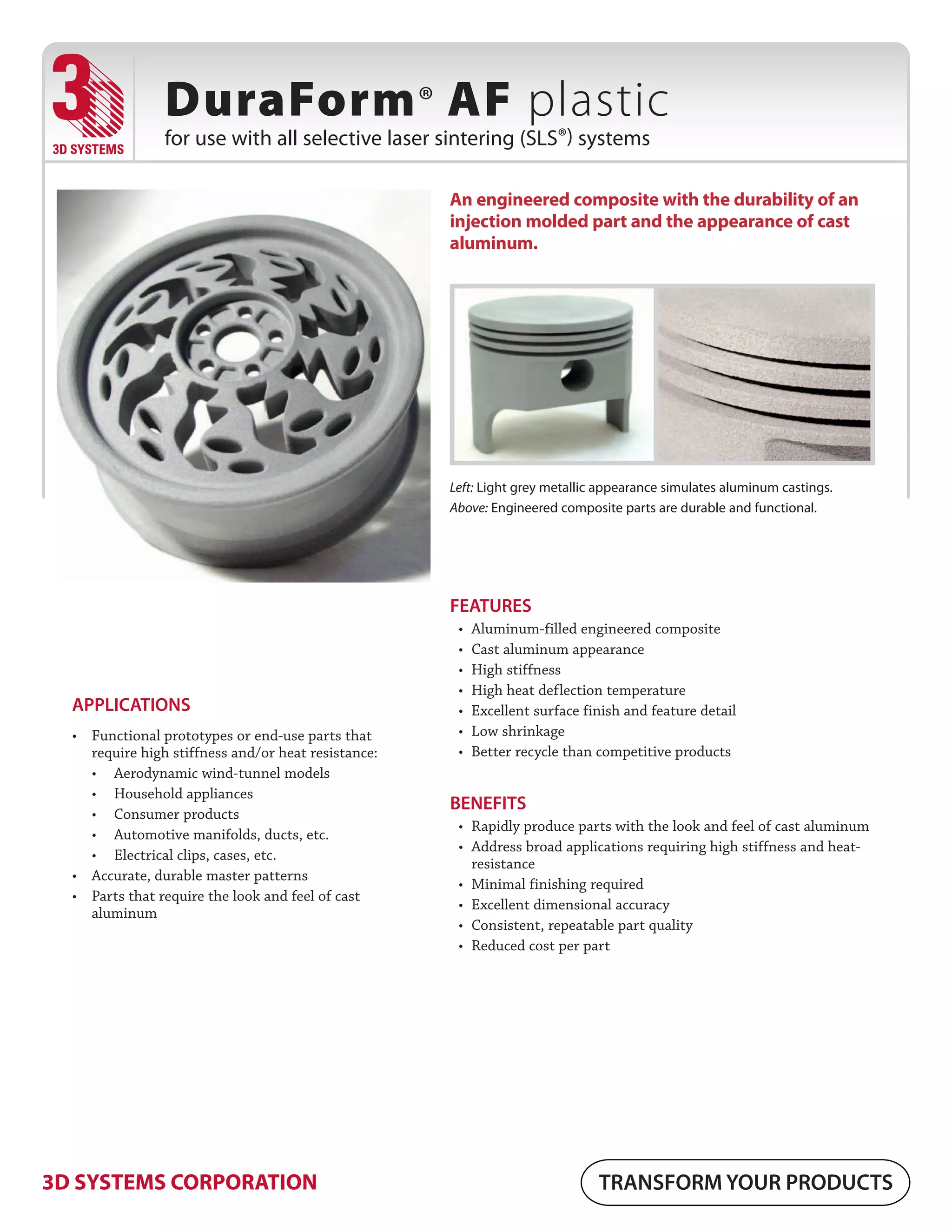

Duraform® AF plastic is an engineered composite designed for selective laser sintering (SLS) systems, offering the durability of injection molded parts and the visual appeal of cast aluminum. This material is characterized by high stiffness, excellent surface finish, low shrinkage, and minimal finishing requirements, making it suitable for functional prototypes and end-use parts that need heat resistance. Its applications span various industries, including automotive and consumer products, while ensuring consistent part quality and reduced cost per part.