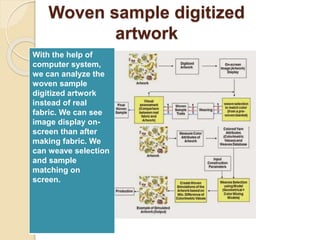

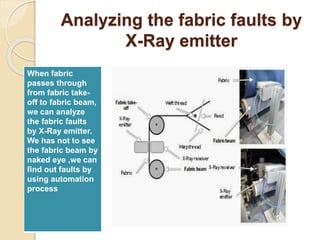

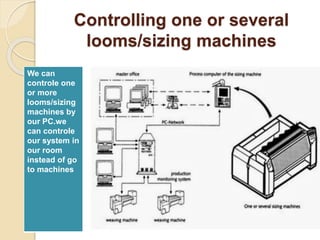

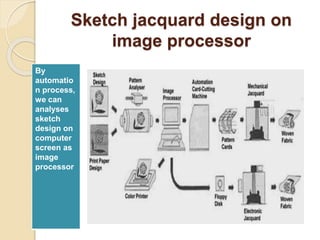

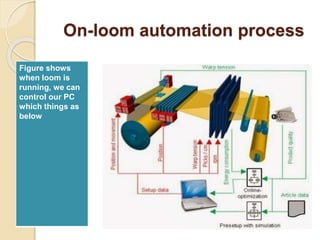

This presentation summarizes automation in the weaving process. It outlines the topics that will be covered, including introductions to automation, how it is applied to weaving, machine requirements, demands on automation, and benefits. Key features of automation solutions for weaving are digitizing artwork, analyzing fabric faults with X-rays, controlling multiple looms from one computer, designing jacquard patterns digitally, and monitoring processes on looms. Automation is important for the weaving sector to increase efficiency and quality while reducing costs. The presentation concludes that automation allows weaving to be done at higher speeds with more intricate patterns and less downtime between styles.

![Machine requirements in

Weaving Automation

Weaving is the most widely used method of fabric

production for the decoration, clothing and home

furnishing textile sectors. However, technical textiles,

including wire cloth, are also produced on modern

weaving machines.

Irrespective of the weft insertion method used, very high

cycle and acceleration rates are essential for weaving

machines. Furthermore, weaving machines are

characterized by a large number of nonlinear motion

sequences and time-critical starting times. Mechatronic

solutions devised from a combination of mechanical

cams and servo drives for warp let-off and fabric take

up are the modern state of the art. More recently,

harness motion and weft insertion have also been

implemented with individual electric drives in some

instances.[3]](https://image.slidesharecdn.com/advacedweaving-160421060938/85/Advaced-weaving-7-320.jpg)

![References

The Automation of Weaving: an examination of the past and future

of loom design by Wendy C. Beatty Union College, 807 Union

Street, Schenectady NY,

https://eb.automation.siemens.com/mall/en/WW/Catalog/Products/1

0087619;sited on :08/01/2014

http://textilelearner.blogspot.com/2013/08/automation-in-weaving-

process-why-is.html

Bennett, S. (1993). A History of Control Engineering 1930-1955.

London: Peter Peregrinus Ltd. On behalf of the Institution of

Electrical Engineers. ISBN 0-86341-280-7.

The elevator example is commonly used in programming texts, such

as Unified modeling language http://www.exman.com/mshoass.ht. A

History of Control Engineering 1800-1930. London: Peter Peregrinus

Ltd. pp. 47, 266. ISBN 0-86341-047-2.

Wiktionary on "[[wikt:automation|]]"

Rifkin, Jeremy (1995). The End of Work: The Decline of the Global

Labor Force and the Dawn of the Post-Market Era. Putnam

Publishing Group. pp. 66, 75. ISBN 0-87477-779-8.](https://image.slidesharecdn.com/advacedweaving-160421060938/85/Advaced-weaving-18-320.jpg)