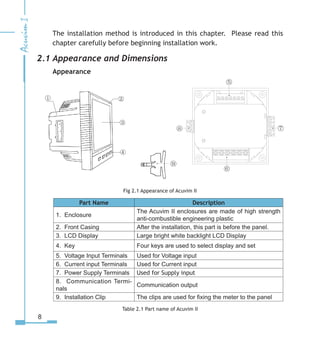

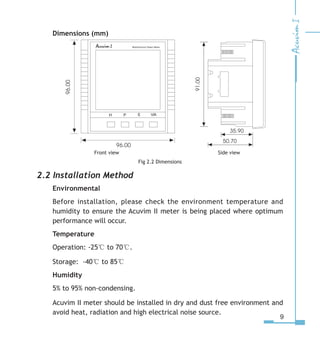

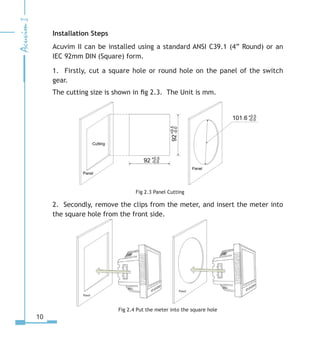

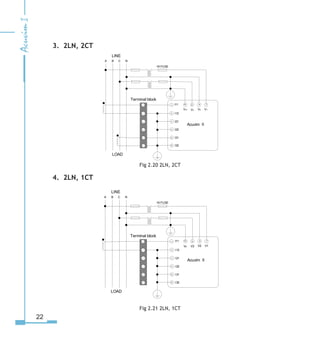

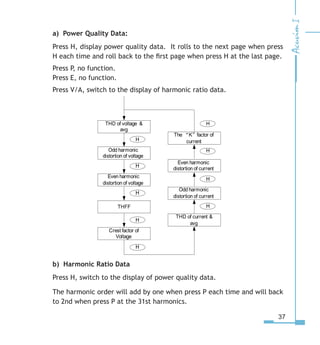

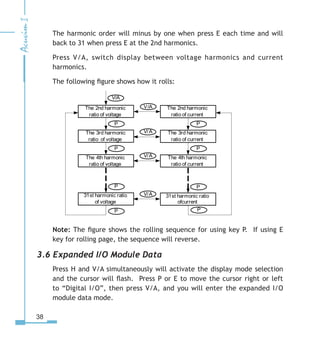

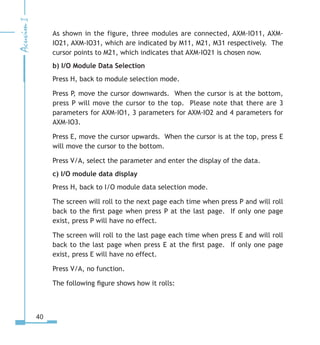

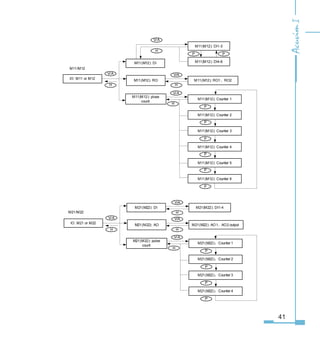

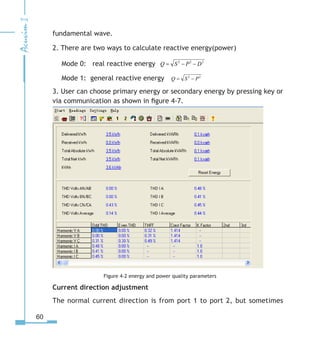

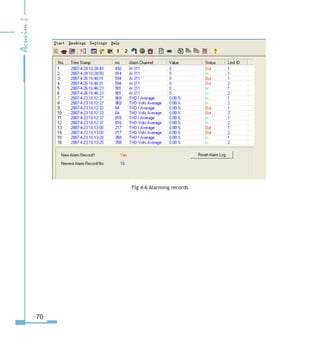

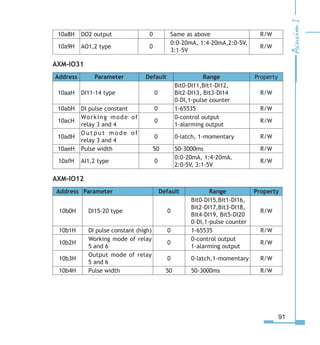

This document provides an introduction and instructions for installing and using the Acuvim II power meter. It describes the purpose and functions of the meter, including energy measurement, power quality analysis, and communication capabilities. Installation and wiring procedures are outlined, and safety precautions are noted. An overview of the user interface and setting parameters is also provided.