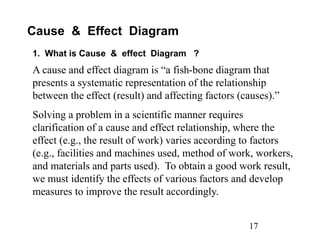

This document provides an overview of 7 quality control tools: Pareto diagram, stratification, scatter diagram, cause and effect diagram, histogram, check sheet, and control chart. For each tool, a definition is given followed by a description of when and how it is used and the typical results obtained. The tools can be used at different stages of problem solving including monitoring situations, analyzing causes, reviewing effectiveness of actions, and implementing improvements. Overall, the tools help collect and visualize data to identify problems, find root causes, and measure results as part of a quality control process.

![11

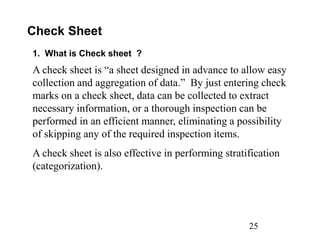

Method Usage Result

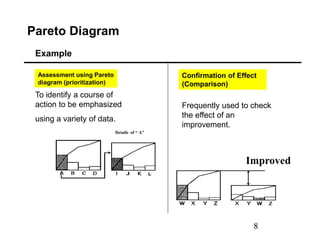

Stratification

Grouping by day,

time, place,

worker, or

process

X

Y

Z

Number of Units

★★★★★★★

△△△△

○○○

•Used to observe variations

among strata.

•Used to identify the

relationship between cause

and effect.

•Used to identify a purpose

and means to serve the

purpose

[Used during phases to monitor

the situation, analyze causes,

review effectiveness of an action,

perform standardization, and

implement a selected control

measure.]

•Allows observation

of variations among

strata.

•By performing a

cause analysis using

the stratified data,

the following can be

accomplished.

1.Identification and control of a

problem

2.“Division of data (obtained by

using each QC tool) into several

groups”](https://image.slidesharecdn.com/7qctools-230213095004-4f05d8d3/85/7-QC-Tools-ppt-11-320.jpg)

![15

Method Usage Result

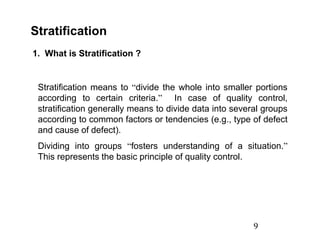

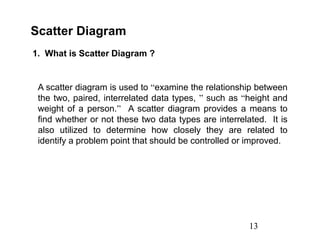

Scatter Diagram

•Used to identify a relationship

between two matters.

•Used to identify a relationship

between two matters and establish

countermeasures based on their

cause and effect relation.

Example Usage

1.Relationship between thermal

treatment temperature of a steel

material and its tensile strengths

2.Relationship between visit made

by a salesman and volume of sales

3.Relationship between the number

of persons visiting a department

store and volume of sales

4 Others

Scatter Diagram

Scatter Diagram

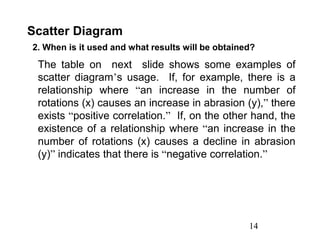

y Axis

x Axis

Abrasion

Number of

Rotations

Scatter Diagram

Scatter Diagram

y Axis

x Axis

Abrasion

Number of

Rotations

[Used during phases to monitor the

situation, analyze causes, and review

effectiveness of an action.]

•Can identify cause

and effect relation.

•Can understand the

relationship

between two

results.](https://image.slidesharecdn.com/7qctools-230213095004-4f05d8d3/85/7-QC-Tools-ppt-15-320.jpg)

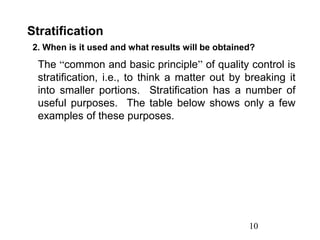

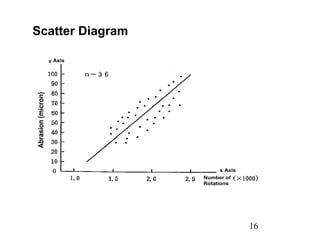

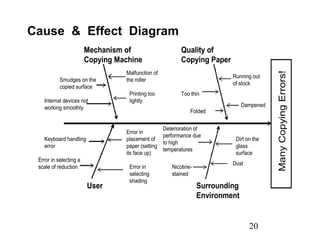

![19

Can obtain a clear

overall picture of causal

relation. (A change in

the cause triggers a

variation in the

result.)○ Can clarify

the cause and effect

relationship.

Can list up all causes

to identify important

causes.

Can determine the

direction of action

(countermeasure).

Method Usage Result

Cause & Effect Diagram

Used when

clarifying a cause

and effect

relationship.[Used

during a phase to

analyze causes.]

Used to develop

countermeasures.

[Used during a phase to plan

countermeasures.]

Material Method

Man

Machine

Cause (4M’s) Result

(Controlled State)

Effect

Cause and Effect

Cause and Effect

Diagram

Diagram

Material Method

Man

Machine

Cause (4M’s) Result

(Controlled State)

Effect

Cause and Effect

Cause and Effect

Diagram

Diagram](https://image.slidesharecdn.com/7qctools-230213095004-4f05d8d3/85/7-QC-Tools-ppt-19-320.jpg)

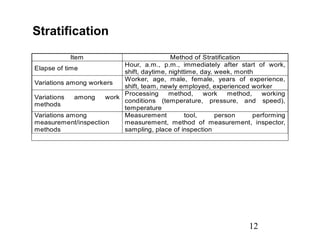

![23

Method Usage Result

Histogram

Histogram

Histogram

Standard

Range

Range of

Variations

X Axis (Values

Actually

Measured)

Histogram

Histogram

Standard

Range

Range of

Variations

X Axis (Values

Actually

Measured)

•Used to assess the actual

conditions.

•Used to analyze a process to

identify a problem point that needs

to be improved by finding the

location of the mean value or

degree of variations in the graph.

•Used to examine that the target

quality is maintained throughout

the process.

•Others

[Used during phases to

monitor the situation, analyze

causes, and review

effectiveness of an action.]

•Can identify the

location of the mean

(central) value or

degree of variations.

•Can find out the scope

of a defect by inserting

standard values.

•Can identify the

condition of

distribution (e.g.,

whether there is an

isolated, extreme

value).](https://image.slidesharecdn.com/7qctools-230213095004-4f05d8d3/85/7-QC-Tools-ppt-23-320.jpg)

![24

Histogram

Frequency Distribution Table

Cutting Length of Steel Wire]

Standard

Lower Limit Upper Limit

Standard

Standard Value

Product

[Histogram of Cutting Length of Steel

Wire]

(Standard: 255 5 mm)

±

Section

Frequency Marking Occurrences

Mean](https://image.slidesharecdn.com/7qctools-230213095004-4f05d8d3/85/7-QC-Tools-ppt-24-320.jpg)

![36

Graph

Sales

(¥million)

Sales

Office

Iwate Tokyo Osaka Shizuoka

[Bar Graph of Sales]

・ Survey Period: Dec. 1999

・ Prepared by: M/T

[Band Chart of Expenses]

(¥million)

Before

Taking

Actions

After

Taking

Actions

Chemicals

Chemicals

(430)

(430)

Chemicals

Chemicals

(240)

(240)

Oils

Oils

(200)

(200)

Oils

Oils

(150)

(150)

Electricity

Electricity

(170)

(170)

Electricity

Electricity

(108)

(108)

(Total: ¥8 million)

(Total: ¥4.95 million)

Sales

(¥million)

Sales

Office

Iwate Tokyo Osaka Shizuoka

[Bar Graph of Sales]

・ Survey Period: Dec. 1999

・ Prepared by: M/T

[Band Chart of Expenses]

(¥million)

Before

Taking

Actions

After

Taking

Actions

Chemicals

Chemicals

(430)

(430)

Chemicals

Chemicals

(240)

(240)

Oils

Oils

(200)

(200)

Oils

Oils

(150)

(150)

Electricity

Electricity

(170)

(170)

Electricity

Electricity

(108)

(108)

(Total: ¥8 million)

(Total: ¥4.95 million)](https://image.slidesharecdn.com/7qctools-230213095004-4f05d8d3/85/7-QC-Tools-ppt-36-320.jpg)