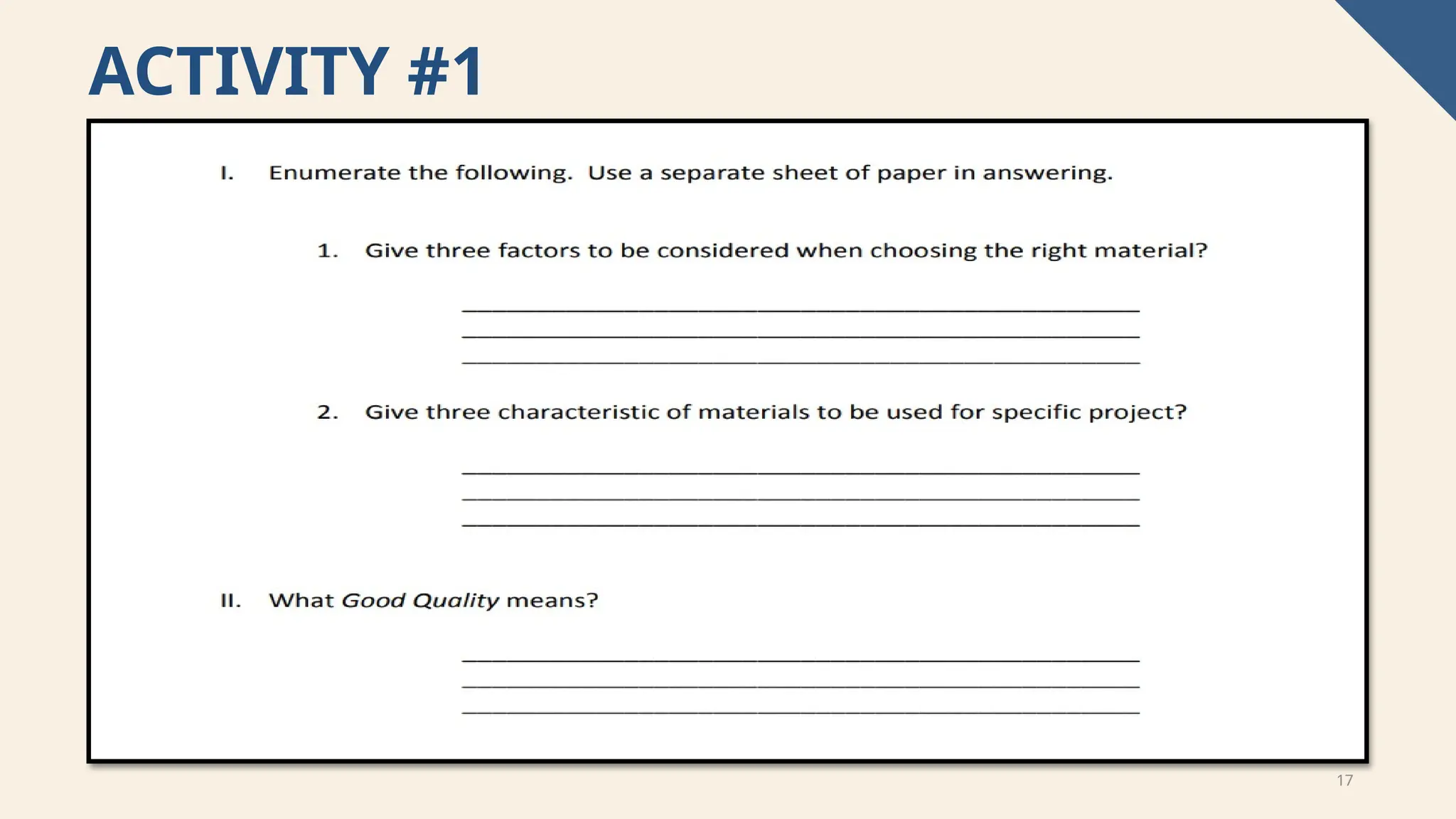

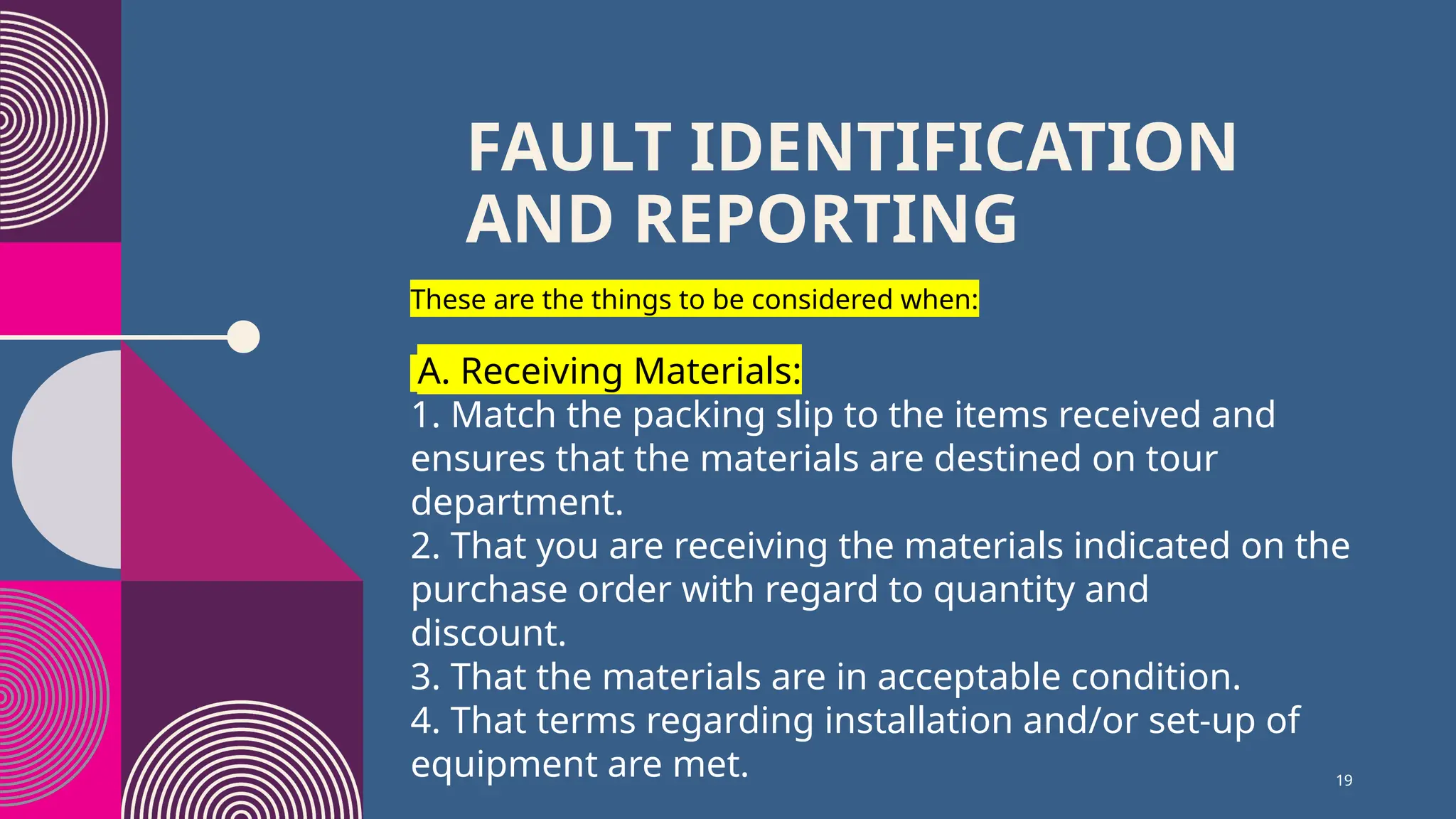

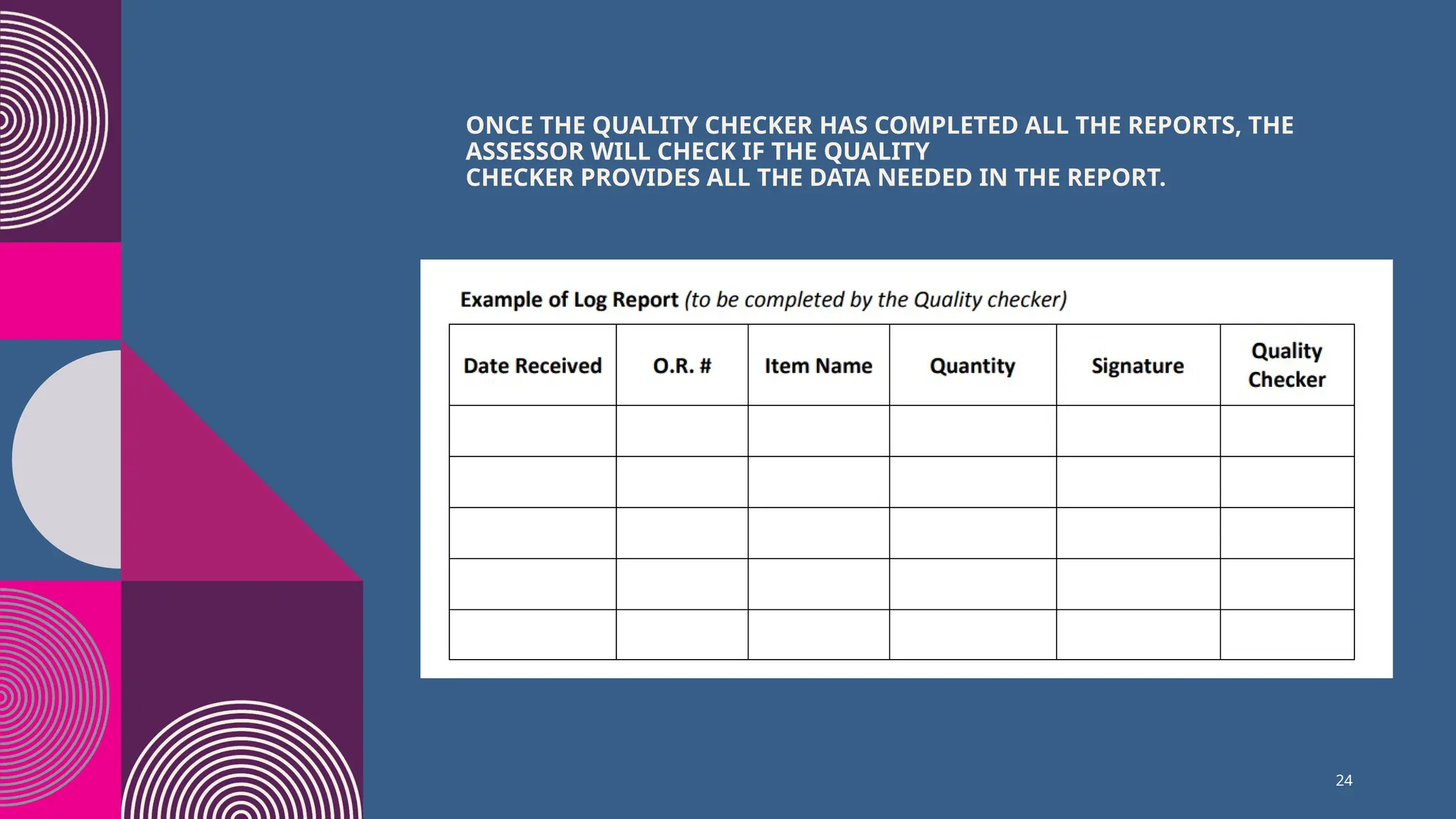

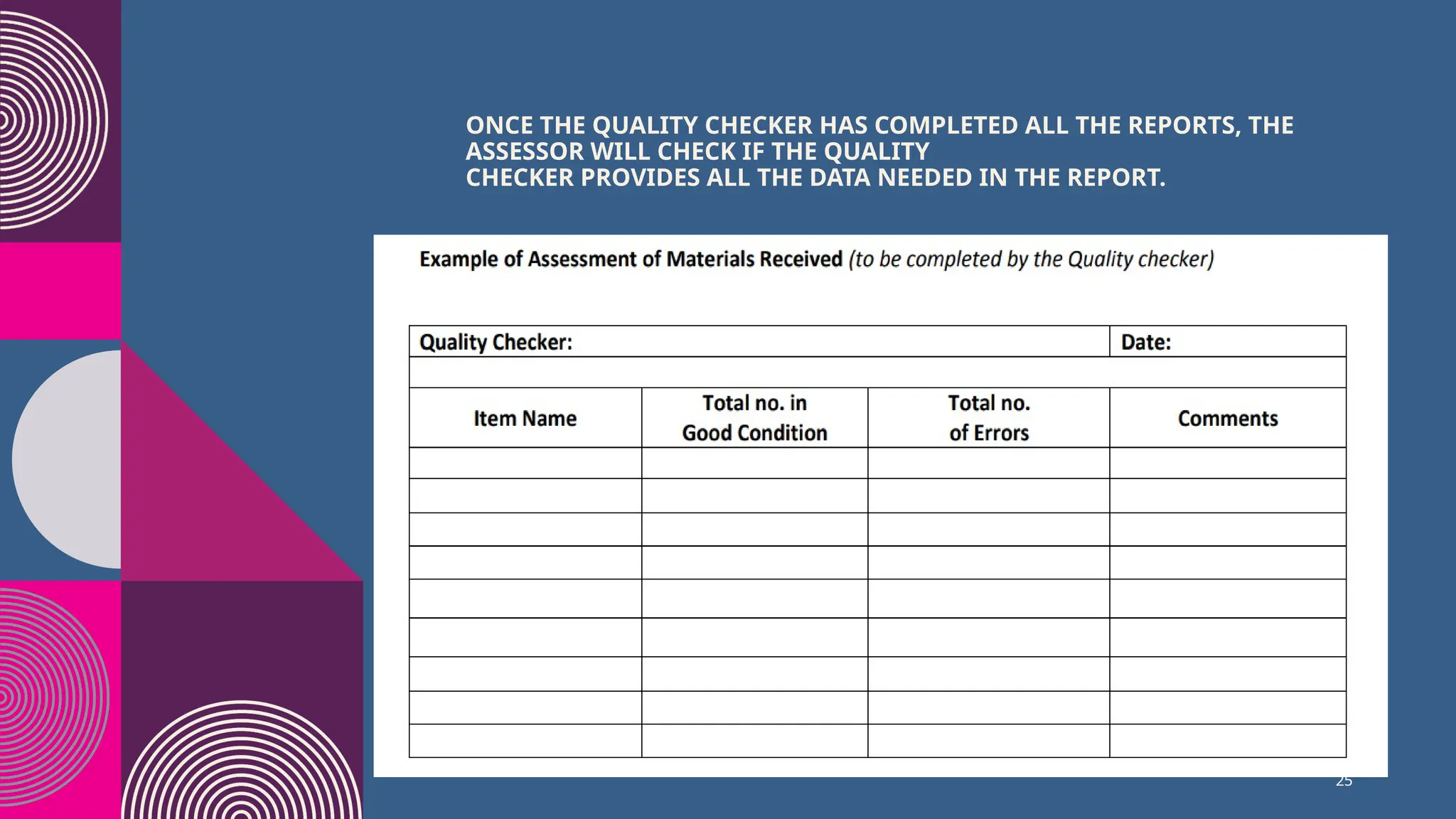

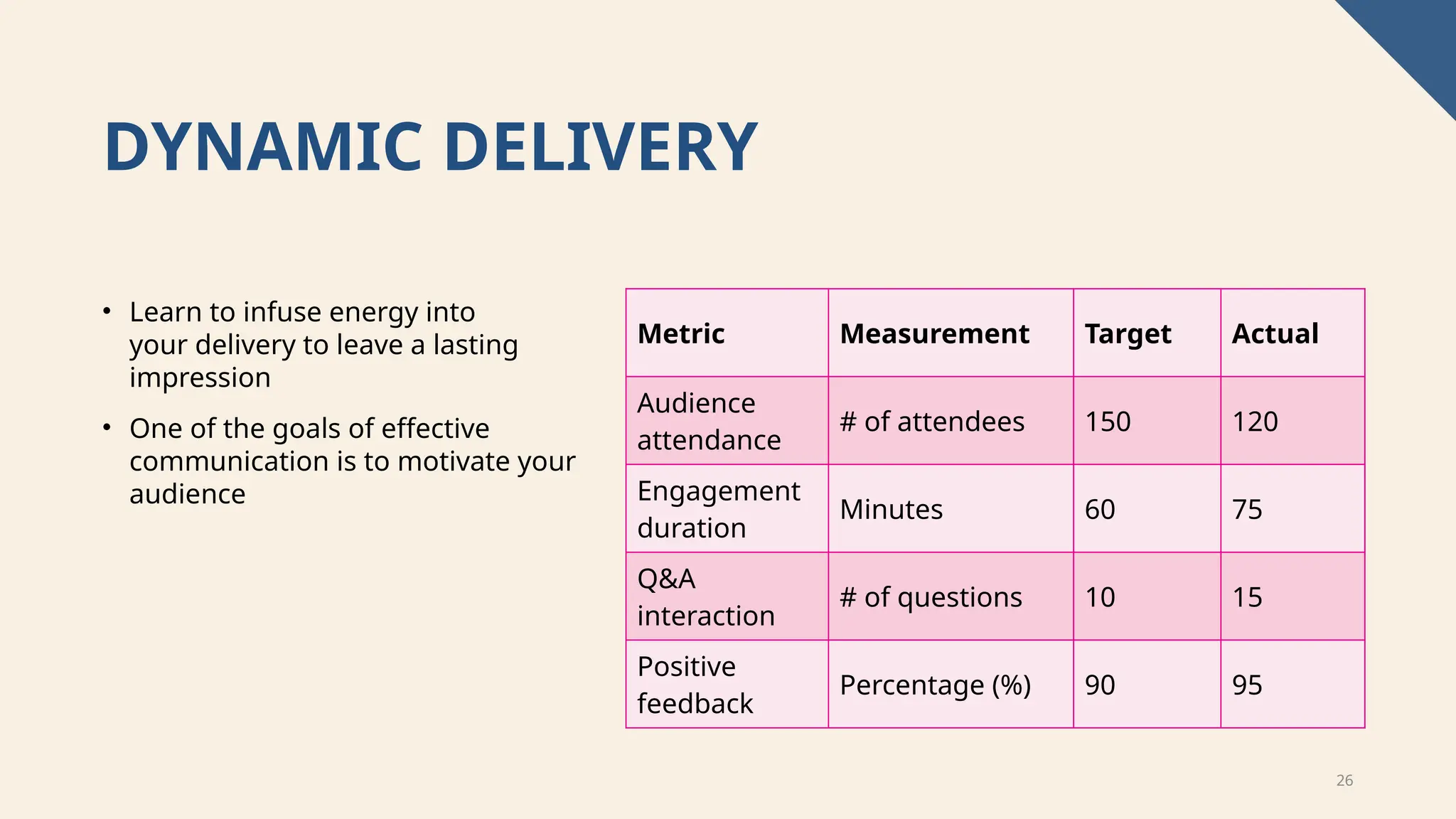

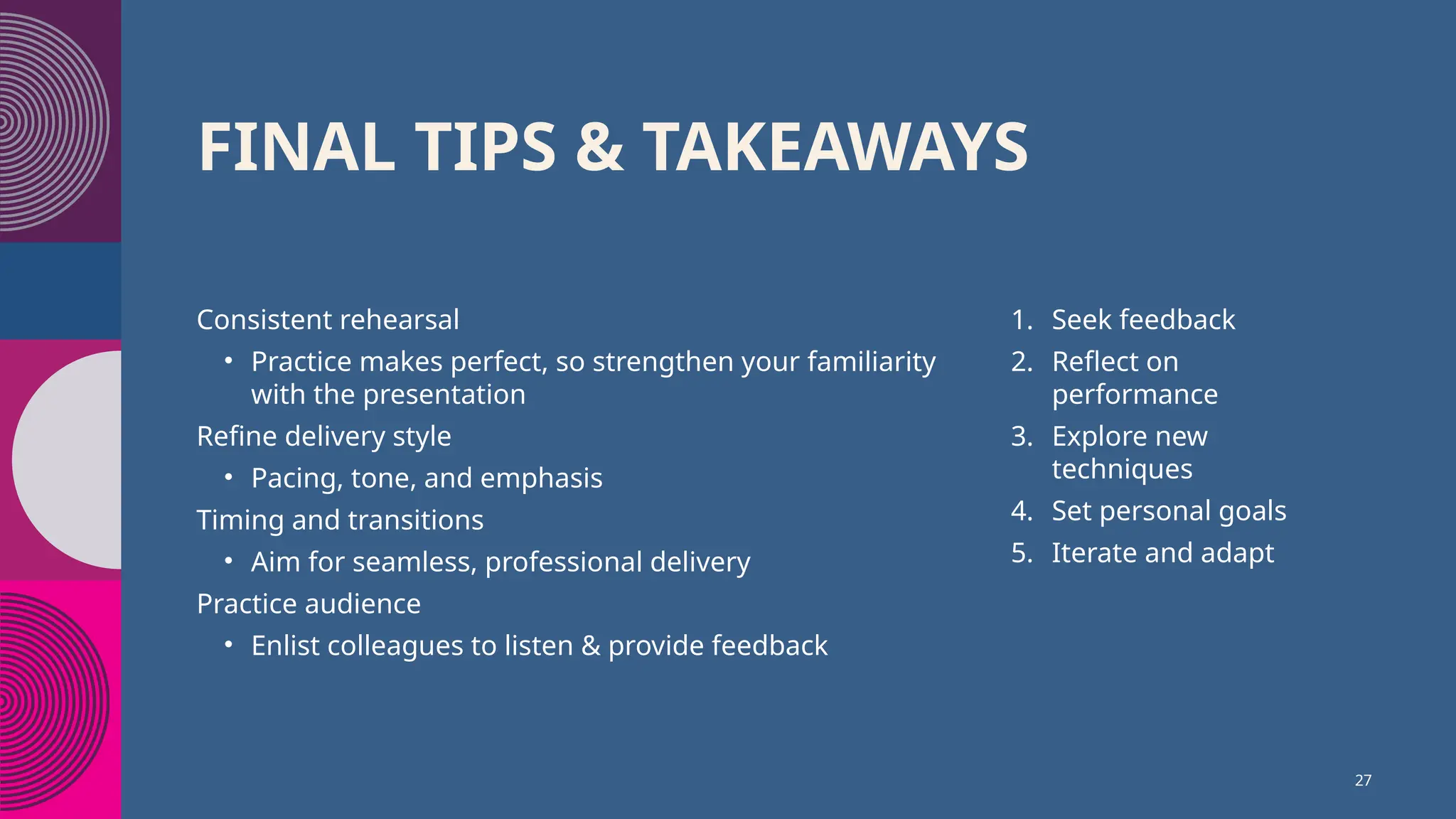

The document outlines key learning outcomes related to assessing the condition of received equipment and emphasizes the importance of quality standards in material selection and testing. It includes definitions of important technical terms, assessment criteria, and considerations for identifying faults in received materials. Additionally, it presents methodologies for effective quality checking and highlights tips for delivering impactful presentations.