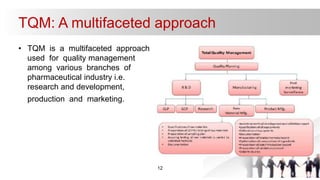

This document discusses Total Quality Management (TQM) in the pharmaceutical industry. TQM is a multifaceted approach that involves building quality into every step of the pharmaceutical process from research and development to manufacturing to marketing. It utilizes various quality management techniques like quality risk management, quality by design, good manufacturing practices, and ISO standards. TQM ensures quality is maintained through all stages of production from raw materials to finished drugs. It is important for the pharmaceutical industry given many drugs are life saving and quality defects could pose health hazards.

![• 1. Research and development: TQM also plays very vital role in quality

management of research and development process.

• It involves following points:[ a]. GLP: It is also called as ‘Good Laboratory

Practices’. It involves strict control over use of animals in the laboratory for

experimentation.

• TQM in GLP involves following points:

• 1] Preparation of protocol or master schedule sheet for the study,

Maintenance of copy of protocol in the laboratory in which study is to be carried

out, 2]• Periodic inspection of facility in which study is to be carried out,3] • If any

change in approved protocol of the study then there should be documentation

and approval of the change along with the reason for carrying out the

change, and Documentation.

13](https://image.slidesharecdn.com/affrintqm-220626052530-fe50e2e1/85/TQM-Modern-pharmaceutics-12-320.jpg)

![• [b]. GCP: It is also called as ‘Good Clinical Practices’. It

involves strict control over use of human beings in clinical trials.

The regulations for GCP are almost similar to that of GLP. The

major difference being that before starting study or involving any

subject or human being into the clinical trials. A complete duly

filled informed consent form should be taken from subjects along

with their signature to make sure that subject is known he/she

is involved in clinical trials. These records should be

maintained. If patient dropout involve during the study then

number of dropouts along with reason of dropout from study

should be documented. 14](https://image.slidesharecdn.com/affrintqm-220626052530-fe50e2e1/85/TQM-Modern-pharmaceutics-13-320.jpg)

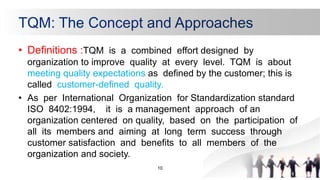

![Approaches for TQM

[1]Six Sigma Technique

Six Sigma involves two methods:[A]DMAIC [B]DMADV

[2]Quality Risk Management (QRM)

[3]Quality by Design (QbD)

[4]ISO Series

[5]Current Good Manufacturing Practices (cGMP)

[6]International Conference on Harmonization (ICH)

16](https://image.slidesharecdn.com/affrintqm-220626052530-fe50e2e1/85/TQM-Modern-pharmaceutics-15-320.jpg)

![• Various approaches as practiced by

industries in TQM of pharmaceutical

process

• [1]Six Sigma Technique: Six Sigma

technique can improve the quality of

process outputs by identifying and

removing the causes of defects (errors)

and minimizing variability in manufacturing

and business processes

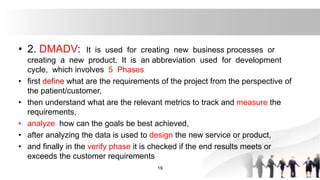

• two methods:1. DMAIC: It is an

abbreviation used for an improvement

cycle, which involves 5 Phases

17

• understand or define what the

problem is,

• then it is measured to receive

existing data at unaltered state,

• once it has been measured the

problem and data is analyzed to

understand the root cause,

• after analyzing improvement

strategies are developed to address

the root cause,

• and lastly is to control the

improvements and look for future

improvements.](https://image.slidesharecdn.com/affrintqm-220626052530-fe50e2e1/85/TQM-Modern-pharmaceutics-16-320.jpg)