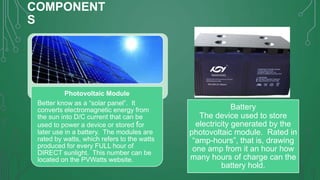

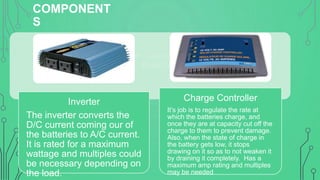

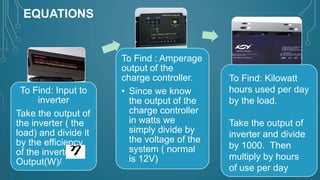

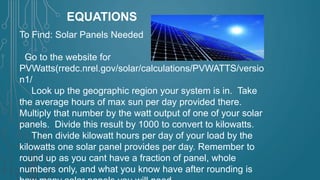

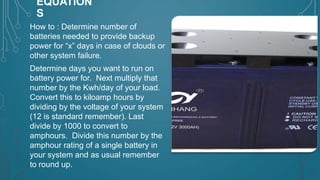

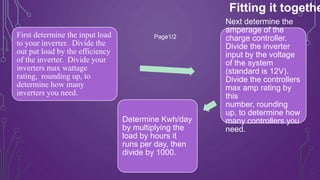

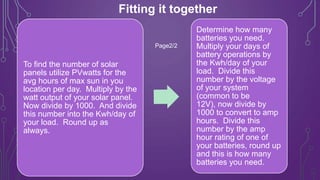

This document provides an overview of photovoltaic (solar panel) system design for beginners. It defines key terms like watt, volt, amp, load, and efficiency. It identifies the main components of a photovoltaic system as the solar panel, battery, inverter, and charge controller. It demonstrates the important equations for determining the input to the inverter, charge controller output, daily kilowatt hours used, number of solar panels needed, and number of batteries required for backup power. Finally, it provides step-by-step instructions on how to fit all the components together into a basic photovoltaic system design.