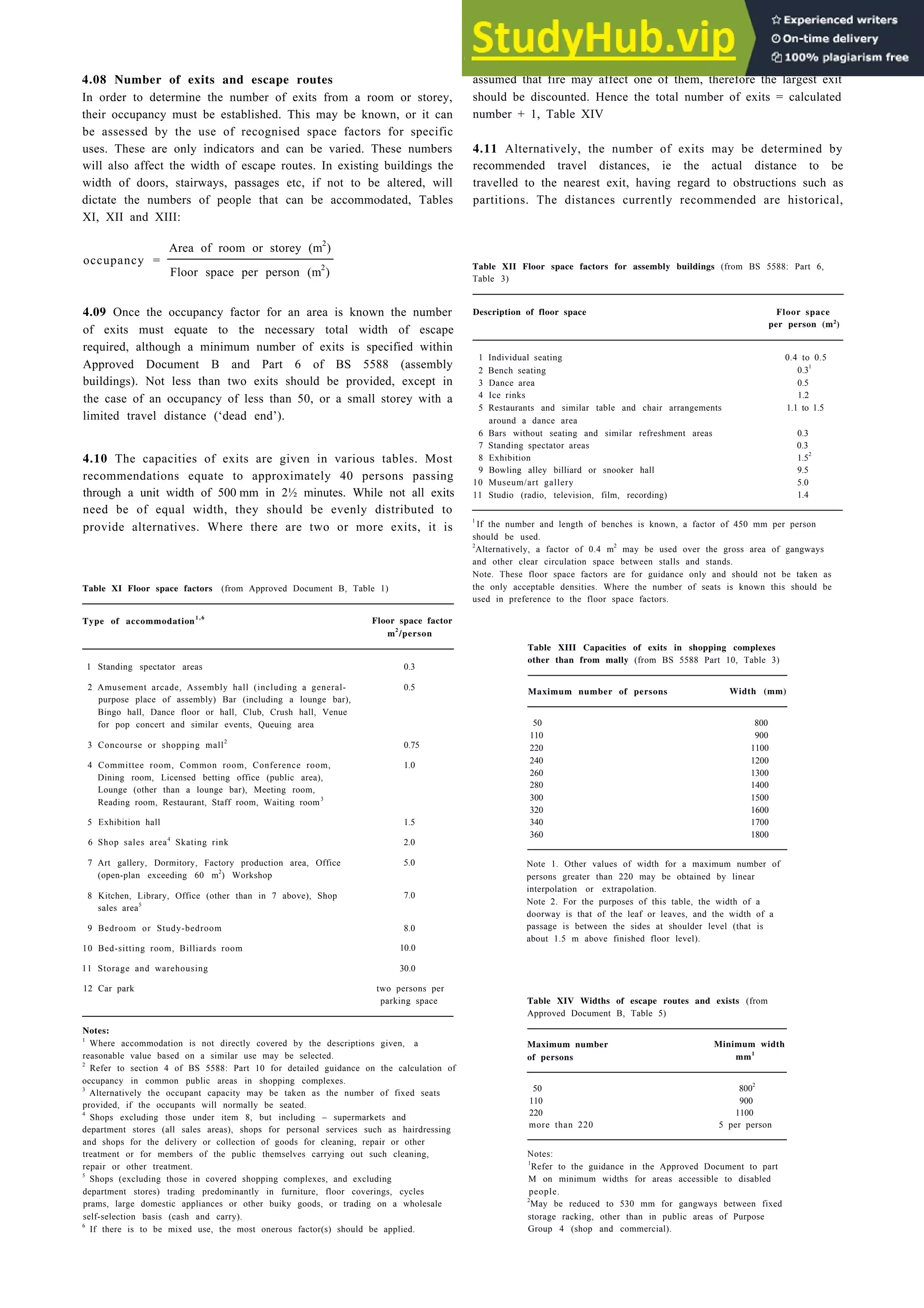

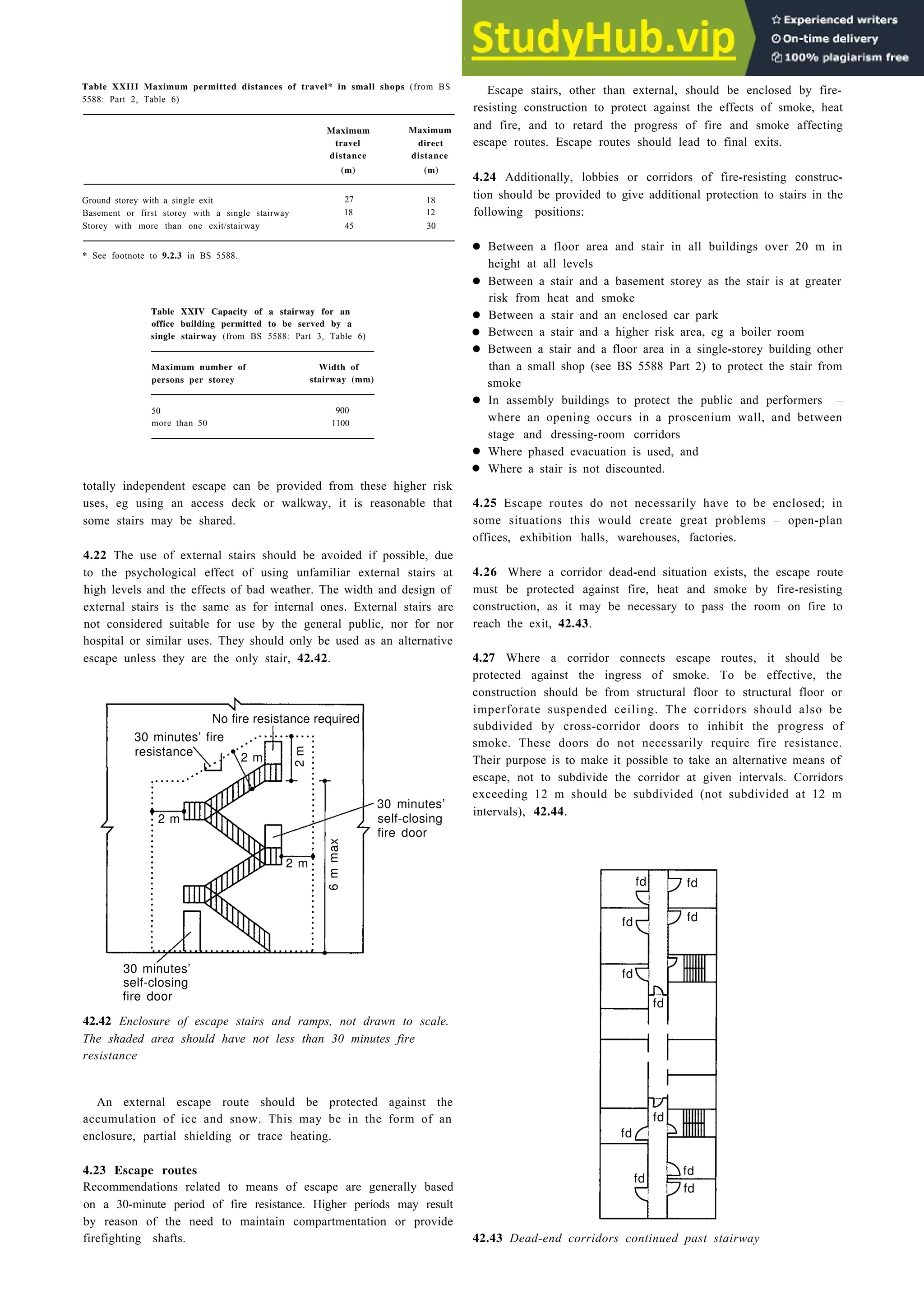

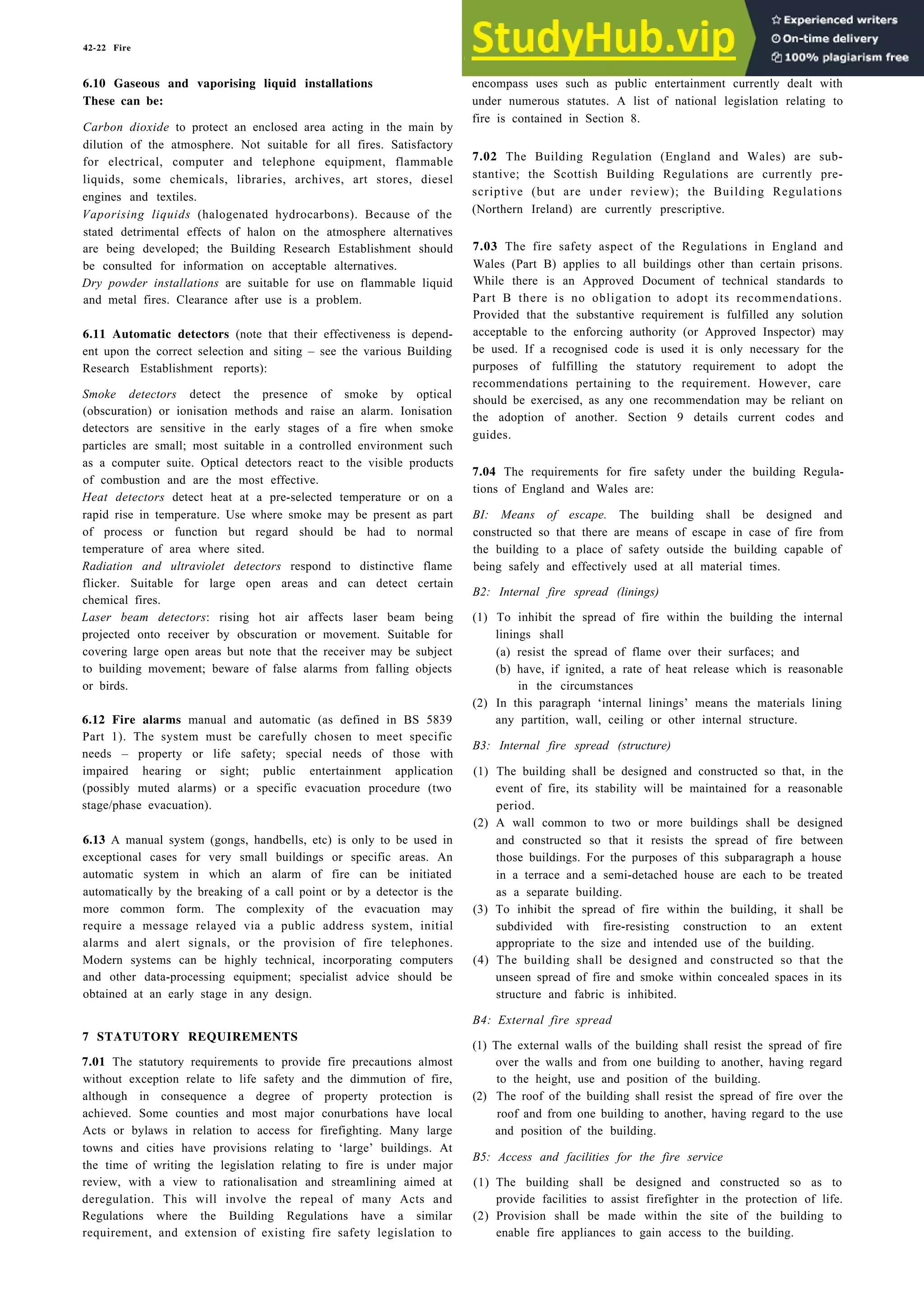

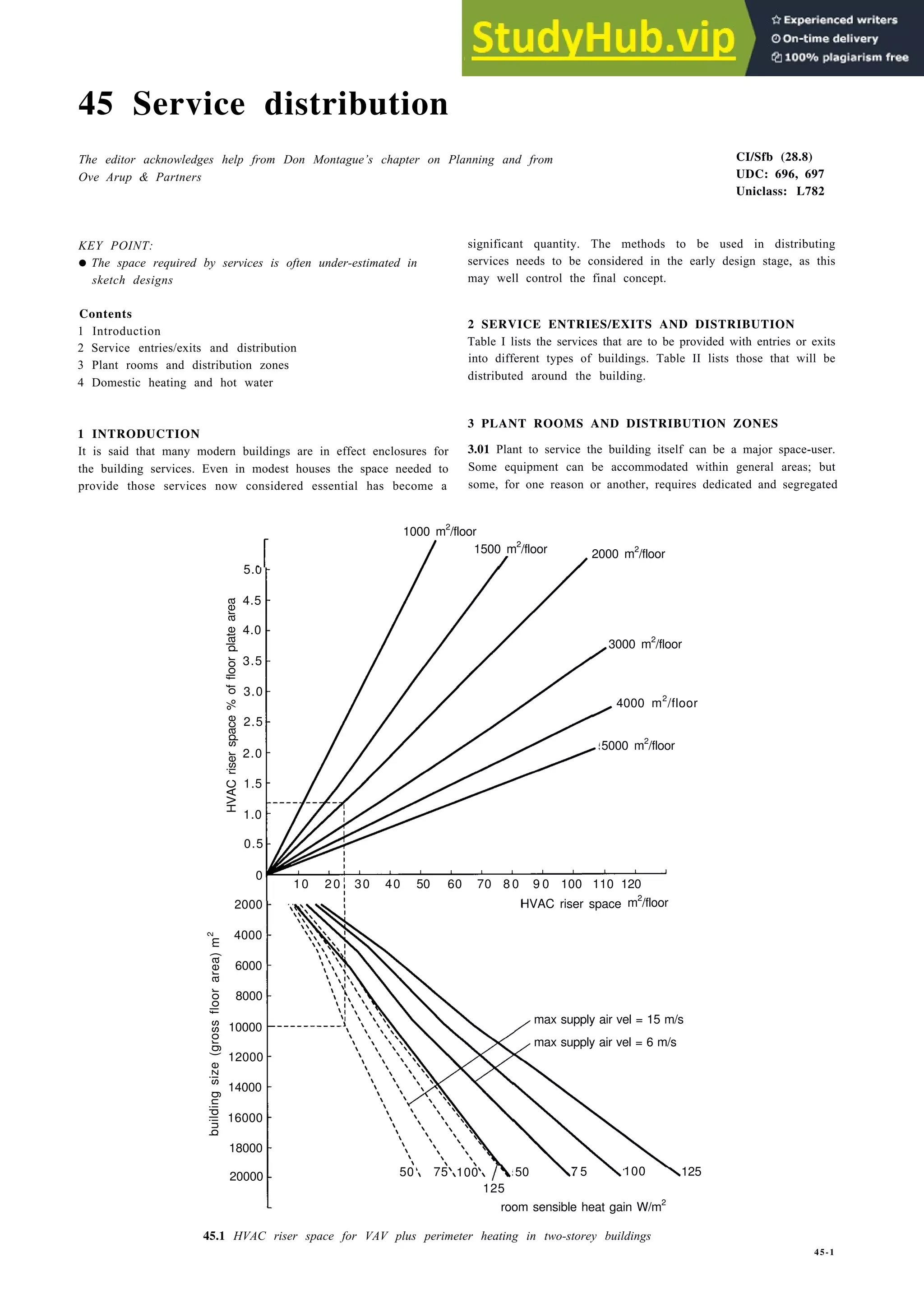

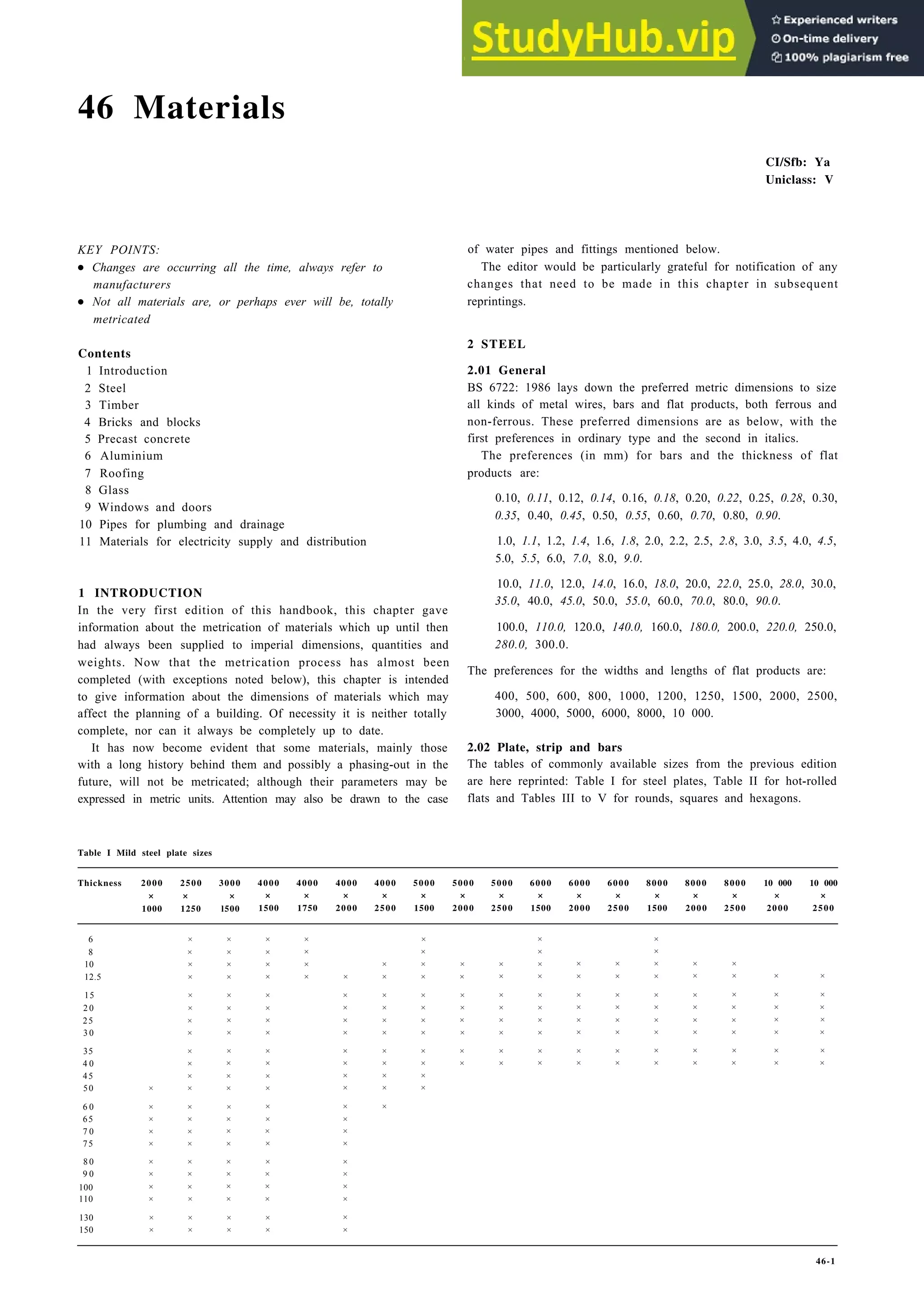

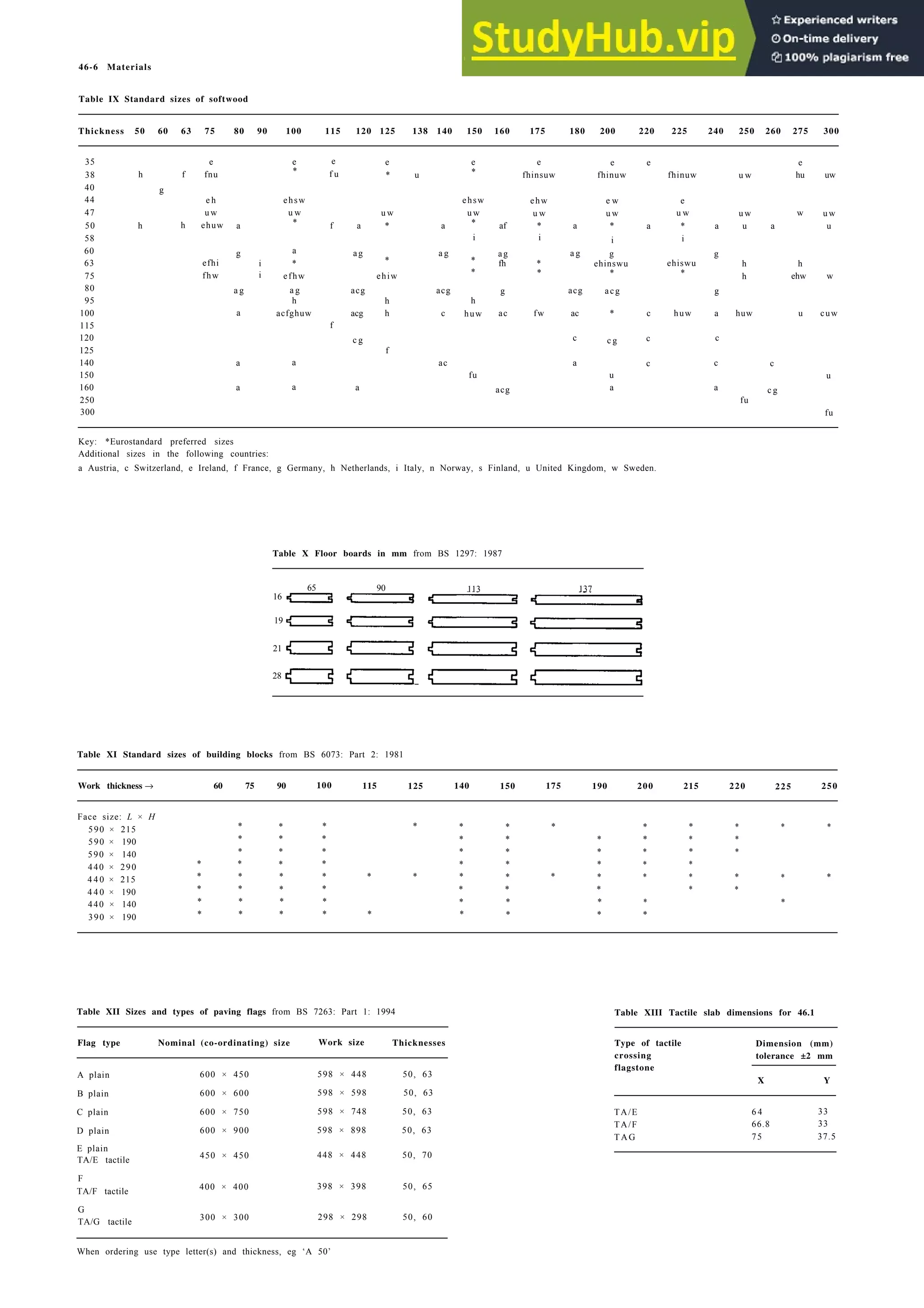

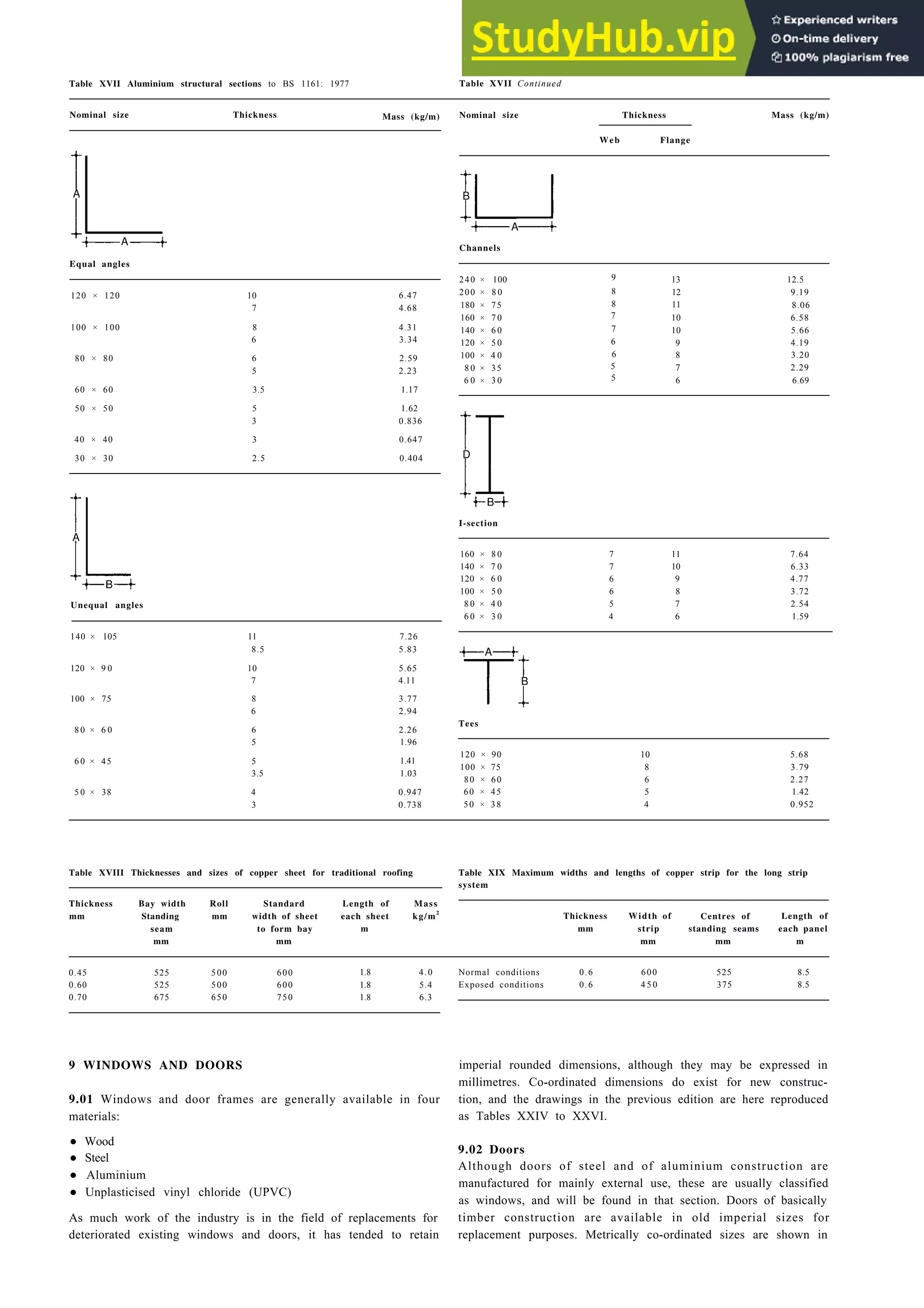

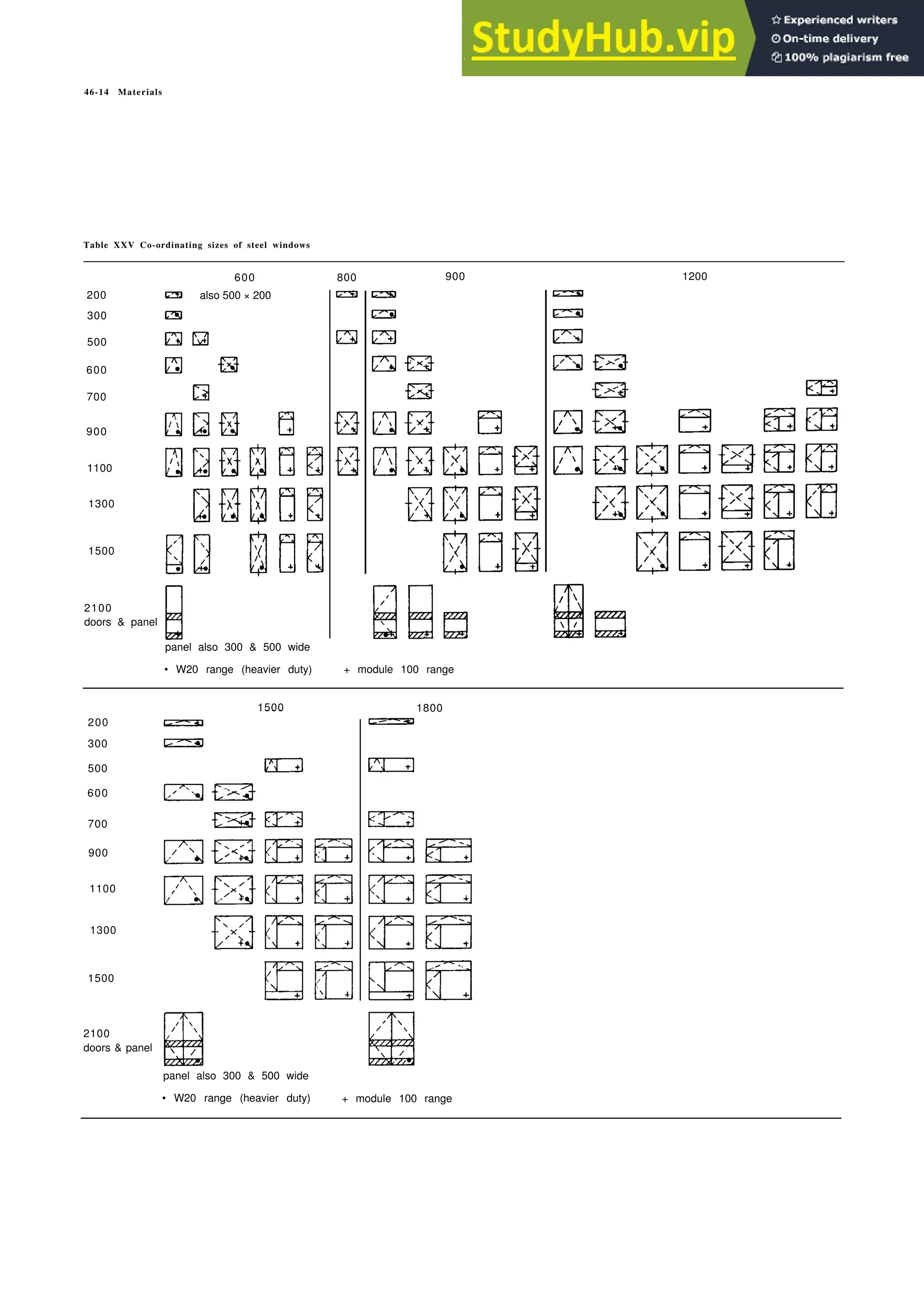

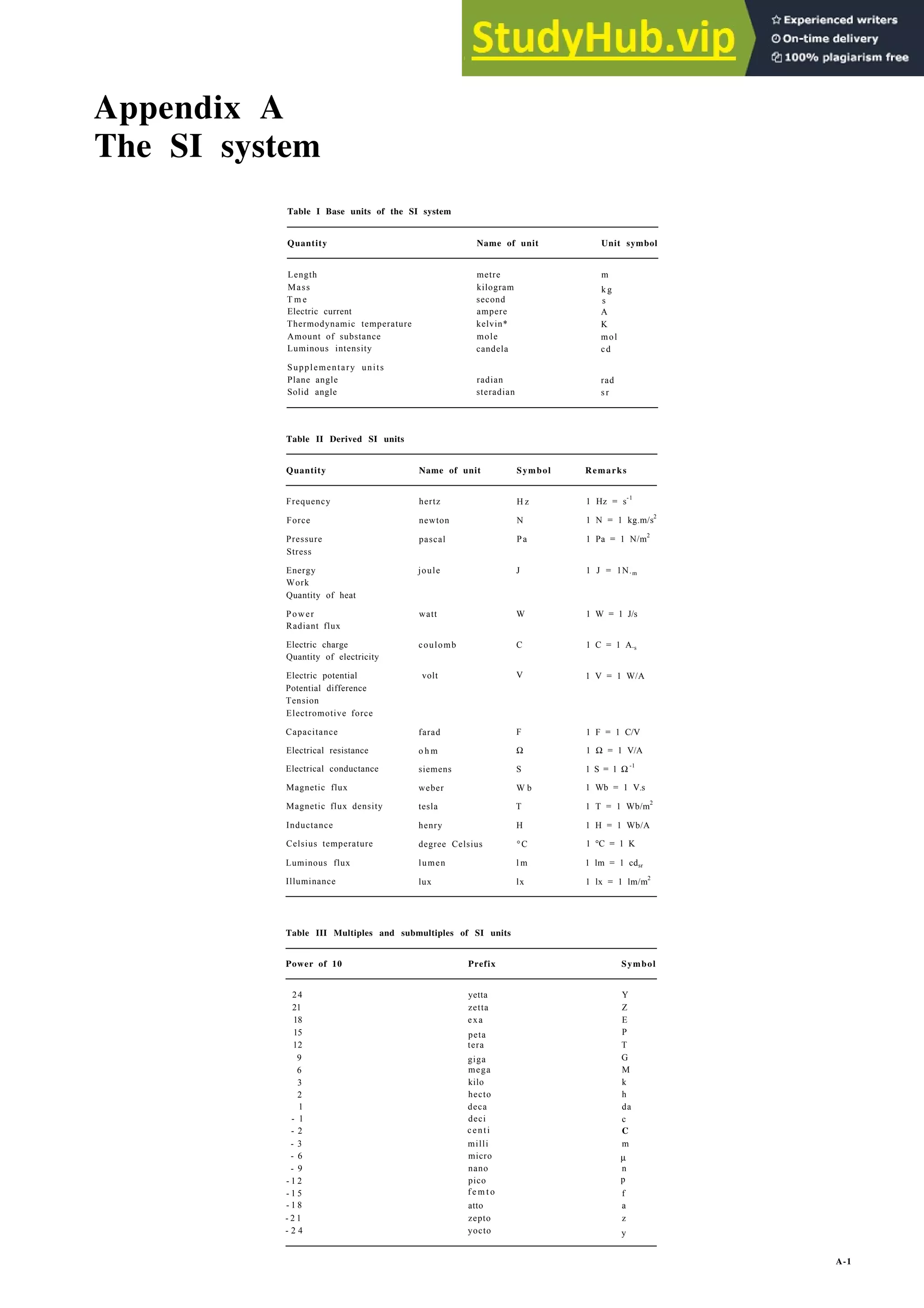

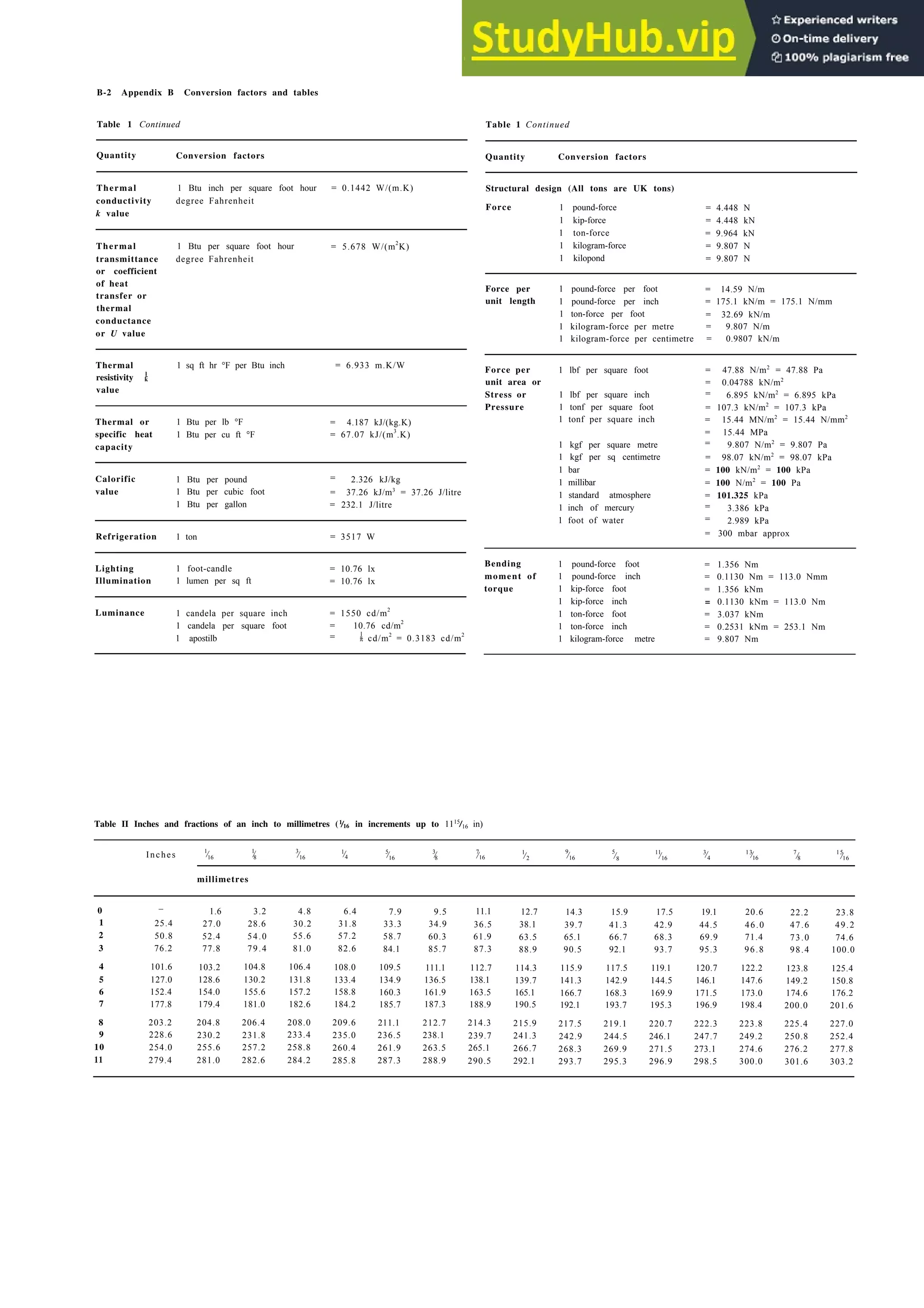

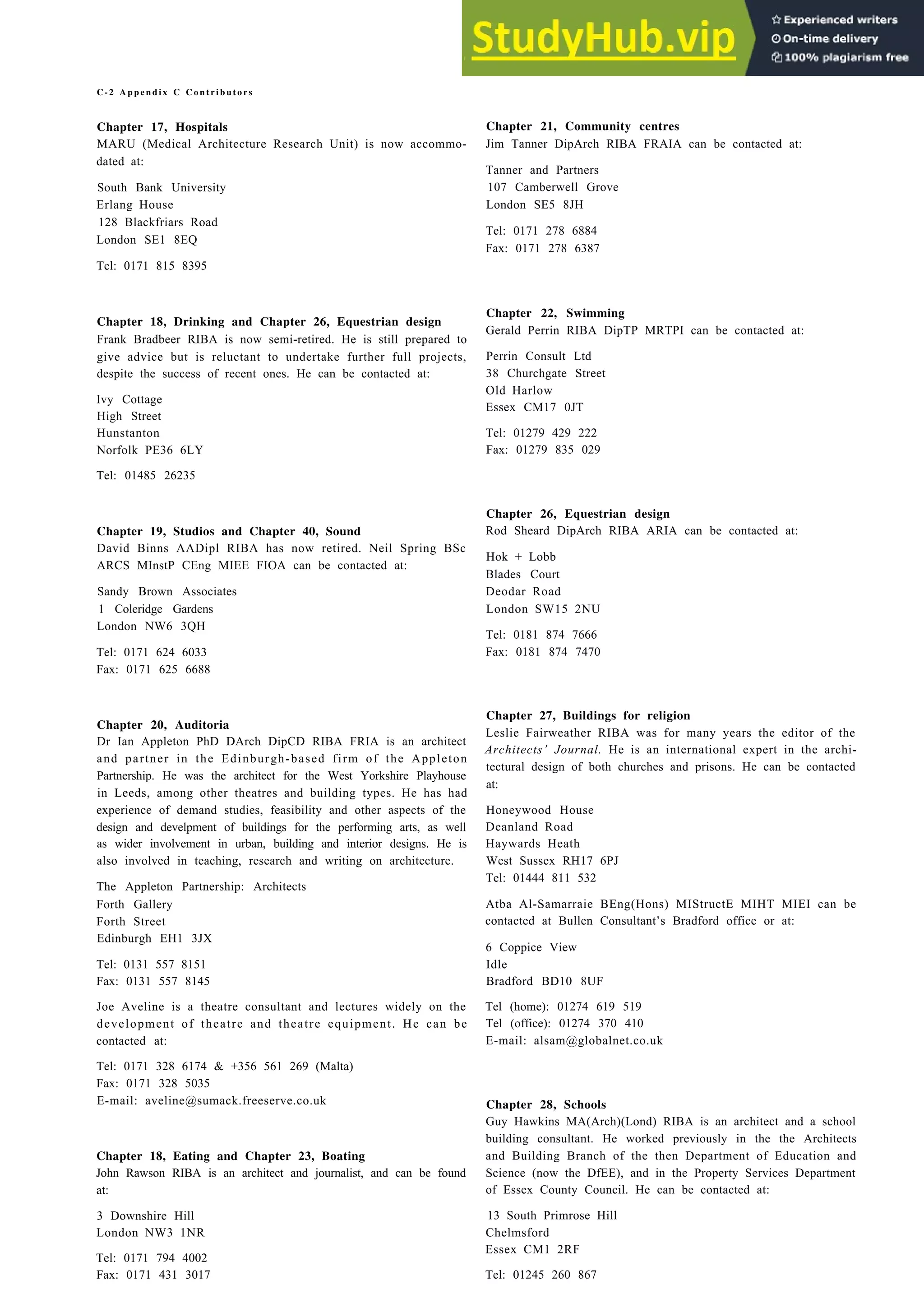

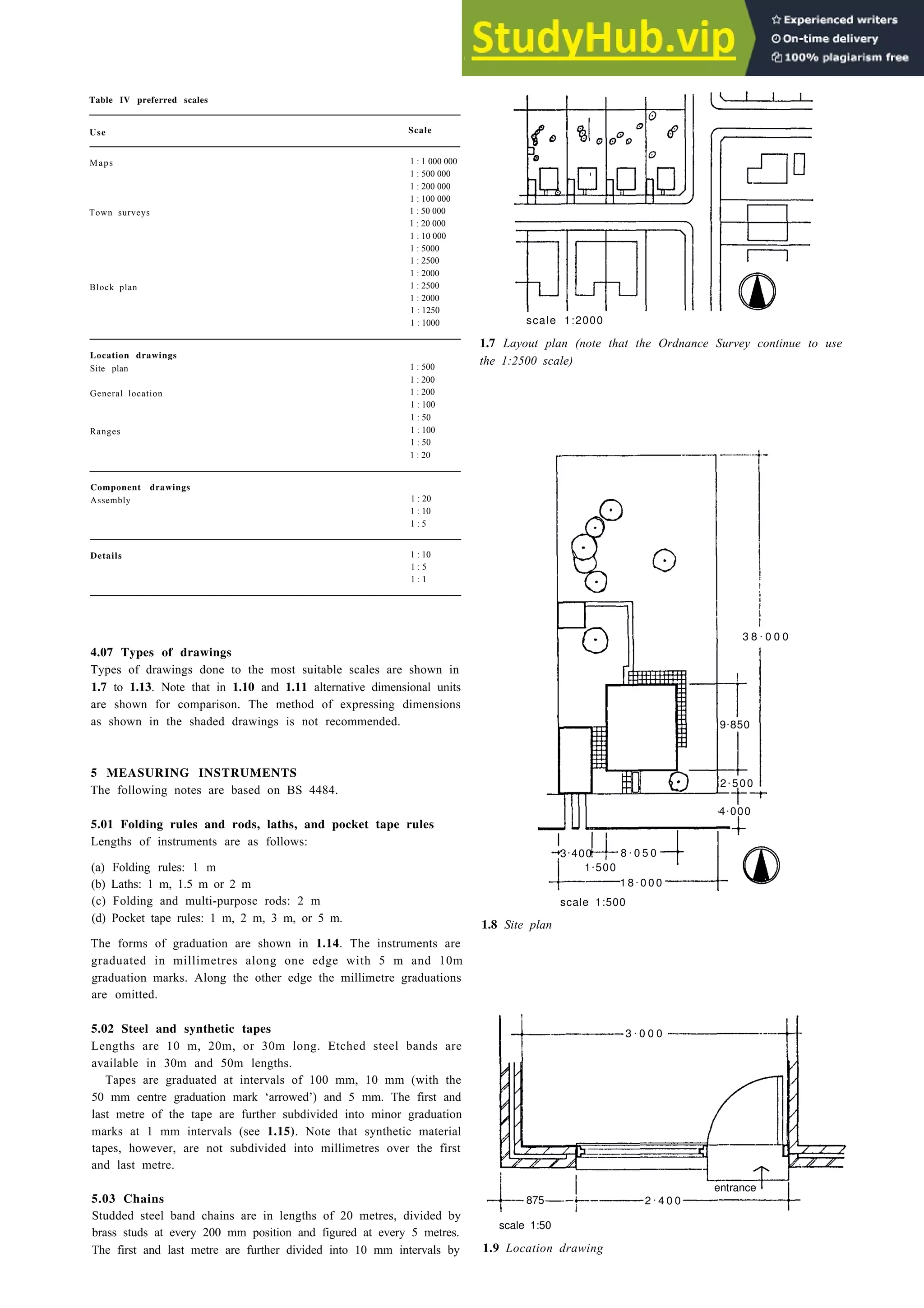

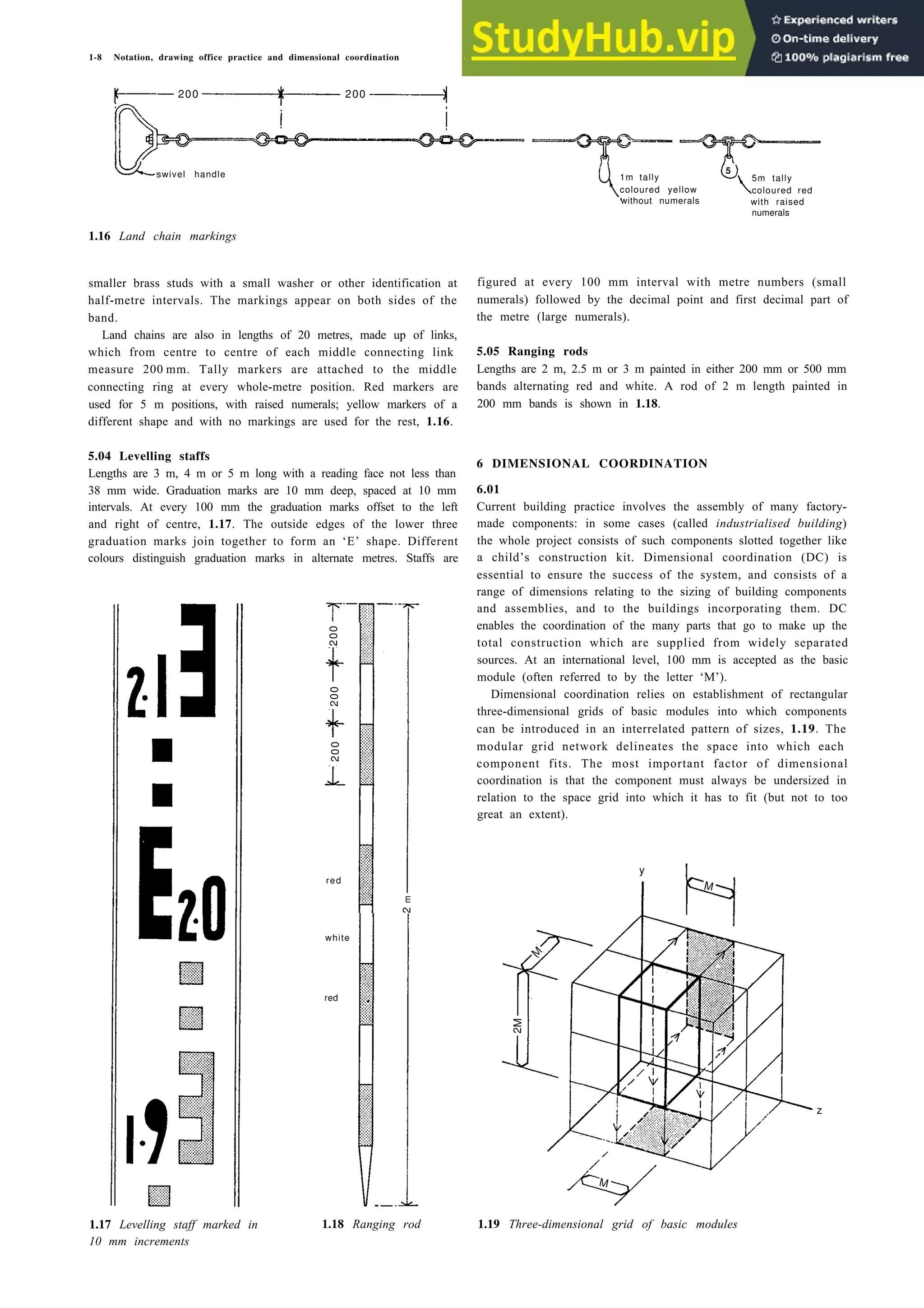

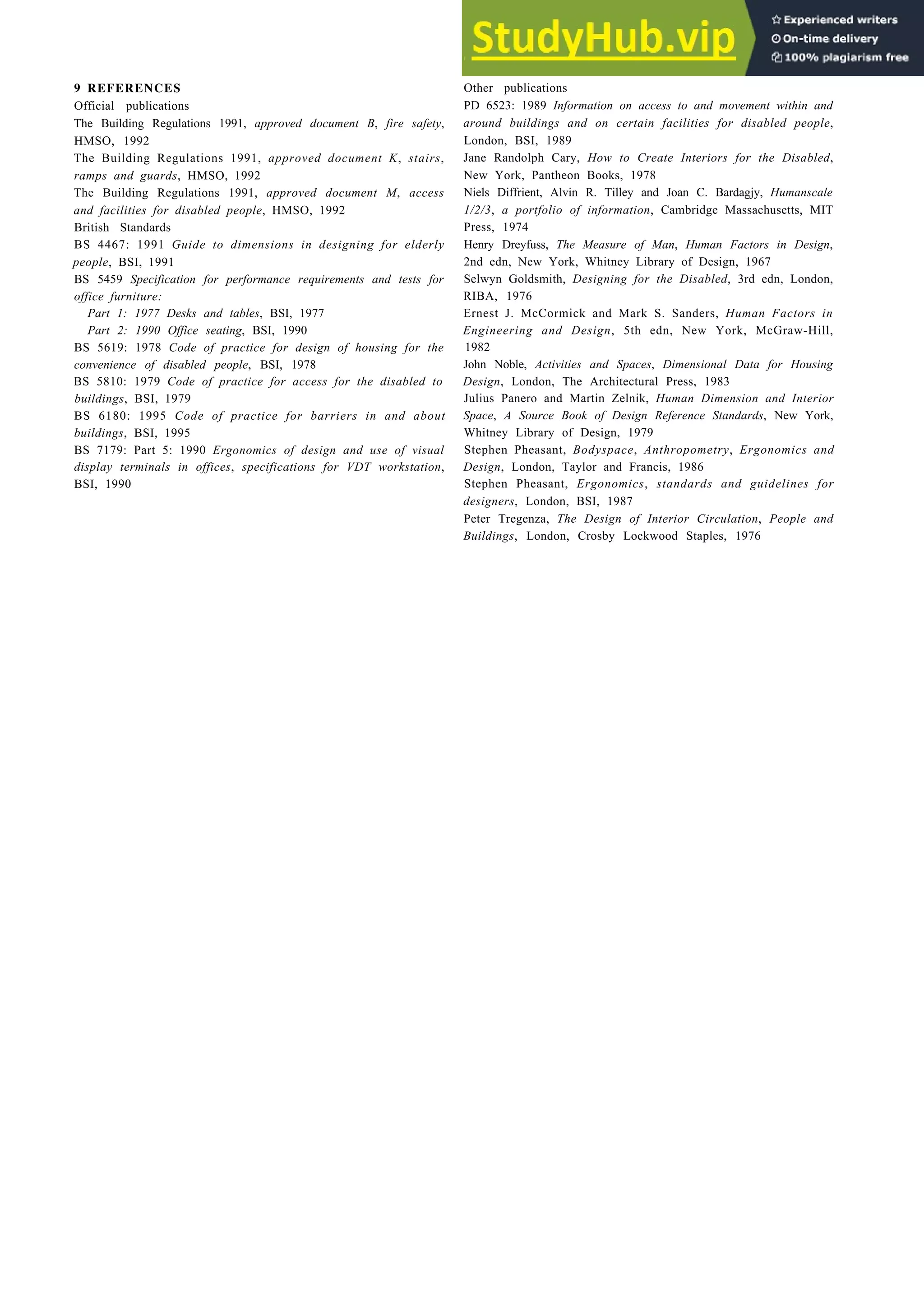

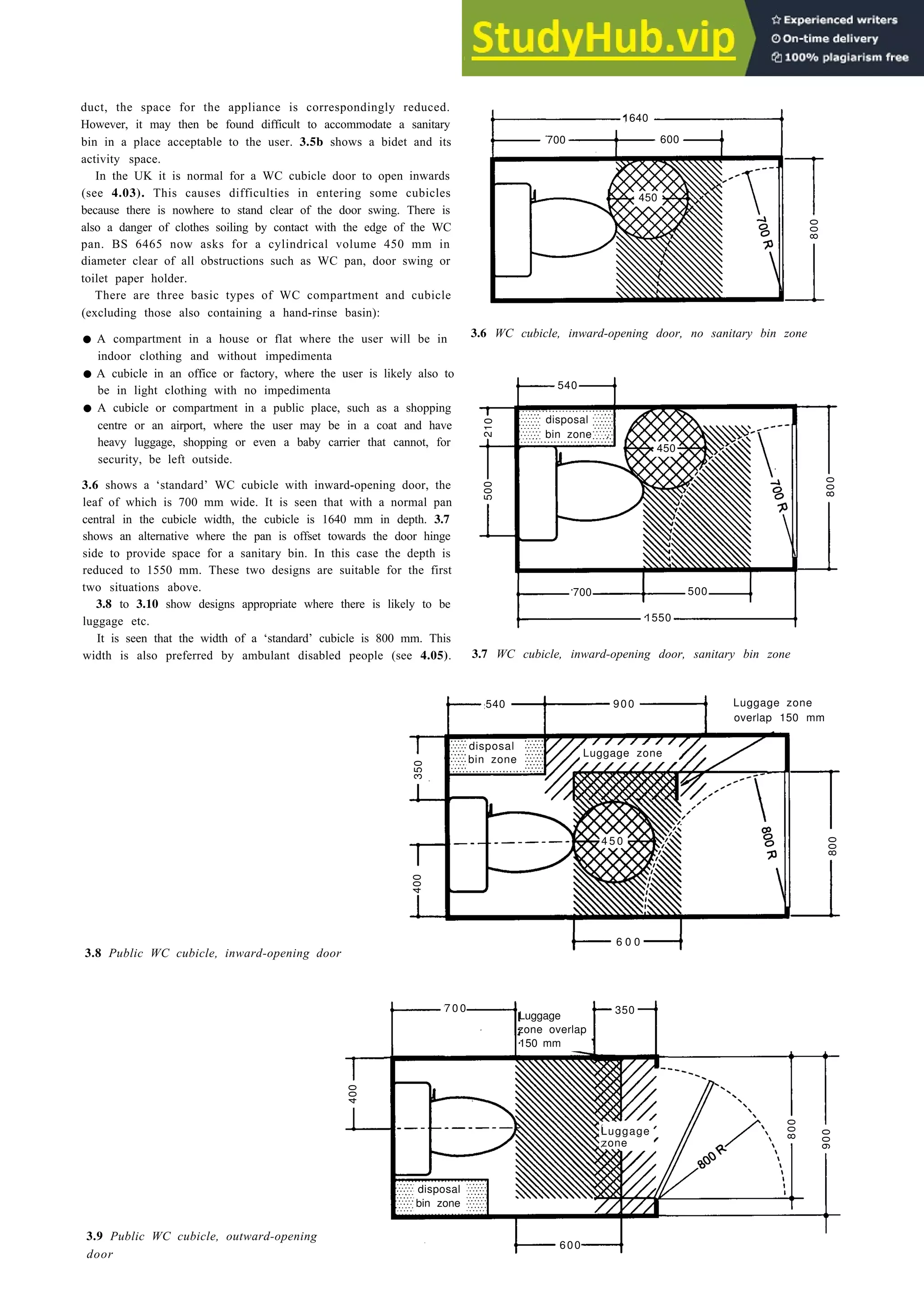

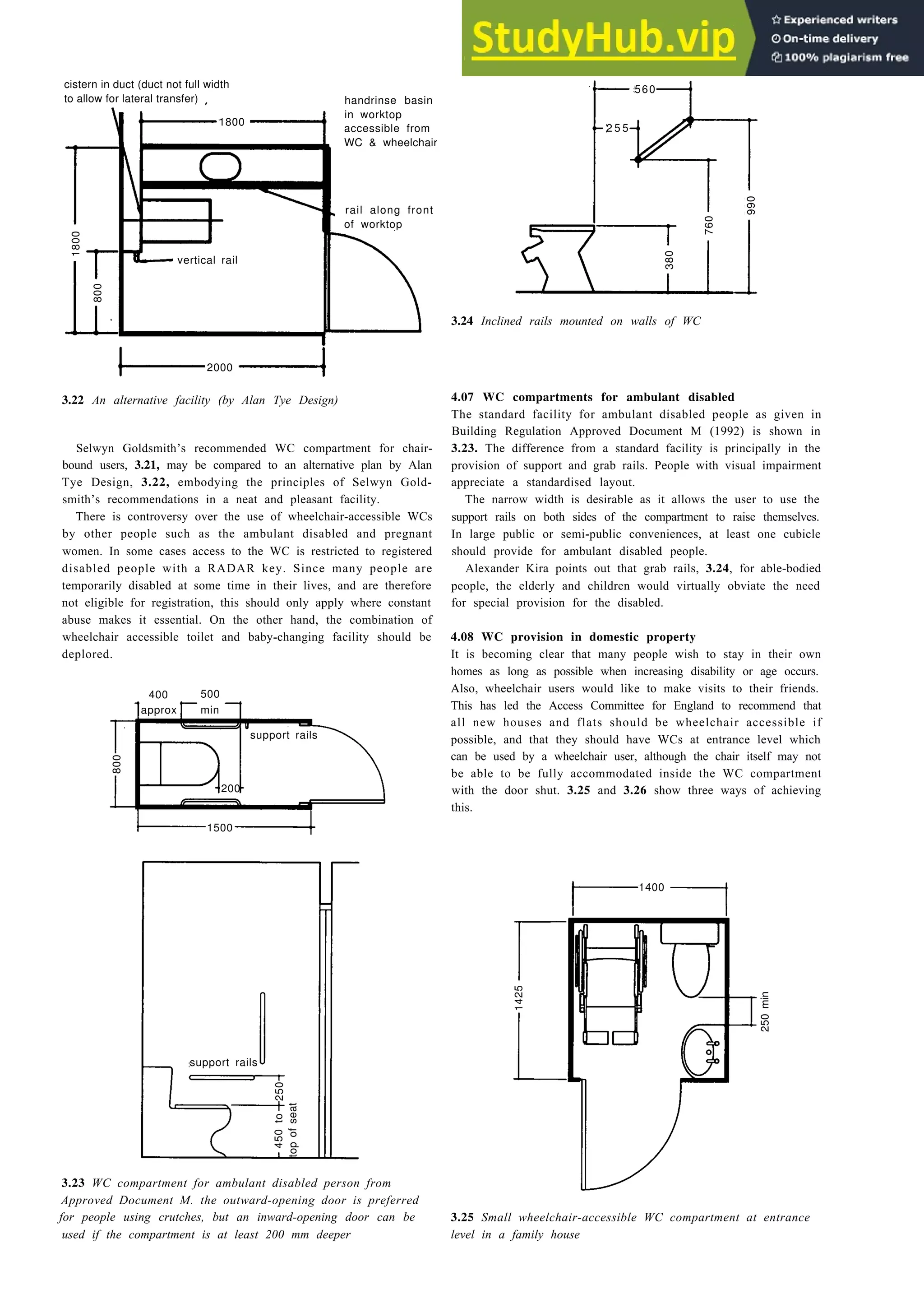

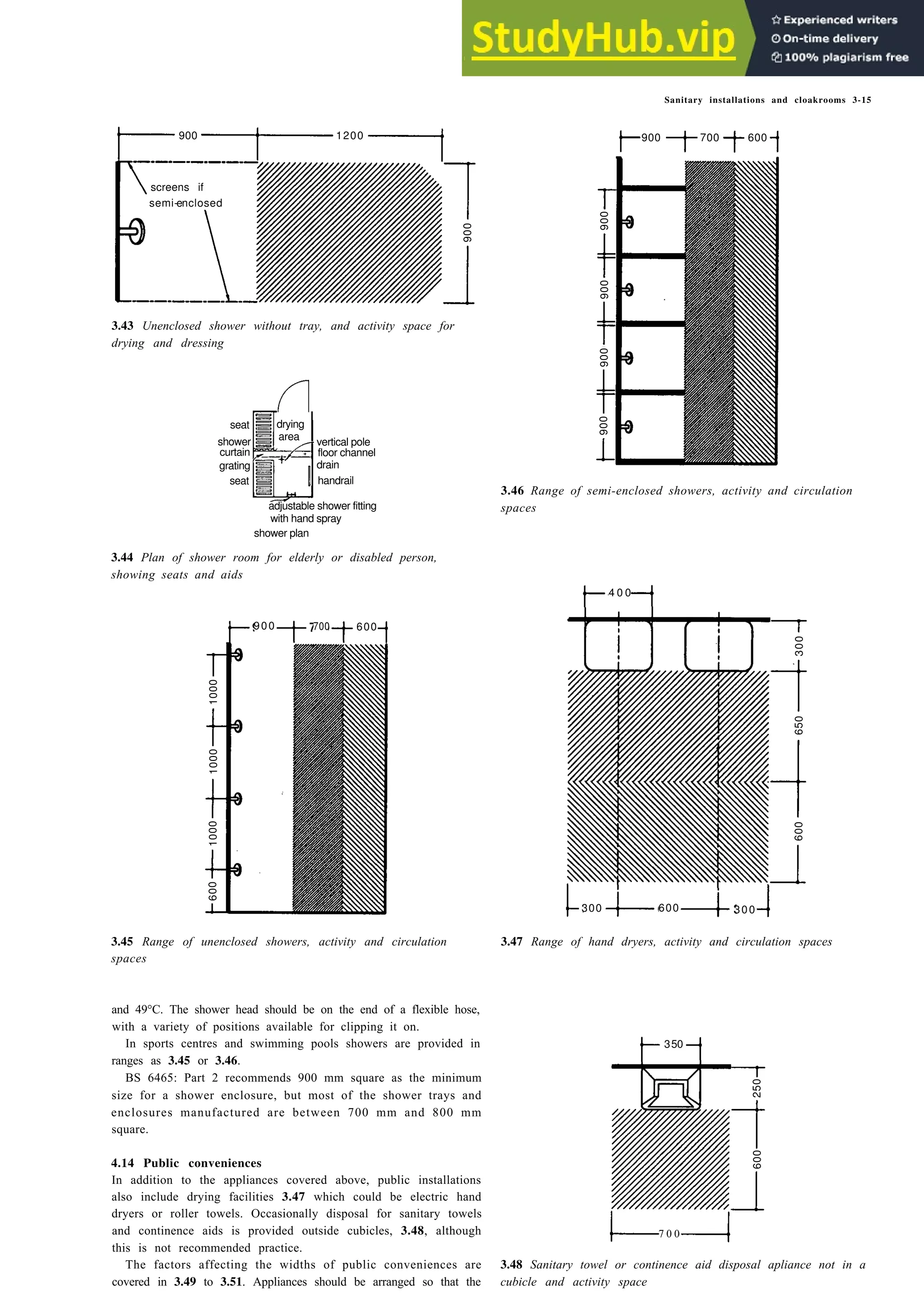

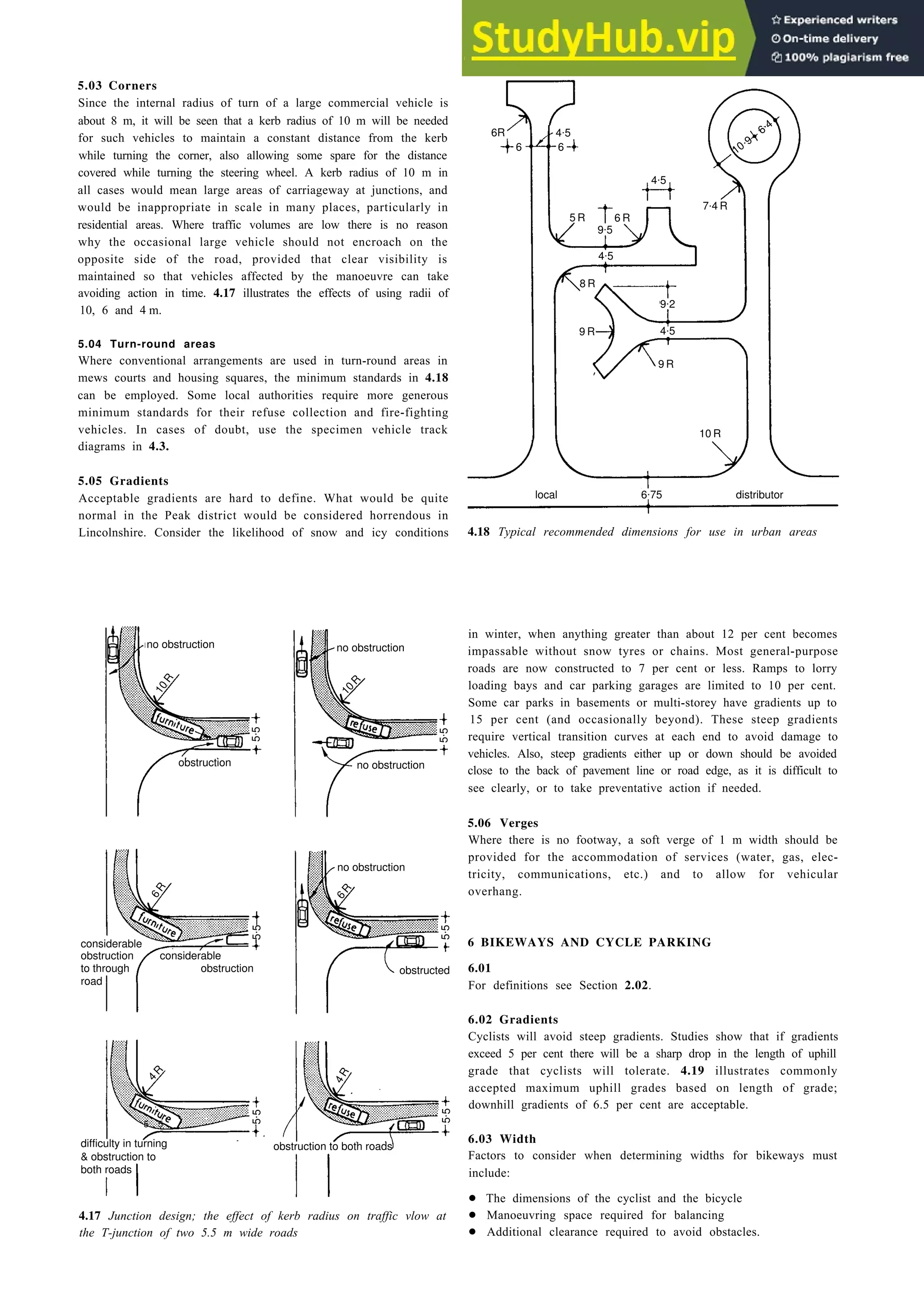

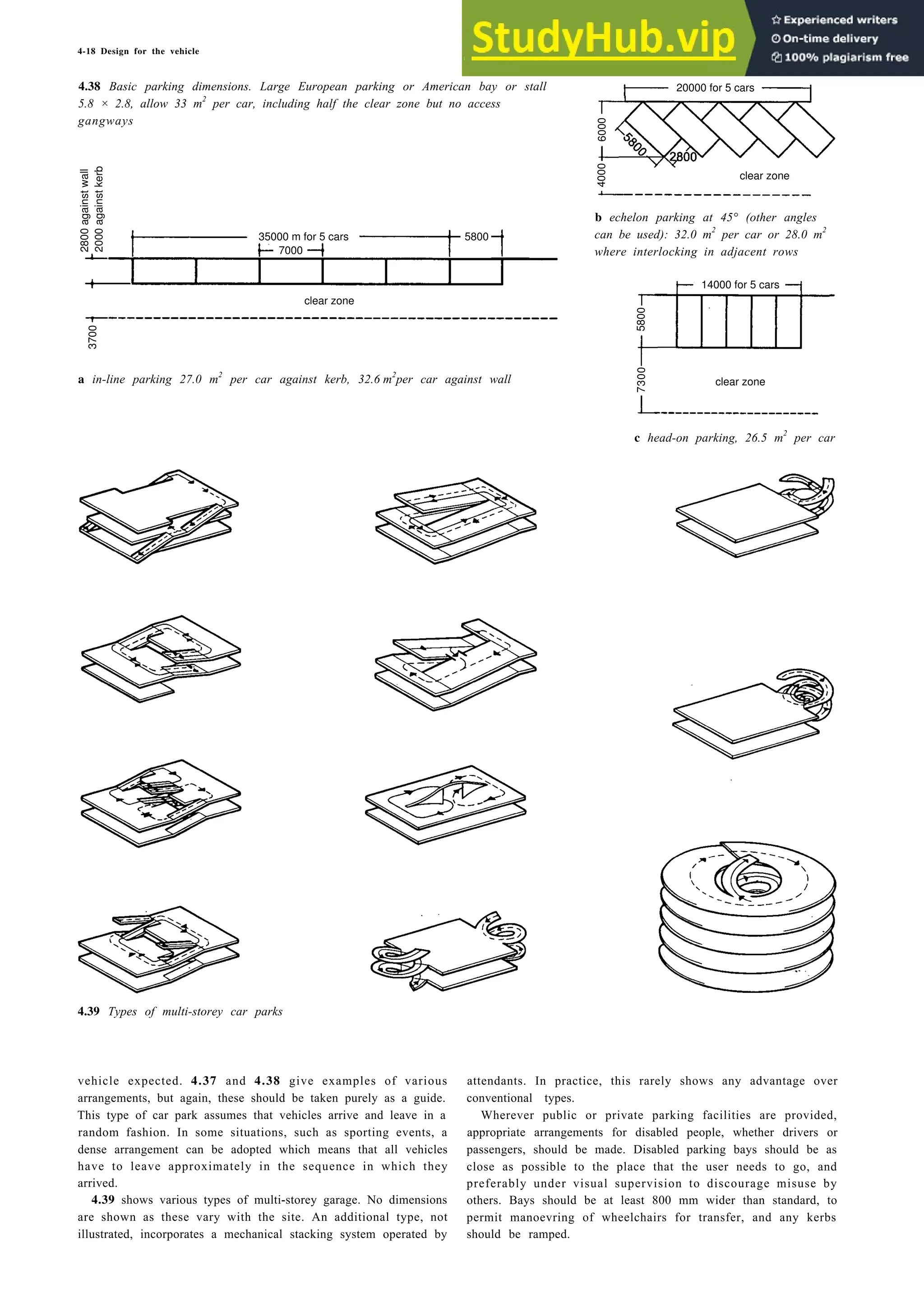

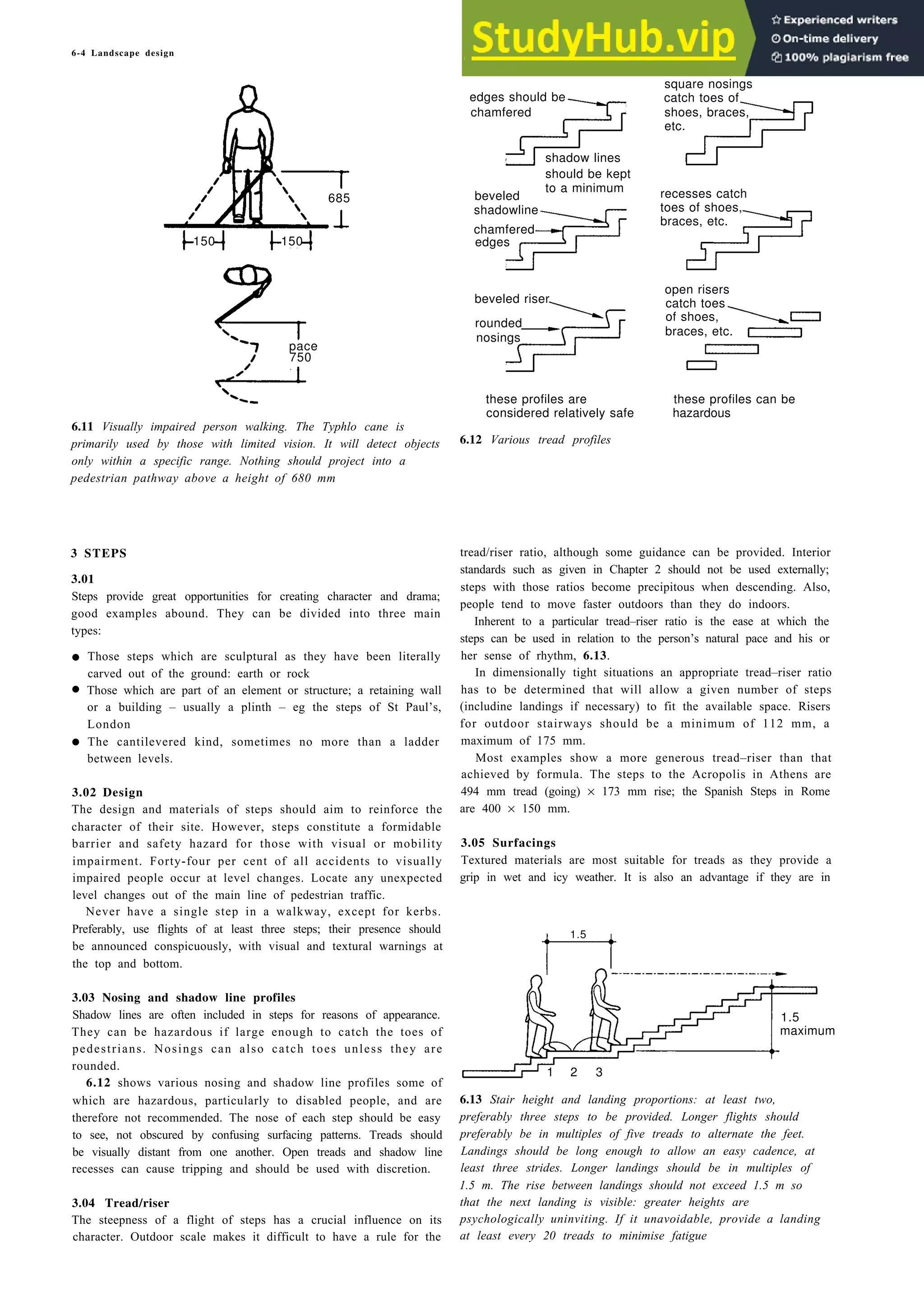

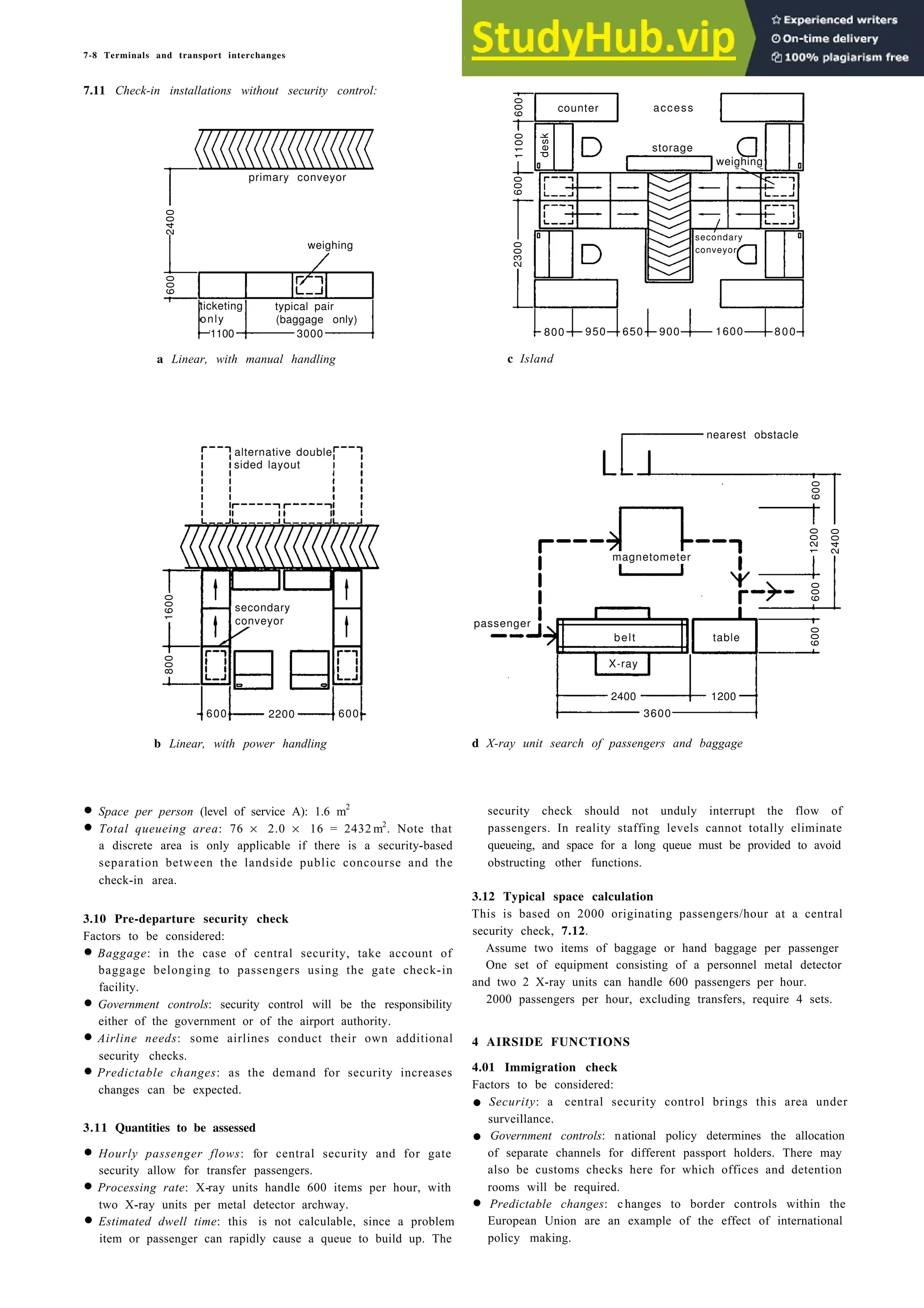

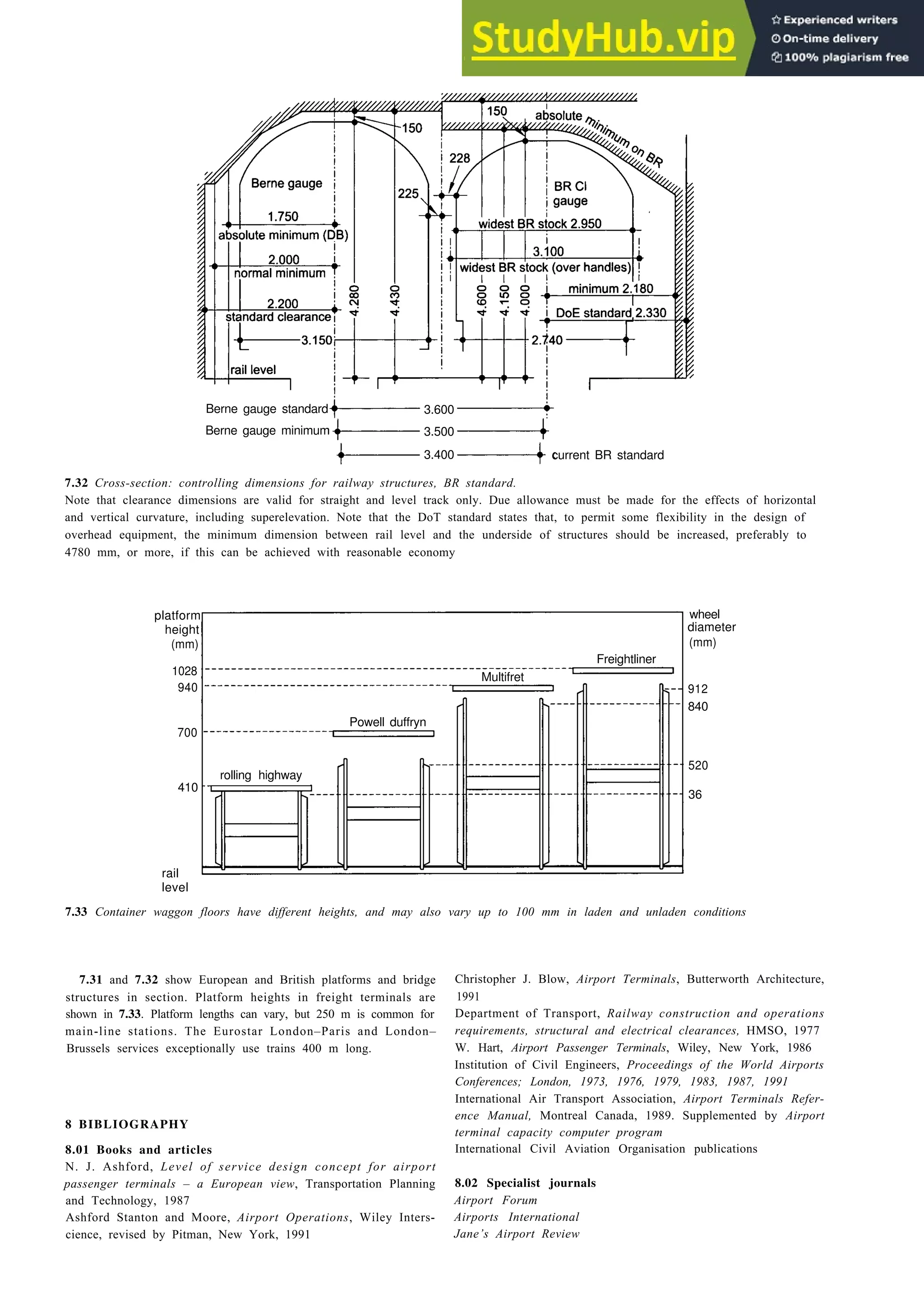

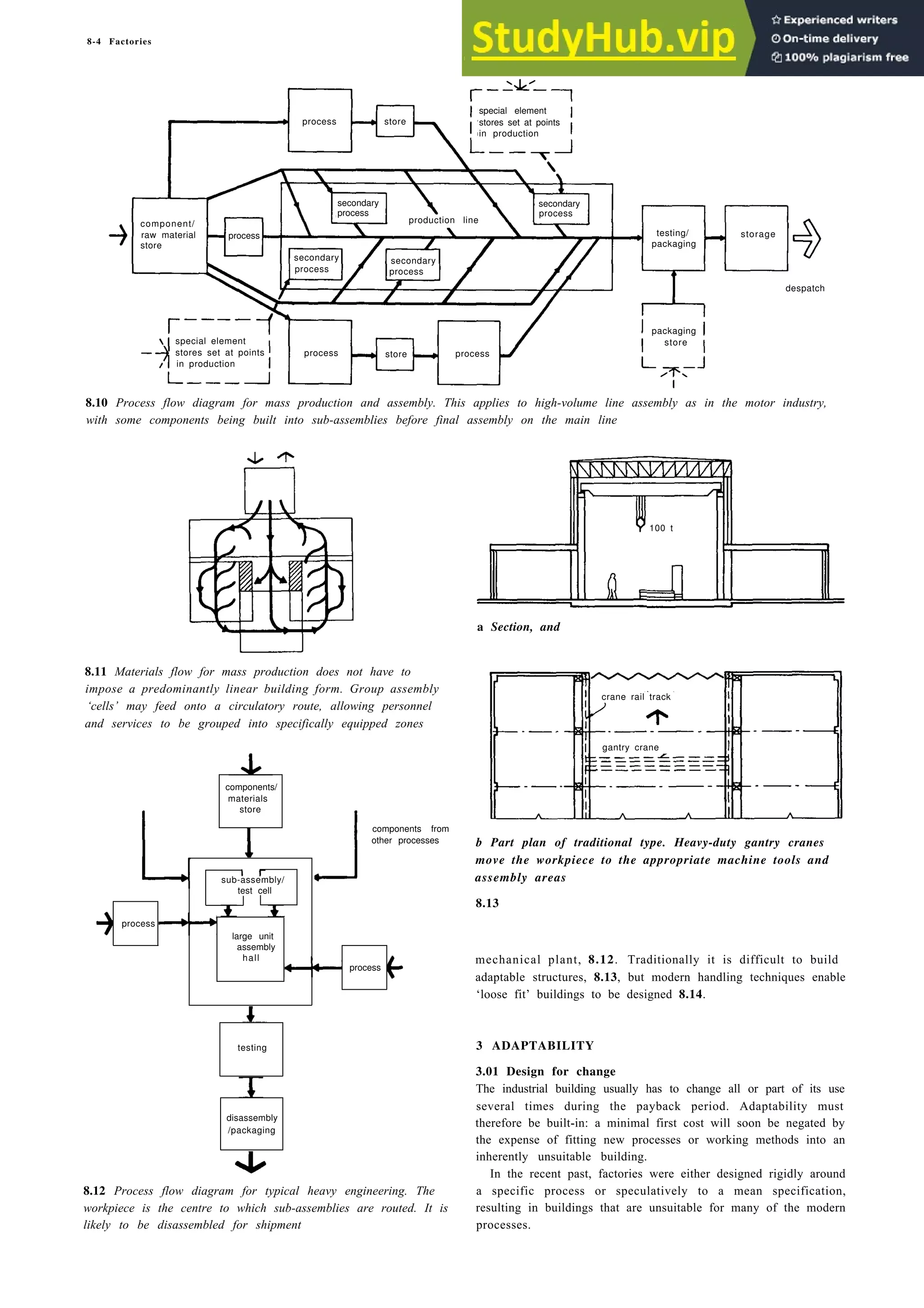

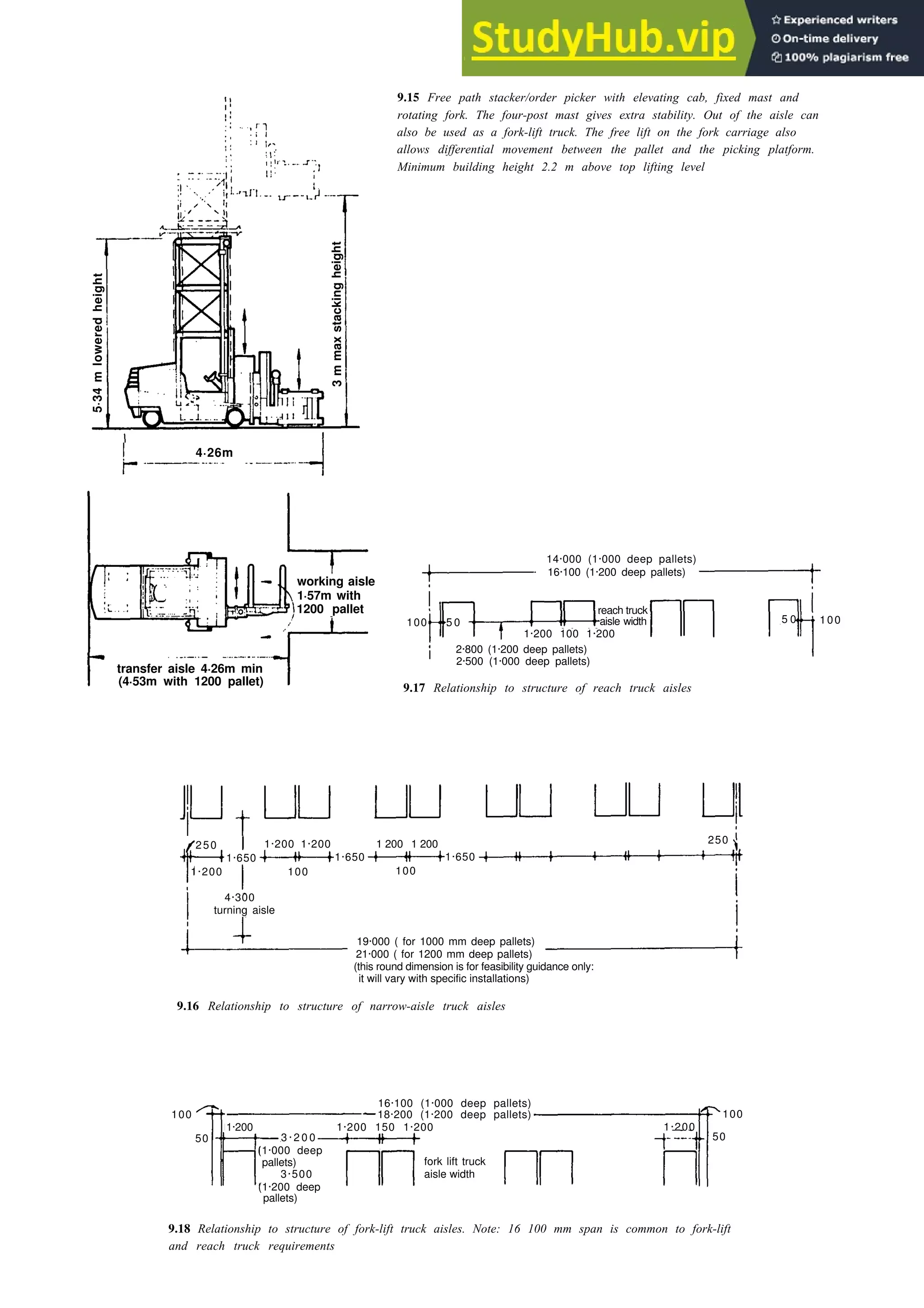

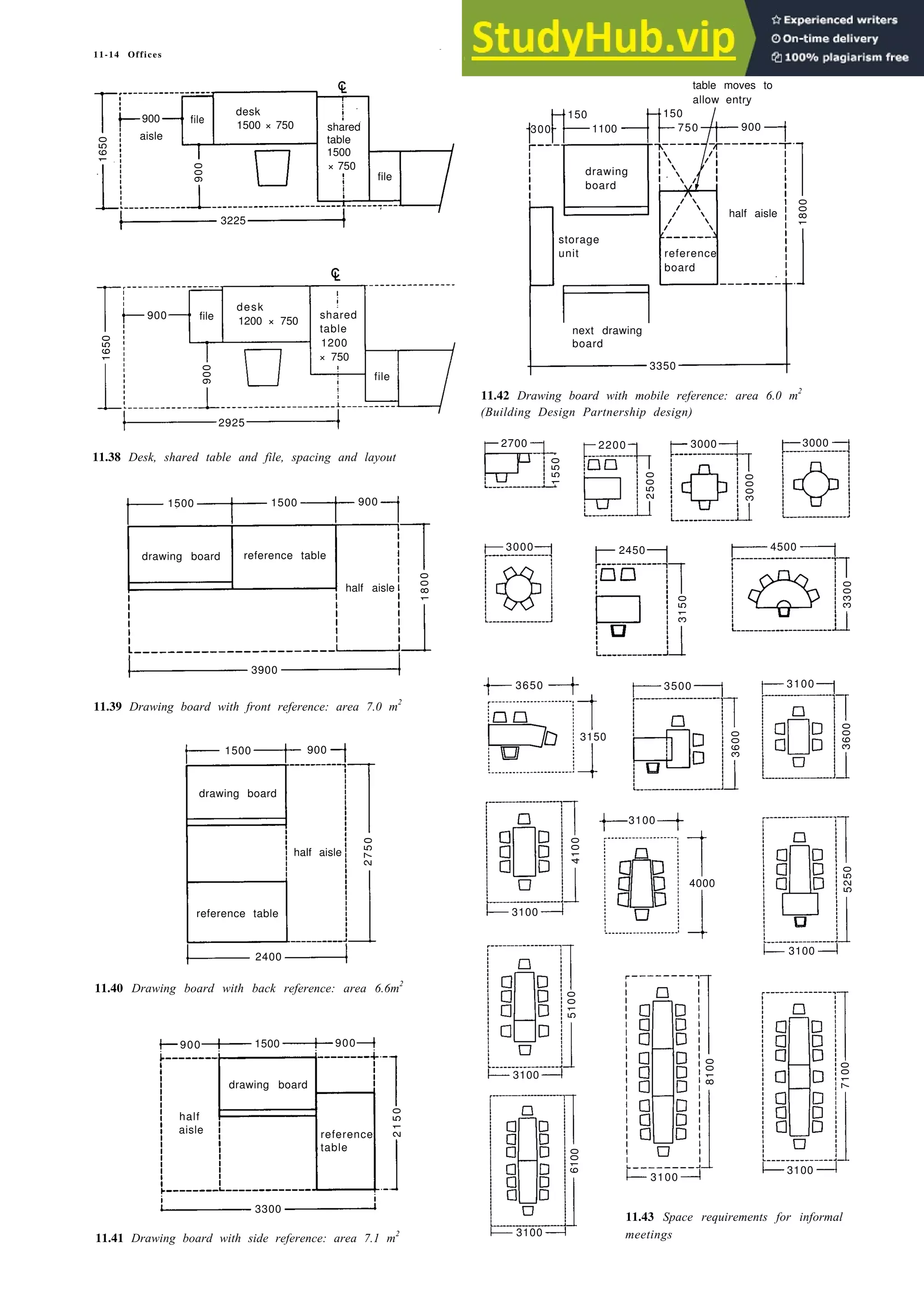

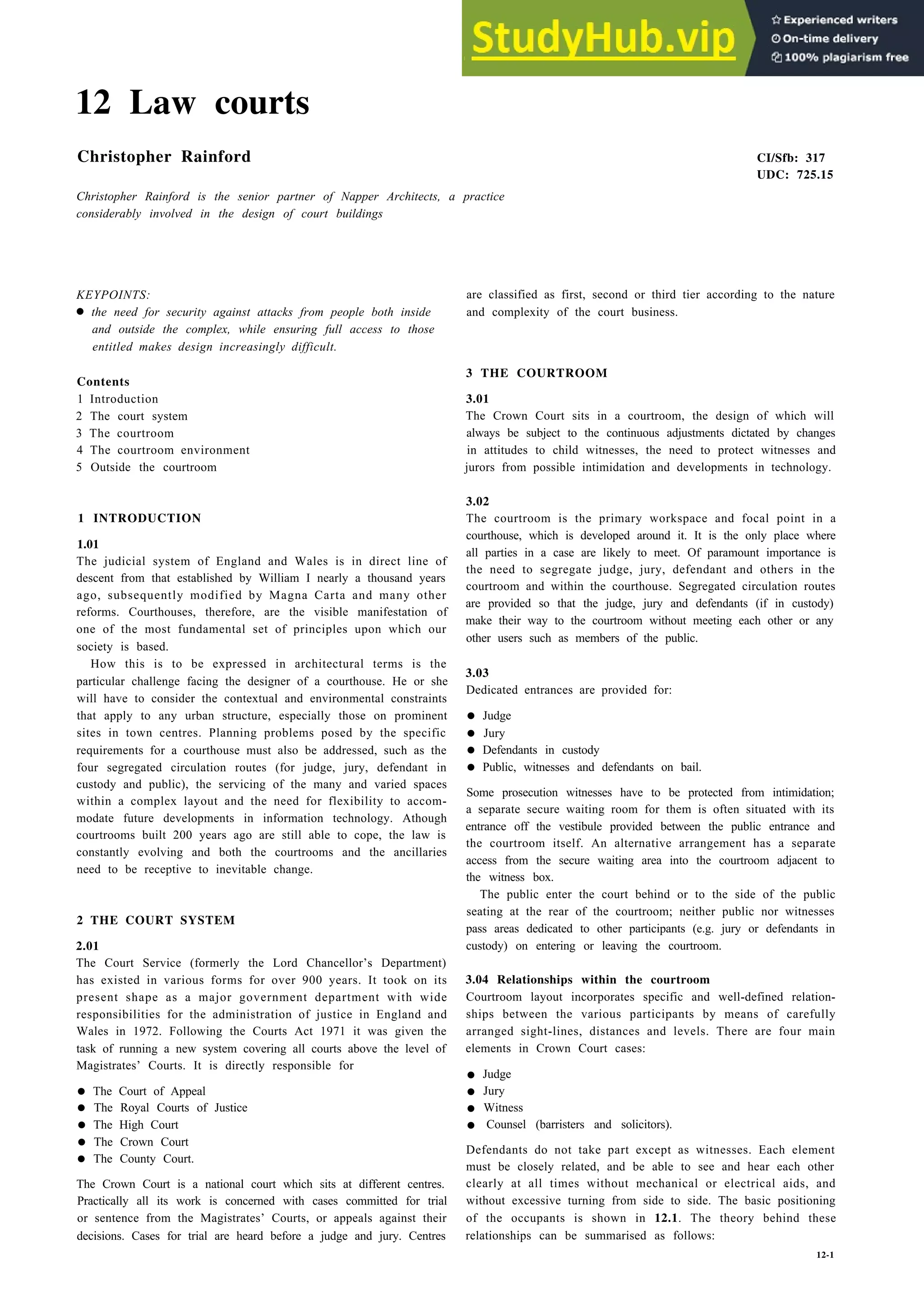

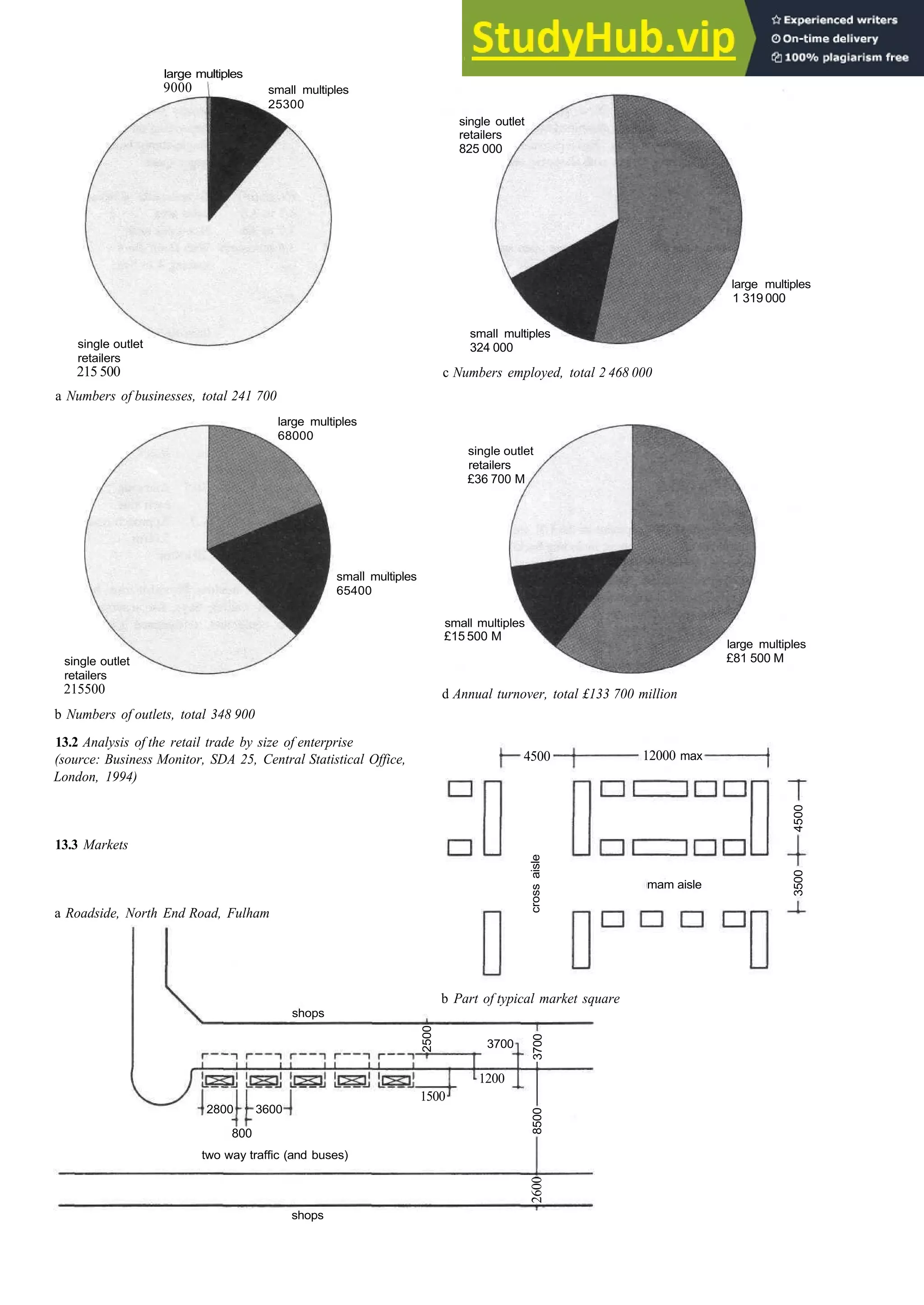

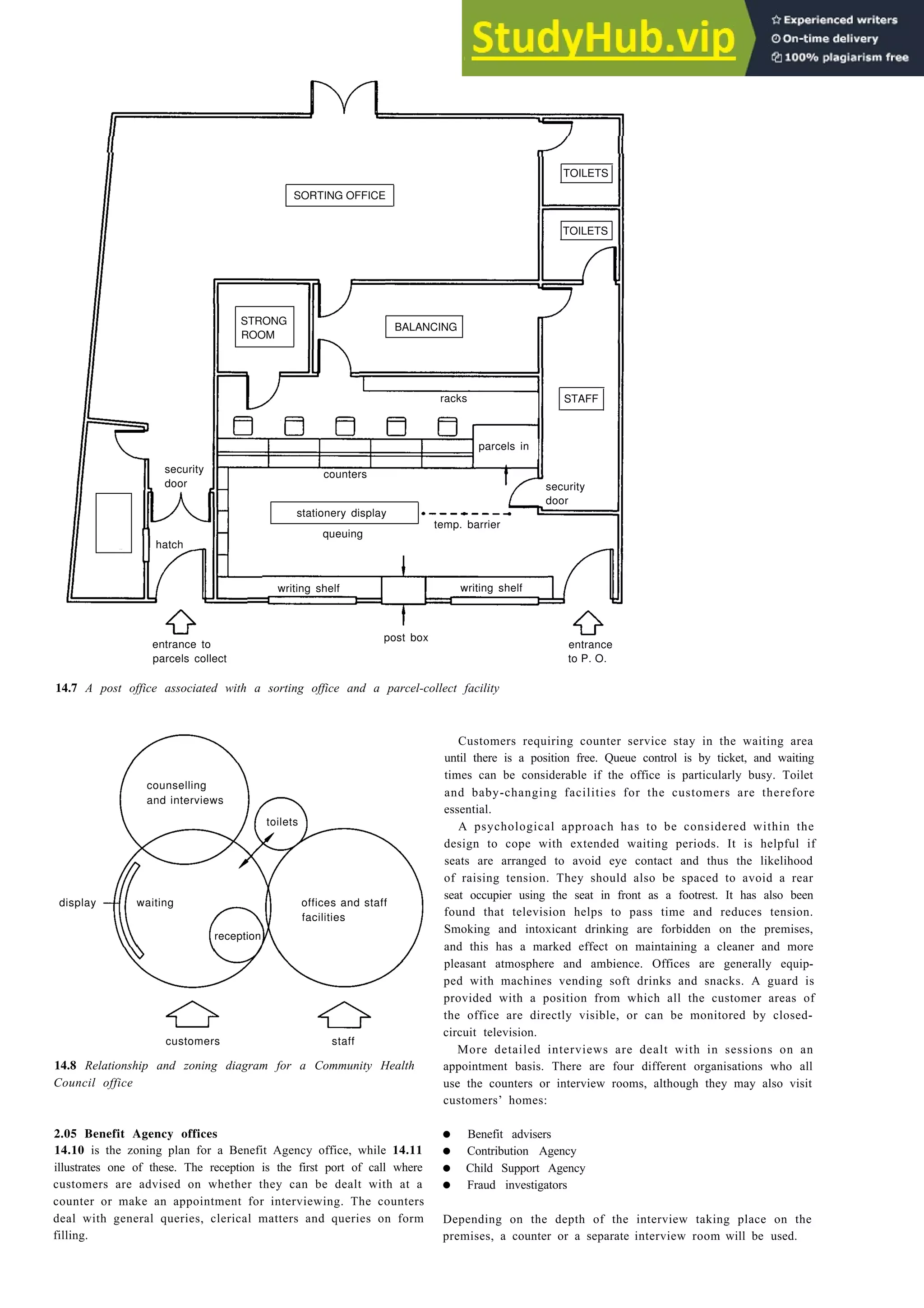

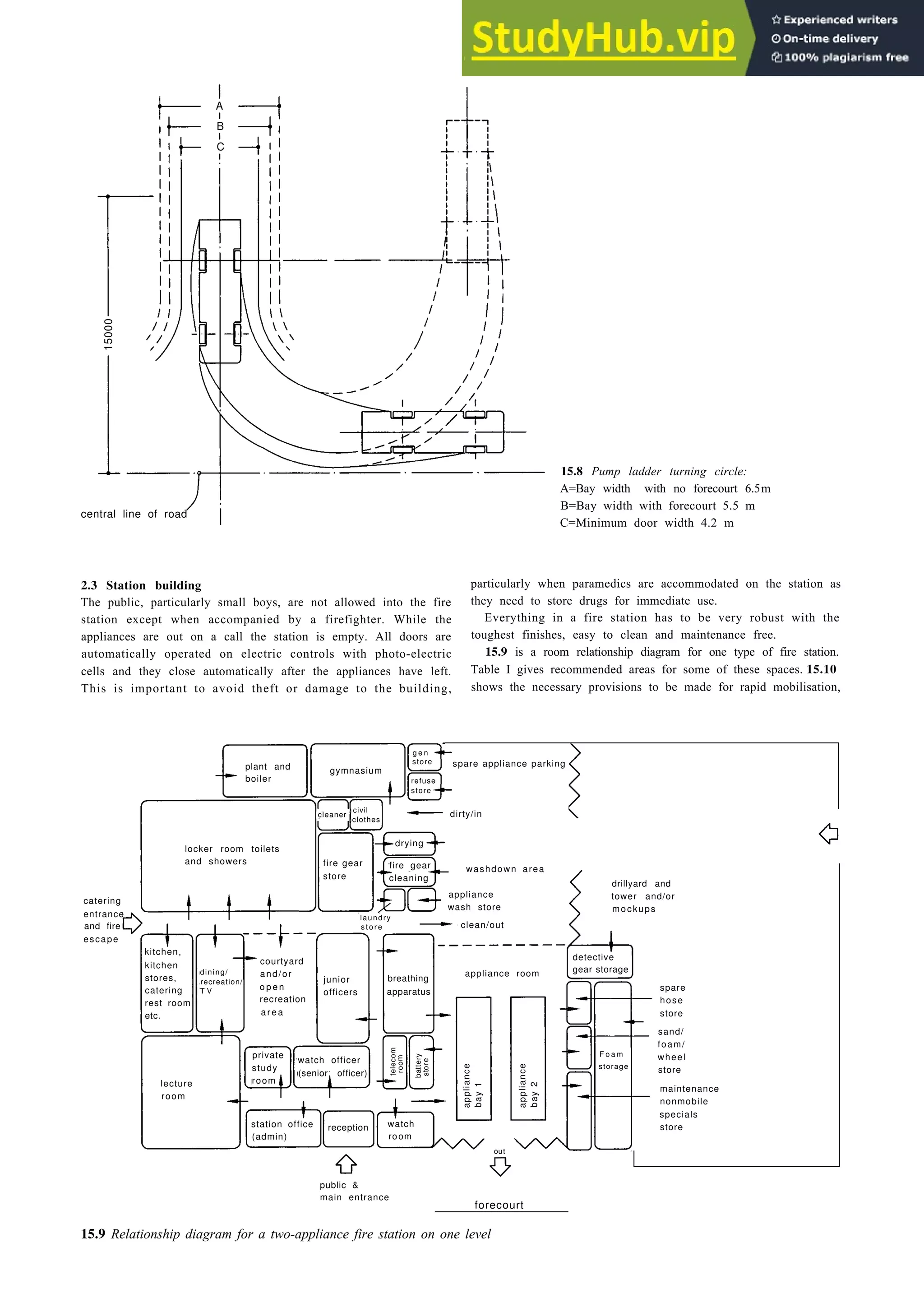

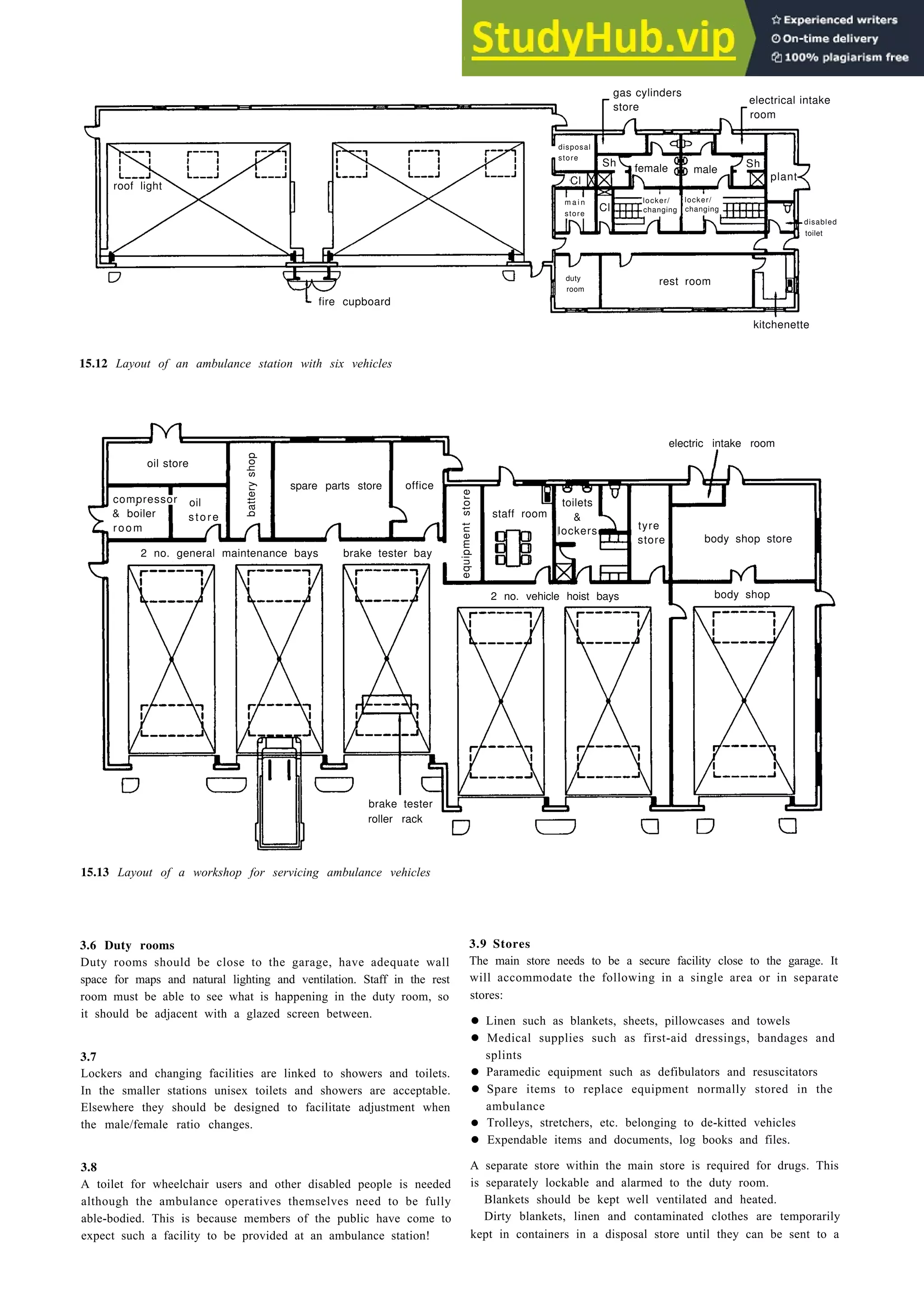

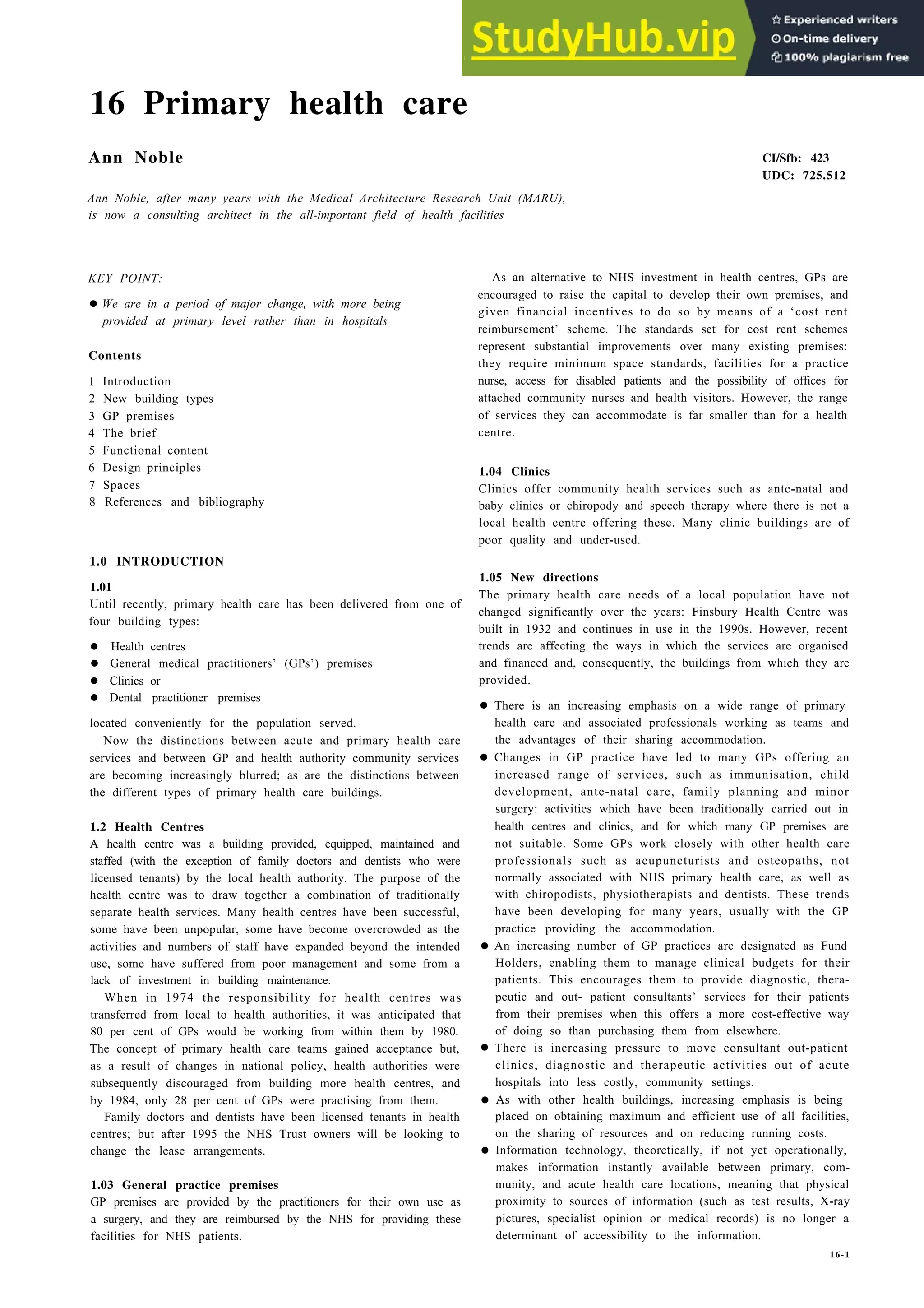

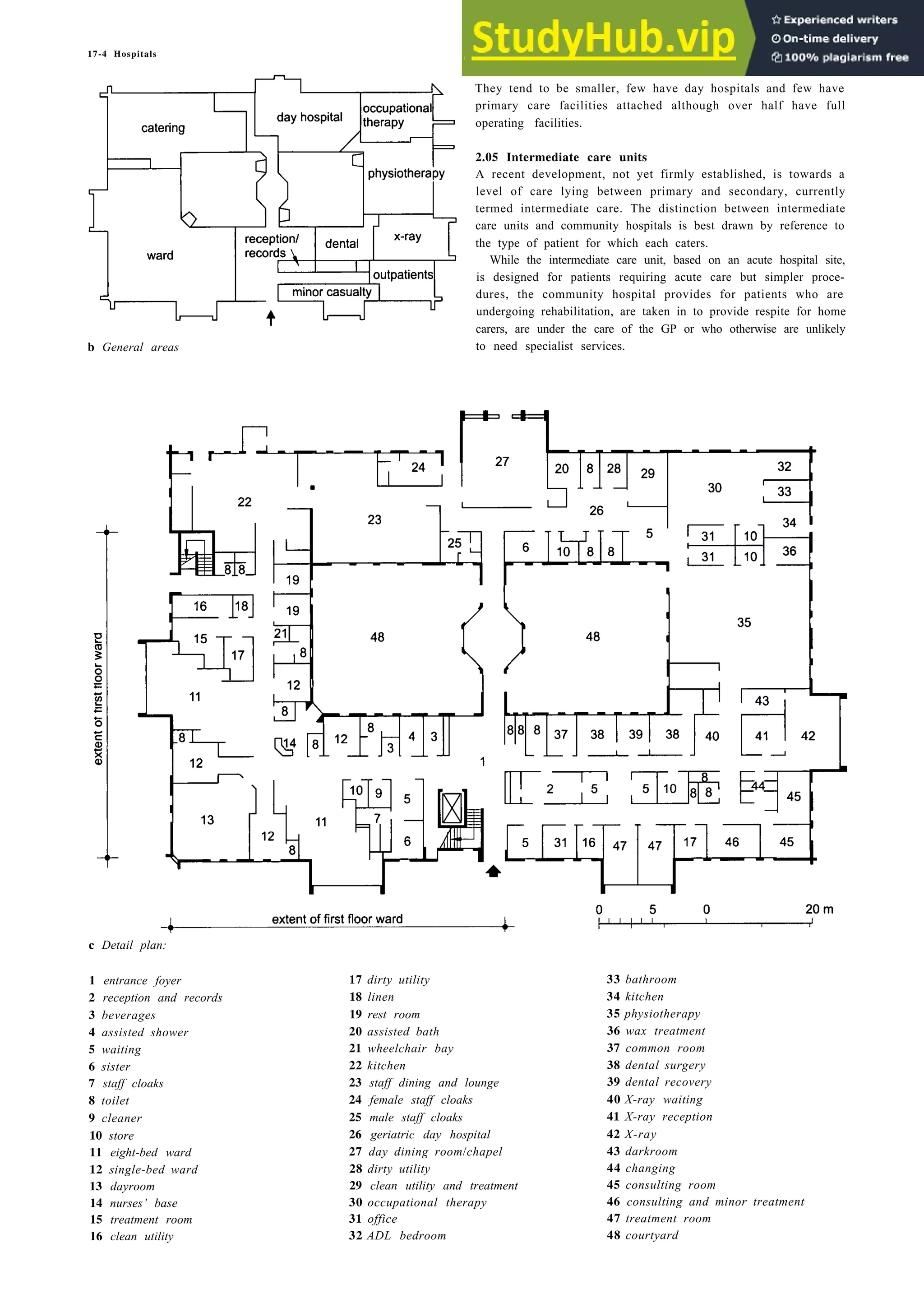

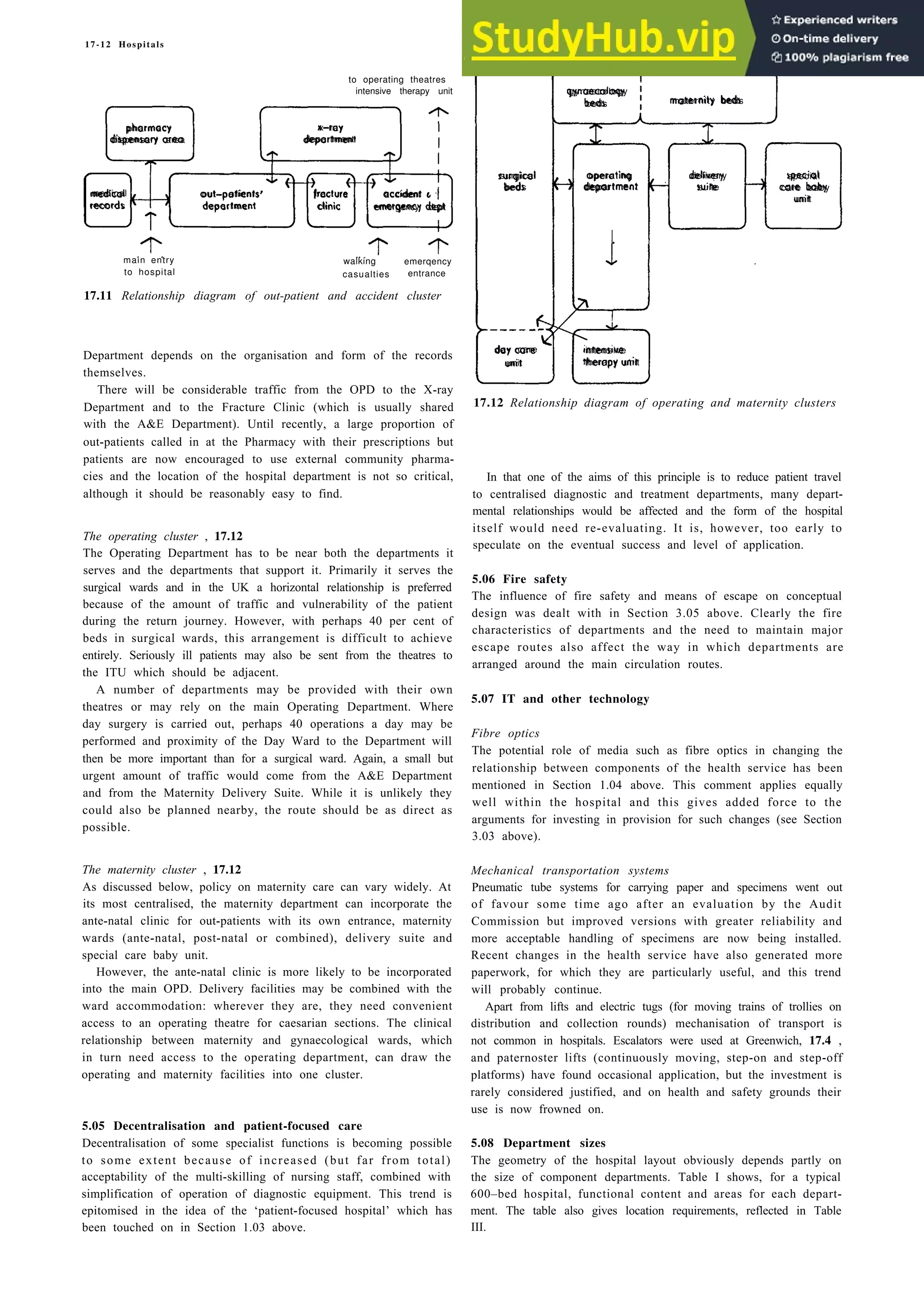

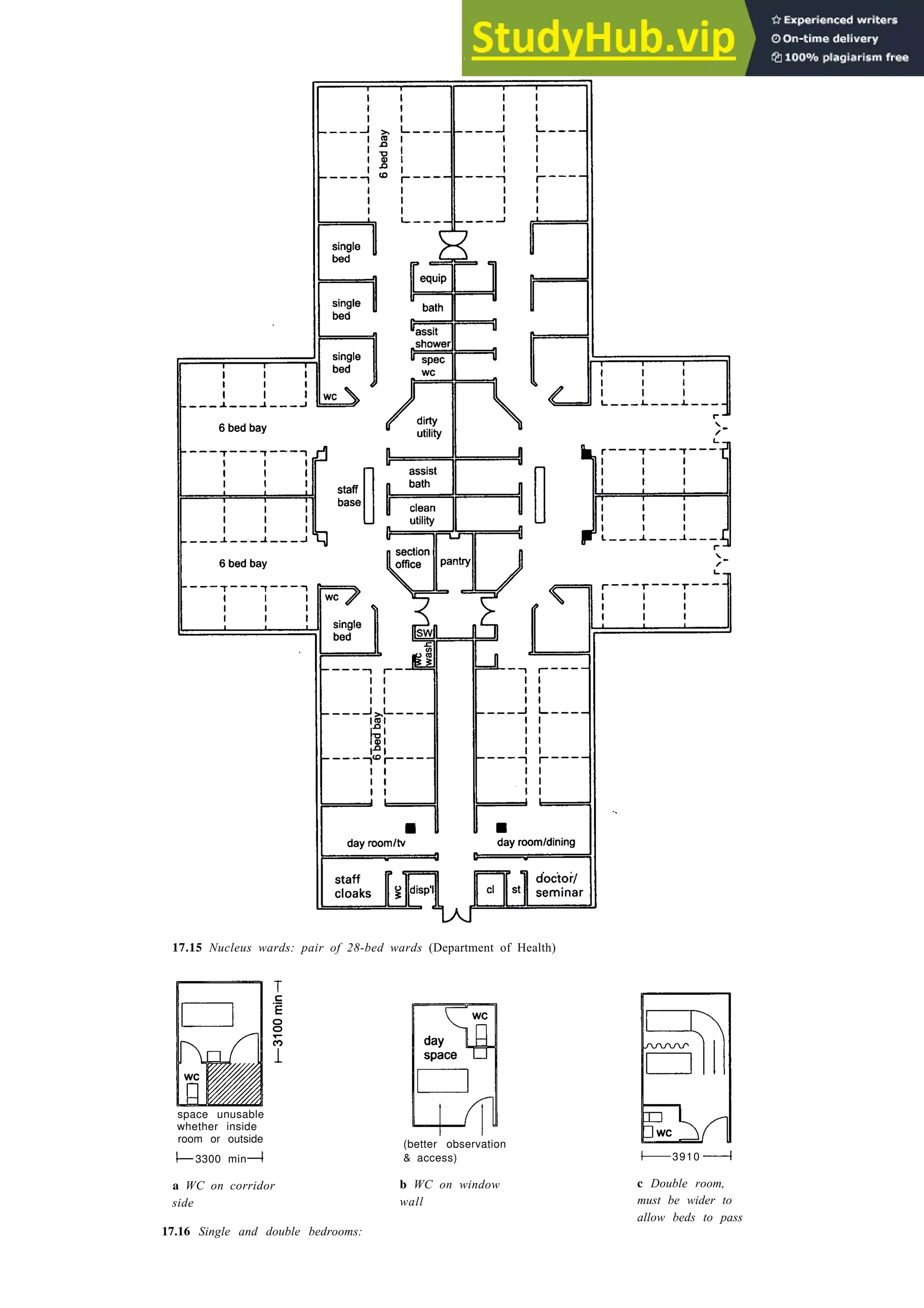

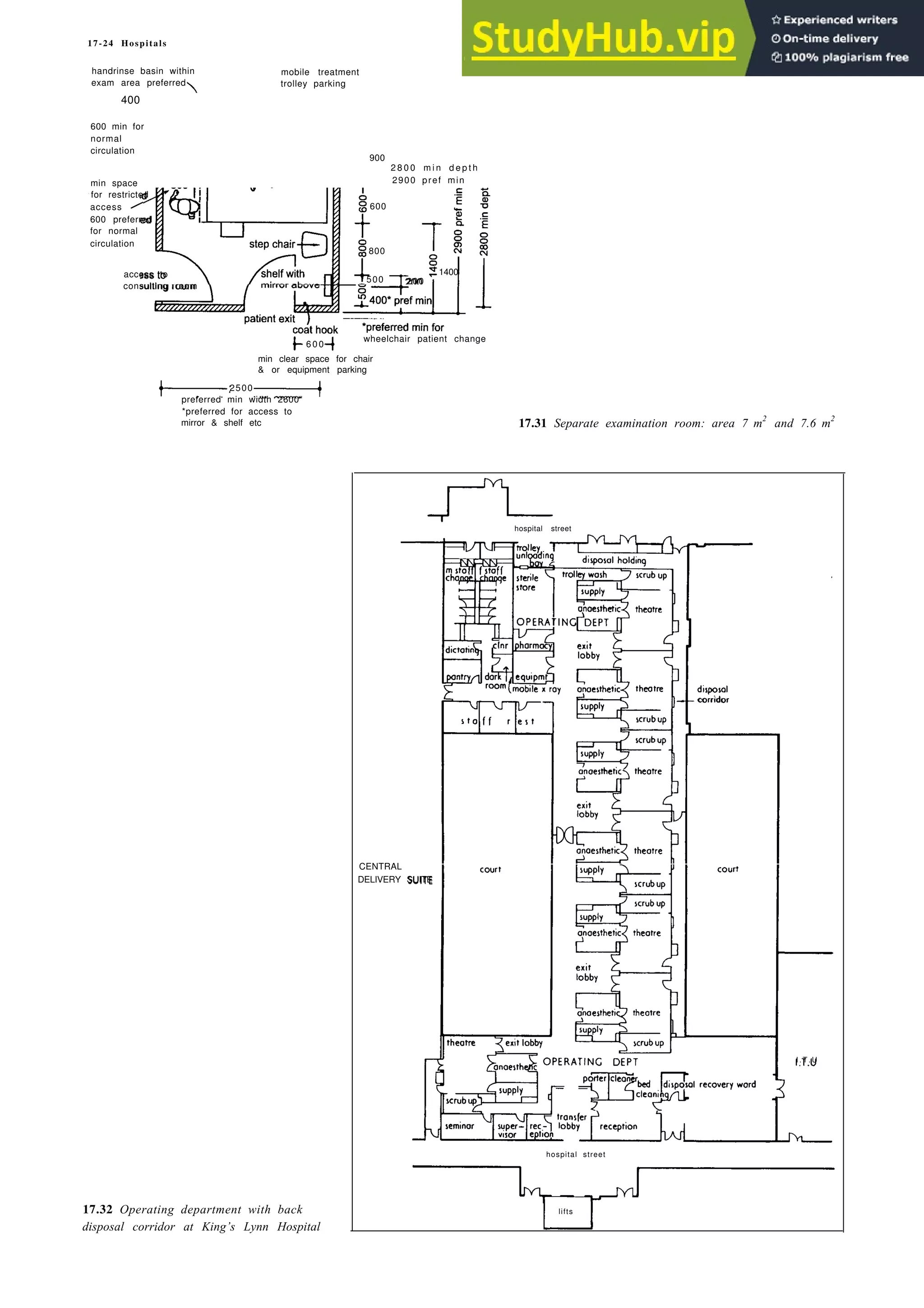

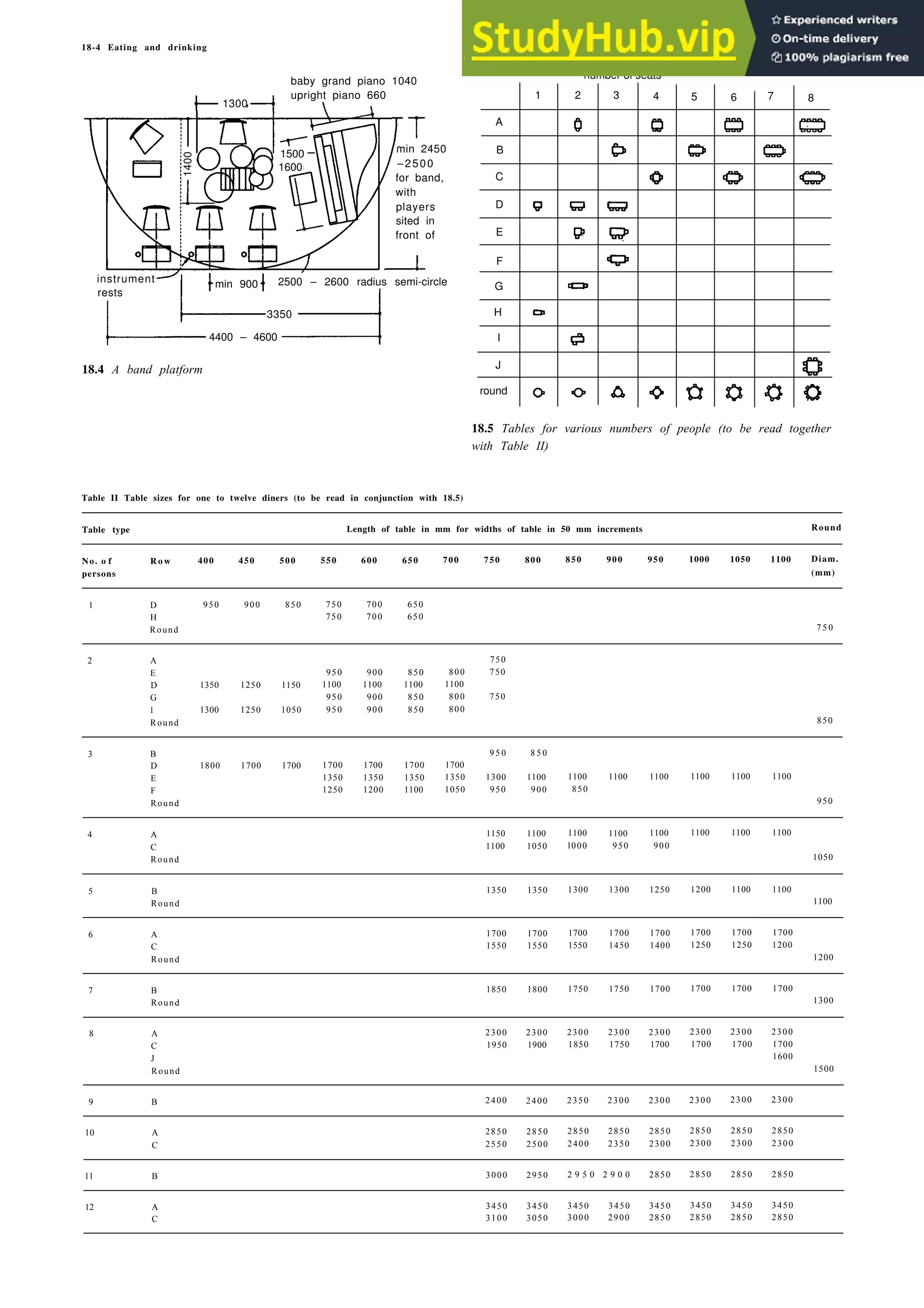

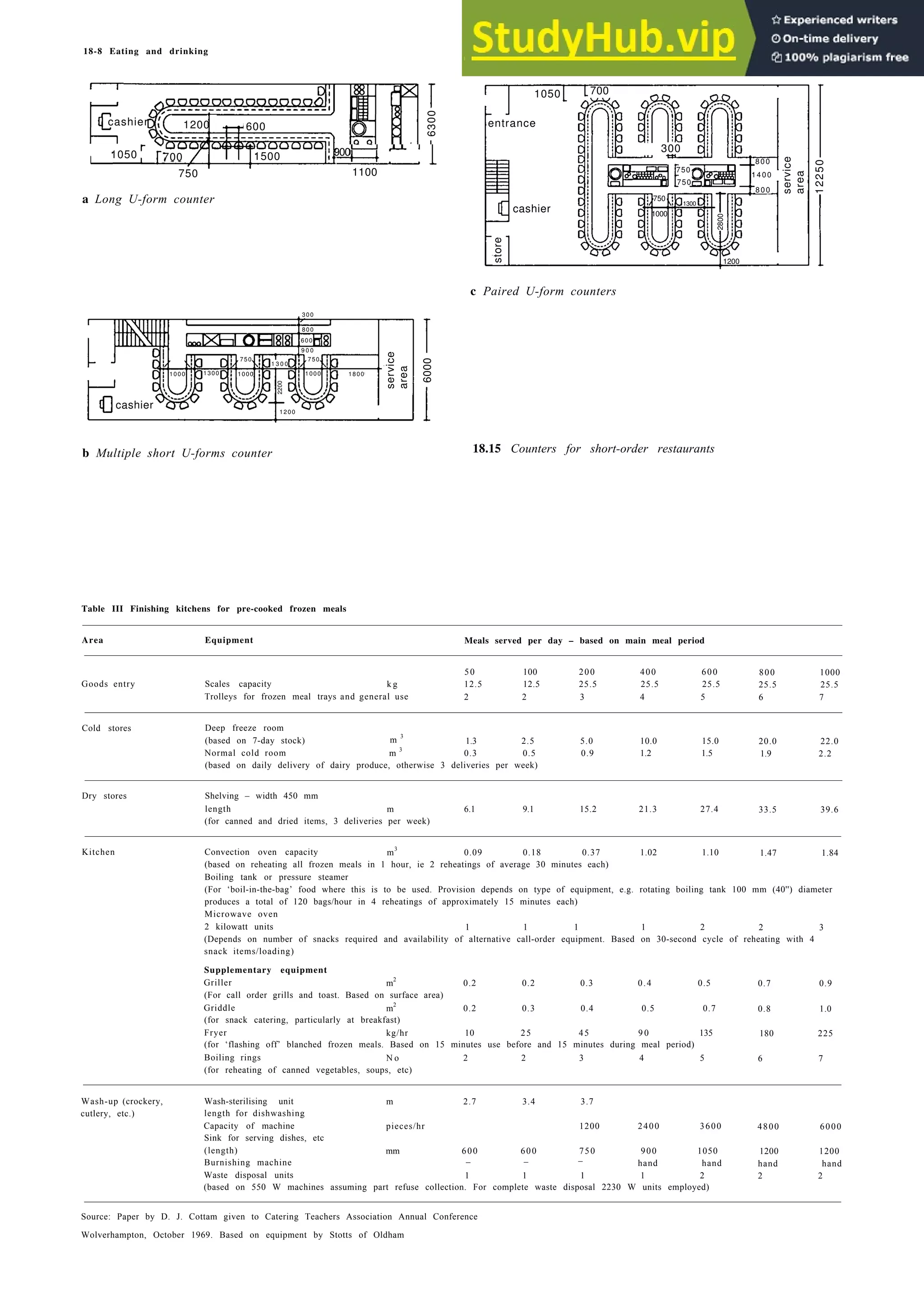

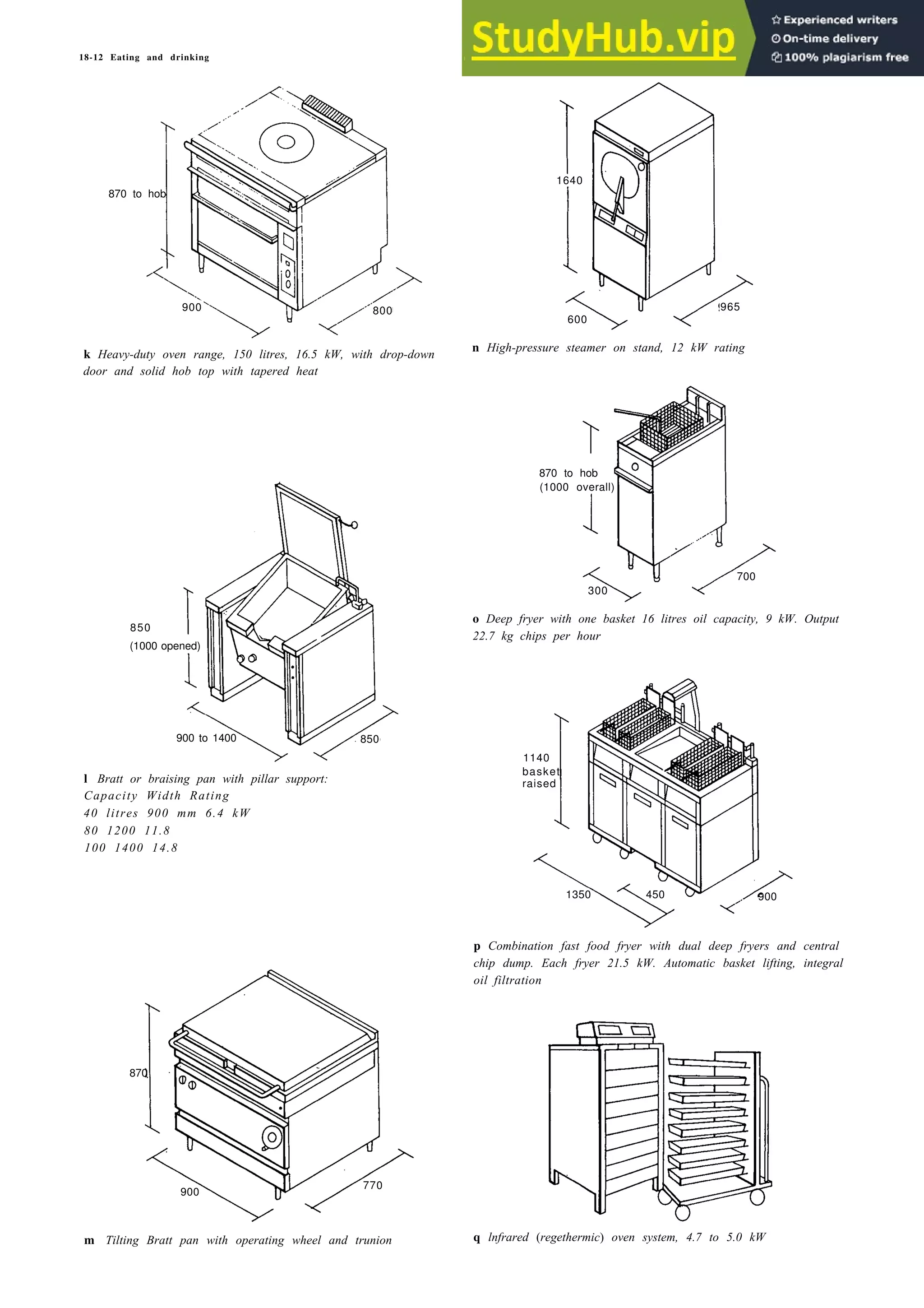

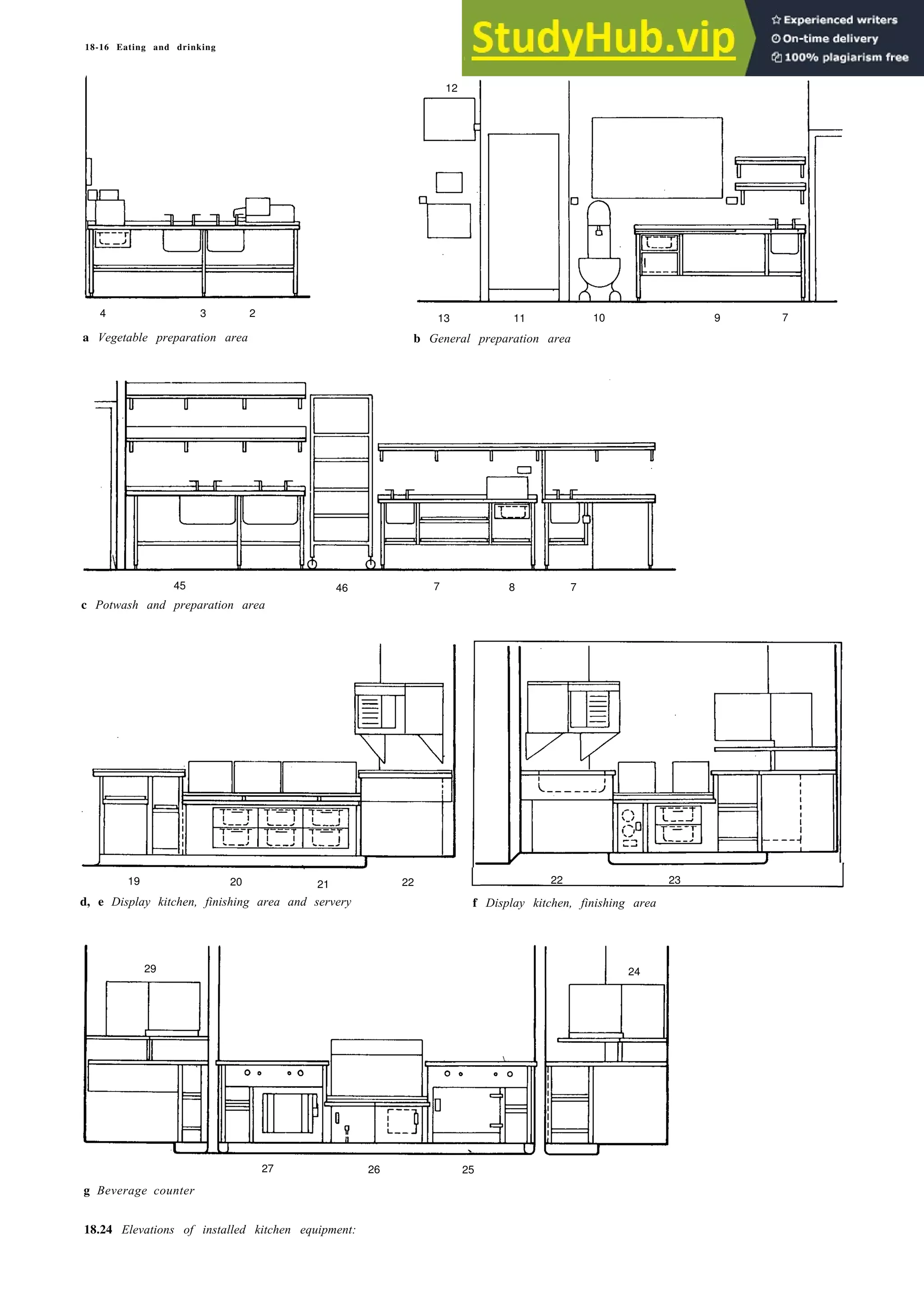

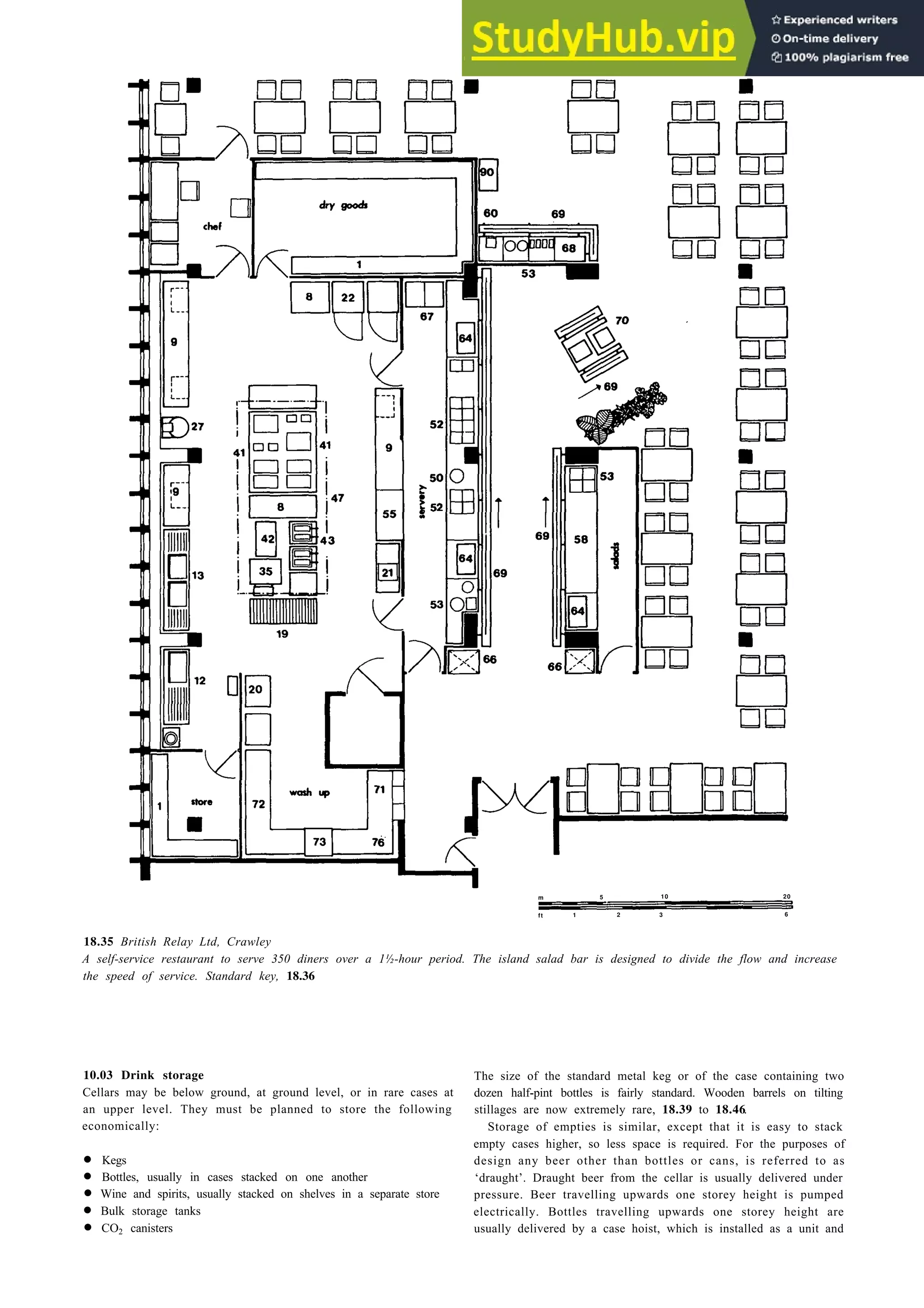

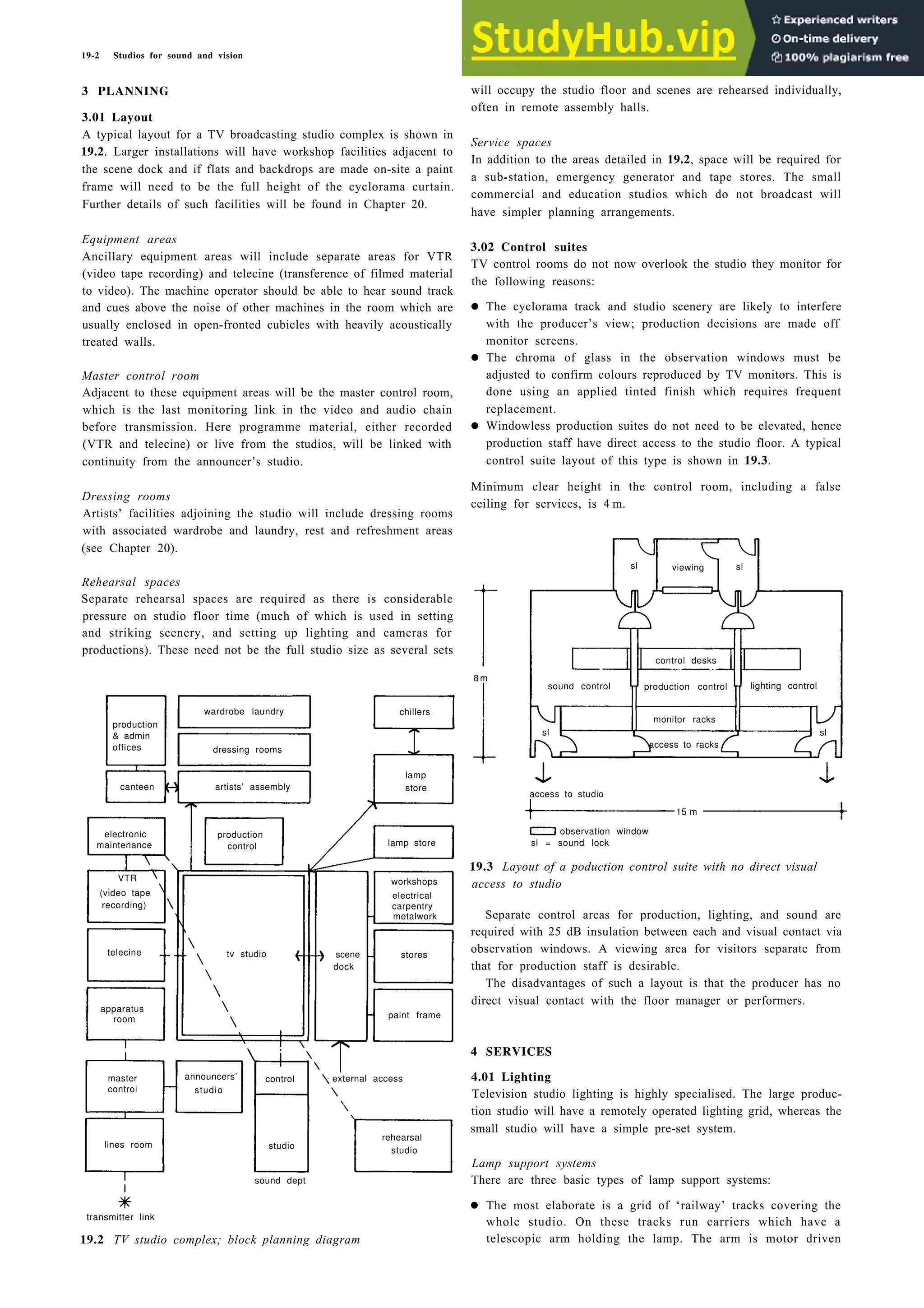

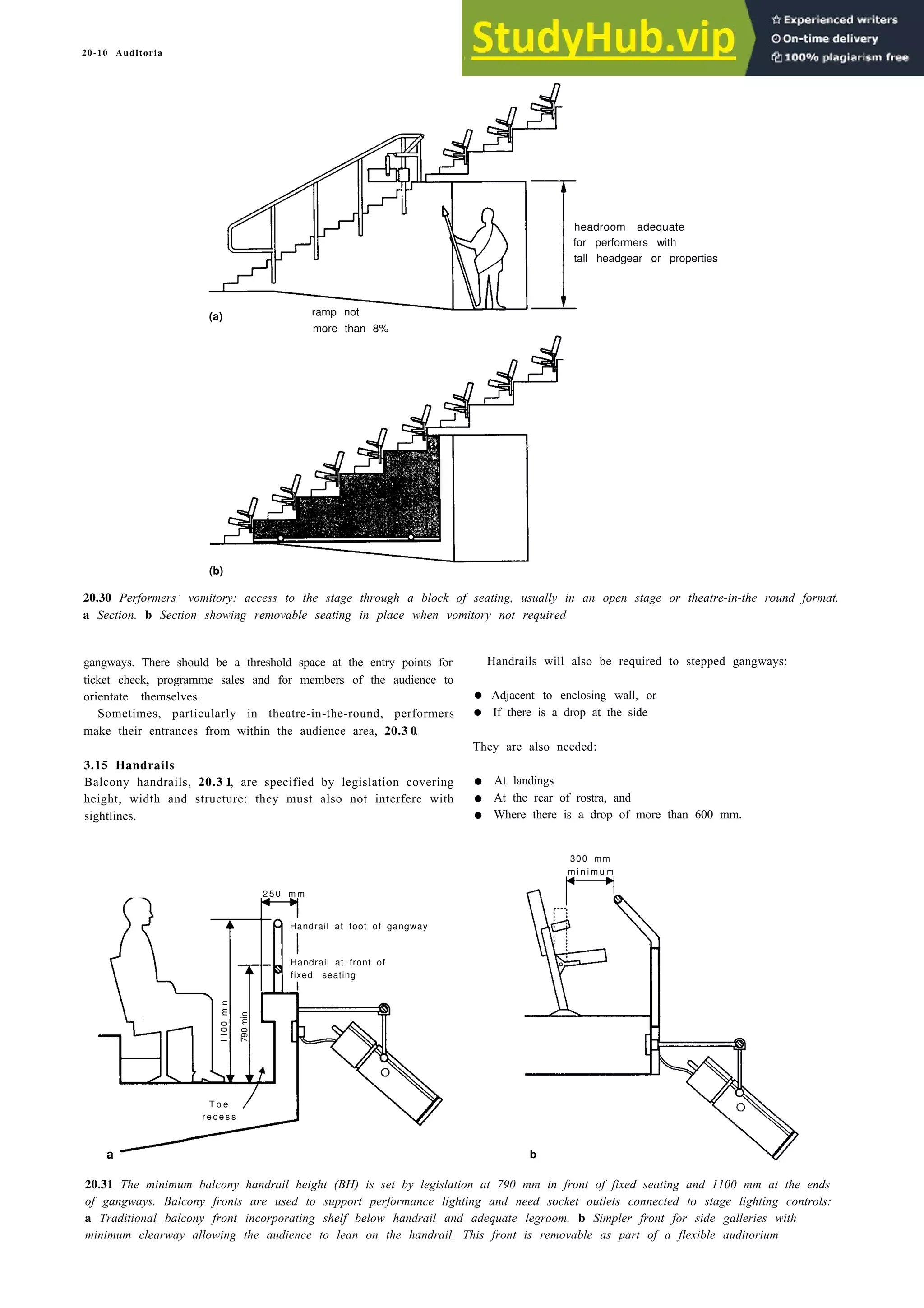

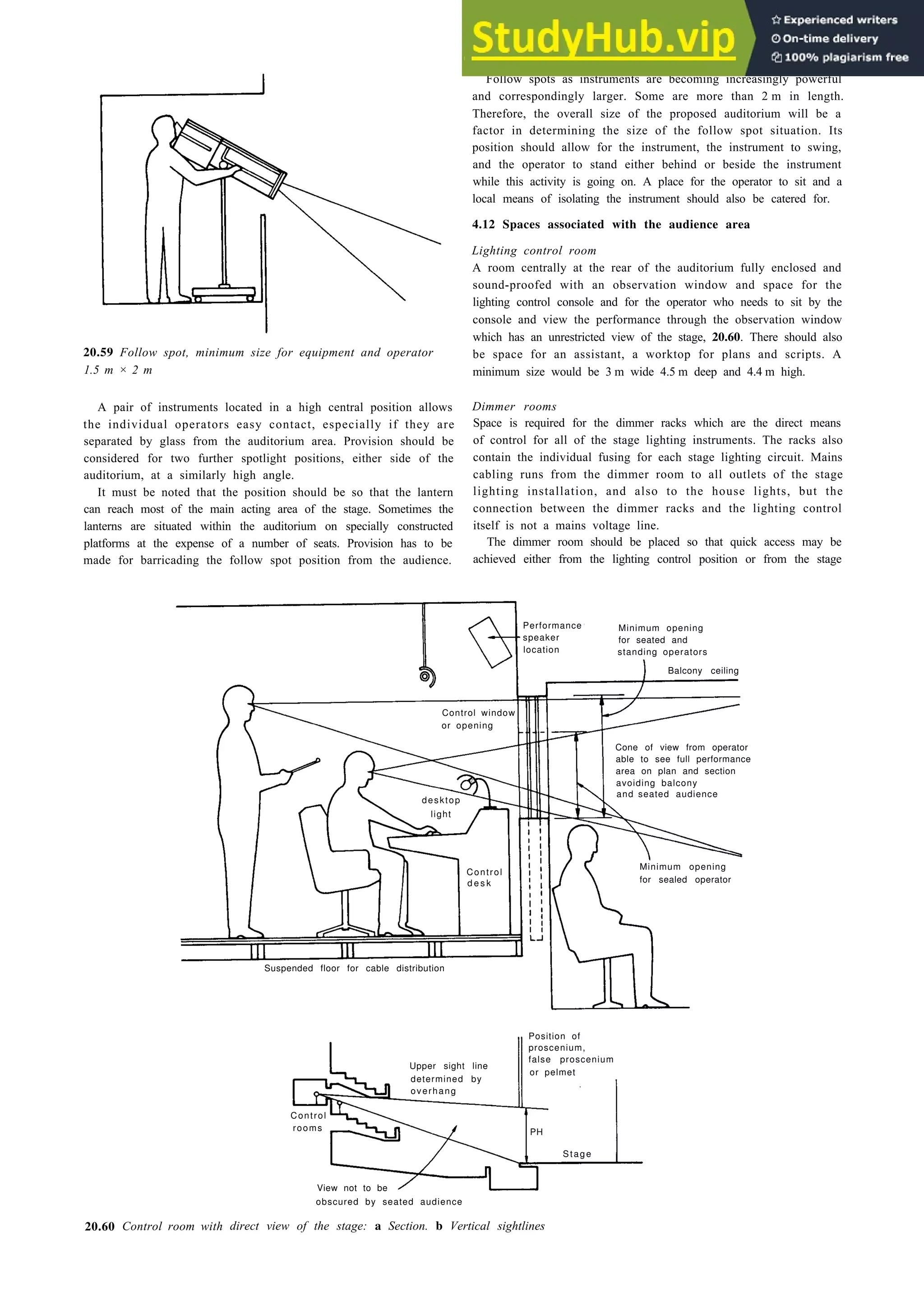

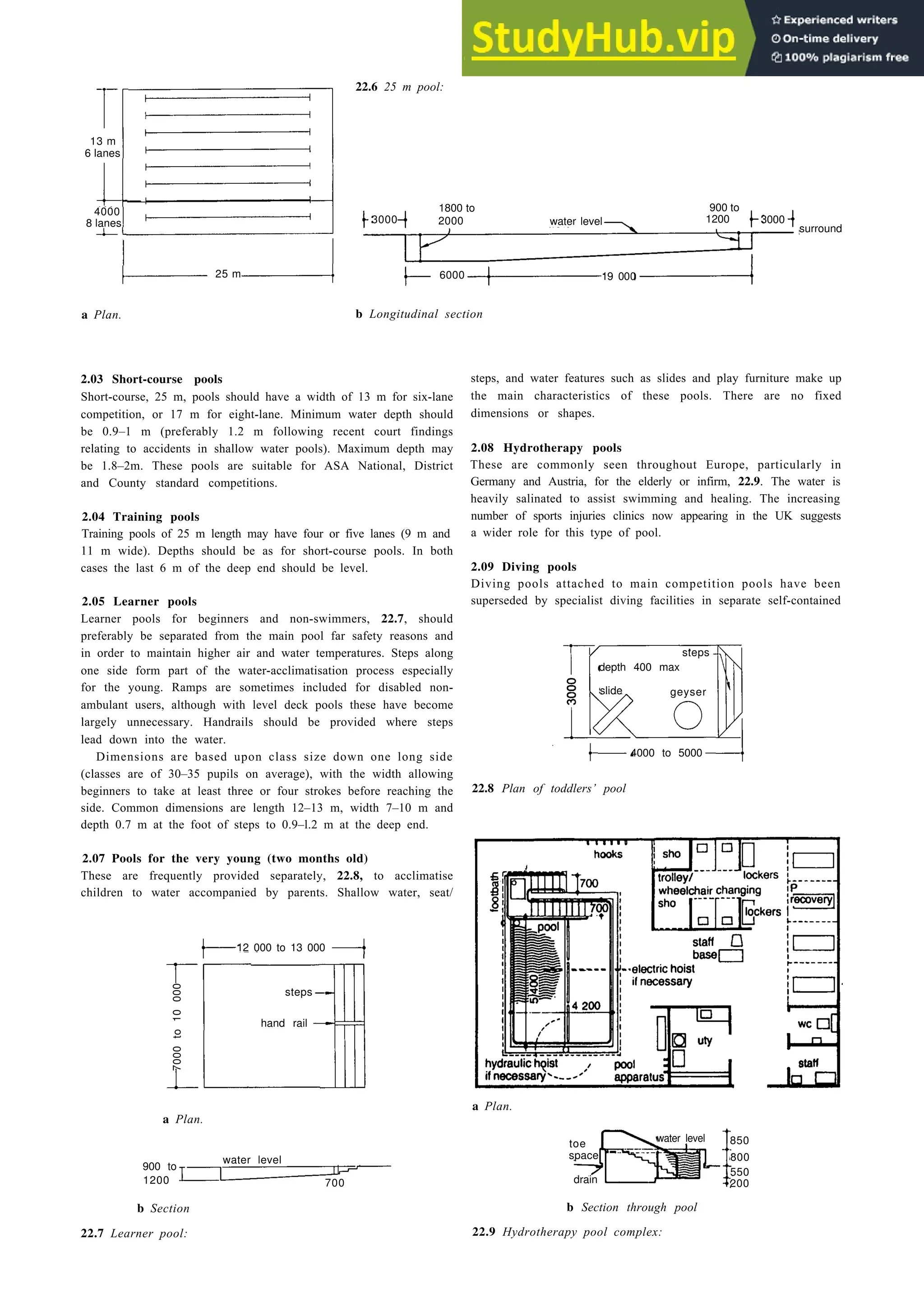

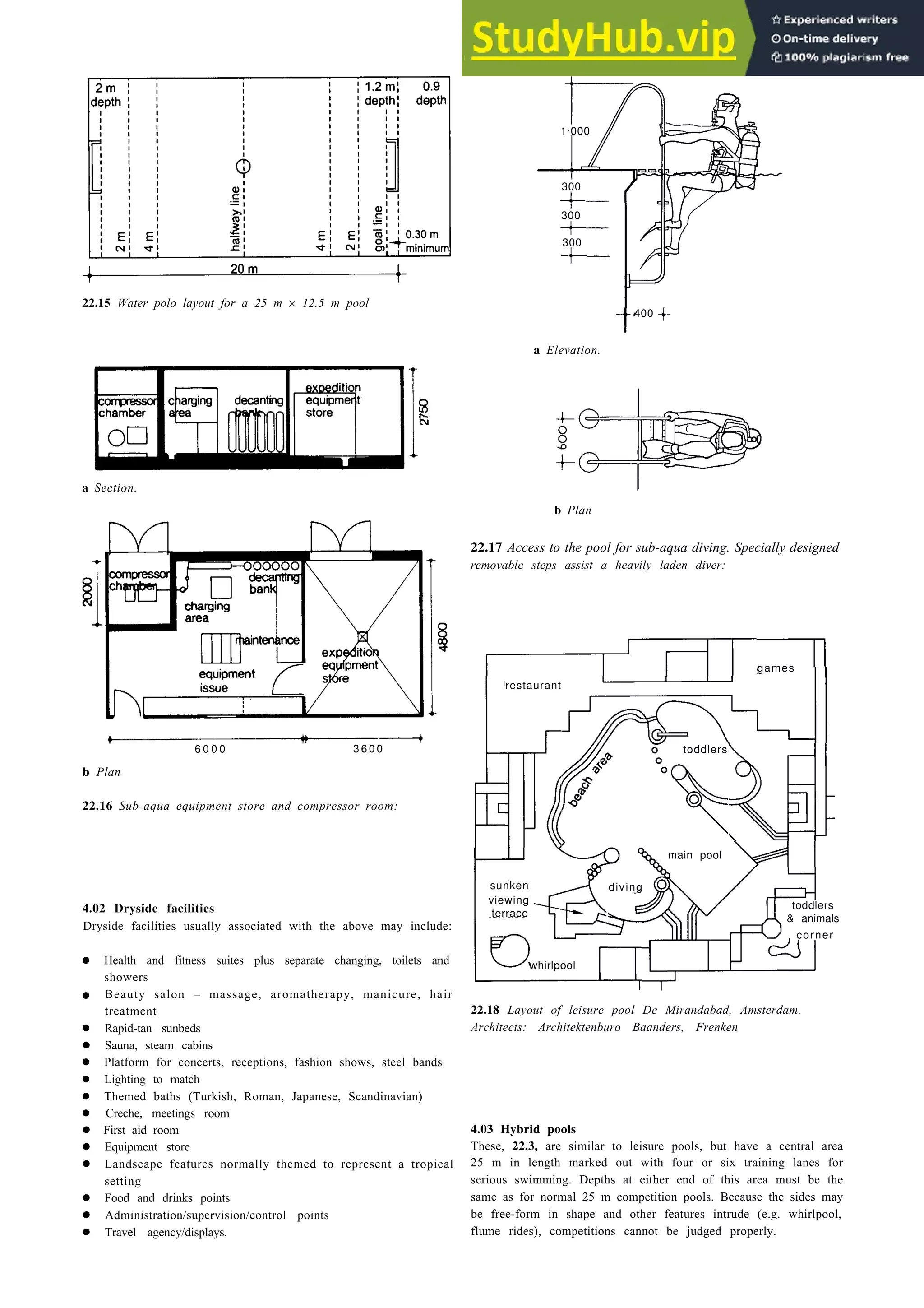

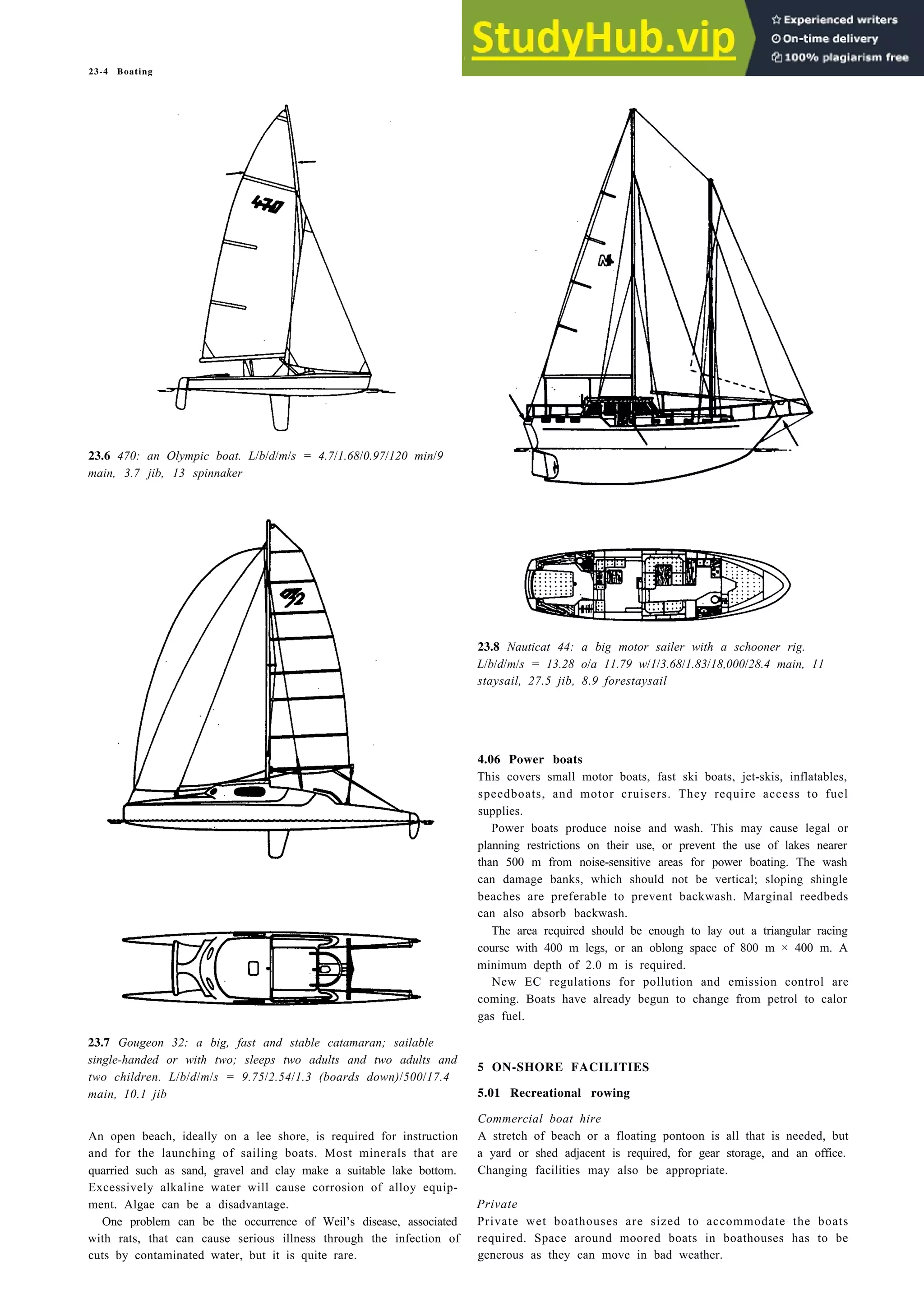

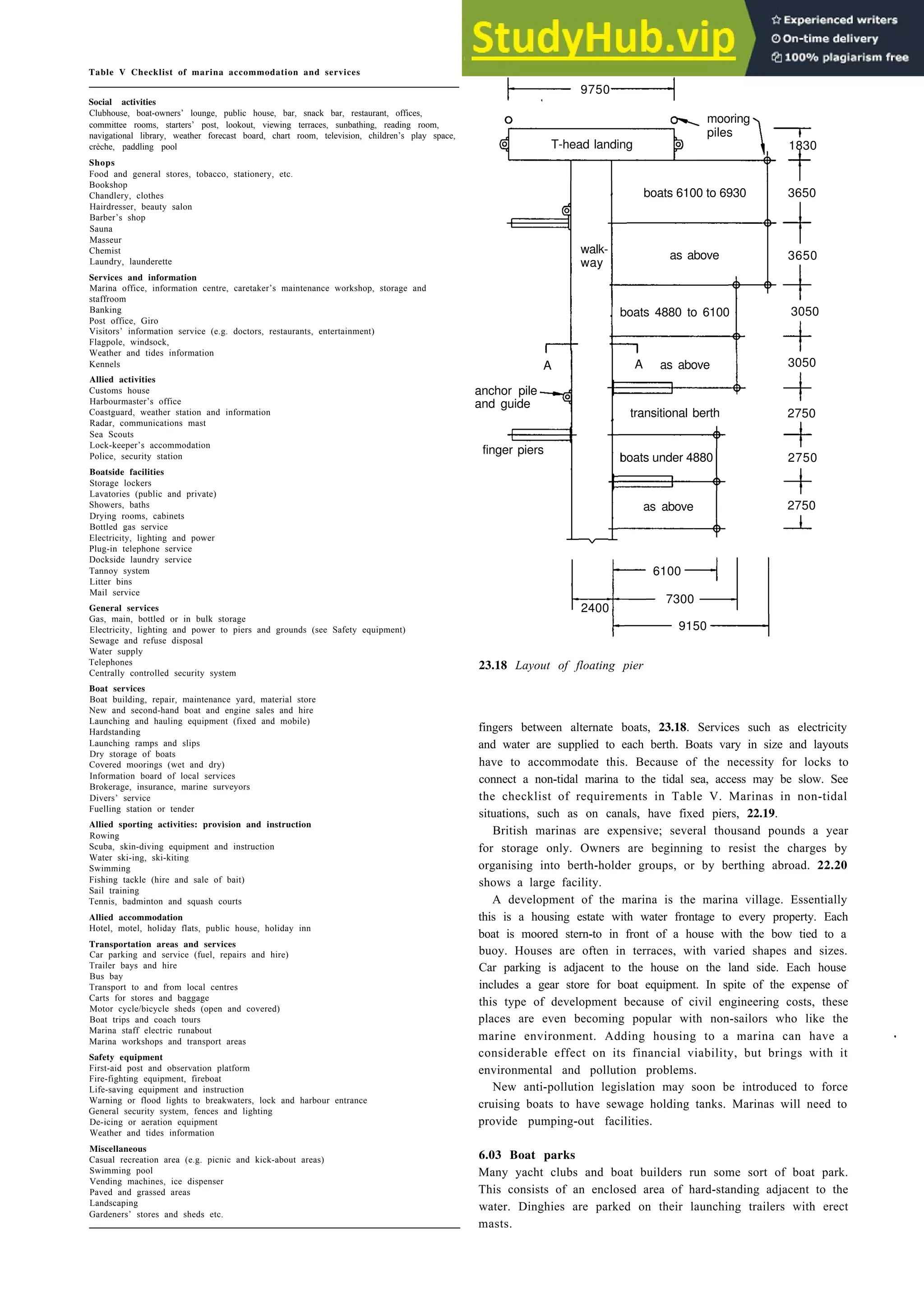

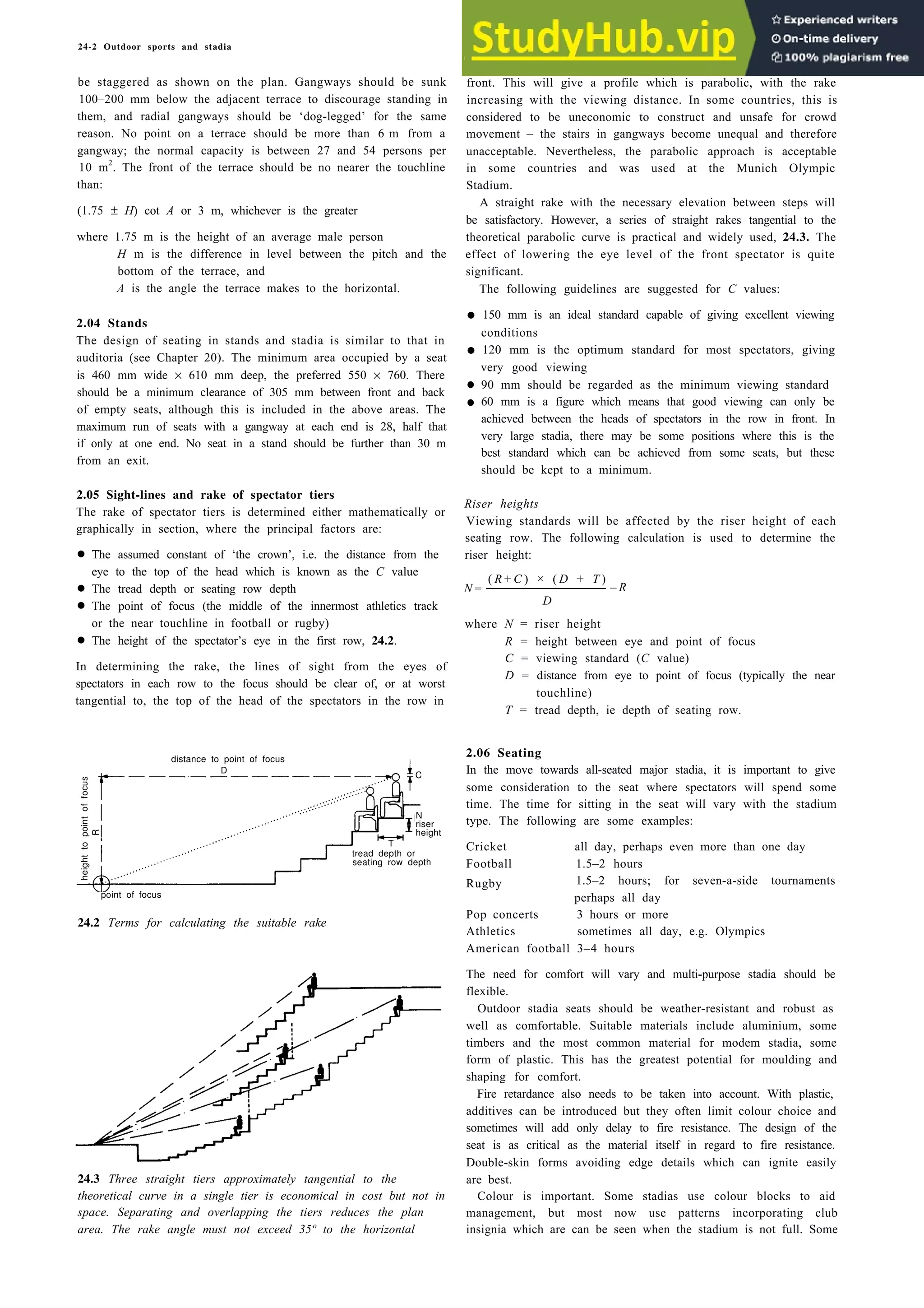

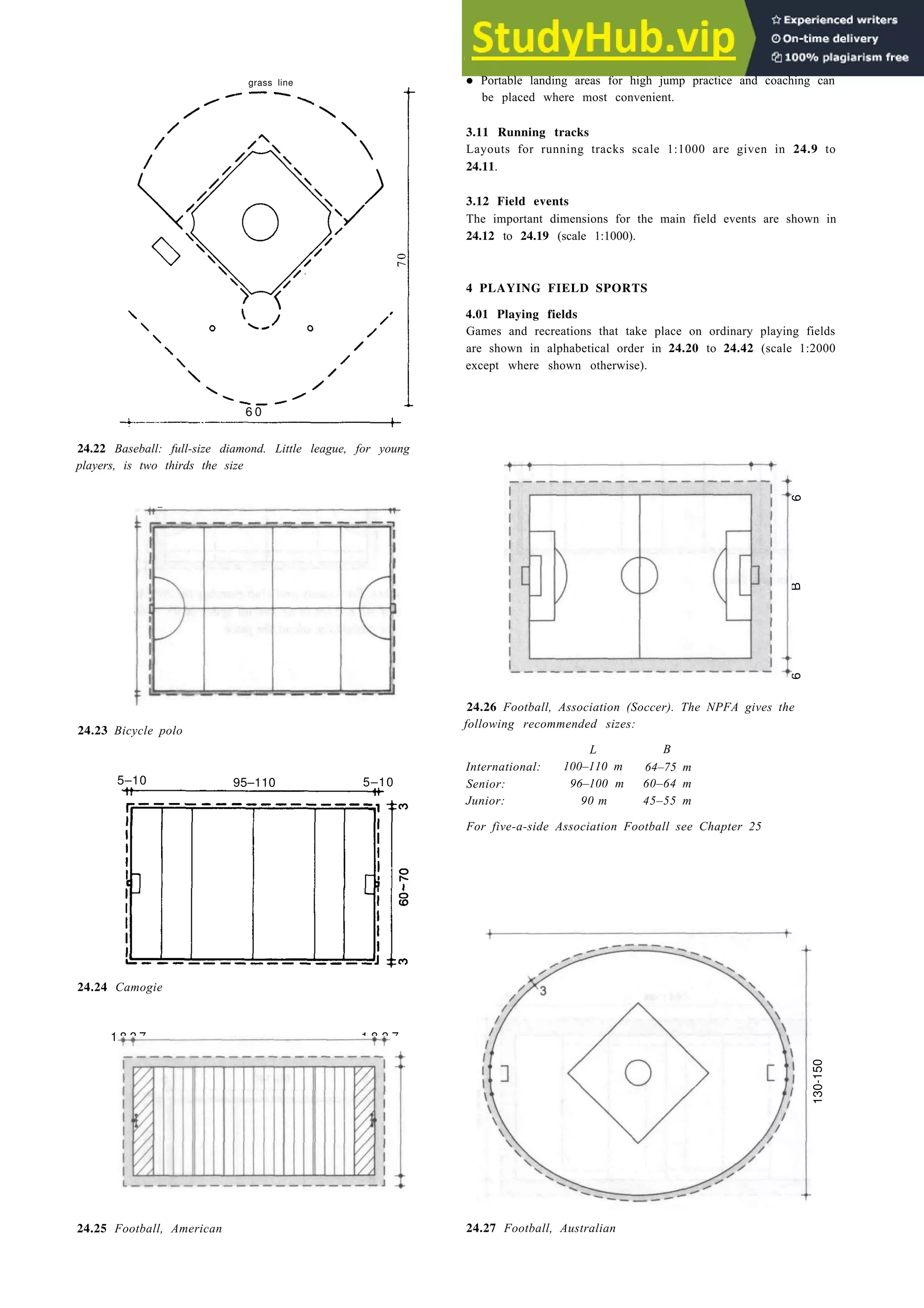

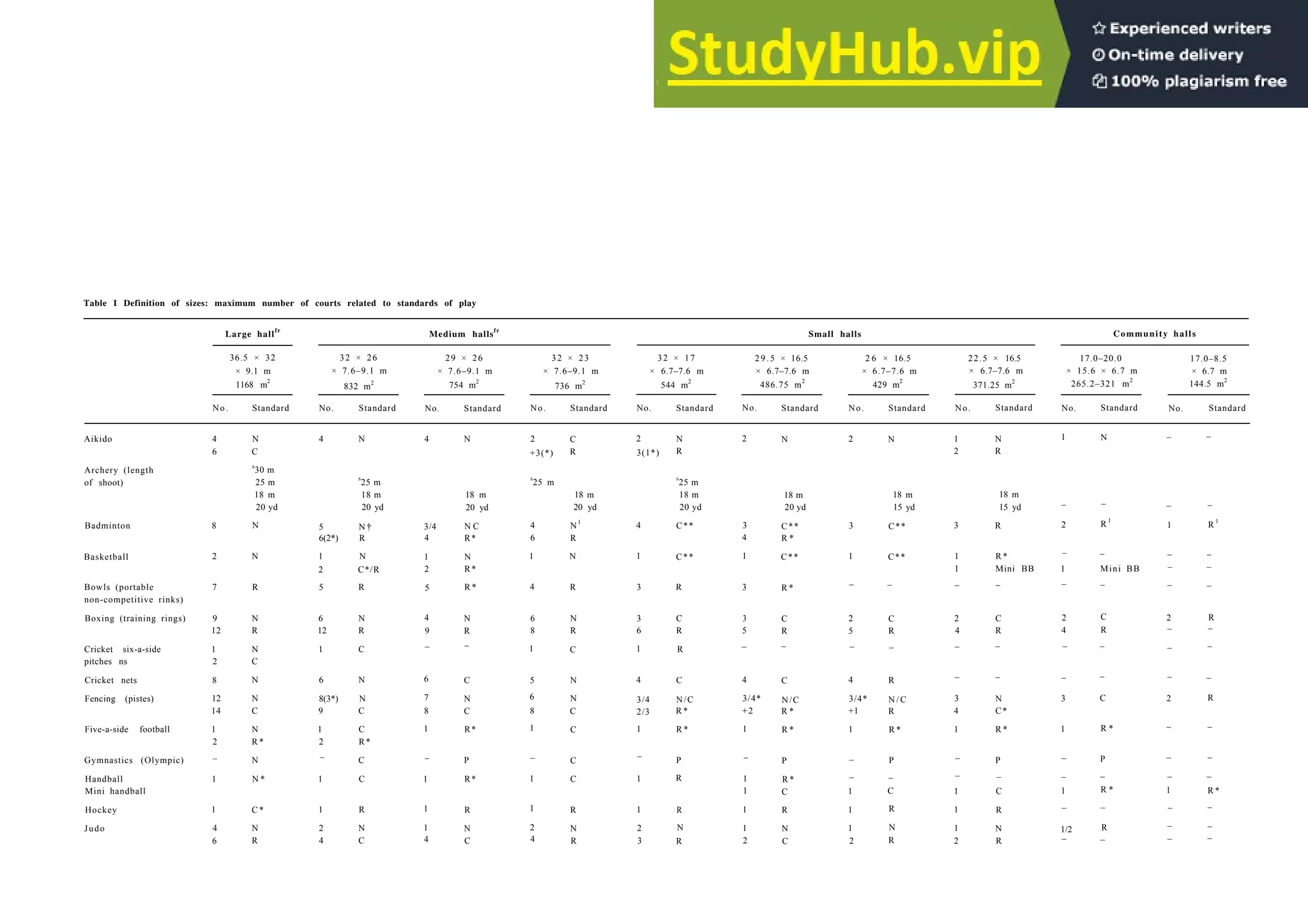

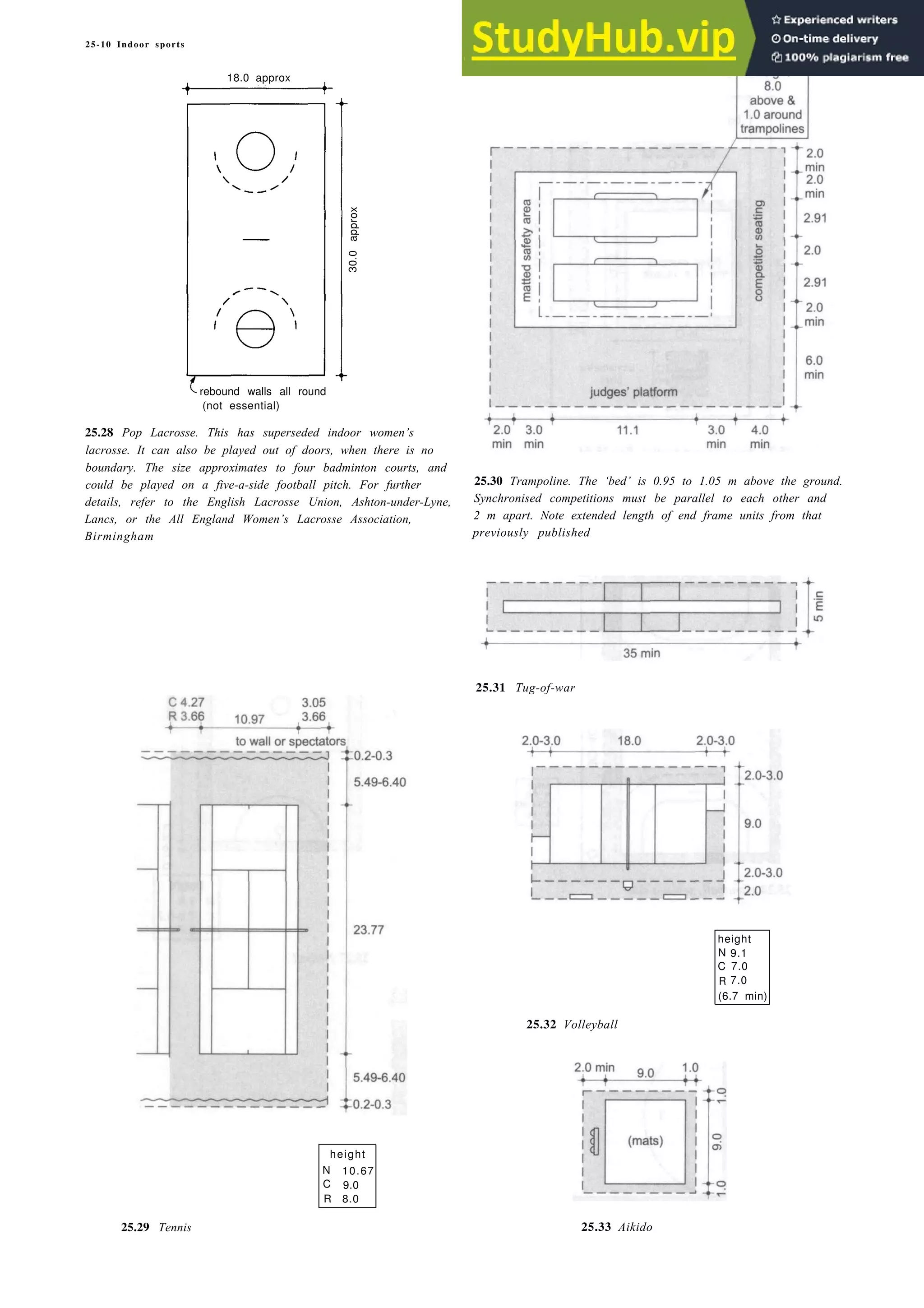

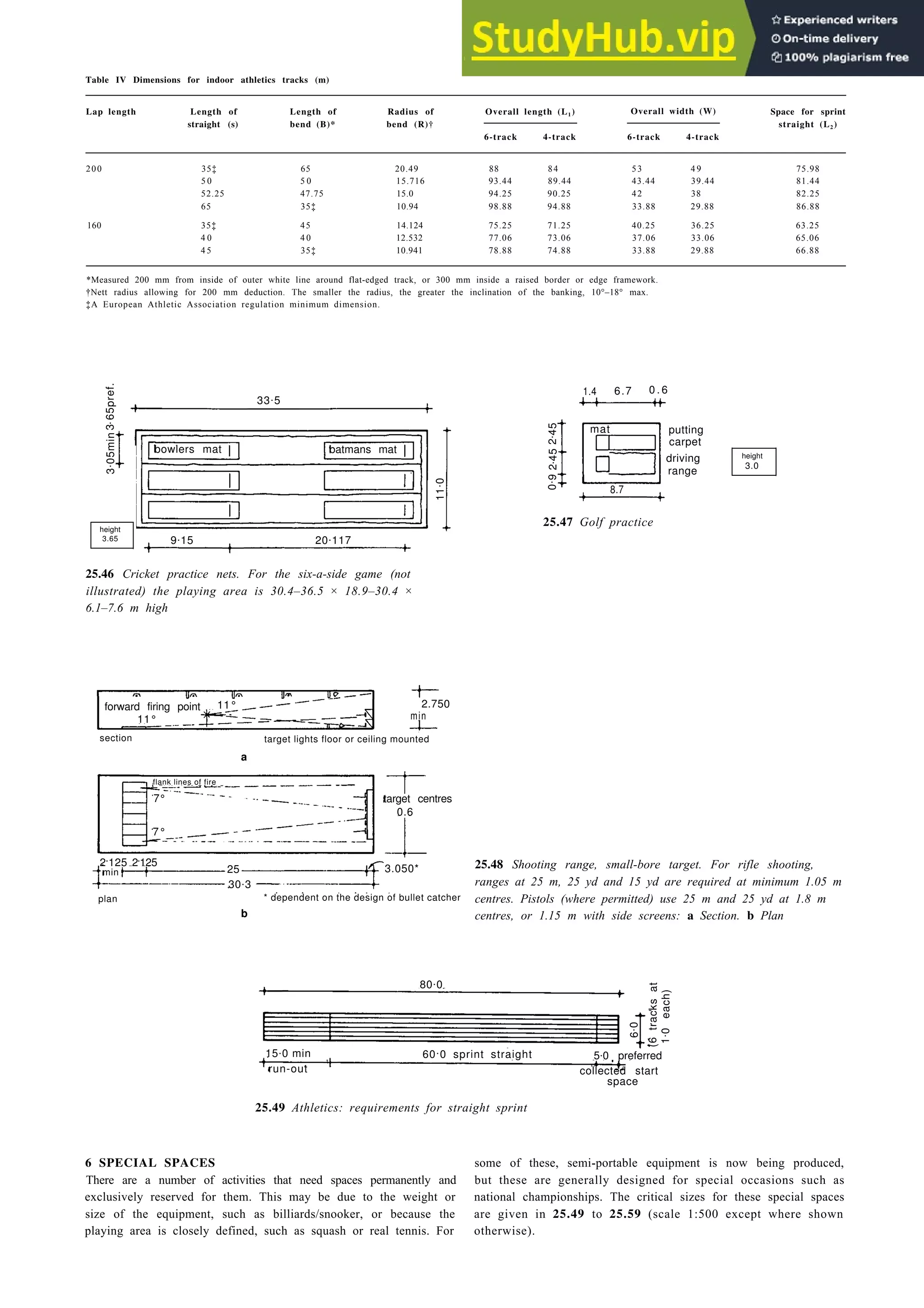

25.50 Athletics: indoor tracks 200 and 160 metre laps, with straight sprint in centre. See Table IV for dimensions. It is no longer

considered satisfactory to fit a running track inside the cycle track in 25.53. If spectator accommodation is needed around the track,

a building of considerable clear span is necessary as supports in the central area are not acceptable

25.51 Billiards and snooker. The

agreed international size, due to

become mandatory in 2025, of 3.5 ×

1.75 m measured inside the cushions,

has had little acceptance, even in

major competitions

25.52 Bowling. Four rinks are the minimum for recreation,

six are required for tournaments

41

.

34

54

.

34

6

.

5

5.0 100.23 5.0

[24.48] can be used internally

sprint straight L2

overall length L1

6

.

5

110.23

straight S](https://image.slidesharecdn.com/architectureebookmetrichandbookplanninganddesigndata-230807180049-33007df6/75/Architecture-Ebook-Metric-Handbook-Planning-and-Design-Data-pdf-418-2048.jpg)