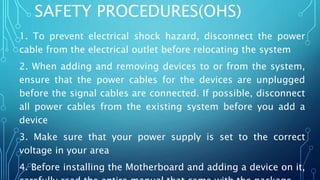

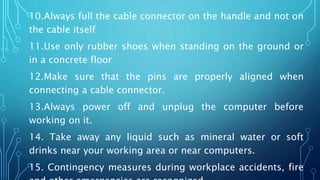

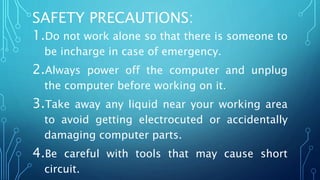

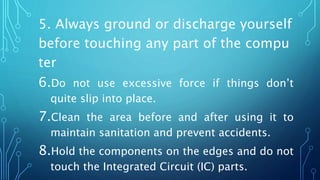

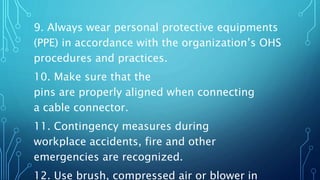

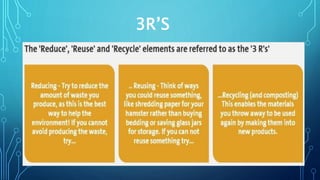

This document outlines the Occupational Health and Safety (OHS) guidelines and procedures for students in computer operations. It emphasizes the importance of planning and preparation for tasks to ensure safety, proper waste disposal, and the use of appropriate tools and equipment. Additionally, it provides detailed safety procedures and measures to follow during potential workplace accidents, highlighting the necessity for cleanliness and organization in the workspace.