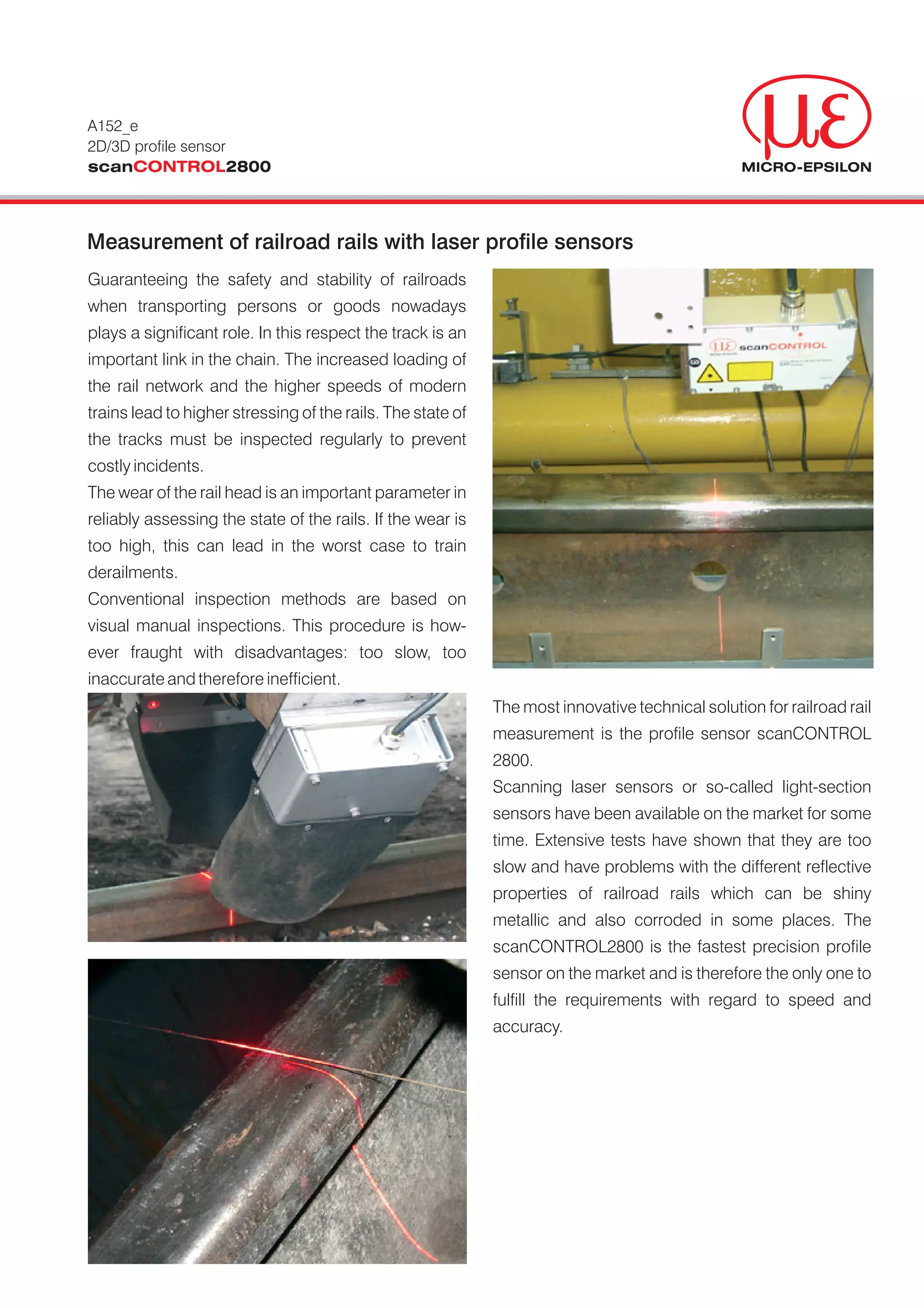

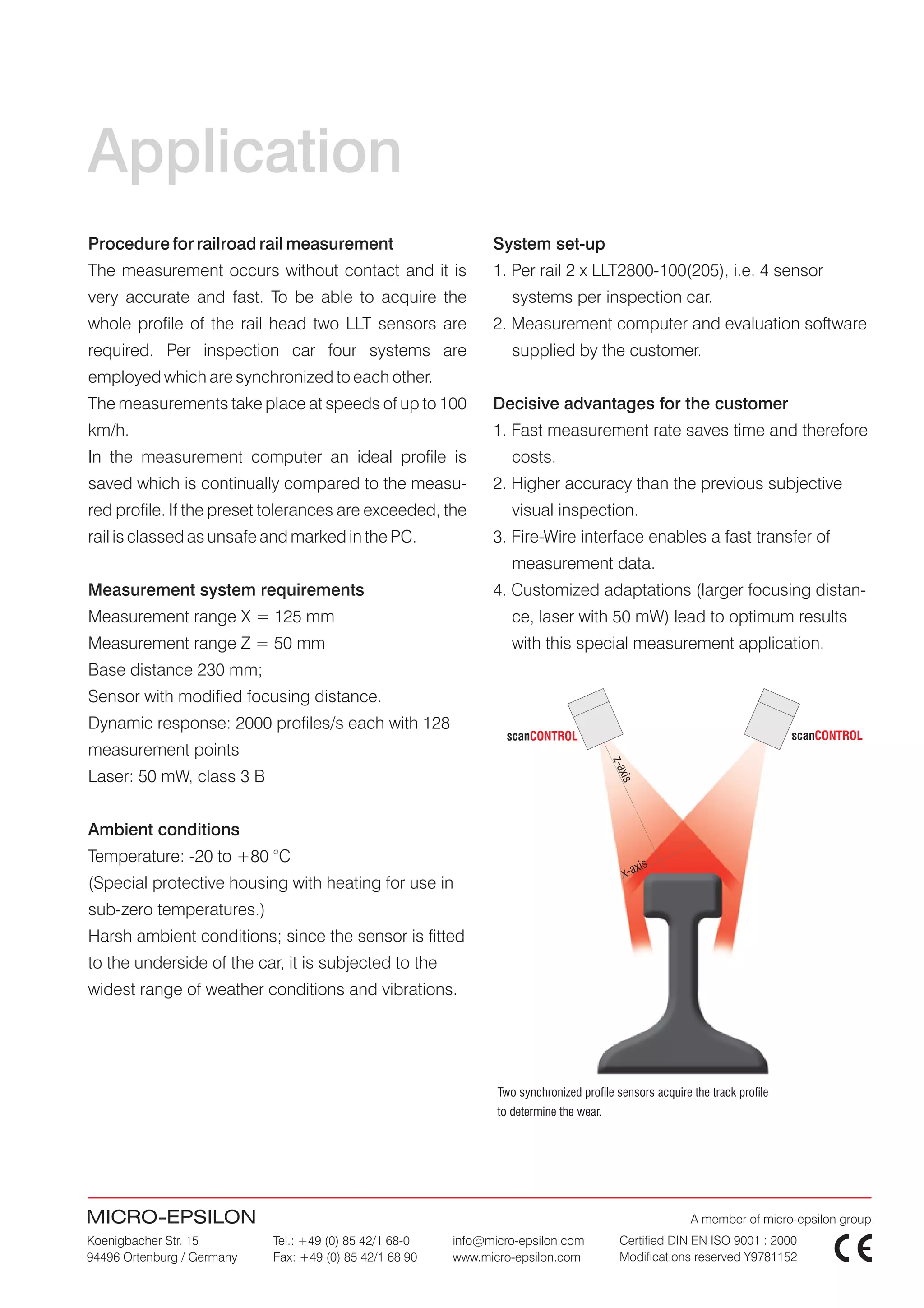

The document discusses using laser profile sensors to measure railroad rails to assess wear and prevent costly incidents from derailment. It describes mounting two synchronized scanCONTROL 2800 sensors under inspection cars traveling up to 100 km/h to quickly and accurately measure full rail profiles. The scanCONTROL 2800 sensors are the fastest and most precise available, meeting the demanding speed and accuracy needs for rail inspection.