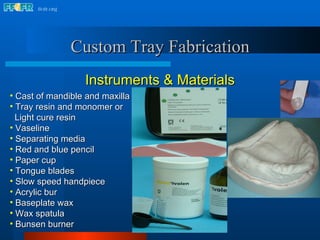

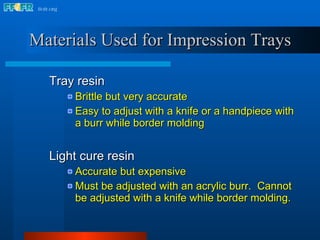

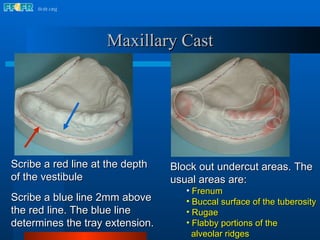

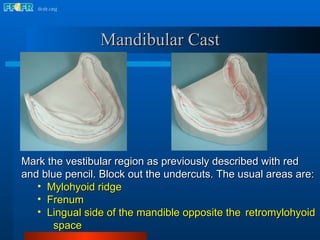

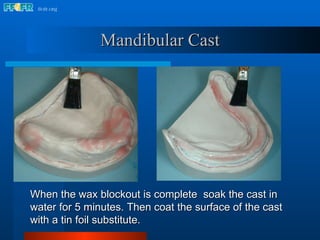

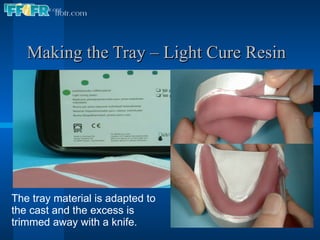

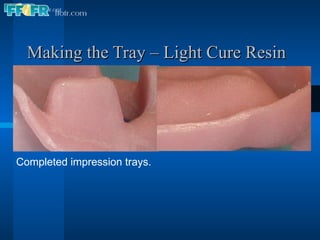

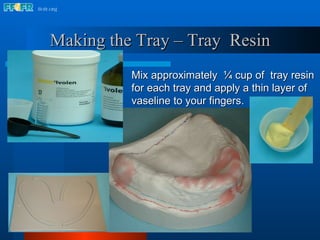

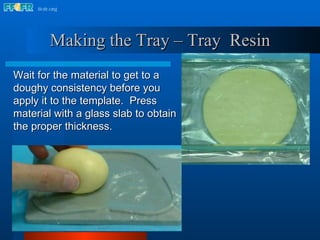

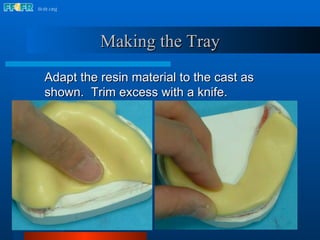

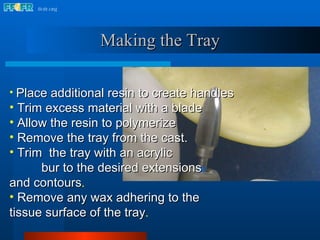

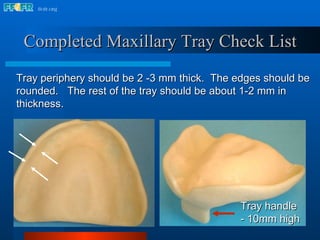

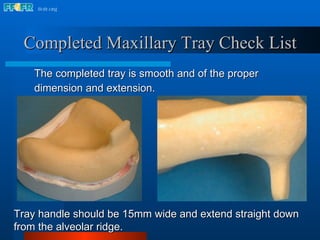

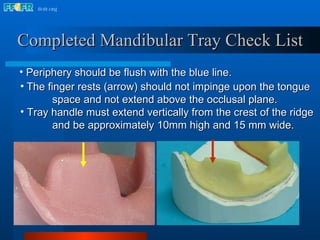

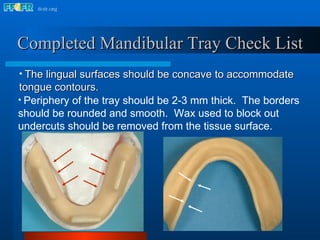

This document provides instructions for fabricating custom impression trays using either light cure resin or tray resin. It describes how to mark registration lines on casts, block out undercut areas, adapt the resin materials, and trim the trays. Completed trays should have rounded, smooth edges of proper thickness and extension, with finger rests and handles as needed.