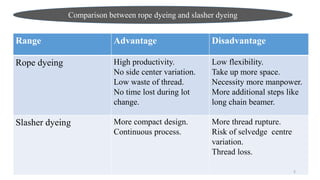

This document provides an overview of denim fabric and its history. It discusses how denim originated as a durable work fabric in 1860 and gained popularity in the 1920s for common work garments. By the 1930s, denim was being used for fashion, and its popularity increased further in the 1950s through Hollywood films. The document outlines the types of denim fabrics and compares rope dyeing and slasher dyeing methods. It also discusses recent finishing techniques for denim like acid washing, ozone effects, and stone washing. The presentation concludes by listing some exceptional non-apparel uses for denim fabrics.

![In 1860 worker use denim as a durable material.

In1920 gain more reputation in common work garment.

In 1930 denim use as a fashion.

In 1950 jeans/denims entered in a new phase fashion by

Hollywood films.

In 1970 different brands come in the market.

In 1980 to 2000 denim revolution.

In 21st denim enter in a new era. [1]

Exceptional history of denim

3](https://image.slidesharecdn.com/135030denim-190114100249/85/135030-denim-3-320.jpg)

![Recent finishing of denim

1 Desizing after garment making in suitable portion..

2 Acid wash.

3 Ozone effect.

4 Bleached effect.

5 Enzyme washing

6 Stone washing

7 Laser effect

8 Denim with repair effect. [2]

8](https://image.slidesharecdn.com/135030denim-190114100249/85/135030-denim-8-320.jpg)