The 5 Expert Medical Packaging Solution Providers.pdf.pdf

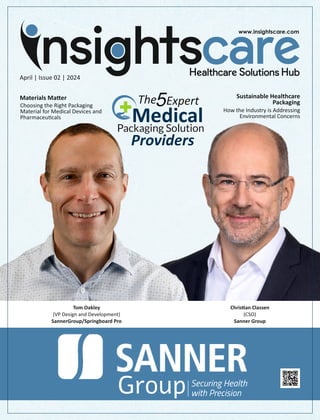

- 1. April | Issue 02 | 2024 Chris an Classen (CSO) Sanner Group Tom Oakley (VP Design and Development) SannerGroup/Springboard Pro 5Expert Medical Packaging Solution Providers The Sustainable Healthcare Packaging How the Industry is Addressing Environmental Concerns Group Securing Health with Precision Materials Ma er Choosing the Right Packaging Material for Medical Devices and Pharmaceu cals

- 5. Smart and Sustainable Solutions edical packaging is like a silent guardian that Mensures the safe and effective delivery of pharmaceuticals and medical devices, protecting them from contamination and damage during transit. This exclusive edition of Insights Care is dedicated to exploring the innovative solutions provided by the industry’s leading experts in medical packaging. While flipping through the pages of this issue, you will discover advanced technologies and materials that are improving the way they package and protect healthcare products. From smart packaging that enhances traceability and security to sustainable solutions that minimize environ- mental impact, these expert providers are at the forefront of a new era in healthcare packaging. In this edition, we are proud to feature The 5 Expert Medical Packaging Solution Providers, who are leading the way in providing high-quality, safe, and efficient packaging solutions for medical products. These expert providers have demonstrated a deep understanding of the unique challenges and requirements of medical packaging and have developed innovative solutions to meet them. We will also highlight the role of innovative materials and design in creating packaging that not only safeguards the integrity of medical devices and pharmaceuticals but also enhances patient adherence and overall healthcare out- comes. The future of healthcare packaging is not just about protecting products; it’s about creating solutions that are responsive to the needs of patients, healthcare providers, and the environment. As the healthcare industry continues to evolve, the need for reliable and effective medical packaging solutions becomes increasingly important. We hope that this edition of Insights Care will provide you with valuable insights and informa- tion on the latest trends and innovations in medical packaging. Join us as we explore the transformative potential of medical packaging and the industry-leading expertise of top providers in this field. Wishing you an insightful read ahead! -Natalie May NatalieMay

- 6. 08. Cover Story Table of Sanner Group Securing Health with Precision CONTENTS

- 7. Profiles 18. Neutroplast Transforming Patient Experiences through Innovative Packaging 26. PackEx GmbH Packaging Solutions for a Green Future 36. Teampac Your Trusted Partner in Medical Packaging Articles 22. Sustainable Healthcare Packaging How the Industry is Addressing Environmental Concerns 32. Materials Matter Choosing the Right Packaging Material for Medical Devices and Pharmaceuticals

- 8. Copyright © 2024 Insights Success Media and Technology Pvt. Ltd., All rights reserved. The content and images used in this magazine should not be reproduced or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior permission from Insights success. Reprint rights remain solely with Insights Success Media and Technology Pvt. Ltd. Insights Care is powered by Insights Success Media and Technology Pvt. Ltd. April, 2024 sales@insightscare.com Contact Us: Follow us on : www.facebook.com/InsightsCare/ https://twitter.com/Insightscare Insights Success Media Tech LLC 555 Metro Place North, Suite 100, Dublin, OH 43017, United States Phone - +1614-602-4132 Email: info@insightscare.com For Subscription: www.insightscare.com Insights Success Media and Technology Pvt. Ltd. Survey No.133/134, Brand Square, Office No. 512, Kunjir Chowk, Pimple Saudagar, Pune, Maharashtra 411027. Phone - India: 7410033802, 8956487823 Email: info@insightscare.com For Subscription: www.insightscare.com Editor-in-Chief Chidiebere Moses Ogbodo Managing Editor Pearl Shaw Executive Editor Natalie May Visualiser David King Art & Design Head Samuel Martinez Co-designer Paul Belin Art & Picture Editor Grace Brown Business Development Manager Emily Jones Marketing Manager Bill Thompson Business Development Executives Anna Smith, Jack Miller Sales Executives Mike, Carl, John Technical Head Jacob Smile Assistant Technical Head Joseph Taylor Technical Consultants David, Robert Digital Marketing Manager Alina Sege Assistant Digital Marketing Manager Daniel Jones SME-SMO Executive Gemson Research Analyst Eric Smith Circulation Manager James Carter We are also available on :

- 9. Brief Featuring Person Company PackEx GmbH offers customized packaging solutions for various industries, including pharmaceuticals, healthcare, food, and cosmetics. Sanner Group is a prominent organization that specializes in developing and manufacturing high- quality packaging solutions for pharmaceutical, medical, and healthcare applications. Neutroplast is a pharmaceutical packaging producer that specializes in high-quality packaging solutions for the pharmaceutical and personal care industries. Sealed Air is a global leader in packaging solutions, offering a variety of medical packaging solutions for pharmaceutical applications, healthcare products, and medical devices. PackEx GmbH packex.com Julian Erhard Managing Director & Co-founder Manuela Redol Administrator & Co-owner Tom Oakley (Vice President of Design & Development) Christian Classen (Chief Sales Officer) Emile Chammas SVP & Chief Operating Officer Neutroplast neutroplast.com Sanner Group sanner-group.com Sealed Air sealedair.com Teampac is a Finnish, internationally operating contract manufacturer of medical devices and liquid-based products for cosmetics, hygiene and healthcare. Jyri Temonen CEO Teampac teampac.com 5Expert Medical Packaging Solution Providers The

- 10. Sanner Group Securing Health with Precision Tom Oakley (VP Design and Development) Sanner Group

- 12. Medical packaging and device development is a cornerstone in ensuring healthcare products' safety, integrity, and efficacy. Adhering to stringent regulatory standards, packaging materials and designs are meticulously developed to uphold these fundamental qualities. Stepping into this pivotal role are Medical Packaging and Development Solution Providers, specialized entities dedicated to tailoring solutions to the unique demands of the medical and healthcare sectors. Leading this specialized field is , an Sanner Group esteemed organization renowned for its proficiency in desiccant closures and effervescent tablet packaging. With a rich legacy of innovation and industry experience, Sanner Group is steadfast in its commitment to delivering solutions that uphold the highest standards of quality and efficacy. Founded in Bensheim, Germany, in 1894, Sanner Group has developed to a global leader in cutting-edge packaging solutions tailored for the medical and healthcare industries. Evolving from its origins, the organization has expanded its scope to provide customized solutions across medical devices, diagnostics, pharmaceuticals, and consumer healthcare. Sanner Group has embraced a resolute commitment to sustainability, seamlessly integrating it into its core corporate strategy. Under the leadership of Christian Classen, the Chief Sales Officer, Sanner Group focused on the pharmaceutical and medical sector, and is manufacturing pre-filled syringes, inhalers, pipettes, and customized drug delivery devices as well as packaging solutions. At the heart of this evolution lies Sanner Group's unparalleled expertise in moisture management within packaging, strengthening product integrity and efficacy. A significant milestone in Sanner Group's journey is the acquisition of Springboard Pro, a strategic move poised to boost its ventures in medical device innovation. Serving as the 'Design Center of Excellence,' Springboard Pro, under the guidance of Tom Oakley, Vice President of Design and Development, brings forth a wealth of expertise spanning end-to-end device development, physics, materials science, mechanical, electronics and human factors engineering, software and more. This exclusive feature offers a glimpse into Sanner Group's transformative journey, showcasing its rise to prominence as an institution of excellence in medical packaging solutions. Agile Approach to Pharmaceutical Packaging Sanner GmbH boasts a robust reputation in healthcare and nutraceutical packaging, anchored on quality, service, and delivery flexibility. They distinguish themselves by offering sustainable packaging solutions crafted from renewable resources. In pharmaceutical packaging, Sanner Group's 'Advance with Agility' approach ensures drug stability through a three-step process, facilitating faster development, packaging changes, and time-to-market. By leveraging stability modeling services, rapid package design or selection, and turnkey commercial packaging guidance, clients can save up to 12 months of product development time, expediting market entry and revenue generation. For medical device development, Sanner GmbH partners with Springboard, a consultancy specializing in guiding concepts to manufacturing implementation. Equipped with a comprehensive suite of engineering, scientific, and forensic capabilities, Springboard delivers end-to-end solutions from pre- to post-product launch. Their expertise spans diverse medical devices and equipment, offering fast, cost-effective regulated development and delivering valuable intellectual property for clients. Moreover, as a next-generation device Contract Development and Manufacturing Organization (CDMO), Sanner Group strengthens its capabilities with cutting-edge prototyping, mold conceptualization, and Design for Manufacturing & Assembly, all upheld by the highest quality standards. Our approach to leadership is to gather and inspire people with the right talent and a tude, have robust and credible plans, and to give them the tools and environment to thrive in the work that they do. – Tom

- 13. Expertise in Medical Packaging Solutions Sanner GmbH stands out as a leading expert in medical device solutions, excelling in three key areas: 1. Springboard Pro-Design Center of Excellence Through Springboard Pro, Sanner GmbH houses a Design Center of Excellence for device and packaging development. This comprehensive facility offers end-to-end device development, encompassing disciplines such as physics, materials science, mechanical and electronics engineering, software development, human factors engineering, and industrial design. This integrated approach ensures that every aspect of device development is carefully addressed, resulting in innovative and effective solutions. 2. Innovative Project Realization Methods Sanner Group has pioneered new methods for executing customer projects efficiently. The Sanner Idea-Design- Product Process® represents a flexible and agile stage-gate development process, facilitated by a Product Lifecycle Management (PLM) System integrated with a project management tool. This system meticulously documents every development step and defines milestones agreed upon by all involved parties. It serves as a single platform for partner collaboration and documentation storage. Additionally, Sanner GmbH offers five different prototyping methods, including additively manufactured, fully functional mold inserts, and utilizes virtual reality simulation to ensure a robust and efficient Design for Assembly process. 3. Advanced Moisture Management Solutions Sanner Group stands as the sole CDMO offering advanced moisture management solutions for devices. This specialization underscores their commitment to addressing critical challenges in device performance and longevity. Christian's Journey—Navigating the Dynamics of the Plastics Industry Throughout his three-decade tenure in the plastics industry, Christian has traversed a diverse landscape, accumulating invaluable experiences across both medium-sized Aligned with market growth aspira ons and customer demands, Sanner Group is poised to acquire a development and produc on facility in the United States. The 5 Expert Medical Packaging Solu on Providers Fully automated high-quality production sites

- 14. enterprises and publicly listed corporations. These varied environments have equipped him with a rich spectrum of insights, instrumental in shaping his professional trajectory. Commencing his career in sales at a medium-sized Original Equipment Manufacturer (OEM) in Germany, specializing in miniature fittings and connectors crafted from special plastics, Christian later transitioned to the globally renowned Swiss Georg Fischer Corporation. Here, he assumed international responsibility for product management, overseeing fluoropolymer piping systems catering to clients in the semiconductor and pharmaceutical sectors. This role cultivated his adeptness in navigating international dynamics, encouraging cross-regional collaboration, and leveraging synergies within diverse teams. In 2005, Christian was heading the establishment of a Medical CDMO division. Despite his background in industrial management and economics, he tackled technical challenges, such as setting up medical clean room production facilities and securing ISO 13485 certification, while delving into strategic business development. Subsequent roles included serving as a member of the management team at Riwisa, a Swiss medium-sized company, where he headed sales and marketing initiatives across medical, industrial, and consumer divisions. Here, he successfully devised and executed a transformative marketing strategy, expanding market share in the diagnostics segment and venturing into the domain of drug delivery devices. Christian's journey continued with a pivotal position at Nolato in Sweden, where he led strategic business development efforts in Central Europe, contributing to the company's expansion into the drug delivery devices sector. In his final four years before joining Sanner Group, Christian held the role of Director of Sales & Marketing Europe at Phillips Medisize, an American company. Here, he focused on driving strategic growth initiatives with European clientele, leveraging the company's global development and manufacturing capabilities. His tenure was marked by promoting team development and driving substantial growth. Reflecting on his career trajectory, Christian emphasizes the profound impact of transitioning between medium-sized and listed enterprises, as well as his exposure to diverse corporate cultures spanning German, Swiss, Swedish, and American companies. These experiences have not only enriched his understanding of varied working methodologies but also deepened his appreciation for cultural diversity within the industry. Leading with Purpose Upon joining Sanner GmbH in October 2022, Christian's foremost priority was acquainting himself with the sales, marketing, and product management teams, understanding each member's background and unique strengths to harness their collective potential. "Over the last years, I have learned that it is important to utilize different perspectives, experiences, knowledge, and skills to leverage the power of diversity. I strongly believe that success as a leader is based on transformation, self-actualization, knowledge sharing and respect," emphasizes Christian. Central to this philosophy is teamwork, wherein the entire team unites behind a shared vision, leveraging individual expertise and supporting one another to attain common objectives. In September 2023, Christian had the pleasure of orchestrating an international sales meeting, reuniting the entire Sanner Group's sales, marketing, and product management teams after a four-year break due to Covid- related travel restrictions. Beyond addressing routine agenda items, the gathering served as a platform for cross- regional knowledge exchange and mutual learning, facilitated by dedicated time slots for discussions and team- building activities. Passion serves as another cornerstone of Christian's leadership philosophy. "As a leader, I try to share my passion for the transformation that is currently taking place at Sanner with my team and encourage them to contribute and actively shape it," affirms Christian. Acknowledged as a global leader in moisture management solu ons, Sanner Group addresses the cri cal need for innova ve approaches in preserving the integrity of drugs and diagnos cs.

- 15. Device Conceptualization and Development Autoinjector development by Springboard

- 16. Ultimately, effective communication is an important part of his leadership approach. Particularly amidst significant change, Christian emphasizes the importance of engaging employees in the transformation process, explaining what and why behind the changes. Through these concerted efforts, Christian has cultivated a positive approach and shared commitment within the team, laying a solid foundation for achieving the ambitious goals ahead. Tom's Mission in Medical Device Development The journey of medical device development is both fulfilling and technically demanding, driven by the desire to positively impact lives globally. For Tom, this aspiration crystallized into the founding of a specialized company dedicated to the development of medical devices and combination products. "Therefore, it had always been my intention to establish a company specializing in the development of medical devices and combination products," recalls Tom. Established in 2013, Springboard experienced organic growth, growing into a team of 30 experts by 2023. The company's success is rooted in its recognition of the multifaceted nature of modern medical device development. From pioneering science to precise engineering and nuanced user insights, a diverse skill set is imperative. Springboard strategically recruits top talent from varied backgrounds to construct multi-disciplinary teams capable of tackling complex challenges. Tom underscores their leadership philosophy, emphasizing the importance of assembling and motivating individuals possessing the right skills and attitude. "Our approach to leadership is to gather and inspire people with the right talent and attitude, have robust and credible plans, and to give them the tools and environment to thrive in the work that they do," Tom asserts. Central to Springboard's operational strategy is effective communication, serving as the key element for project execution. Collaborating closely with colleagues at Sanner Group's manufacturing sites worldwide, Springboard ensures the delivery of high-quality, safety-critical designs. Driving Innovation in MedTech In the dynamic landscape of MedTech, Sanner Group stands at the forefront of innovation, with a keen focus on several key areas: - Next-Generation Drug Delivery Devices: Sanner Group is dedicated to developing drug delivery devices that can administer medications with complex stability, viscosity, or volume characteristics, all while prioritizing user- friendliness and minimizing environmental impact. - Biotechnology Advancements: The growing field of biotechnology necessitates continuous innovation in equipment for the production and analysis of biological materials. Sanner Group actively engages in developing cutting-edge solutions tailored for applications such as cell and gene therapy and diagnostics. - Enhanced Surgical Tools and Consumables: Sanner Group recognizes the need for innovation in surgical tools and As a leader, I try to share my passion for the transforma on that is currently taking place at Sanner with my team and encourage them to contribute and ac vely shape it. – Chris an Design for Assembly by Virtual Reality Simulation

- 17. consumables, striving to deliver products that excel in quality, cost-effectiveness, and sustainability. - Innovative Moisture Management: Acknowledged as a global leader in moisture management solutions, Sanner Group addresses the critical need for innovative approaches in preserving the integrity of drugs and diagnostics. Strategic Expansion in MedTech Industry The partnership with GHO Capital, renowned as Europe's premier healthcare specialist investor, marks a pivotal milestone in driving Sanner Group towards global prominence in the MedTech sector. With a focused agenda, this collaboration aims to transform Sanner Group into a preeminent MedTech CDMO, amplifying manufacturing capabilities across Europe and Asia, and paving the way for transatlantic expansion into the US market. A significant stride on this path is the recent acquisition of Springboard Pro, a distinguished entity specializing in designing and developing medical devices for regulated markets. This strategic move not only enhances Sanner Group's in-house medical device development competence but also marks the establishment of a cutting-edge Design Center of Excellence in the UK. In line with this trajectory, Sanner Group inaugurated its second state-of-the-art manufacturing facility in Kunshan, China, last autumn, strengthening production capacity in the Asia-Pacific region. Simultaneously, in Bensheim, Germany, construction is underway for a groundbreaking production facility and innovative development center, tailored to meet sustainability objectives while offering clients with additional capacity to support projects across Central Europe. Supported by expansions in Asia and Europe, the focus now shifts towards North America. Aligned with market growth aspirations and customer demands, Sanner Group is poised to acquire a development and production facility in the United States. This strategic move aims to streamline supply chains, enabling efficient delivery of high-quality Sanner products and CDMO services to US clientele. The successful execution of these strategic imperatives within a condensed timeframe underscores the indispensable role played by GHO Capital. Leveraging its extensive experience and network, GHO has been instrumental in realizing these ambitious initiatives, positioning Sanner Group as an unstoppable force in the global MedTech landscape. Championing Health Protection Sanner Group's commitment to 'Protecting Health' serves as its guiding principle. This slogan encapsulates the core value of the company. The development and production endeavors of Sanner Group are directed towards developing medical device components and active primary healthcare packaging that prioritize superior usability, patient adherence, and sustainability through innovative solutions. Drawing strength from robust internal and external collaborations, Sanner GmbH emerges as a trusted international partner renowned for its dedication to delivering the highest quality products and leveraging extensive experience. In doing so, the company plays a vital role in safeguarding the health and well-being of individuals worldwide. Sanner Group's Commitment to Sustainability The Sanner Group adopts a comprehensive approach to safeguarding both people and natural resources in alignment with Environmental, Social, and Governance (ESG) guidelines. At the heart of Sanner Group's ESG initiatives are the following major goals: Ÿ CO reduction at all production sites 2 Ÿ Increased use of sustainable energy supplies Ÿ Increased recyclability of its products Ÿ Promotion of equality in the company Ÿ Providing the framework of governance

- 18. Stay in Touch. Subscribe to Insightscare Get Insights Care Magazine in print, & digital on www.insightscare.com Corporate Office Insights Success Media Tech LLC 555 Metro Place North, Suite 100, Dublin,OH 43017, United States Phone - (614)-602 - 1754,(302)-319-9947 Email: info@insightscare.com For Subscription : www.insightscare.com Cheque should be drawn in favor of : INSIGHTS SUCCESS MEDIA TECH LLC www.insightscare.com

- 19. Never Miss An Issue

- 20. Manuela Redol Administrator & Co-owner Neutroplast www.insightscare.com April 2024 18

- 21. The packaging industry is more than just boxes and wrappers—it's a crucial component of healthcare, ensuring medications reach patients safely and effectively. But imagine if packaging could do more than just hold pills. Imagine if it could actively monitor medications, support patient adherence, and even contribute to better healthcare experiences. Bringing this imagination to reality with the innovative approaches is Neutroplast. At Neutroplast, traditional packaging norms are not merely satisfactory. Instead, they're pioneers in bio-packaging, integrating cutting-edge technology and sustainability practices to create packaging solutions that go beyond the ordinary. Making this groundbreaking work possible is Manuela Redol, an experienced Administrator and Co- owner with a passion for revolutionizing the industry. For over thirty years, Neutroplast has been a driving force in pharmaceutical packaging, collaborating with industry leaders and research centers to push the boundaries of what packaging can achieve. But what truly sets them apart is their constant commitment to understanding and meeting the diverse needs of their clients, fostering lasting relationships built on transparency and quality. With a presence in over 30 countries, Neutroplast navigates the complexities of global operations with ease, all while staying true to their core values of sustainability and innovation. As the healthcare industry continues to grow, Neutroplast remains as the lead, shaping the future of medical packaging and improving patient outcomes every step of the way. So, let's understand in detail Neutroplast's groundbreaking innovations and industry insights in our exclusive interview ahead! Can you provide a brief overview of your professional journey in the medical packaging industry and how it led you to your current role within your company? Manuela Redol, administrator and co-owner of the company, has been involved in the packaging industry for the healthcare sector for several decades and has vast knowledge of the market and all the factors that surround it. It is natural for her to assume leadership of the company and try to guide it towards an even more promising future. Please share some key highlights about your company's establishment, its mission and vision, and how it has evolved to become one of the leading medical packaging solution providers. Neutroplast is a company that produces plastic packaging whose main focus is supplying the Pharmaceutical Industry. Present on the market for over thirty years, it is a prominent player in the Pharmaceutical Packaging Industry panorama and has, over time, followed a constant search for Transforming Patient Experiences through Innovative Packaging Neutroplast is in constant interac on with its customers to understand their current and future needs. It seeks to adapt its products to meet the specific needs of each of them, thus working to maintain long-las ng commercial rela onships. The 5 Expert Medical Packaging Solu on Providers www.insightscare.com April 2024 19

- 22. developing a vital sector for society, in partnership with pharmaceutical laboratories, universities, centres of research, industry associations and other stakeholders. How does your company maintain a customer-centric approach to meet the diverse needs of clients in the healthcare industry? Neutroplast is in constant interaction with its customers to understand their current and future needs. It seeks to adapt its products to meet the specific needs of each of them, thus working to maintain long-lasting commercial relationships. Guiding its communication in a transparent and effective way, keeping customers properly informed about topics related to their products. Quality is a priority, ensuring that regulatory standards and healthcare industry best practices are met. How does your company ensure a strong international presence, and what challenges and opportunities does this global reach bring to your operations? Located in Portugal, a country with a small domestic market, Neutroplast early on sought to identify market opportunities in different regions and countries around the world to expand its operations. Cultural adaptation, respecting and recognizing cultural differences in different countries, as well as marketing and communication strategy were fundamental to the success of internationalization. On the other hand, strategic partnerships were also created in some of the markets to take advantage of the knowledge and contact network of these partners, also contributing to the mitigation of cultural barriers. Throughout its history, Neutroplast has exported to more than 30 countries, located on different continents. How does your company integrate sustainability into its medical packaging solutions, and what initiatives are in place to contribute to environmental responsibility? Using raw materials derived from oil, Neutroplast has been working tirelessly to optimize its production process, to ensure an irrelevant waste of materials, having reached waste levels below 0.2% in 2023, and even these materials are sent to recycling companies for subsequent incorporation into other products that are less demanding in terms of quality. All packaging produced is susceptible to recycling and thus has a prolonged life cycle. Our company has carried out tests with bioplastic, recycled and biodegradable materials, thus being prepared for their use when our customers request it. The company is certified to www.insightscare.com April 2024 20

- 23. the ISO 14001 standard and has implemented several measures aimed to reduce energy consumption from non- renewable sources, including the implementation of 600 solar panels for the production of photovoltaic energy. How does your company prioritize quality assurance and compliance with industry regulations? Neutroplast has implemented several Quality Management Systems (QMS) standards, including ISO 9001, ISO 15378 - Good Manufacturing Practices for primary packaging and ISO 13485, specifically for medical devices. In addition, it is also authorized to produce medical measuring devices with CE Marking and also has a line of products with FDA authorization. All of our products are manufactured taking into account the quality requirements required by the aforementioned standards, which include various conformity tests. To maintain the certificates of the various standards and continuous improvement, the company is annually subject to several monitoring audits by external entities duly accredited for that purpose. Are there specific projects or case studies that stand out as milestones for your company in the realm of medical packaging solutions? Neutroplast has repeatedly participated in several national and international innovation projects, with various partners, always in the search for innovative solutions that allow, on the one hand, to make life easier for users of medicine packaging and thus improve adherence to the correct using medical prescriptions and on the other hand making the packaging more environmentally friendly, either by using new materials or by reducing the carbon footprint in their production. What are the key trends and developments that your company anticipates in the medical packaging industry, and how are you preparing to address them? One of the trends we foresee is related to the growing importance of sustainability and the need to transform the production process, as well as the materials used, more environmentally friendly, without compromising the safety and quality of the products to be packaged. Another trend is the emergence of intelligent packaging, with the integration of technology to control product conservation and interaction with patients to ensure adherence to medical prescriptions. How does your company plan to contribute to the broader healthcare ecosystem, beyond providing packaging solutions, to improve overall patient outcomes and experiences? As mentioned above, some of the projects in which Neutroplast participates aim to facilitate patient's adherence to correct compliance with medical prescriptions. This facilitation results from the incorporation of new technologies in the packaging, allowing it to communicate with other devices to create alerts for timely intake of medicines and assessing their conservation status. www.insightscare.com April 2024 21

- 24. n recent years, the healthcare industry has been Iincreasingly focusing on sustainability, particularly in the area of packaging. The need for sustainable healthcare packaging has become more pressing as environmental concerns continue to rise globally. This shift towards eco-friendly packaging solutions is not only driven by regulatory requirements but also by a growing awareness among consumers and healthcare providers about the impact of packaging waste on the environment. This article explores how the industry is innovating to create sustainable healthcare packaging, focusing on the use of bio-based and renewable materials, the development of sustainable sterile packaging, and the broader shift towards reducing, reusing, and recycling. The Environmental Impact of Healthcare Packaging The packaging for healthcare products is of utmost importance, as it safeguards the well-being and upholds the quality of medical products. However, the traditional materials used in healthcare packaging, such as plastics and non-recyclable materials, have significant environmental consequences. These materials often end up in landfills, contributing to pollution and harming ecosystems. More- over, the production and disposal of these materials generate greenhouse gas emissions, further exacerbating climate change. The Push for Sustainability Recognizing these challenges, the healthcare industry is actively seeking sustainable alternatives for packaging. It is increasingly focusing on bio-based and renewable materials to mitigate environmental impact. Companies are exploring various options, such as biodegradable materials, recyclable plastics, and reusable packaging systems. The use of sugarcane-derived ethylene, a carbon-negative process that utilizes carbon dioxide (CO ) and releases 2 oxygen, represents a significant innovation. This shift towards renewable resources is not just about reducing carbon footprints but also about ensuring the integrity and performance of medical packaging materials. By adopting these sustainable solutions, the industry aims to reduce its environmental footprint and contribute to a healthier planet. Sustainable Sterile Packaging One of the most critical challenges in achieving sustainable medical packaging is the reliance on sterile packaging, which is essential for patient safety. Traditional sterile packaging, often made from plastics, is single-use and not recycled, leading to substantial waste. A study in a German hospital found that plastic packaging accounted for 16g of waste per patient per day, highlighting the urgent need for How theIndustry is Addressing Environmental Concerns www.insightscare.com April 2024 22

- 26. innovation in this area. To address this, manufacturers are exploring the use of recyclable plastics and bioplastic alternatives. For example, packaging opened in surgical theaters must go into a biohazard stream of waste, requiring medical practitioners to advocate for changes within operating rooms to facilitate recycling. Reducing, Reusing, and Recycling Beyond the specific challenges of sterile packaging, the medical sector can adopt more generalized sustainability practices. This includes reducing unnecessary packaging, designing product lines with reusable containers, and switching to recyclable or biodegradable materials to minimize landfill waste. The plastics industry, in particular, faces the challenge of traditional plastics not being biodegradable and contributing to pollution through landfill contribution and microplastics contamination. To counter these environmental consequences, there is a push towards reducing packaging quantity and using recyclable or biodegradable replacements for plastic. Furthermore, advancements in recycling technologies are enabling the recycling of certain types of plastics used in healthcare packaging. By implementing closed-loop recycling systems, companies can reduce waste and promote a circular economy where materials are reused and recycled, rather than disposed of after a single use. Innovations in Sustainable Healthcare Packaging Innovations in sustainable healthcare packaging are driving positive change in the industry. For example, companies are developing packaging materials made from plant-based sources, such as cornstarch and sugarcane, which are biodegradable and compostable. These materials offer a renewable alternative to traditional plastics and help reduce the industry's reliance on fossil fuels. Collaboration and Partnerships Addressing environmental concerns in healthcare packag- ing requires collaboration across the industry. Companies are partnering with suppliers, recyclers, and regulatory bodies to develop and implement sustainable packaging solutions. By working together, stakeholders can share knowledge, resources, and best practices to drive innova- tion and sustainability in healthcare packaging. Regulatory Landscape Regulatory bodies are also playing a crucial role in promoting sustainable healthcare packaging. Governments around the world are introducing regulations and guidelines to encourage the use of eco-friendly materials and practices in packaging. By complying with these regulations, companies can demonstrate their commitment to sustainability and contribute to a greener future. Consumer Awareness and Demand Consumer awareness about environmental issues is growing, leading to an increased demand for sustainable products, including healthcare packaging. Healthcare providers and patients are becoming more conscious of the environmental impact of packaging waste and are seeking products that are eco-friendly and responsibly sourced. By responding to this demand, companies can not only meet consumer expectations but also differentiate themselves in the market. The Path Ahead The future of medical packaging is bright, with businesses recognizing the importance of adaptable packaging that not only keeps drugs secure but also minimizes environmental impact. The industry's shift towards sustainable healthcare packaging is a testament to the growing awareness of environmental concerns and the commitment to innovate and adapt. By focusing on bio-based and renewable materials, developing sustainable sterile packaging, reducing, reusing, and recycling, and replacing protective packing materials with sustainable options, the medical packaging industry is making significant strides towards a more sustainable future. As the industry continues to innovate, the future of healthcare packaging promises to be not only effective in protecting and delivering medications but also environmentally responsible and sustainable. -Natalie May www.insightscare.com April 2024 24

- 28. GmbH Packaging Solutions for a Green Future Julian Erhard Managing Director & Co-founder PackEx GmbH www.insightscare.com April 2024 26

- 29. The expansion of the medical sector has substantially increased the volume of packaging waste, impacting the environment significantly. This stresses the need for packaging providers to develop innovative solutions that minimize environmental harm. Dedicated to sustainable packaging practices and delivering a seamless client experience, PackEx GmbH stands out for its future-driven approach. The company specializes in customized packaging solutions, offering folding boxes, shipping packaging, labels, and solid board materials. Emphasizing sustainability, PackEx adopts small batch production methods resulting in up to an 87% reduction in raw material consumption and overall resource usage. Central to their innovative business model is a commitment to minimizing CO emissions. The company offers clients a 2 host of advantages including accelerated market entry, decreased operational costs, and enhanced product management options. With a focus on quality assurance through Video Quality Assurance protocols, PackEx ensures adherence to strict standards. Julian Erhard, Managing Director & Co-founder at PackEx GmbH, brings extensive expertise to his role in the organization. His significant contributions have been instrumental in driving the company towards success and growth. In a recent interview with our team, Julian shared valuable insights into the world of medical packaging, shedding light on PackEx’s journey to becoming a recognized expert in the industry. Can you provide a brief overview of your professional journey in the medical packaging industry and how it led you to your current role within your company? I originally started out in the printing industry. During my training as a Press Operator, I learned the traditional printing process and products. Therefore, it wasn’t a big leap to transition to the related packaging industry. After completing my studies and a short trip in the banknote industry, I worked at Faller Packaging for over three years. With almost 2,000 employees and well-established processes, the renowned company produces packaging for the pharmaceutical industry. In 2017, we founded PackEx GmbH as a spin-off. With physical distance, new processes, innovative procedures and the courage to question and rethink established processes, we aimed to bring a fresh perspective to the industry. Please share some key highlights about your company’s establishment, its mission and vision, and how it has evolved to become one of the leading medical packaging solution providers. Through technology that guarantees us not only CO2 savings, but above all fast delivery times, we enable our customers to act and react quickly and agilely to the dynamic requirements of the market. Everything we do for our customers is geared towards sustainability and automation. At our chosen location in Worms, we work with the latest and highly specialized machines, lasers, and robotics. In October 2018, we produced the first folding carton using a completely new process. We have been growing ever since. In line with the motto “Why compensate when you can avoid from the outset?”, we have organized our production in such a way that we do not need to offset CO emissions. 2 Compared to conventional packaging companies, we save up to 1,389 tons of CO per year. This proves that 2 profitability, sustainability, and manufacturing in Germany are not incompatible. How does your company maintain a customer-centric approach to meet the diverse needs of clients in the healthcare industry? Compared to conventional packaging companies, we save up to 1,389 tons of CO2 per year. ,,,, ,,,, The 5 Expert Medical Packaging Solution Providers www.insightscare.com April 2024 27

- 30. We always strive to adopt the perspective of our (potential) customers and address their specific problems by offering solutions. Easy access and a straightforward ordering process are also part of our service offering. In general, there are three customer groups for us: One group has a need for small-batch packaging production while maintaining flexibility and a simple, straightforward ordering process. They have been repeatedly told that only large runs are economically viable. We work with a cloud- based virtual warehouse for quick reorders and enable our customers to produce runs of just a few pieces without significantly increasing costs. The second group of customers values sustainable packaging without greenwashing – both in production and parcel shipping. The last group wants to avoid working with several suppliers. As a one-stop-shop, we provide high-quality standardized folding boxes, labels, as well as shipping boxes. How does your company ensure a strong international presence, and what challenges and opportunities does this global reach bring to your operations? PackEx has been growing every year since its foundation in 2017. Despite the corona crisis the turnover could be tripled in 2021 and doubled in 2022. In 2023, we experienced again a great double-digit growth. So far, our customers are mainly in Germany, some in Austria and Switzerland, and a few in France. In order to accelerate our growth, the main focus is on internationalization, initially in other European countries. How does your company integrate sustainability into its medical packaging solutions, and what initiatives are in place to contribute to environmental responsibility? PackEx was founded out of conviction even before the whole sustainability trend and therefore has the topic authentically anchored in its DNA. We wanted to use our pioneering spirit and create innovative technologies to help build a world worth living in for future generations. For our products, we only use FSC certified paper – meaning more trees are planted than cut down. We solely work with cardboard for our folding boxes and corrugated cardboard for shipping boxes. However, when it comes to sustainability, it’s not as simple as avoiding potentially harmful materials – all processes must be geared towards avoiding CO . 2 Our printing inks and the absence of finishes were also selected with sustainability in mind. Instead of the www.insightscare.com April 2024 28

- 31. established die-cutting process with tools, we use an innovative laser-cutting process - eliminating the need for individually produced tools. We also apply the Braille digitally, thus saving on tools in production, transport, etc. Our shipping solution also differs from the standard: We use parcels instead of shipping on pallets. Our shipping packaging is tailored to every order—ensuring we only ship goods and not air. Shipping by parcel service also enables us to achieve considerable CO savings of around 1.4 tons 2 per year. Often, it is the small measures that have a big impact. How does your company prioritize quality assurance and compliance with industry regulations? For our packaging, we set high standards that comply with pharmaceutical regulations. With PackEx, quality control is therefore integrated into the production process. In terms of an efficient production process, quality assurance is video- based. With the help of cameras, we ensure seamless 100 % monitoring of each single carton and sort out faulty products in the final production step. This means that even the smallest errors, especially in the Braille area, can be detected and corrected. What are the key trends and developments that your company anticipates in the medical packaging industry, and how are you preparing to address them? In the medical packaging industry, we anticipate a growing focus on accessibility, even for non-prescription products. We’re preparing by exploring innovative packaging solutions to enhance accessibility. Additionally, we’re investing in agility and flexibility to navigate dynamic market dynamics, ensuring we can quickly respond to changes and deliver high-quality packaging solutions to our customers. How does your company plan to contribute to the broader healthcare ecosystem, beyond providing packaging solutions, to improve overall patient outcomes and experiences? Mistakes can be fatal, especially when taking medication. Braille, therefore, plays a central role. Conventionally, it is punched into the packaging material. This has disadvantages: the surface of the carton board of the dots can “burst open” during production, the design is limited by the tool, and costs are incurred. PackEx has therefore introduced “Digital Braille”, which is barrier-free and independent of the pharmaceutical industry: Using an injection process, the Braille is applied to the surface of the packaging with pinpoint accuracy, creating raised areas. A special UV varnish is used for this. With innovative ideas, we aim to not only improve the production method but also enhance the quality of packaging for the pharmaceutical industry. A significant achievement for PackEx GmbH was the implementation of digital braille technology in its packaging solutions. This innovative approach eliminates the reliance on traditional tools, streamlining the braille production process for faster delivery and reduced environmental impact. Moreover, digital braille enhances readability for visually impaired individuals compared to conventional embossed methods, thereby improving accessibility. Another noteworthy project milestone entails the integration of laser technology into PackEx GmbH’s operations. This technological advancement empowers the company to address the intricate and unique demands of medical inlays effectively. Leveraging laser technology enables PackEx GmbH to craft unique packaging solutions tailored to individual product specifications, ensuring optimal protection and presentation quality. Precision in Packaging www.insightscare.com April 2024 29

- 35. Medical devices and pharmaceuticals are essential for the healthcare industry, and their packaging plays a critical role in ensuring their safety, efficacy, and stability. The choice of packaging material is crucial in protecting the products from external factors, such as moisture, light, and contamination, while also ensuring their integrity and sterility. In this article, we will explore the different types of packaging materials available for medical devices and pharmaceuticals and the factors to consider when choosing the right packaging material. The Importance of Packaging Materials The packaging of medical devices and pharmaceuticals is not just about containment; it’s about providing a protective shell that can withstand the rigors of transportation, handling, and storage. Improper packaging can lead to device damage, which can have serious implications, including delayed medical procedures, increased costs, and potential harm to patients. Therefore, the choice of packaging material is a critical decision that can significantly impact the safety and integrity of medical devices during transit. Key Considerations for Packaging Materials When selecting packaging materials for delicate medical devices, several factors come into play, including the Choosing the Right Packaging Material for Medical Devicesand Pharmaceuticals Materials Ma er www.insightscare.com April 2024 33

- 36. device’s fragility, size, weight, and value. The packaging material must offer sufficient cushioning to effectively absorb shocks and vibrations experienced during transit. It should also be resistant to punctures and tears. Moreover, the packaging should be appropriate for the device’s storage environment, taking into account temperature, humidity, and light exposure. Replacing Protective Packing Materials For delicate or sensitive medical equipment, the transporta- tion process necessitates large amounts of protective packing. The widespread use of polystyrene for this purpose results in landfill waste and microplastic contamination. However, sustainable packing options, such as recycled or biodegradable materials like paper bubble wrap, shredded cardboard, and biodegradable foam peanuts, are already in use and could be adopted by medical device manufacturers. This approach not only reduces environmental impact but also opens up opportunities for circularity within plastics manufacturing, where waste packaging can be recycled into new packing materials. Types of Packaging Materials There are various packaging materials available for medical devices and pharmaceuticals, including: 1. Glass: Glass is a popular packaging material for pharmaceuticals due to its inertness, transparency, and impermeability. It is suitable for storing liquids, powders, and tablets. However, glass is heavy and fragile, which can make it challenging to transport and handle. 2. Plastics: Plastics are lightweight, versatile, and cost- effective packaging materials. They are suitable for a wide range of medical devices and pharmaceuticals, including syringes, vials, and pouches. Plastics can be transparent, opaque, or colored, and they can be coated to enhance their barrier properties. 3. Metals: Metals, such as aluminium and stainless steel, are durable and impermeable packaging materials. They are suitable for storing liquids, powders, and tablets. Metals can be coated to enhance their barrier properties and prevent corrosion. 4. Paper and Cardboard: Paper and cardboard are lightweight and cost-effective packaging materials. They are suitable for packaging medical devices and pharmaceuticals, such as bandages, syringes, and tablets. Paper and cardboard can be coated to enhance their barrier properties and prevent moisture absorp- tion. Factors to Consider When Choosing the Right Packag- ing Material When choosing the right packaging material for medical devices and pharmaceuticals, several factors must be considered, including: 1. Product Compatibility: The packaging material must be compatible with the product it contains. It must not react with the product or affect its quality, efficacy, or stability. 2. Barrier Properties: The packaging material must provide a barrier to external factors, such as moisture, light, and contamination. It must prevent the entry of microorganisms, dust, and other particles that can affect the product’s quality and safety. 3. Sterility: The packaging material must maintain the product’s sterility until it is opened. It must prevent the entry of microorganisms and ensure that the product remains sterile during transportation and storage. 4. Mechanical Properties: The packaging material must have the necessary mechanical properties to protect the product during transportation and handling. It must be able to withstand pressure, impact, and vibration without breaking or damaging the product. 5. Regulatory Compliance: The packaging material must comply with the relevant regulations and standards for medical devices and pharmaceuticals. It must be approved by the relevant regulatory authorities, such as the FDA, EMA, and MHRA. 6. Cost-effectiveness: The packaging material must be cost-effective and provide value for money. It must be affordable and offer a good balance between cost and performance. Conclusion Choosing the right packaging material for medical devices and pharmaceuticals is a critical decision that can affect the product’s safety, efficacy, and stability. The choice of packaging material depends on several factors, including product compatibility, barrier properties, sterility, mechani- cal properties, regulatory compliance, and cost- effectiveness. By considering these factors, healthcare companies can ensure that their products are safely and effectively packaged, meeting the needs of their customers and the regulatory requirements. -Natalie May www.insightscare.com April 2024 34

- 39. Your Trusted Partner in Medical Packaging With precision, quality, and innovation at the forefront, the landscape of healthcare manufacturing finds itself transformed by companies driven by excellence. Reflecting on the current environment where the demand for reliable and innovative medical packaging solutions continues to soar, businesses like Teampac Oy stand as leaders in the field. With over five decades of industry experience, Teampac leads as a prime example of such leadership. Teampac has established itself as a symbol of excellence in the healthcare industry, offering comprehensive end-to-end solutions tailored to meet the diverse needs of the sector. Deeply committed to putting customers first and maintaining high-quality standards, Teampac ensures that every product, from disinfectants to medical devices, is carefully made to ensure effectiveness and safety like no other Moreover, Teampac's dedication to sustainability showcases its responsible leadership within the industry, promoting eco-conscious practices and environmental preservation. Guided by visionary CEO, Jyri Temonen, Teampac represents a culture of innovation and excellence. With a foundation rooted in family business values, Jyri and his team have propelled Teampac to the forefront of North Europe's healthcare manufacturing landscape. Let's explore the secret to Teampac's success and what drives its remarkable journey. Teampac Oy stands out as a leader in delivering excellent medical packaging solutions that set new industry standards, all in an ever-changing field where quality and reliability are key! Please share some key highlights about your company's establishment, its mission and vision, and how it has evolved to become one of the leading medical packaging solution providers. Teampac Oy is a Finnish healthcare contract manufacturer. With over 50 years of rich industrial experience, we develop and produce a wide range of products for healthcare needs, such as disinfectants, adhesive removers, and stoma and wound cleaning products. We manufacture wet wipes (sachets and flowpacks) for cleaning and disinfecting skin and surfaces. Teampac also delivers liquid-based products like lotions, intimate gels, lubricants, toothpaste, shampoos, and ultrasound gels in tubes, bottles, and jars. Our special expertise is medical devices, for which we support the customer throughout the entire production process. We rely strongly on our family business values and provide expertise, guaranteed quality, and great service to our customers. Our vision is to be the leading HC contract manufacturer in North Europe. The goal is tough, but at the same time, we know we are heading in the right direction. Can you provide a brief overview of your professional journey in the medical packaging industry and how it led you to your current role within your company? The 5 Expert Medical Packaging Solu on Providers www.insightscare.com April 2024 37

- 41. I have a long history in the hygiene and healthcare sectors from different kinds of roles in sales and management in globally operating organizations. Mainly I have been working in Finland, but I have also led some projects in Sweden, Russia and Baltic countries. From management positions, I have over 20 years of experience. In 2020 I was asked to join Teampac, a family- owned innovative growth company, and I was excited to accept the offer. And now I can say it was a great choice since I have enjoyed working with this very committed and motivated organization a lot. How does your company maintain a customer-centric approach to meet the diverse needs of clients in the healthcare industry? Teampac can take care of the production process from an idea to a finished product – whether it is a new product line or an update to an existing product family. We cover either the entire production chain or, if desired, a part of it. It is also possible to transfer the production of an existing product to Teampac. We always start from the customer’s needs, and we do what we promise. Our production is precise and of high quality and our clients can rest assured that our production process meets all necessary legislative requirements and certificates. For us, success is when the customer is smiling and happy about what we have achieved together. We have worked hard to achieve our common goal – to support our customers and their business needs as best as we can – and we will continue working for that. How does your company ensure a strong international presence, and what challenges and opportunities does this global reach bring to your operations? Teampac operates in international markets. Over 70 % of our production is exported directly to 19 countries, and products produced by Teampac are used in all the continents as our global customers distribute products through their distribution channels. How does your company integrate sustainability into its medical packaging solutions, and what initiatives are in place to contribute to environmental responsibility? Teampac has the ISO 14001 environmental certificate, which shows our commitment to improving environmental efficiency. We are actively seeking out and using sustainable materials that are recyclable, biodegradable or derived from renewable natural resources. We also encourage our customers to choose sustainable and responsibly produced ingredients and packaging for their products. In the design phase, we survey for as little material use as possible from the point of view of the final product, while maintaining the integrity and safety of the medical products. Our goal is to reduce our dependence on fossil fuels and reduce our carbon footprint. None of our products contain microplastics. What’s more, we can opt for biodegradable materials to prevent the release of microplastics into the environment during the product lifecycle. Labeling helps consumers dispose of our packaging appropriately. Read more about our commitments here: https://teampac.com/sustainability/ How does your company prioritize quality assurance and compliance with industry regulations? We at Teampac place the highest priority on quality assurance and compliance with industry regulations to ensure the safety and efficacy of our medical packaging solutions. The quality of our work comes from the contribution of each of our employees. Therefore, quality must take part in everything from planning to production and from machines to the knowledge of the people. We utilize various tools to ensure the quality of our products and operations. Central to our approach is our adherence to Good Manufacturing Practices (GMP) and our ISO 13485 certification for medical device quality management systems. ISO 9001 standard is used for analyzing our processes in working methods, decision- making models, division of responsibilities and customer needs, and to achieve the set goals. These frameworks guide every aspect of our operations, from design and manufacturing to distribution. We conduct regular internal audits and participate in external audits to verify our compliance with industry standards and regulations. Teampac also invests in continuous training for the employees to ensure they are up to date with the latest quality assurance practices and regulatory requirements. www.insightscare.com April 2024 39