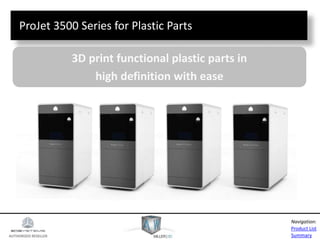

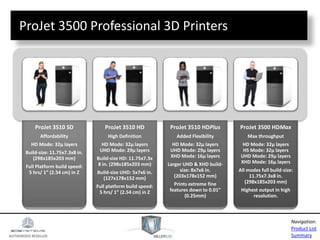

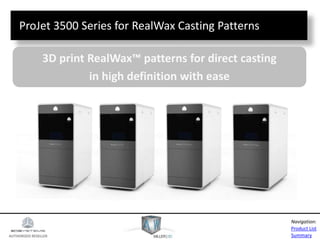

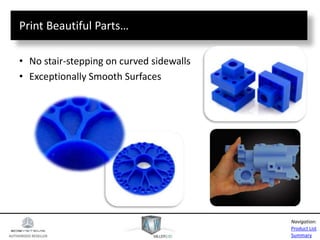

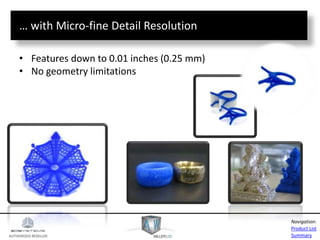

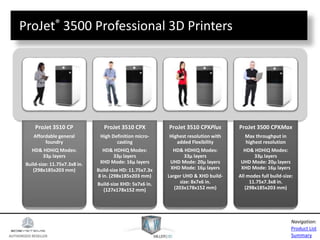

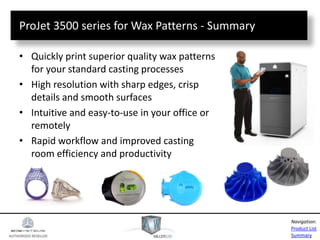

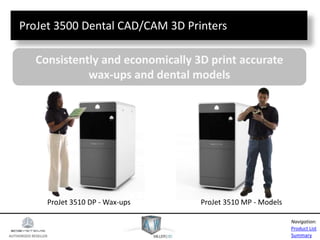

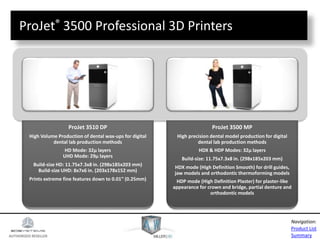

3D Systems is a pioneer in 3D printing technologies, having introduced several key methods since the late 1980s. The document provides an overview of the ProJet 3500 series printers, highlighting their capabilities in producing high-quality, functional plastic parts and wax patterns for casting, with an emphasis on ease of use and performance. It details features such as precision, printability, and various models suited for different applications, including dental and industrial uses.

![AUTHORIZED RESELLER

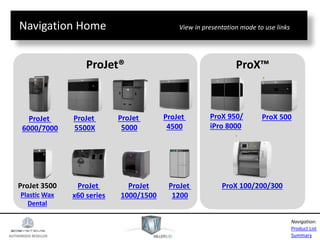

Product List

Summary

Navigation:

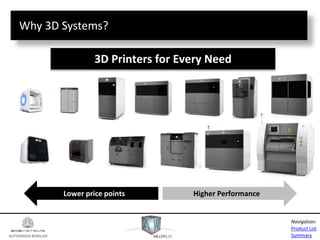

Why 3D Systems?

7 Print Engines

~100

Performance

Materials

Expanding

Technology

Platform

Innovation

Leadership

~1,300 Patents

World Class

Customers

Global

Footprint

~1300

Teammates

: 2' ./24%!" #1&.>, 12.34!

: 0#, ;!&#' !^3>%!` 3 3!

!

!

!

)

)

)

)

)

)

)

)

)

Q%, 4( &%( . )' D)? 4&%. ( &)

M0, !;2' #1 !, ;20, 2./34!431 F3 , !#&!20, !89 !>, ;. 1;!.1!#F' !" #44, /2.#1!03;!322' 3/2, >!;, Y, ' 34!

/#< $31., ;!&' #< !>.&&, ' , 12!.1>F;2' ., ;)!b , !03Y, !;, Y, ' 34!/3;, ;!U0, ' , !U, !4./, 1;, !#F' !#U1!

>, ;. 1;!#' !3' 2U#' H!2#!20, ;, !/#< $31., ;)!DF2!3 3.15!20, !< #;2!.< $#' 2312!&3/2#' !&#' !20, ;, !

$' #Z, /2;!.;!2032!.1!$' .1/.$4, !U, !34U3%;!' , 23.1!' . 02;!2#!+, !3+4, !2#!&F' 20, ' !/#< < , ' /.34.], !

#F' !U#' H!20' #F 0!#F' !#U1!' , 23.4!31>!#14.1, !/0311, 4;)!=2!.;!GF.2, !.' #1./5!2032!20, !;03$, ;!

, 1, ' 32, >! U.20! 89 ! $' .12.1 ! 31>! 89 ! /#< $F2, ' ! ' 3$0./;! 3' , ! 34;#! +, .11.1 ! 2#! +, /#< , !

.12, ' , ;2.1 !&#' !/#< $31., ;!.1!20, !< #;2!2' 3>.2.#134!&., 4>;5!;F/0!3;!F;.1 !20, ! ' 3$0./;!#&!#F' !

>, ;. 1;!#1!+, >!4.1, 1)!M0.;! .Y, ;!F;!3 3.1!< #' , !/' , >.+.4.2%!#&!20, !3//, $231/, !#&!3!1, U!

3' .;.1 !>. .234!4.&, ;2%4, )!M0, !2%$./34!' #%342%!&, , ;!&#' !20, ;, !H.1>!#&!$' #>F/2;!3' , !+, 2U, , 1!8!

31>!J e !#&!;34, ;)!

!

: #< , !, P3< $4, ;c!!

?)! ( ` a!+%!( 32, ' .34.;, !RD, 4 .F< S!U.20!4. 02!>, ;. 1;d!

A)! : . 1#' .3!C.' , 1], !R=234%S!&#' !+, >!4.1, 1d!

8)! 6P$31>< , >.3!R: U, >, 1S!&#' !+311, ' ;!31>!;231>!, GF.$< , 12d!

@)! =.22343!RC.1431>S!&#' !;< 344!/#1;F< , ' ! ##>;d!

!

!](https://image.slidesharecdn.com/b56c8a73-cf87-4af1-9444-980bb8b80fa3-150715211057-lva1-app6891/85/3D-Systems-Printer-Overview-MJP-ProJet-35X0-Series-4-320.jpg)