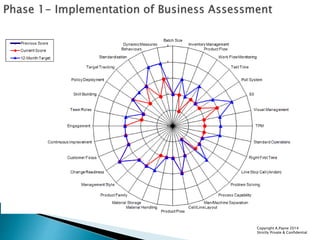

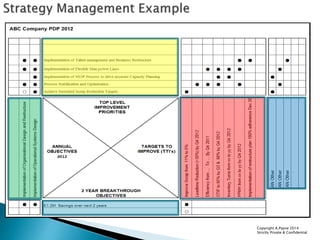

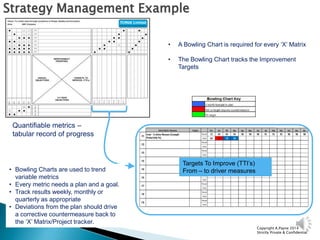

The document outlines various production management strategies, including batch size, inventory management, and process optimization, focusing on methodologies like FIFO, visual management, and continuous improvement. It emphasizes the importance of aligning projects with business assessments and developing corrective action plans based on performance metrics. Additionally, it discusses change management principles aimed at enhancing productivity, reducing errors, and achieving better inventory and lead time management.