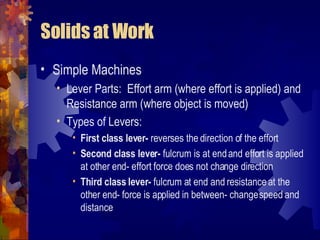

The document discusses work, power, and simple machines. It defines work as the movement of an object by force, measured in foot-pounds or joules. Power is defined as the rate of work over time. It then discusses the six simple machines: lever, wheel and axle, pulley, inclined plane, wedge, and screw. Levers in particular are described as multiplying force or speed with or without changing the direction of effort, consisting of a rigid bar and fulcrum.