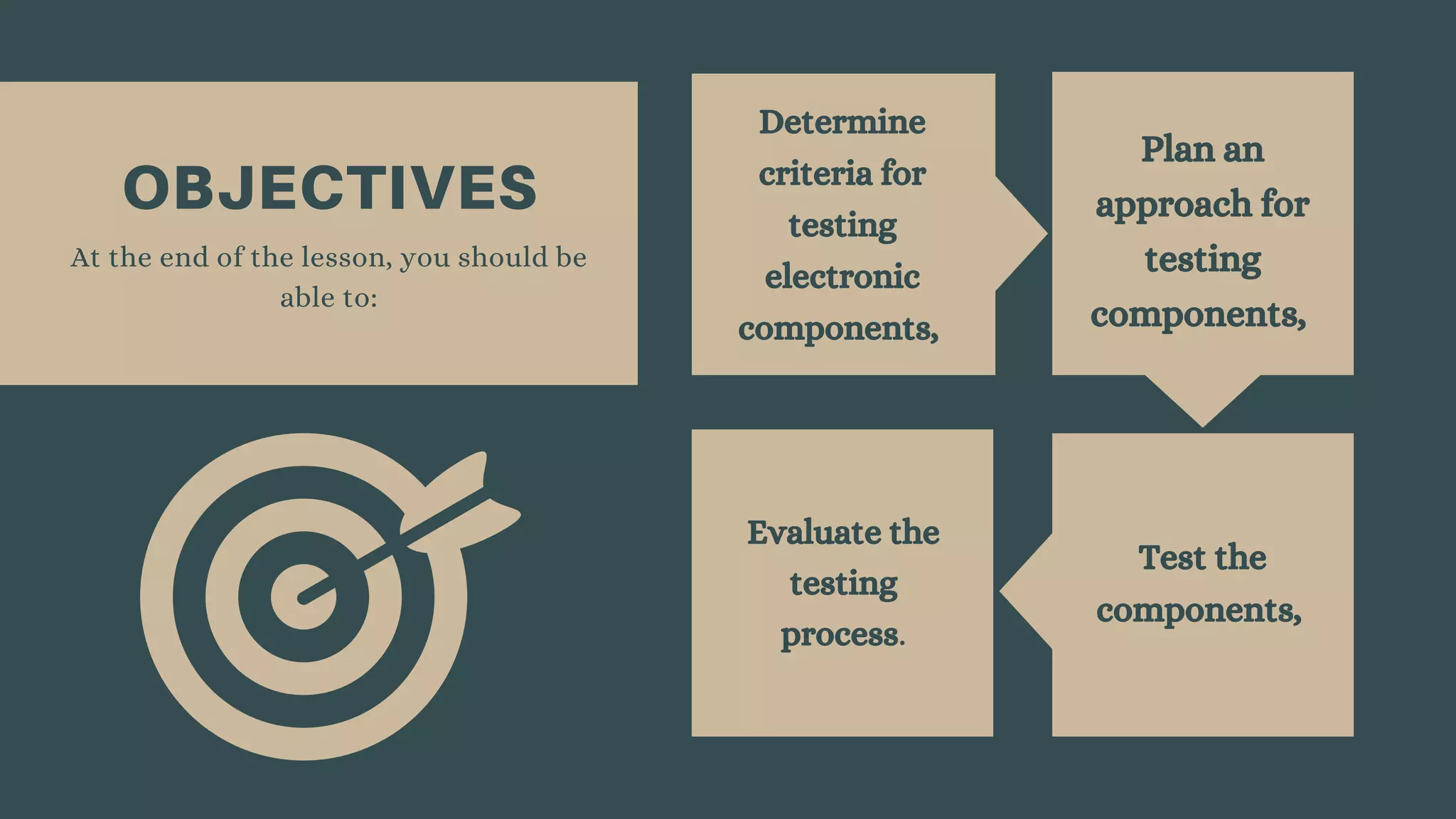

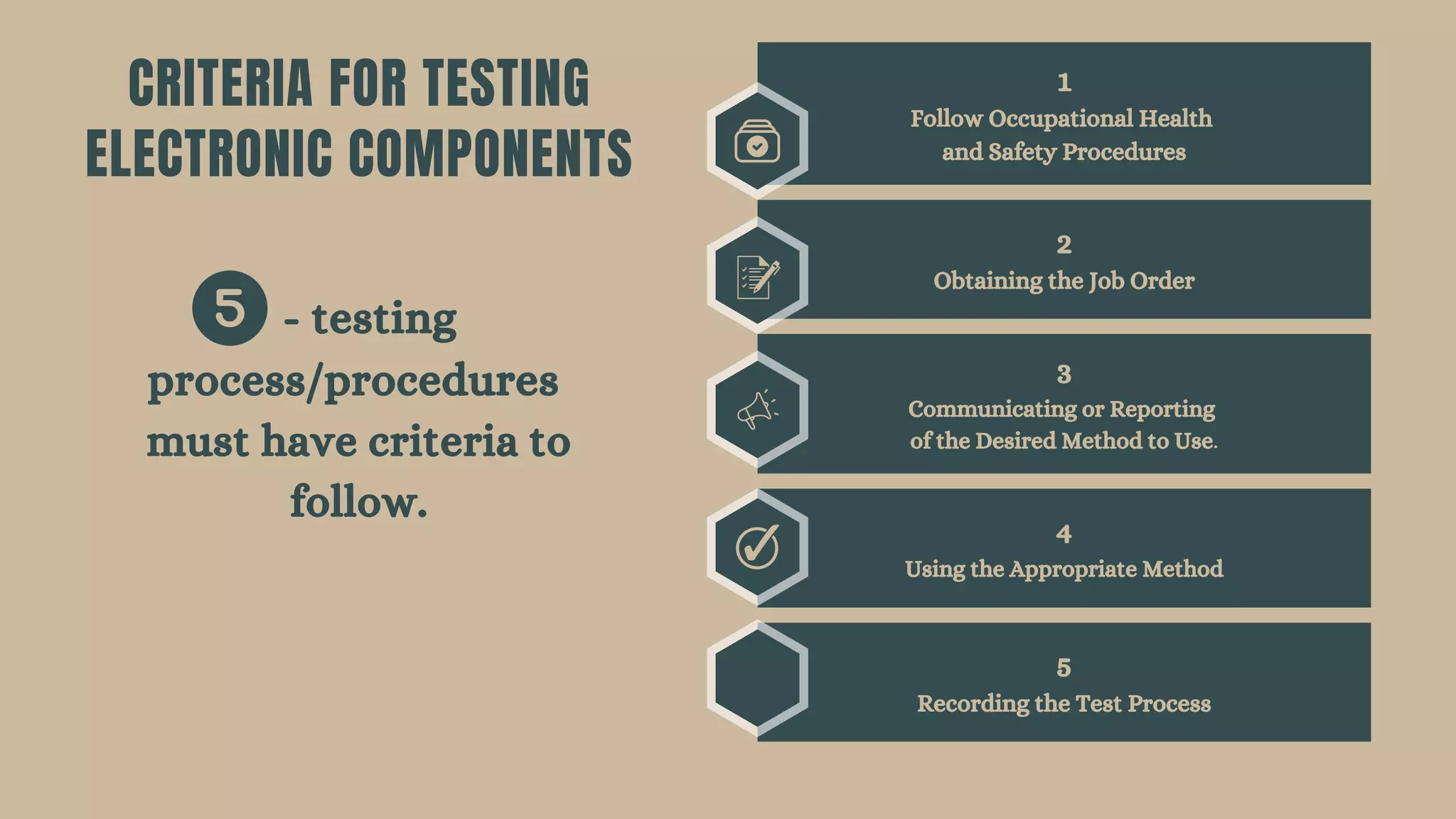

Testing electronic components is important to do correctly whether as a beginner or professional. There are criteria to follow which include following safety procedures, obtaining the job order, communicating the testing method, using the appropriate method, and recording the test process. The key steps are to obtain the job order which specifies the task, communicate the testing method to get approval, and use the most appropriate method based on the component's specifications. It is important to record the test process for evaluation.