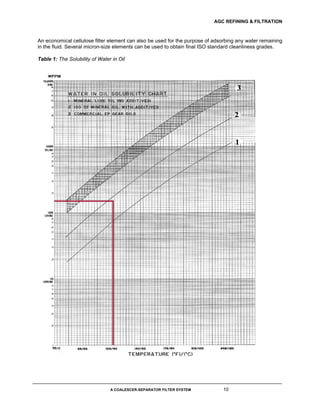

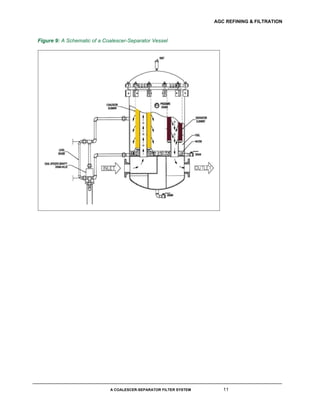

The document summarizes a coalescer-separator filter system that removes water from oil emulsions. It discusses:

1) How coalescers use fibers to accelerate the merging of small water droplets in oil into larger droplets, allowing the water to be separated out more quickly.

2) The three step coalescing process - collection on fibers, collision and merging of droplets, then separation in the bottom of the vessel.

3) Design considerations for coalescer elements like fiber material and flow velocity to promote droplet merging without breakup.

4) How separator elements then repel the coalesced water droplets to fully separate water from treated oil.