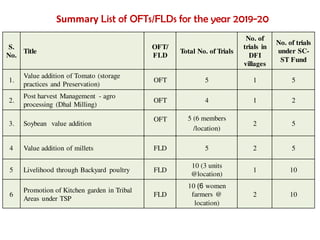

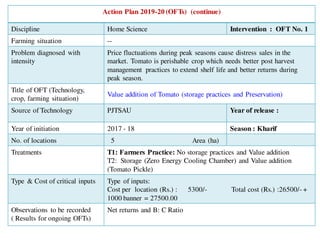

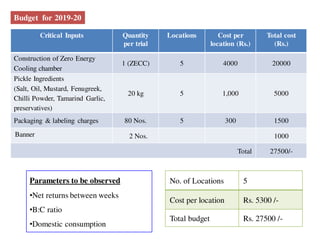

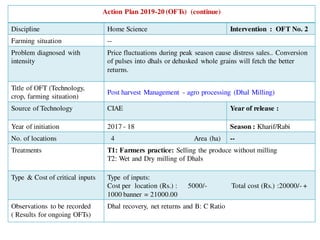

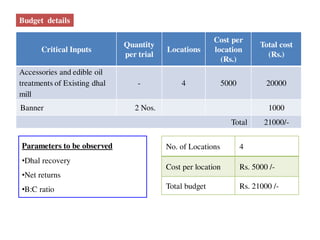

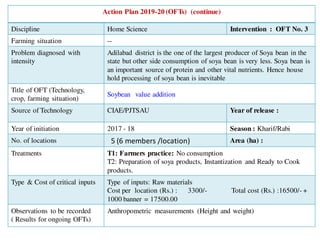

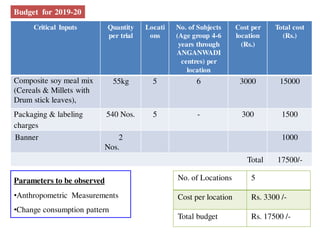

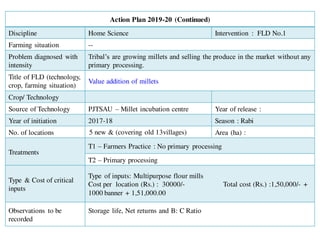

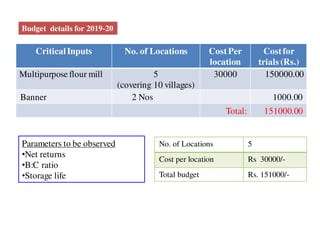

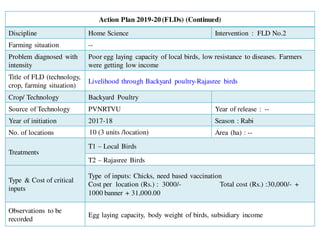

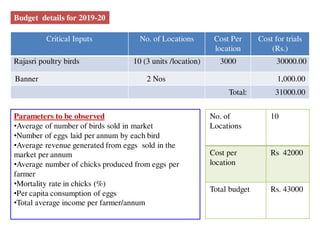

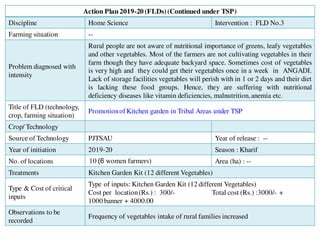

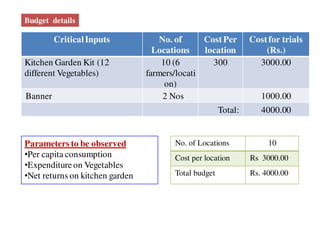

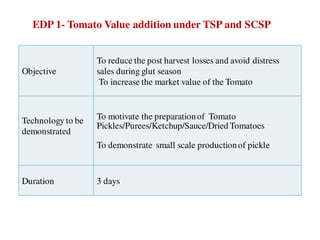

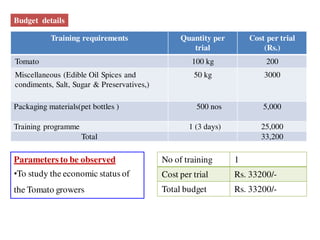

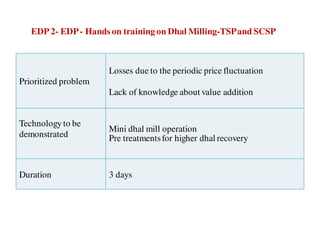

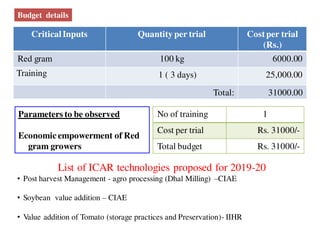

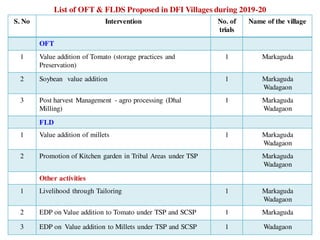

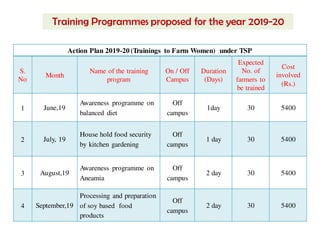

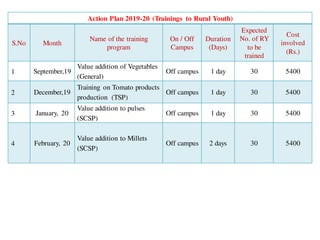

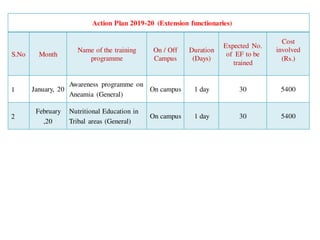

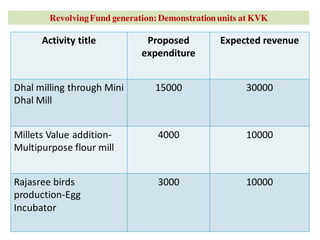

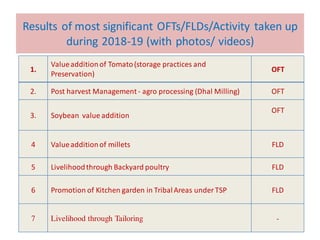

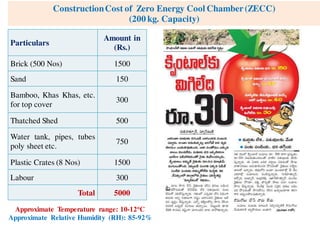

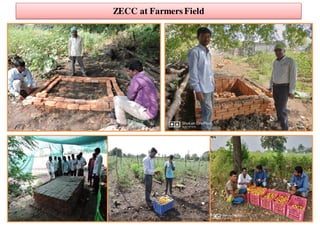

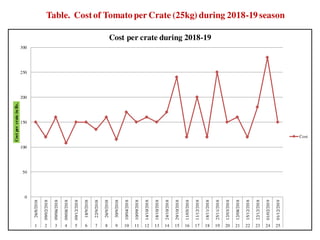

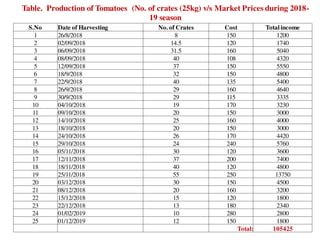

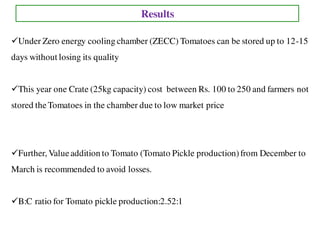

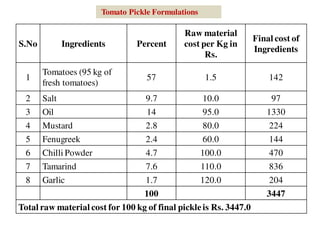

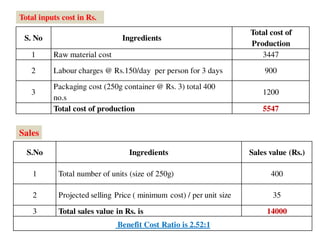

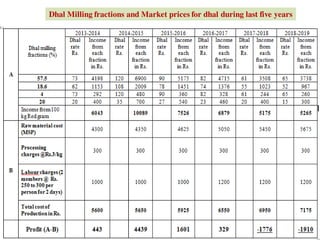

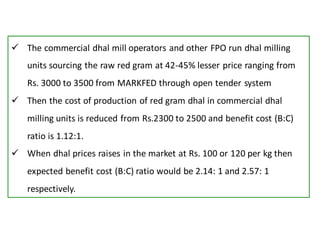

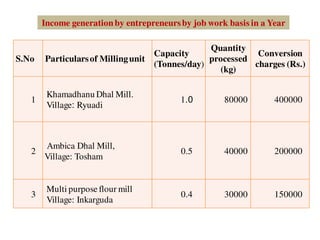

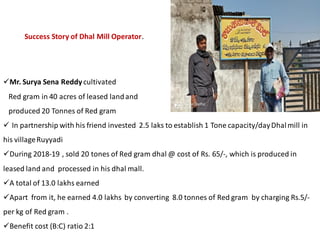

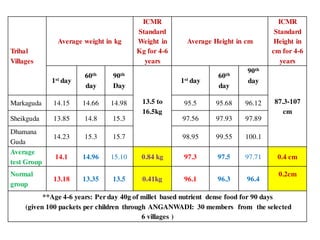

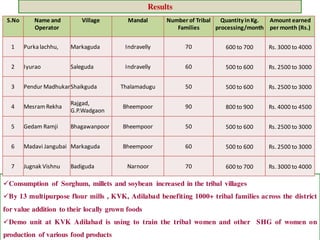

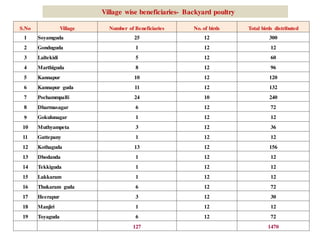

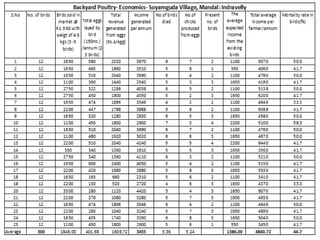

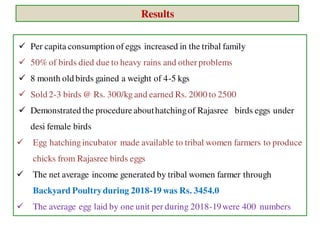

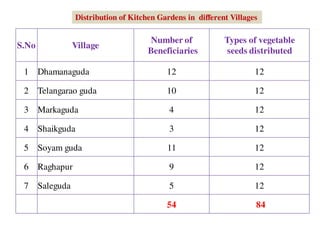

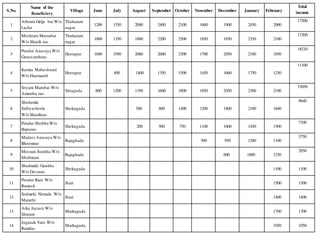

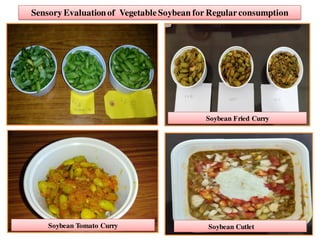

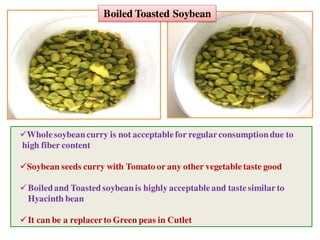

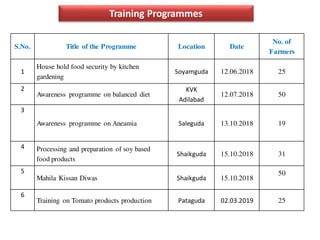

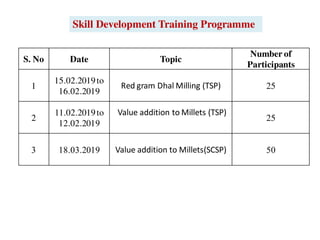

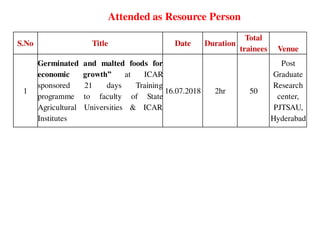

The document outlines various agricultural research and development initiatives applicable to rural farming communities, focusing on post-harvest management techniques and value addition for various crops including tomatoes, soybeans, and millets. It presents an action plan for 2019-20, detailing trials, budgets, and farming interventions aimed at improving economic viability and nutritional outcomes for farmers, particularly in tribal areas. Each initiative includes parameters to observe for effectiveness such as net returns, cost-benefit ratios, and the promotion of kitchen gardens.