This document presents a thermoeconomic analysis of replacing equipment in a cogeneration system at a university campus. The existing cogeneration system uses a gas turbine to generate approximately one-third of the campus' electricity needs and produces steam for use on campus. The analysis evaluates different gas turbine models to determine the best replacement option based on factors like payback period, annual savings, and exergetic manufacturing cost. Equations related to the thermodynamics and economics of the cogeneration system are provided.

![cogeneration plant generates approximately one third of the campus’ electrical requirements as

well as 1.764 kg/s of saturated steam (at 0.861 MPa) from a single fuel source. Fig. 1 shows a

schematic of the current SDSU cogeneration plant.

3. Energy analysis

The following equations are based on the thermodynamic principals according to the indicated

procedures by Wu [1] and Taki et al. [2]. The equations are valid for any situation described in the

previous items.

T2 ¼ T1=gc

ð Þ P2=P1

½ ðK1Þ=K

n

1

o

þ T1T2 ð1Þ

T3 ¼ ðT4

½

f T1Þ þ T2ð1 gtÞ=ð1 gtÞg ð2Þ

Ef ¼ mCpðT3 T2Þ=gcc ¼ mgCPF ð3Þ

W ¼ mCp½ðT3 T4Þ ðT2 T1Þ ð4Þ

Hd ¼ mCpðT4 T1Þ ð5Þ

Ep ¼ ggW ð6Þ

gt ¼ gcc ðT3

½ T4 T2 þ T1Þ=ðT3 T2Þ ð7Þ

gel ¼ Ep=Ef ð8Þ

Ec ¼ mCpðT4 TeÞ ð9Þ

Fig. 1. Schematic of the current SDSU cogeneration plant.

1474 J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-4-320.jpg)

![ghr ¼ Ec=Ef ð10Þ

gG ¼ ðEp þ EcÞ=Ef ¼ gel þ ghr ð11Þ

To calculate the recovered heat flux in the form of steam Eq. (12) may be used.

Hs ¼ msðhs hwÞ ¼ wbEc ð12Þ

Table 1

Gas turbines systems selected [3]

Reference Manufacturer Models Ep (kW) gT (%) m (kg/s) T4 (°C)

1 Deutz MWM-Gastechnik RA 151 4907a

30.57a

19.69a

476.67a

4459b

29.87b

18.11b

490.97b

2 Ishikawajima–Harima

Heavy Industries

IM400

HI-FLECS

6450a

37.91a

18.51a

496.67a

5861b

37.04b

17.03b

511.57b

3 Solar Turbines Taurus 60S 5200a

30.33a

21.36a

480.56a

4725b

29.63b

19.66b

494.98b

4 Deutz MWM-Gastechnik RA 141 4214a

29.92a

17.74a

510.00a

3829b

29.23b

16.32b

525.30b

5 European Gas Turbines Typhoon 4.3 4340a

29.92a

17.74a

510.00a

3944b

29.23b

16.32b

525.30b

6 European Gas Turbines Typhoon 4.7 4694a

30.38a

18.78a

510.56a

4226b

29.69b

17.28b

525.88b

7 Solar Turbines Centaur 50S 4345a

29.23a

19.01a

501.11a

3949b

28.56b

17.85b

516.14b

8 Stewart Stevenson TG-Typhoon 4907a

30.62a

19.69a

513.89a

4459b

29.92b

18.11b

529.31b

9 Hitachi Zosen CCS7 5943a

38.54a

17.92a

524.44a

5,401b

37.66b

16.48b

540.17b

10 Kawasaki Heavy Industries M1T-03 2680a

20.30a

18.10a

540.00a

2435b

19.83b

16.65b

556.20b

11 Kawaski Heavy Industries M1T-06 2670a

20.98a

18.60a

525.00a

2426b

20.50b

17.11b

540.75b

12 Allison Engine Company 501-KB5 3926a

28.67a

15.60a

549.44a

3568b

28.02b

14.35b

565.92b

13 Dresser–Rand KG2-3E 1830a

16.19a

14.97a

550.00a

1663b

15.82b

13.77b

566.50b

14 Allied Signal ASE50 3815a

30.71a

14.29a

562.22a

3,467b

30.00b

13.15b

579.09b

15 Allison Engine Company 501-KB5S 4103a

29.49a

15.60a

579.44a

3729b

28.82b

14.36b

596.82b

16 Centrax Gas Turbine CX501-KB5 3832a

27.90a

15.69a

571.00a

3482b

27.26b

14.44b

588.13b

17 Hitachi Zosen GT10-5 4096a

28.81a

15.60a

576.67a

3722b

28.15b

14.36b

593.97b

18 Ishikawajima–Harima

Heavy Industries

IM400 4540a

29.77a

16.42a

577.22a

4126b

29.09b

15.11b

594.54b

a

ISO conditions.

b

Local conditions.

J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483 1475](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-5-320.jpg)

![In order to select gas turbine systems commercially available, the following considerations were

made [4]:

(a) The gas turbine systems were selected in the ISO conditions (ambient temperature of 15 °C; sea

level; relative humidity of 60%) and for the performance correction on site were used the local

conditions (average ambient temperature of 25 °C; relative humidity of 80%);

(b) exhaust gases temperature in the atmosphere in steam production at 150 °C (‘‘pinch-point’’

method);

(c) for the calorific power of natural gas the value of 35,356 kJ/N m3

was used;

(d) for specific heat at constant pressure the value of 1.055 kJ/kg K was used;

(e) for the mechanical yield of the electrical generator was used the value of 95%;

(f) for the combustion chamber efficiency, the value of 97% was used;

(g) for the waste recuperation boiler was used the value of 70%.

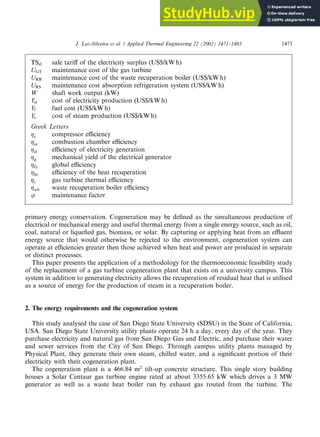

Considering the necessary values for the mass flux of exhaust gases and turbine exit temper-

ature, the turbine systems selected are shown in Table 1. These equipments are selected in thermal

parity. Table 2 displays the results of energy analysis of the turbine systems selected.

4. Energy-economic analysis

The investment decisions are usually based on capital costs and on the payback period. The

costs of electricity and steam production can be determined from the Eqs. (13)–(16) [4]. These

Table 2

Results for energy analysis of the systems selected

Reference Manufacturer Models Ef (kW) Ec (kW) gel (%) ghr (%) gG (%)

1 Deutz MWM-Gastechnik RA 151 15,715.23 6555.481 28.38 29.46 57.83

2 Ishikawajima-Harima

Heavy Industries

IM400

HI-FLECS

16,655.77 6624.998 35.19 28.09 63.28

3 Solar Turbines Taurus 60S 16,784.89 7142.096 28.15 30.05 58.20

4 Deutz MWM-Gastechnik RA 141 13,788.41 6649.257 27.77 34.05 61.83

5 European Gas Turbines Typhoon 4.3 14,200.69 6649.257 27.77 33.07 60.84

6 European Gas Turbines Typhoon 4.7 15,126.00 7003.682 28.20 32.70 60.90

7 Solar Turbines Centaur 50S 14,554.90 6876.817 27.13 33.37 60.49

8 Stewart Stevenson TG-Typhoon 15,687.07 7376.283 28.43 33.21 61.63

9 Hitachi Zosen CCS7 15,095.89 7000.620 35.78 32.75 68.52

10 Kawasaki Heavy Industries M1T-03 12,926.03 7380.537 18.84 40.32 59.16

11 Kawaski Heavy Industries M1T-06 12,460.28 7246.198 19.47 41.07 60.54

12 Allison Engine Company 501-KB5 13,404.78 6651.547 26.61 35.04 61.66

13 Dresser-Rand KG2-3E 11,063.14 6427.239 15.03 41.03 56.06

14 Allied Signal ASE50 12,163.24 6376.801 28.50 37.02 65.53

15 Allison Engine Company 501-KB5S 13,620.64 7185.013 27.37 37.25 64.63

16 Centrax Gas Turbine CX501-KB5 13,447.76 7070.278 25.90 37.13 63.02

17 Hitachi Zosen GT10-5 13,917.06 7135.573 26.75 36.21 62.95

18 Ishikawajima–Harima

Heavy Industries

IM400 14,928.05 7471.048 27.64 35.34 62.98

1476 J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-6-320.jpg)

![equations consider all the pertinent aspects for the construction and operation of a cogeneration

plant, since they do not fasten important parameters such as the total plant capital cost including

capital taxes and insurance (IPL) or interest rate (r).

Yel ¼ ðIPL

½ IHRÞf =ðHEpÞ þ ðYf =EpÞðEf

Ec ðLos=2ÞÞ

þ UGT ð13Þ

Ys ¼ IRBf

½ =ðHHsÞ þ ðYf =HsÞðEc

½ þ ðLos=2ÞÞ þ URB ð14Þ

f ¼ qk

q

ð

1Þ

= qk

1

ð15Þ

q ¼ 1 þ r=100

ð Þ ð16Þ

In these equations (Eqs. (13)–(16)), the cost of electricity production (Yel) and steam production

(Ys) is a function of the plant capital cost including capital taxes and insurance (IPL), the operation

cost and maintenance cost. The annuity factor (f) associated to the plant capital cost is a function

of payback period (k) and the annual interest rate (r).

Eqs. (17) and (18) show the savings due to electric power production in case of electrical surplus

and in case of an electrical deficit, respectively. The savings due to steam production can be

determined by using the Eq. (19). The total annual saving is calculated using the Eq. (20) [4].

Sel ¼ ErHðTel YelÞ þ ðEp ErÞHðTSel YelÞ ð17Þ

Sel ¼ EpHðTel YelÞ ð18Þ

Ss ¼ HsHðPEs YsÞ ð19Þ

R ¼ Sel þ Ss ð20Þ

Table 3 shows the considerations for the energy-economic analysis applied to the cogeneration

plant. Table 4 displays the cogeneration products costs for the energy-economic analysis.

5. Exergy-economic analysis

The development of design techniques for an energy system with minimized costs is a necessity

in a world with finite natural resources and the increase of the energy demand. The presented

method combines the Second Law of Thermodynamics through the exergy concept, associated to

Table 3

Considerations for energy-economic analysis [4]

Annual interest rate (r) 8%

Fuel cost (Yf ) 0.0200 US$/kW h

Electricity tariff (Tel) 0.1000 US$/kW h

Sale tariff of the electricity surplus (TSel) 0.0800 US$/kW h

Pay-back period (k) 10 years

Equivalent utilization period (H) 7200 h/year

Electricity required (Er) 3000 kW

J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483 1477](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-7-320.jpg)

![an economical approach of the thermal system. For the analysis of the cogeneration system in

question, the following steps were taken:

1. identification of the system functions of cogeneration as a whole and each unit individually;

2. evaluation of the exergy input and output stream value of each unit;

3. construction of the thermoeconomic function diagram;

4. selection of the fixed parameters and its values;

5. formulation of the exergetic increment function associated with the output and input of each

unit;

6. formulation of the exergetic manufacturing cost equation.

According to Moran and Sciubba [5] and Kotas [6], in the evaluation of the exergy input and

output stream value of each unit, the steam exergy is defined by:

ei ¼ ½ðhi hoÞ Toðsi soÞ ð21Þ

The exergy of the air and gas stream are defined by [4]:

ei ¼ CpGðTiÞ: Ti

½ To ln Ti=To

ð Þ þ RGTo ln Pi=Po

ð Þ ð22Þ

where: CpG

is Cpair

or Cpgas , for specific heat of air and gases, respectively.

Table 4

Results for energy-economic analysis (cogeneration products costs)

Manufacturer Models For k ¼ 10 years Based on pay

back period

Electricity Steam Savingsa

Yel (US$/kW h) Ys (US$/kW h) R (US$/year) k (year)

Deutz MWM-Gastechnik RA 151 0.0591 0.0496 2,972,185 1.10

Ishikawajima–Harima

Heavy Industries

IM400

HI-FLECS

0.0558 0.0483 3,381,534 1.21

Solar Turbines Taurus 60S 0.0588 0.0491 3,203,936 1.01

Deutz MWM-Gastechnik RA 141 0.0580 0.0464 3,040,208 1.00

European Gas Turbines Typhoon 4.3 0.0583 0.0471 3,027,733 1.02

European Gas Turbines Typhoon 4.7 0.0578 0.0472 3,194,990 1.02

Solar Turbines Centaur 50S 0.0586 0.0470 3,087,812 1.08

Stewart Stevenson TG-Typhoon 0.0573 0.0467 3,370,287 0.99

Hitachi Zosen CCS7 0.0534 0.0448 3,629,887 1.06

Kawasaki Heavy Industries M1T-03 0.0659 0.0453 2,860,070 0.93

Kawaski Heavy Industries M1T-06 0.0647 0.0448 2,857,643 0.92

Allison Engine Company 501-KB5 0.0587 0.0462 2,988,714 0.99

Dresser-Rand KG2-3E 0.0744 0.0459 2,256,037 0.97

Allied Signal ASE50 0.0567 0.0445 2,993,921 0.97

Allison Engine Company 501-KB5S 0.0568 0.0447 3,280,092 0.94

Centrax Gas Turbine CX501-KB5 0.0583 0.0451 3,148,199 0.95

Hitachi Zosen GT10-5 0.0578 0.0454 3,211,048 0.96

Ishikawajima–Harima

Heavy Industries

IM400 0.0571 0.0456 3,391,485 0.96

a

Maximum savings.

1478 J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-8-320.jpg)

![5.1. Thermoeconomic functional diagram

The functional diagram of the cogeneration system, which allows the intended analysis, is

composed of geometric figures representing the units and a network of lines representing the

unitary function distributions in terms of exergy. These units correspond to the real plant’s

components. The notation Yi;j (jth input of ith unit) and Yik (kth output of ith unit) is used by

Frangopoulos and Evans [7] and Tuna and Silveira [8].

Fig. 2 shows the functional diagram of the system presented in Fig. 1. It is important, to follow

the development of the proposed method of this work, notice that each unit (or component) will

receive an identification number. It is also essential to understand the transposition of Fig. 1

(physical diagram) to Fig. 2 (functional diagram) that considered fluxes refers to the exergetic

increment and not to the absolute value of this thermodynamic property.

The frontier functional line is the one that takes apart the supplies and the products of the

system from the environment and leaves the process outside.

To evaluate the exergetic functions associated to the functional thermoeconomic diagrams and

in order to simplify the calculation procedures, the loss in the pipes was neglected.

Fig. 2. Cogeneration system functional diagram.

J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483 1479](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-9-320.jpg)

![5.2. Exergetic increment function

From the physical diagram (Fig. 1) and from the thermodynamic property values of input and

output of each component, it is possible to obtain the exergetic increment functions associated

with the functional thermoeconomic diagram (Fig. 2). With this procedure, these expressions for

these functions are [8]:

Unit A: Compressor

YA;1 ¼ Exair

ð23Þ

YA;2 ¼ Wcomp ð24Þ

YA1 ¼ mairðe2 e1Þ ð25Þ

Unit B: Combustion chamber

YB;1 ¼ Exfuel

ð26Þ

YB;2 ¼ YA1 ð27Þ

YB1 ¼ Exgases ¼ mgasese3 ð28Þ

Unit C: Gas turbine

YC;1 ¼ YB1 ð29Þ

YC;3 ¼ YA;2 ð30Þ

YC1 ¼ Ep ð31Þ

YC2 ¼ mgasese4 ð32Þ

Unit D: Waste boiler

YD;1 ¼ YC2 ð33Þ

YD;2 ¼ mwf e9 ð34Þ

YD1 ¼ mwf e7

ð e9Þ ð35Þ

YD2 ¼ mgases e5

ð e4Þ ð36Þ

Unit F: Pump

YF1 ¼ YD;2 ð37Þ

YF;1 ¼ mwf e7

ð e8Þ ð38Þ

YF;2 ¼ Wpump ð39Þ

1480 J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-10-320.jpg)

![5.3. Thermoeconomic cost equations

Fig. 3 shows the costs diagram. The exergetic manufacturing cost (EMC) is defined by the

produced electricity cost plus the consumed steam cost plus the electricity cost bought from the

concessionaire in deficit situation (Eq. (40)) or minus the earnings received from the sell of

the electricity exceeding (Eq. (41)). Eqs. (42) and (43) show the expressions of specific costs Yel and

Ys, respectively [8].

EMC ¼ EpYel þ EcYs þ ðEr EpÞTel ð40Þ

EMC ¼ EpYel þ EcYs ðEp ErÞTSel ð41Þ

Yel ¼

ðIPL IWBÞf u

HYC1

þ Yf

ðYB;1 YD2Þ

YC1

ð42Þ

Ys ¼

IWBf u

HYD2

þ Yf

YB1

YD2

ð43Þ

Fig. 3. The cost diagram.

Table 5

Results for exergy-economic optimization.

Reference Manufacturer Models Electricity (Yel)

(US$/kW h)

Steam (Ys)

(US$/kW h)

EMC

(US$/year)

1 Deutz MWM-Gastechnik RA 151 0.1542 0.2103 6,483,294

2 Ishikawajima–Harima

Heavy Industries

IM400

HI-FLECS

0.1358 0.1961 6,324,524

3 Solar Turbines Taurus 60S 0.1554 0.2079 6,852,354

4 Deutz MWM-Gastechnik RA 141 0.1693 0.1971 6,458,717

5 European Gas Turbines Typhoon 4.3 0.1661 0.1997 6,469,866

6 European Gas Turbines Typhoon 4.7 0.1626 0.1997 6,679,015

7 Solar Turbines Centaur 50S 0.1687 0.2000 6,625,946

8 Stewart Stevenson TG-Typhoon 0.1629 0.1978 6,909,216

9 Hitachi Zosen CCS7 0.1436 0.1820 6,410,176

10 Kawasaki Heavy Industries M1T-03 0.2354 0.1950 7,007,572

11 Kawaski Heavy Industries M1T-06 0.2340 0.1927 6,902,036

12 Allison Engine Company 501-KB5 0.1765 0.1963 6,466,572

13 Dresser-Rand KG2-3E 0.2775 0.1980 6,472,360

14 Allied Signal ASE50 0.1755 0.1880 6,191,836

15 Allison Engine Company 501-KB5S 0.1781 0.1898 6,724,540

16 Centrax Gas Turbine CX501-KB5 0.1842 0.1923 6,695,837

17 Hitachi Zosen GT10-5 0.1775 0.1931 6,724,447

18 Ishikawajima–Harima

Heavy Industries

IM400 0.1710 0.1938 6,936,902

J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483 1481](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-11-320.jpg)

![Table 5 shows the specific costs associated to the cogeneration products and the value of the

exergetic manufacturing cost. In Table 5, the best system, which has the lowest EMC, is the

system that used the gas turbine ‘‘ASE50’’ of Allied Signal followed by ‘‘IM400 HI-FLECS’’ of

Ishikawajima–Harima Heavy Industries. This result is associated with the irreversibility level of

each system and other parameters as the electricity sell price and the plant investment.

6. Conclusions

The feasibility of the replacement of the gas turbine system in a gas turbine cogeneration system

existing on a university campus has been shown. The system design and operational parameters

are important to evaluate cogeneration systems. The energy-economic study shown that the best

system, based on pay-back period, was the system that used the gas turbine ‘‘M1T-06’’ of Ka-

waski Heavy Industries followed by ‘‘M1T-03’’ of Kawasaki Heavy Industries. The best system,

based on the maximum savings (in 10 years), was the system that used the gas turbine ‘‘CCS7’’ of

Hitachi Zosen followed by ‘‘IM400’’ of Ishikawajima–Harima Heavy Industries.

The development of the EMC method, overcoming the initial complexities, is revealed a

powerful tool of optimization in cogeneration context. The advantage of this method is its lowest

computational time, because it is a direct algebraic method, easy to handle and to change its

parameters to others. In this paper, the exergy-economic study shown that the best system, which

has the lowest EMC, was that that used the gas turbine ‘‘ASE50’’ of Allied Signal followed by

‘‘IM400 HI-FLECS’’ of Ishikawajima–Harima Heavy Industries.

Acknowledgement

The authors wish to express their thanks to support of FAPESP (Fundac

ß~

a

ao de Amparo a

Pesquisa do Estado de S~

a

ao Paulo––Brazil, Process number 99/08851-0).

References

[1] C. Wu, Power optimization of an endoreversible Brayton gas heat engine, Energy Conversion Management 31

(1991) 561–565.

[2] Y. Taki, R.F. Babus’Haq, R.L. Elder, S.D. Propert, Design and analysis of a compact gas turbine for CHP system,

Heat Recovery System and CHP 11 (1991) 149–160.

[3] V. Biasi, For project planning, design and construction––gas turbine world, in: The 1997–98 Handbook, Pequot

Publishing, Washington, 1999.

[4] J.L. Silveira, A.C.S. Walter, C.A. Luengo, A case study of a compact cogeneration system for a hospital––techno-

economic analysis, Proceedings of third Asian-Pacific International Symposium on Combustion and Energy

Utilization, vol. 2, 1992, pp. 756–762.

[5] M. Moran, E. Sciubba, Exergy analysis: principles and practice, Journal of Engineering for Gas Turbines and Power

116 (1994) 285–290.

[6] T.J. Kotas, The Exergy Method of Thermal Plant Analysis, Anchor Brendon Ltd., Great Britain, 1985.

1482 J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-12-320.jpg)

![[7] C.A. Frangopoulos, R.B. Evans, Thermoeconomic isolation and the optimization of thermal systems components,

in: A. Bejan, R.L. Reid (Eds.), Second Law Aspects of Thermal Design, American Society of Mechanical Engineers,

New York, 1984.

[8] Heat and power systems, Proceedings of fifth ASME/JSME Thermal Engineering Joint Conference, CD-ROM,

1999, pp. 1–7.

J. Luz-Silveira et al. / Applied Thermal Engineering 22 (2002) 1471–1483 1483

All in-text references underlined in blue are linked to publications on ResearchGate, letting you access and read them immediately.](https://image.slidesharecdn.com/acontributionforthermoeconomicmodellingamethodologyproposal-230804175506-3c070078/85/A-Contribution-For-Thermoeconomic-Modelling-A-Methodology-Proposal-13-320.jpg)