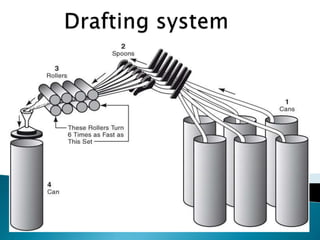

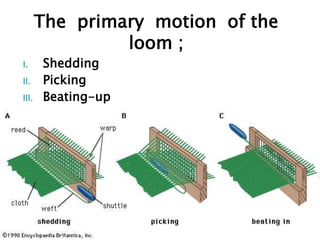

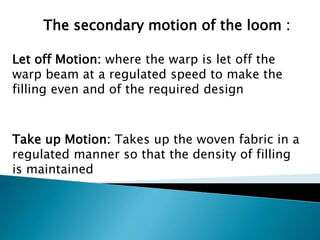

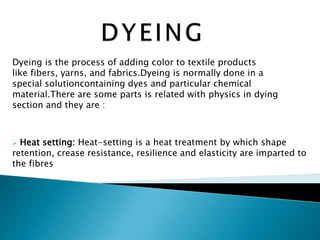

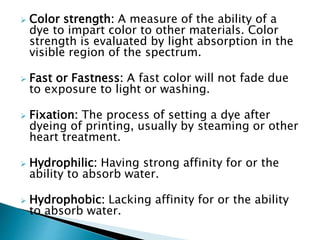

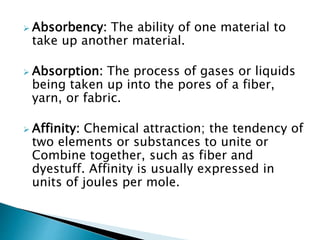

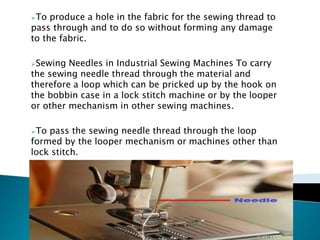

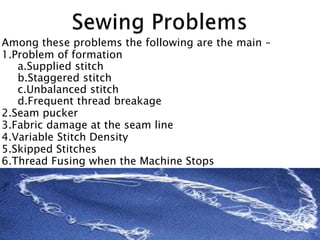

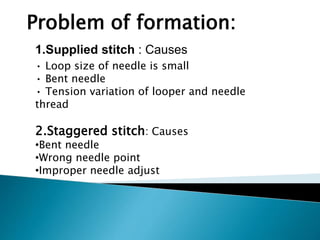

Physics principles are essential in textile manufacturing processes like weaving, knitting, dyeing, and sewing. Weaving involves interlacing warp and weft yarns at right angles using three primary loom motions: shedding, picking, and beating-up. Knitting produces fabric through interlooping of yarn using stitch formation. Dyeing adds color using heat, chemicals, and dye absorption principles. Sewing joins garment pieces using needles and threads governed by physics concepts. Problems can occur during these processes if physics variables like tension, heat, and mechanics are not properly controlled.