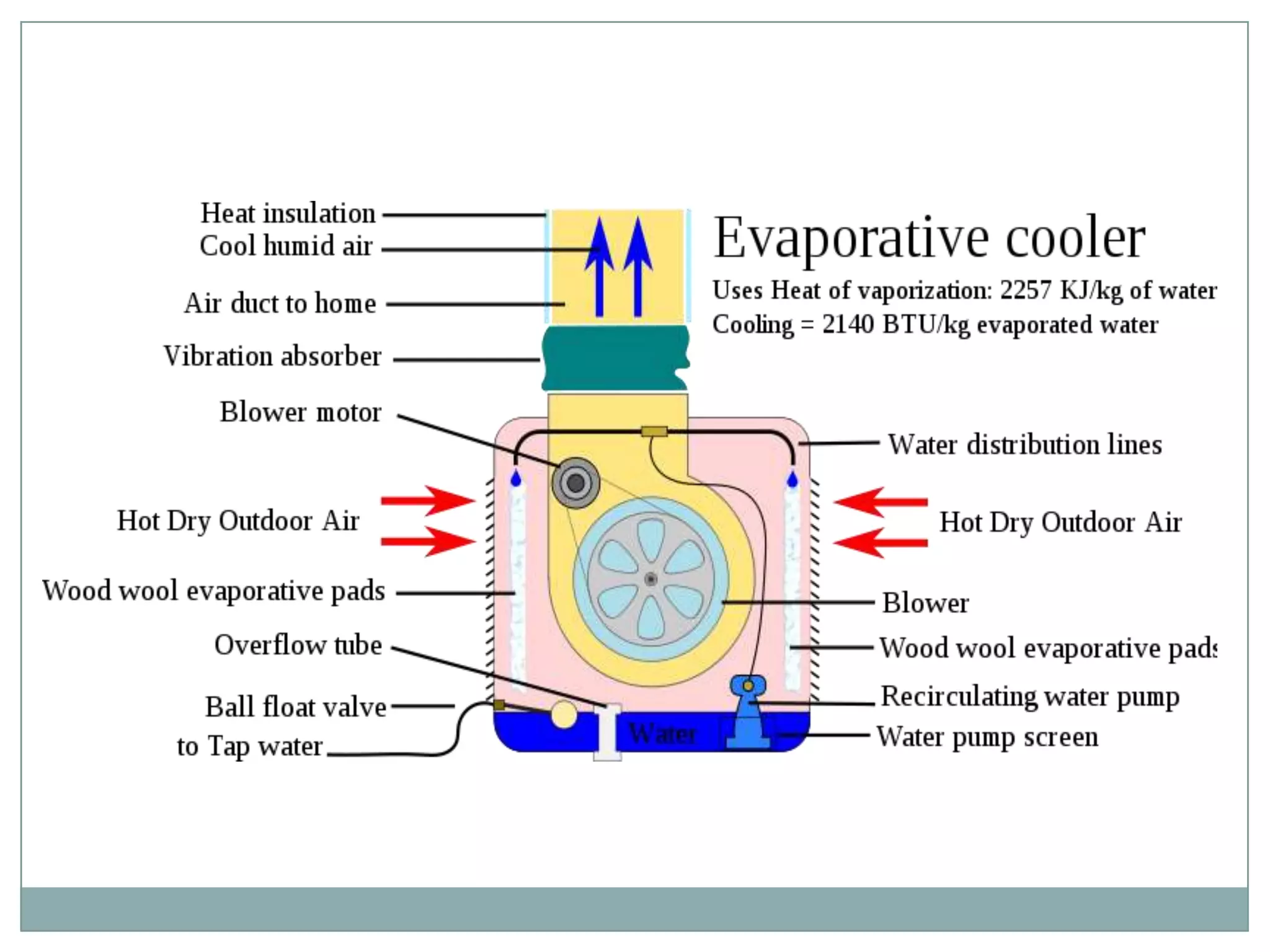

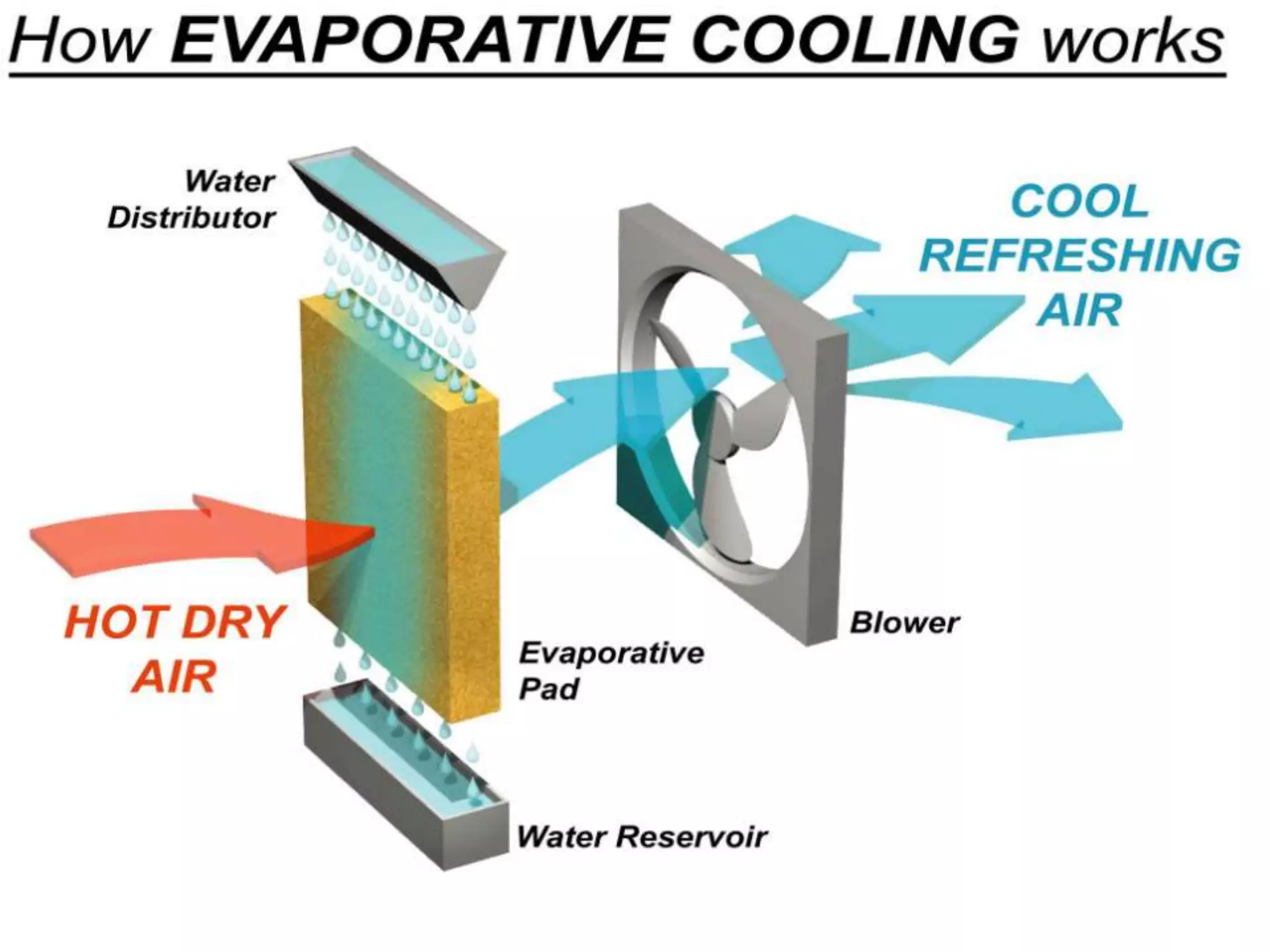

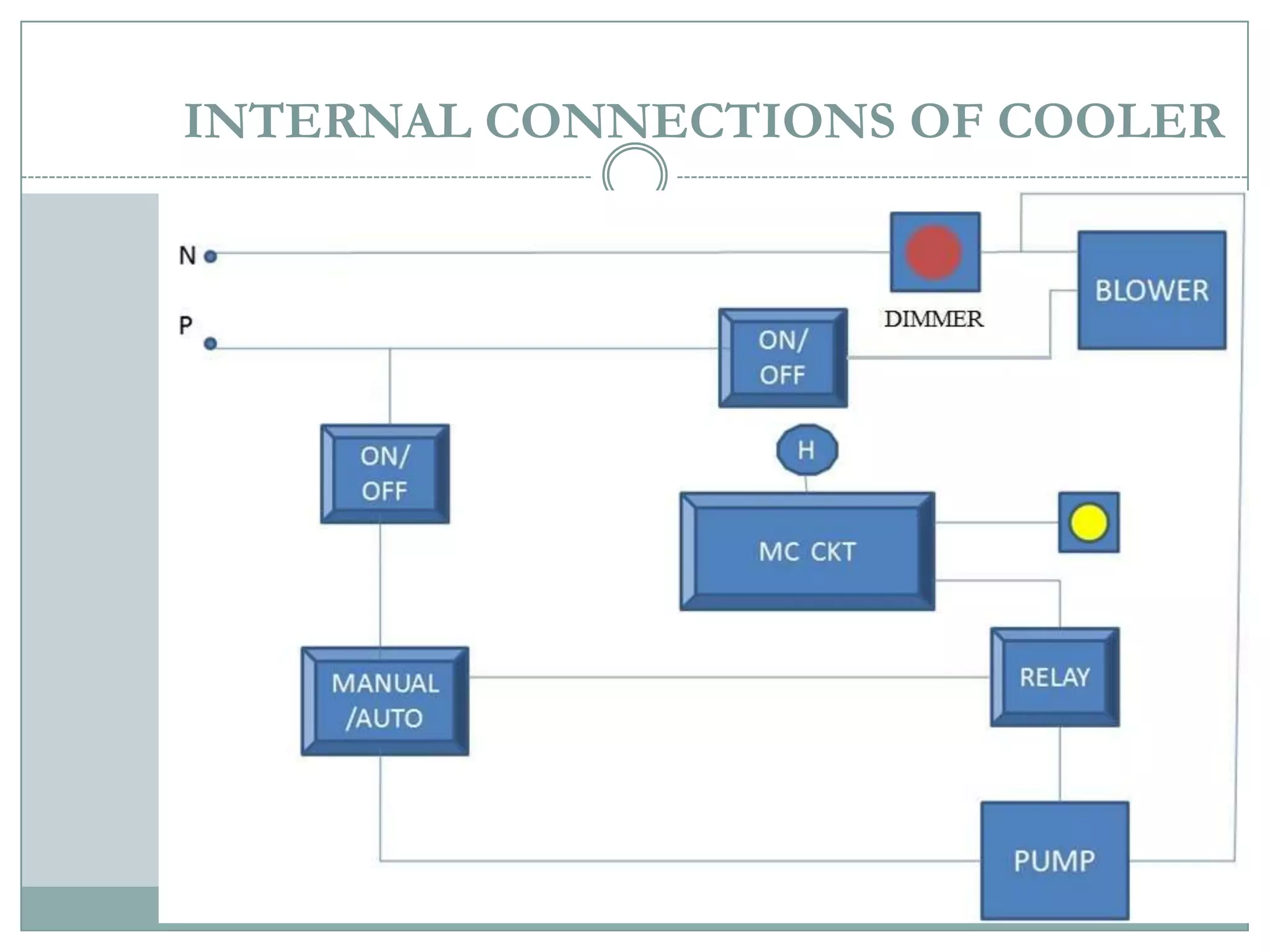

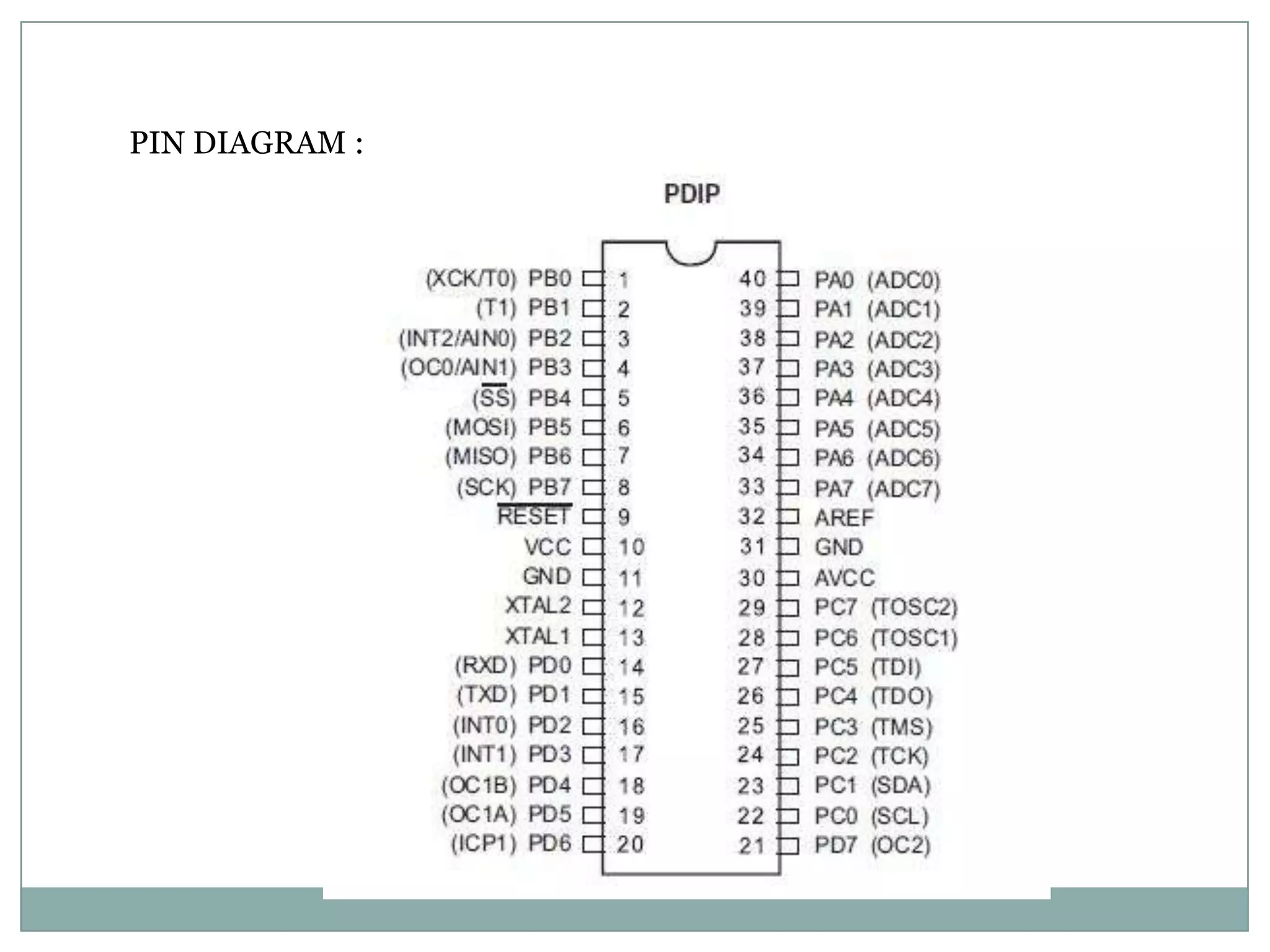

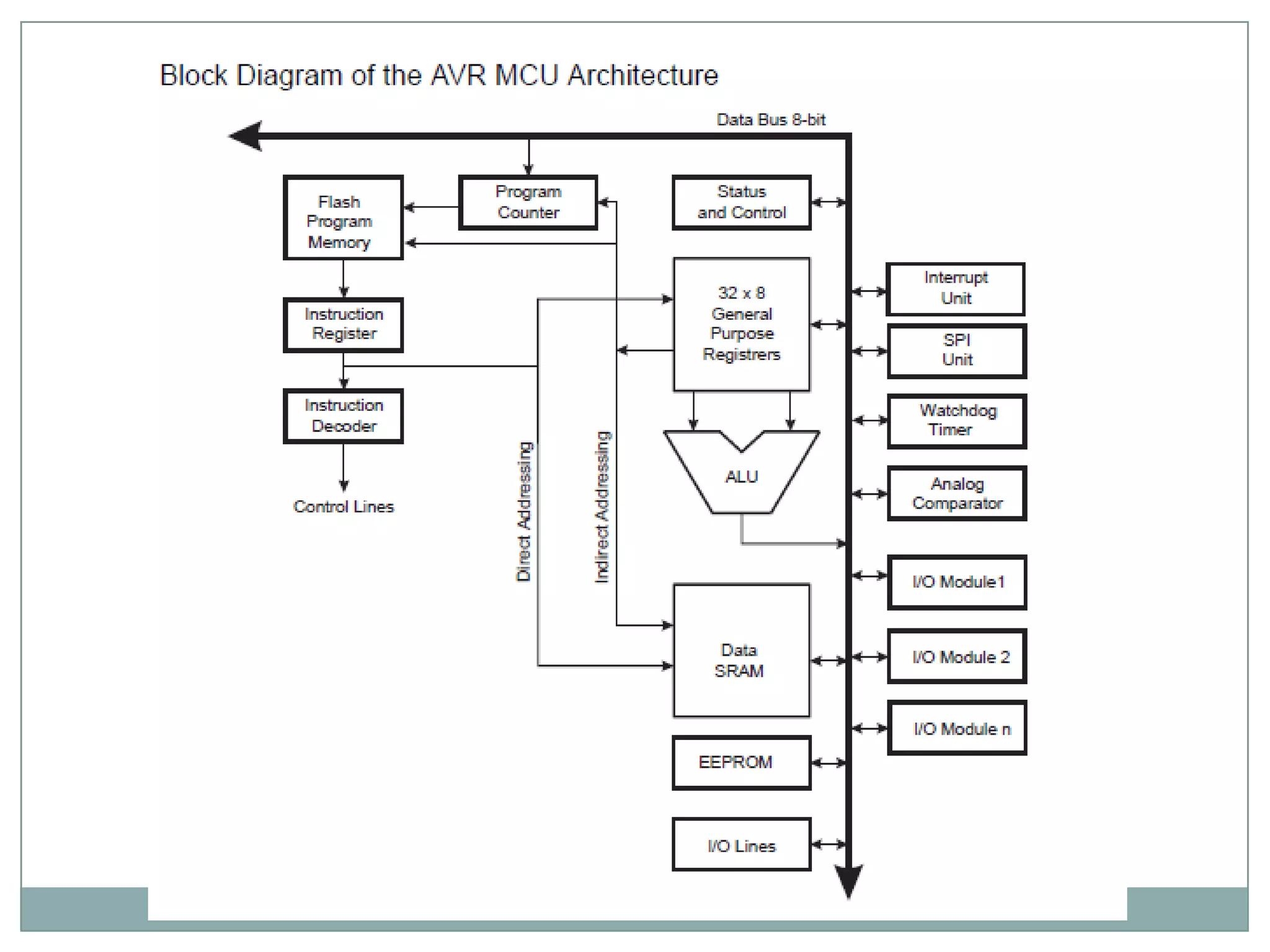

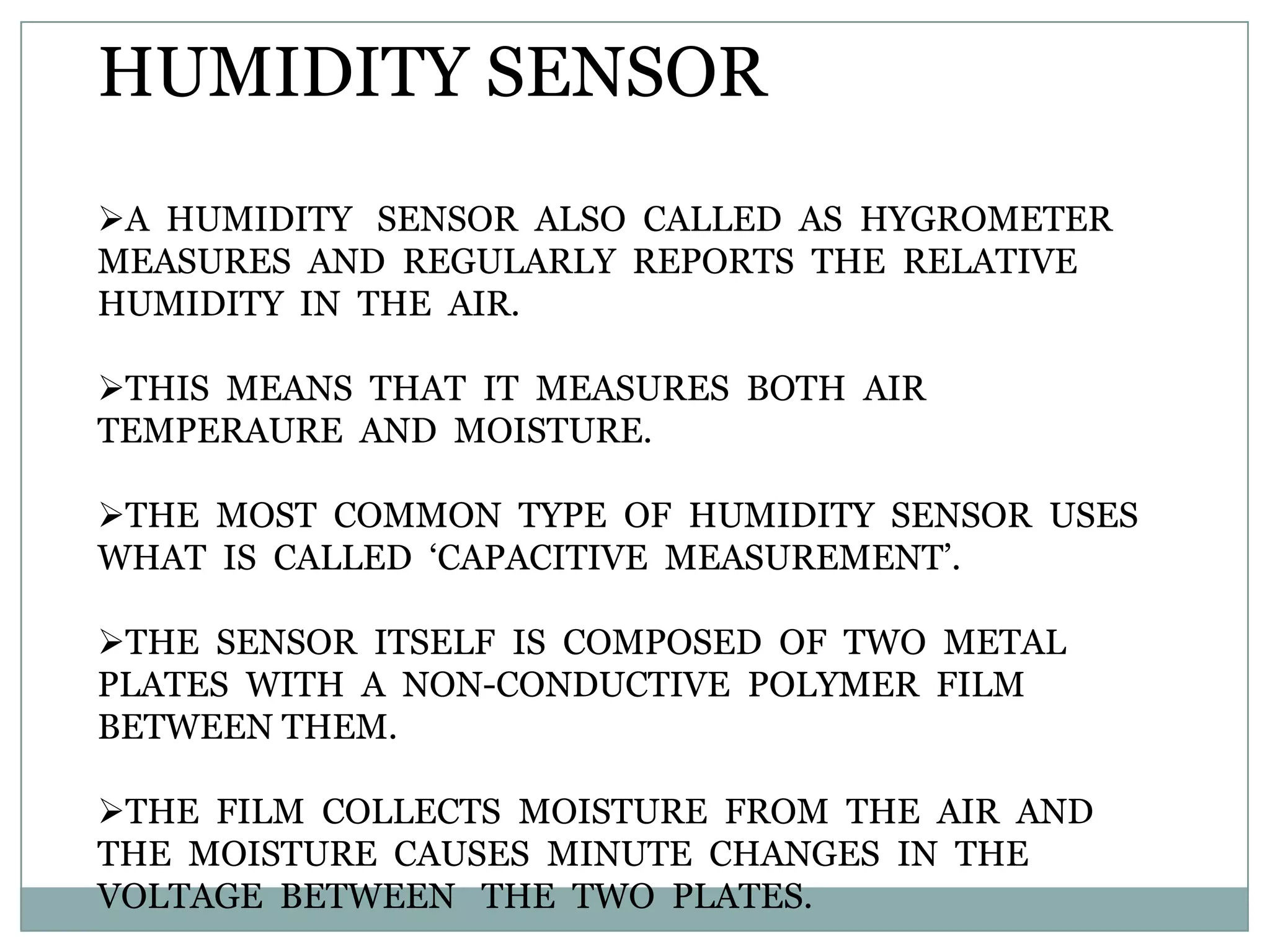

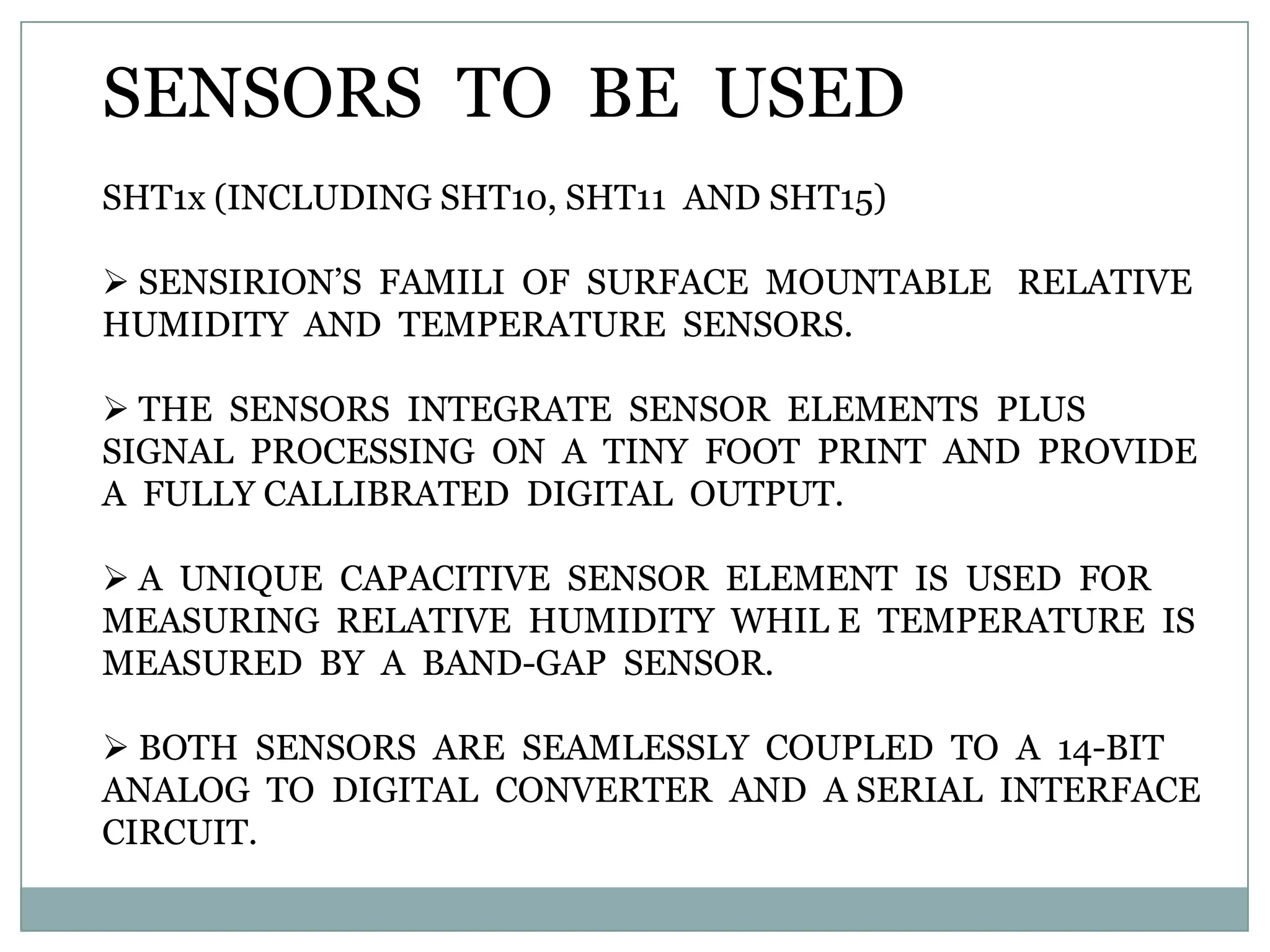

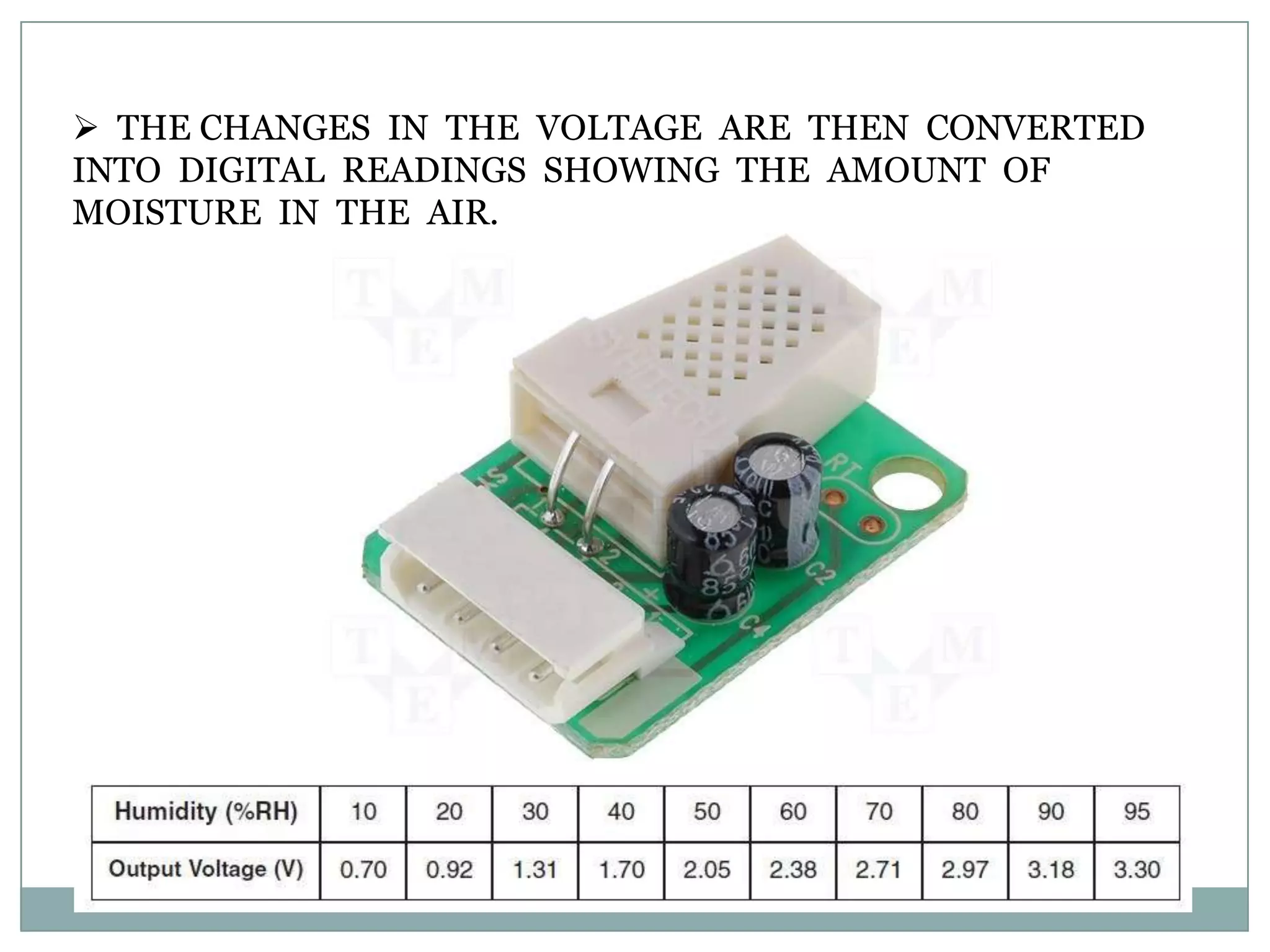

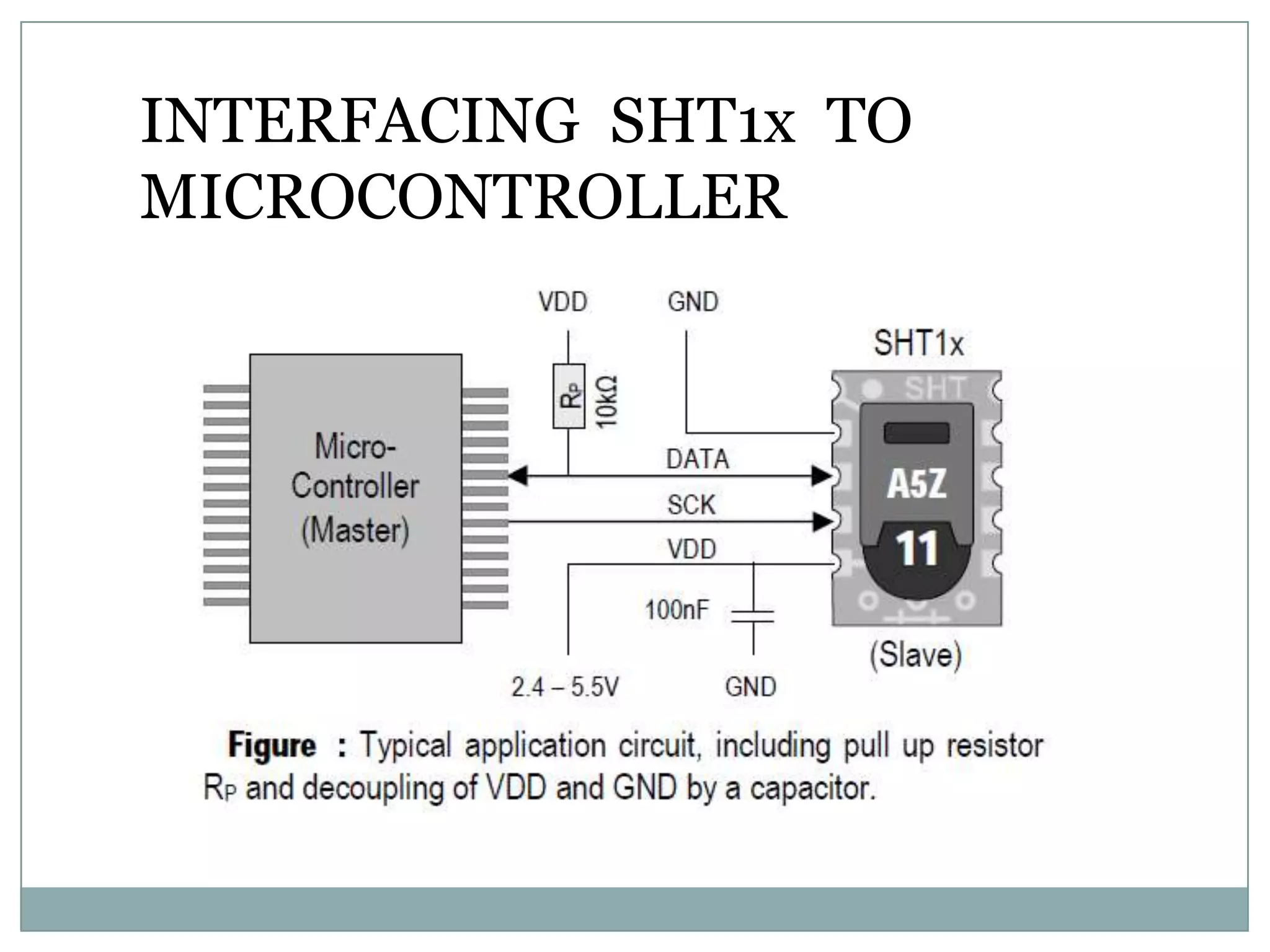

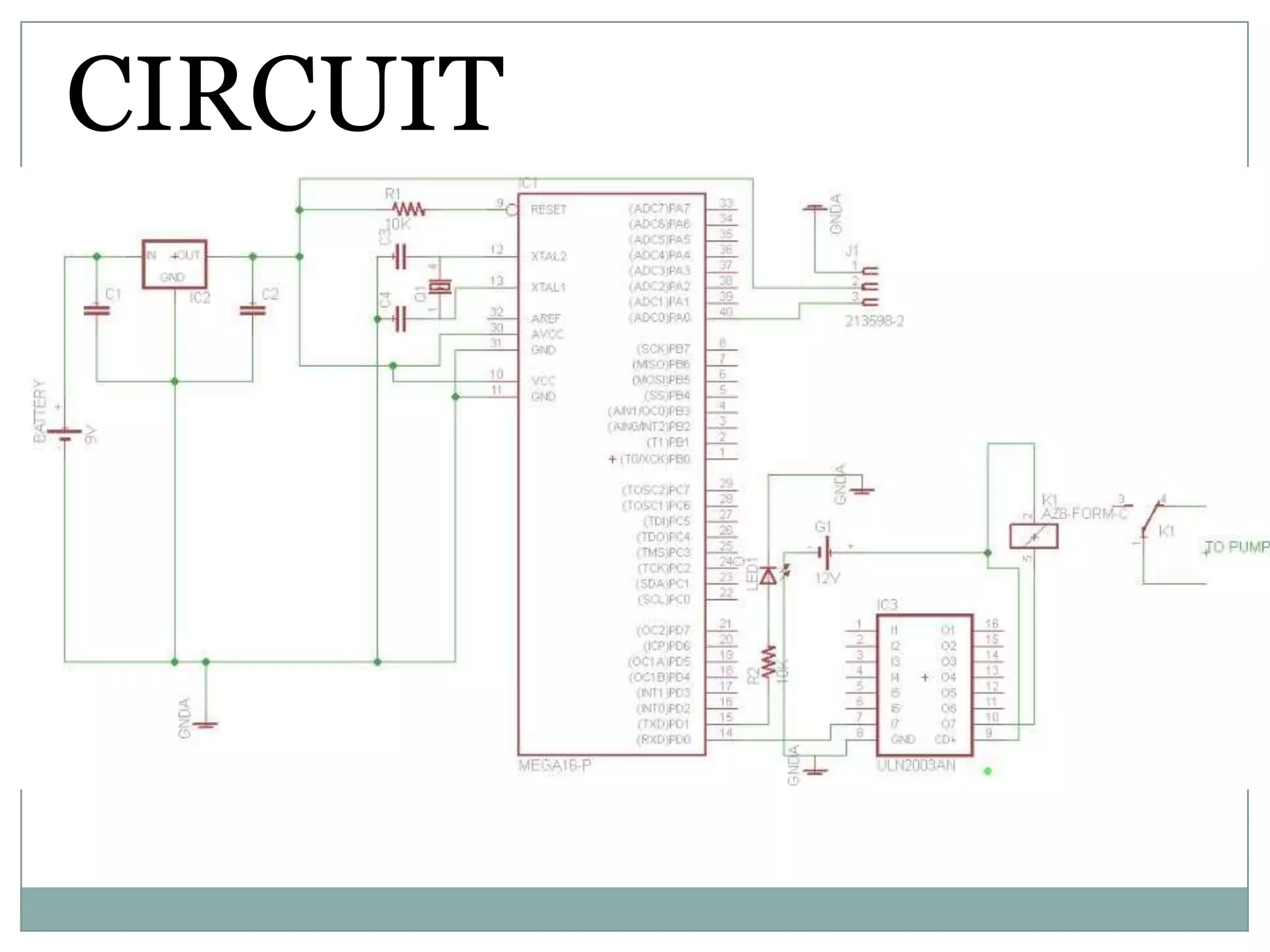

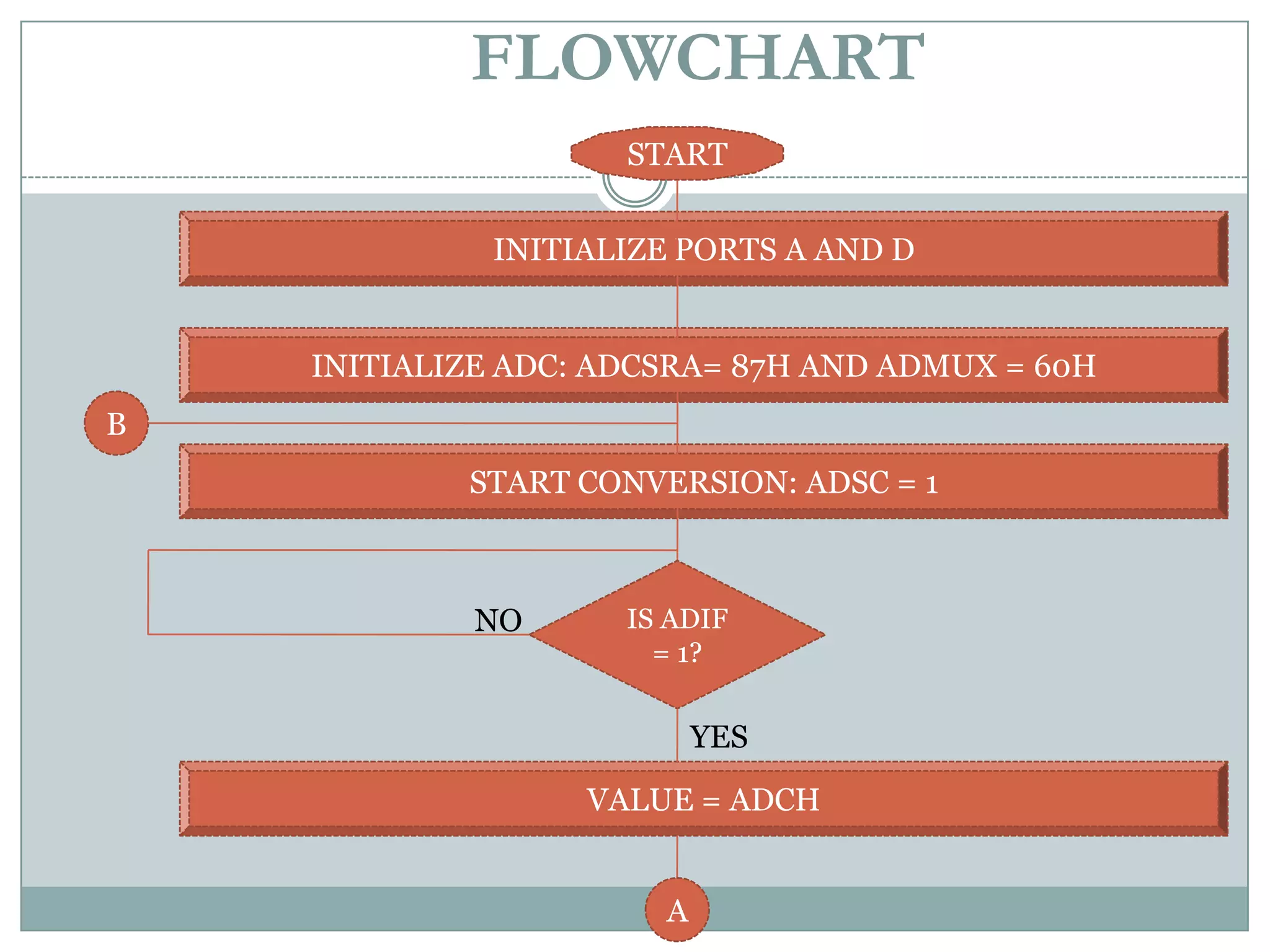

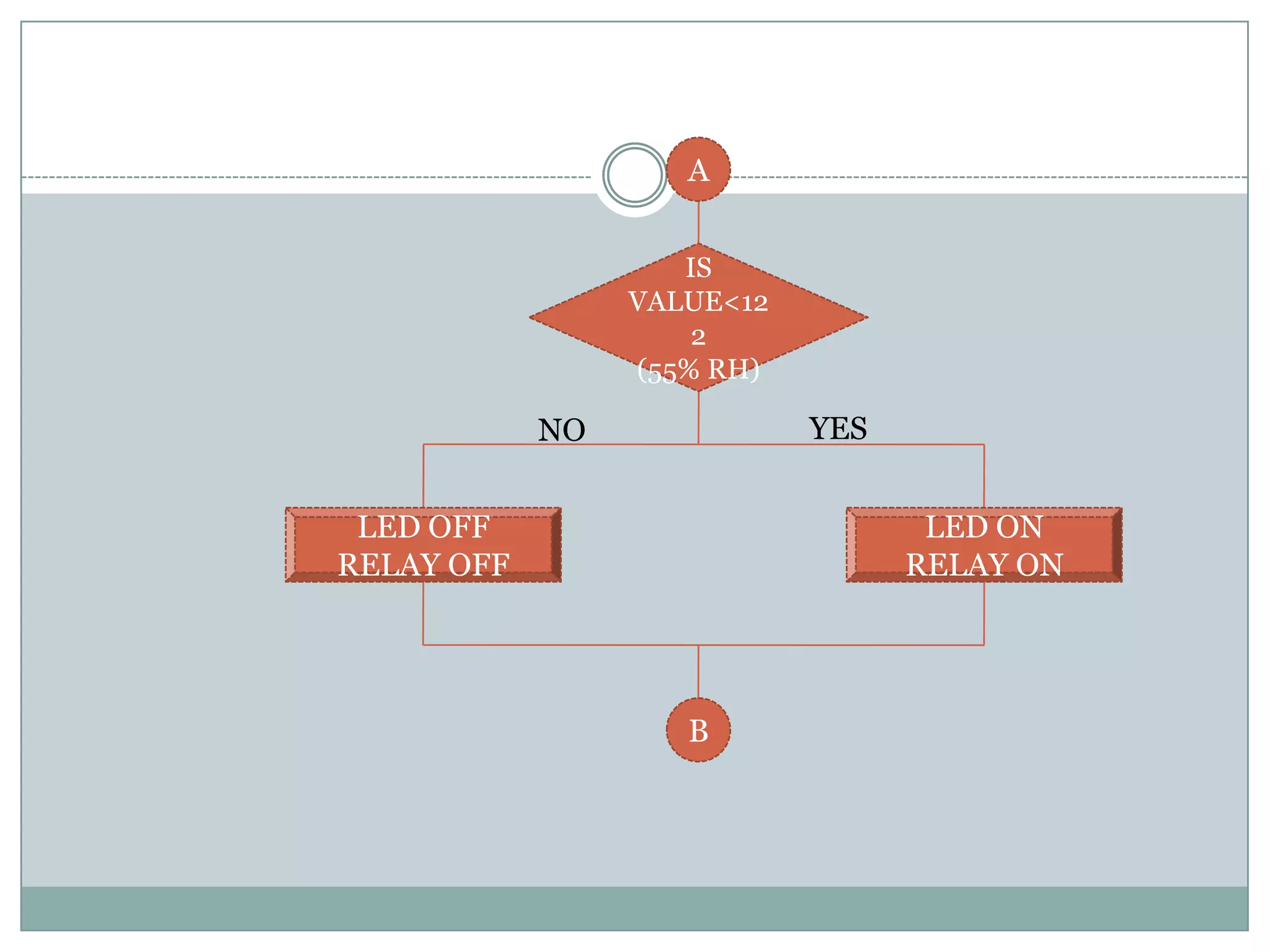

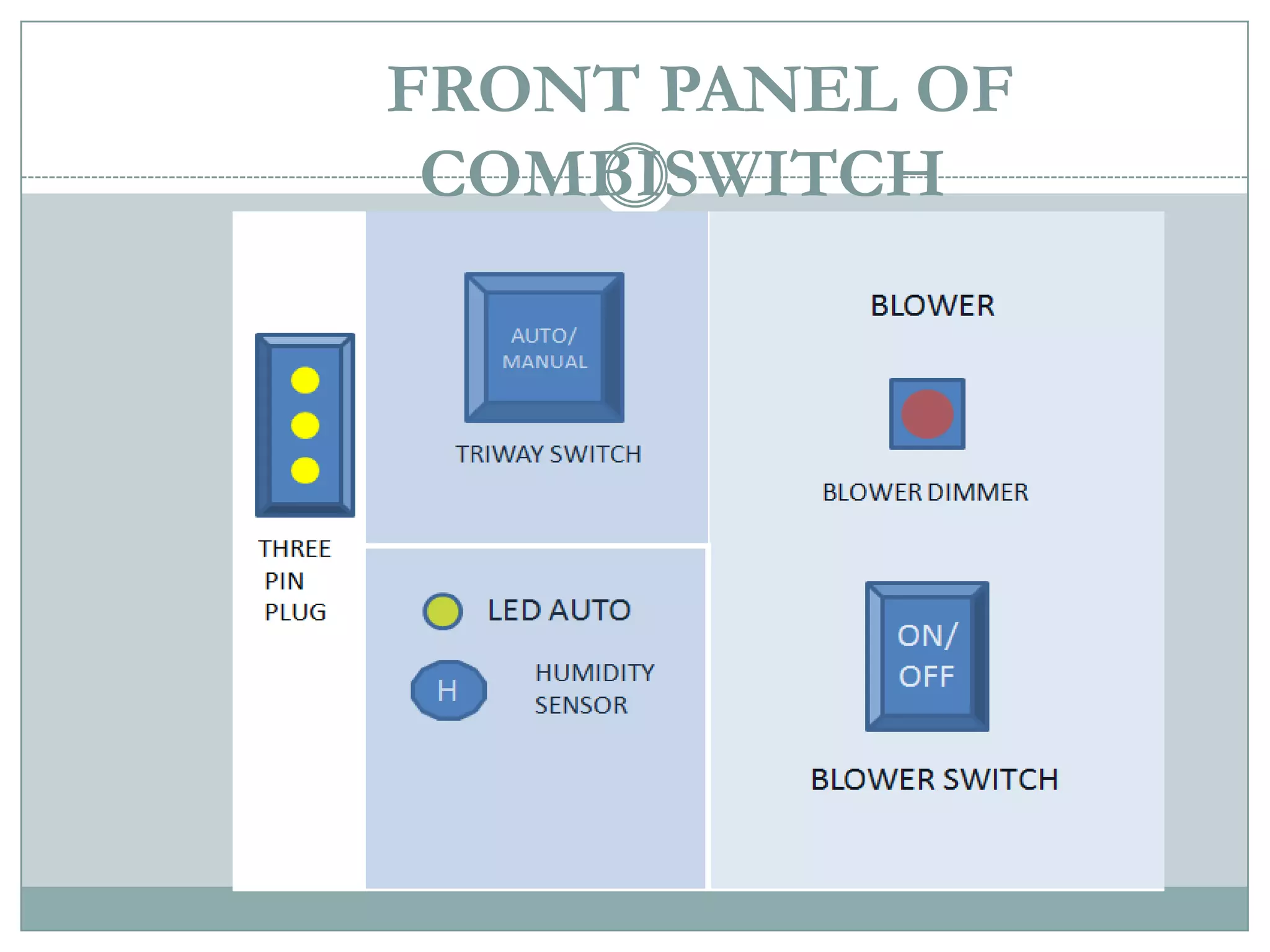

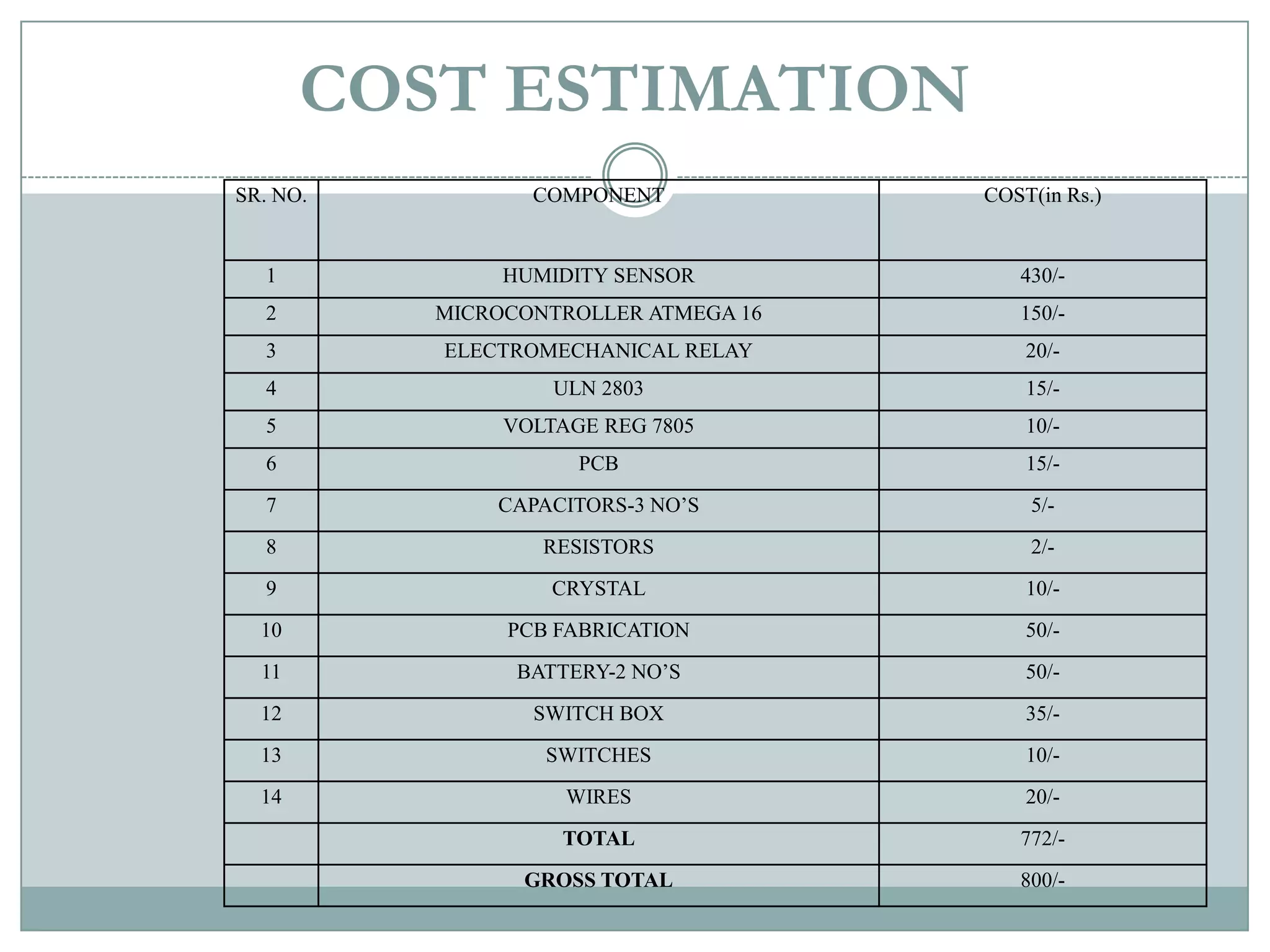

The document describes the design of an efficient evaporative air cooler system called Combiswitch. The Combiswitch is connected to existing cooler systems and controls the cooling effect based on humidity variations. It uses a humidity sensor and microcontroller to automatically govern the water pump speed, maintaining optimum humidity levels for human comfort while minimizing water and energy usage. The system provides improved performance over existing evaporative coolers in high humidity environments.