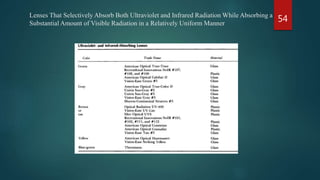

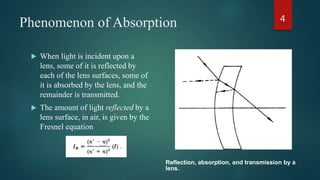

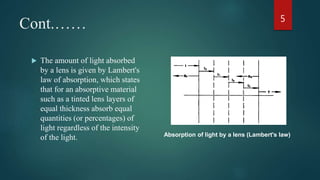

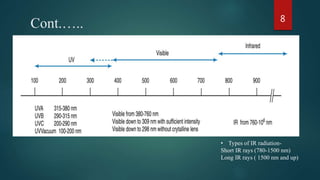

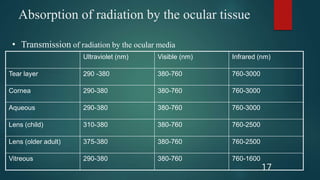

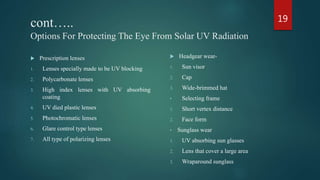

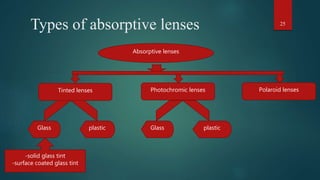

The document discusses absorptive lenses, detailing their functions, types, and effects on eye health from different forms of radiation, including UV and IR. It covers the manufacturing process of these lenses, tinting methods, and their potential uses for cosmetic, safety, and therapeutic purposes. Light absorption principles, like Lambert's law, and the need for UV protection through specialized lenses and eyewear are also emphasized.

![48

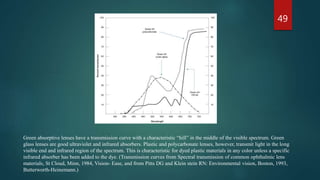

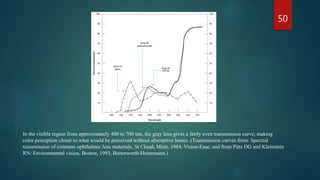

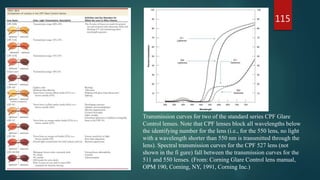

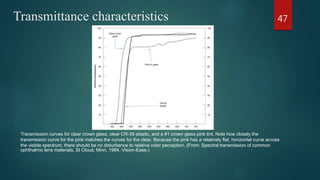

Transmission curves for yellow and brown tints. Yellow has a characteristic sudden drop in transmission between 500 and 450 nm. Brown also

shows a drop, but that drop is spread over a larger part of the visible spectrum. Note how dyed plastic and polycarbonate lenses transmit the long

end of the spectrum, including the infrared. It is possible to use lens dyes that absorb in the infrared region of the spectrum, if desired. (Yellow

crown glass and tan #3 [brown] glass transmission curves are redrawn from: Spectral transmission of common ophthalmic lens materials, St Cloud,

Minn, 1984, Vision-Ease, pp 9, 10. Brown #3 CR-39 and polycarbonate transmission curves from Pitts DG and Kleinstein RN: Environmental

vision, Boston, 1993, Butterworth-Heinemann.)](https://image.slidesharecdn.com/absorptivelensesbypratu2autosaved-190918052916/85/Absorptive-lenses-48-320.jpg)