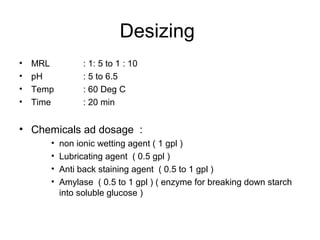

This document summarizes the denim processing steps including desizing, abrasion, bleaching, and finishing. It defines key terms like denim fabric composition and dyeing methods. The processing involves both dry techniques like sandblasting and wet processes like enzyme washes using amylase, cellulase and other chemicals to break down starch, weaken fibers, and decolorize indigo for stonewashed effects. Proper chemicals, temperatures, pH and times are outlined for each wet processing step.