The document discusses key parameters to consider when selecting a vacuum oil purifier:

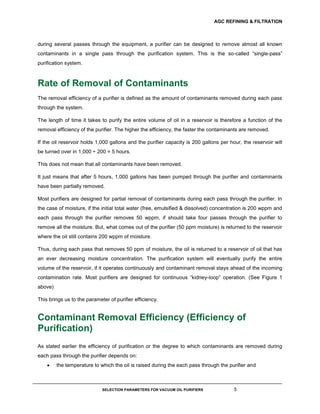

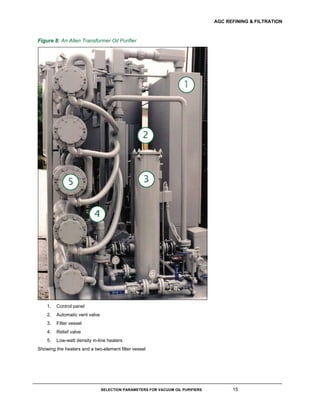

1) Types of contaminants in the oil such as moisture, gases, solids, and acidity determine the purifier's design.

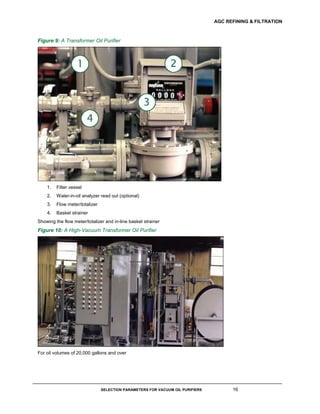

2) Flow rate depends on contamination entry rate and budget. Higher flow requires more efficient purification.

3) Efficiency is influenced by temperature, vacuum depth, and residence time - deeper vacuum and higher heat improve efficiency.

4) Cost depends on required flow rate, efficiency, vacuum pump type, and controls - higher performance means higher cost.