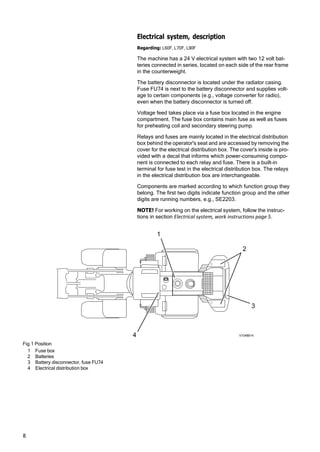

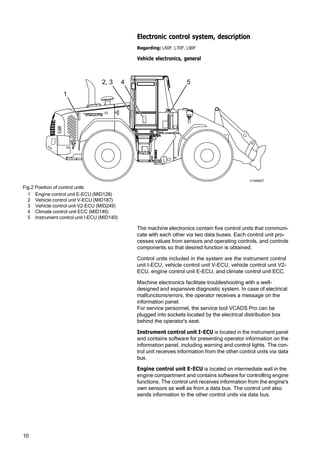

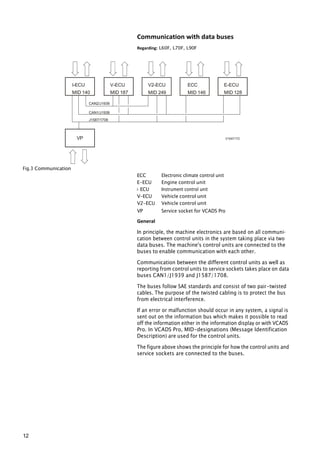

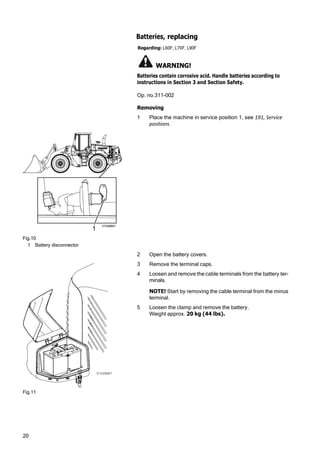

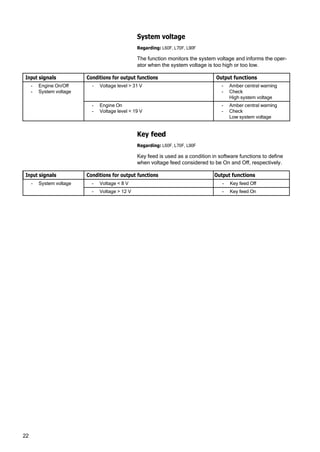

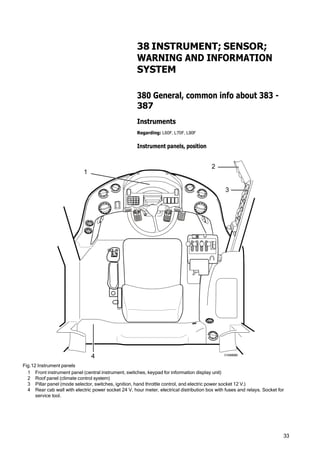

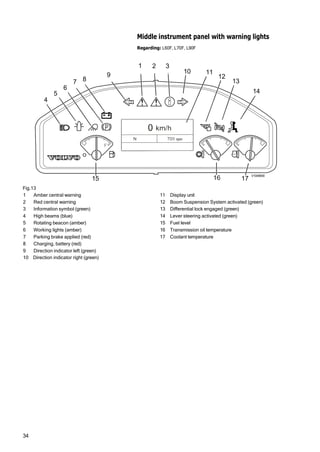

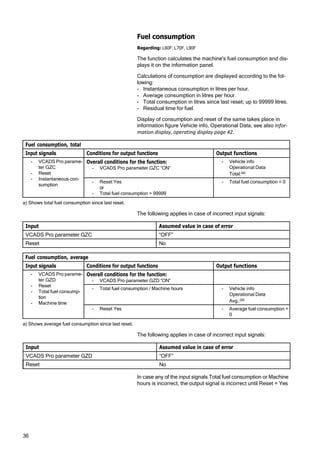

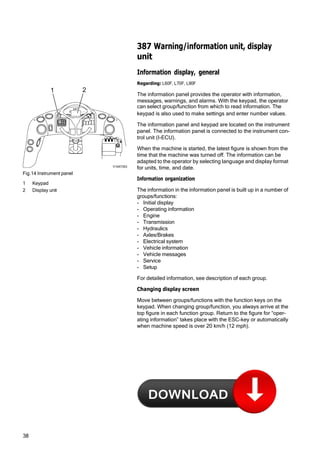

The document is a service manual for Volvo construction equipment models L60F, L70F, and L90F, detailing the electrical and information systems. It includes comprehensive information on the electrical system components, battery management, alternator, starting system, and electronic control units, along with safety warnings and troubleshooting instructions. The manual emphasizes the importance of proper battery maintenance and the functionality of various control units in ensuring efficient operation of the machinery.