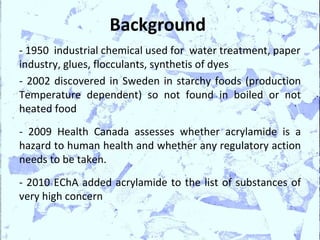

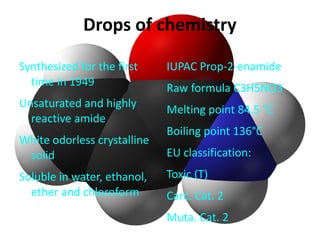

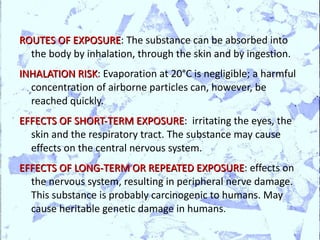

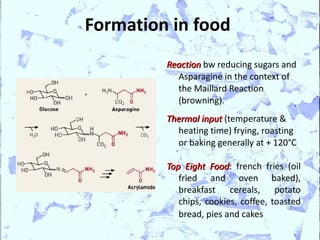

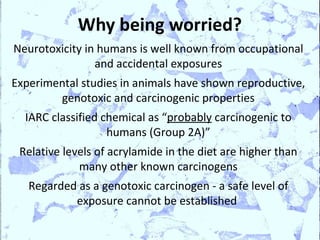

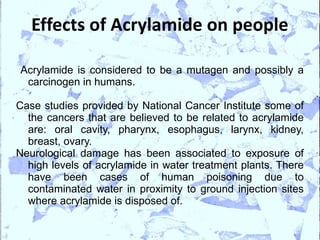

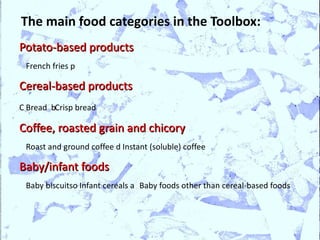

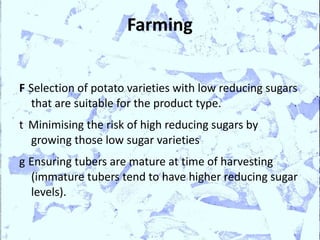

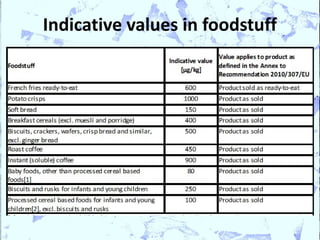

Acrylamide is a chemical that forms in some foods when they are cooked at high temperatures, such as frying, roasting or baking. It has been found to be potentially harmful to human health. Initiatives have been taken by food industries and regulatory bodies to reduce acrylamide levels in foods through best practices in farming, storage, processing and cooking. These include selecting potato varieties with low sugar levels, controlling cooking temperatures and times, and providing guidance to consumers on recommended cooking methods. Ongoing research continues to aim to further lower acrylamide content in foods.