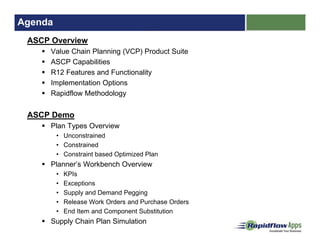

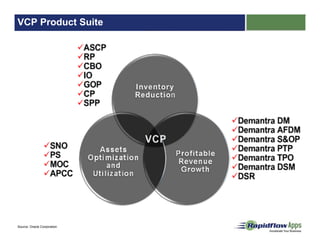

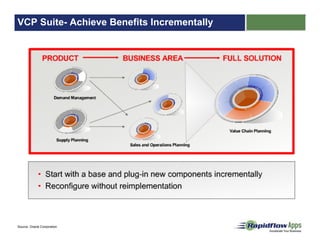

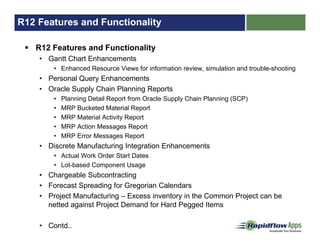

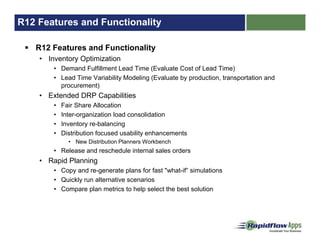

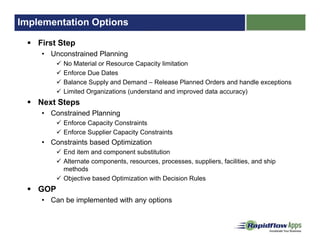

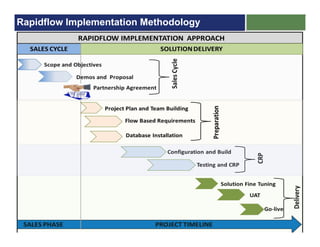

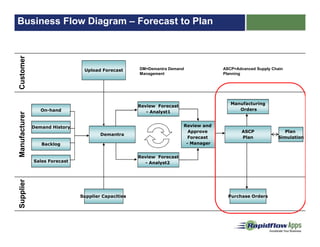

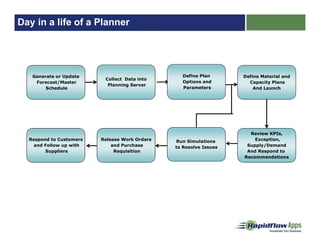

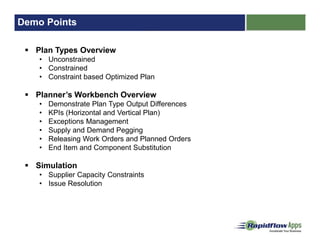

This document summarizes an online seminar on Oracle Advanced Supply Chain Planning (ASCP). The agenda includes an overview of ASCP, its capabilities, new features in R12, implementation options, and a demonstration. Key topics covered are plan types (unconstrained, constrained, optimized), the planner's workbench, simulation capabilities, and the Rapidflow implementation methodology. The demo shows the different plan outputs, KPIs, exception management, order release, and resolving supply constraints through simulation.