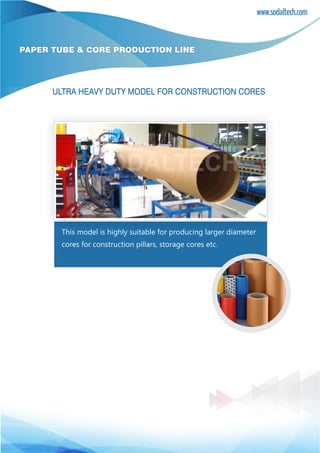

The document outlines the features and specifications of various paper tube and core production line machines, including slitter rewinders, tube winders, and automatic core cutters. Key highlights include high output capabilities, various inner diameters and wall thickness options, automated operations, and applications for different industries. These machines are designed for efficiency, safety, and ease of use in producing a range of paper tubes and cores.