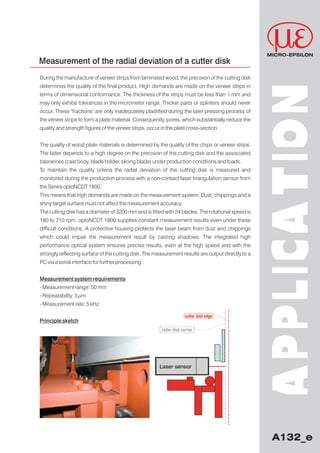

The radial deviation of a cutting disk during veneer production is measured using a laser triangulation sensor to ensure quality. The sensor measures the disk with a diameter of 3200mm rotating at 180-210rpm in a dusty environment. It provides precise measurements at 5kHz to monitor the disk's radial deviation and ensure the veneer strips have a consistent thickness under 1mm with micrometer tolerances. The sensor housing protects it from dust and chips while maintaining high accuracy over the large base distance and shiny, fast-moving surface.