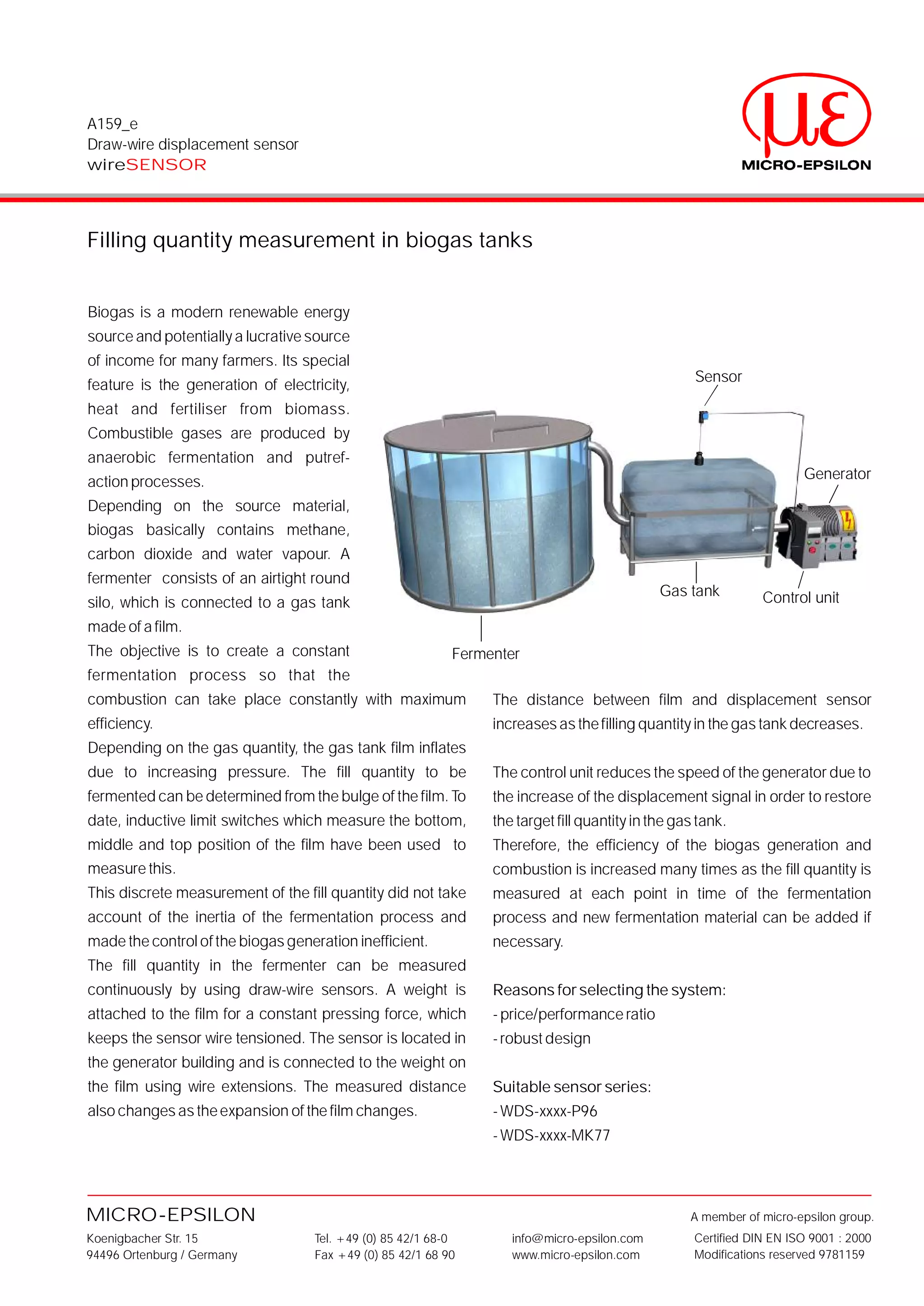

The document discusses using a draw-wire displacement sensor to continuously measure the filling quantity in biogas tanks. As the gas in the tank increases pressure, it inflates the flexible film of the gas tank. A weight attached to the film keeps the sensor wire tensioned so the sensor can measure the changing distance as the film expands and contracts based on gas quantity. This continuous measurement allows for more efficient control of biogas generation compared to discrete level switch measurements, improving the efficiency of biogas production and combustion.