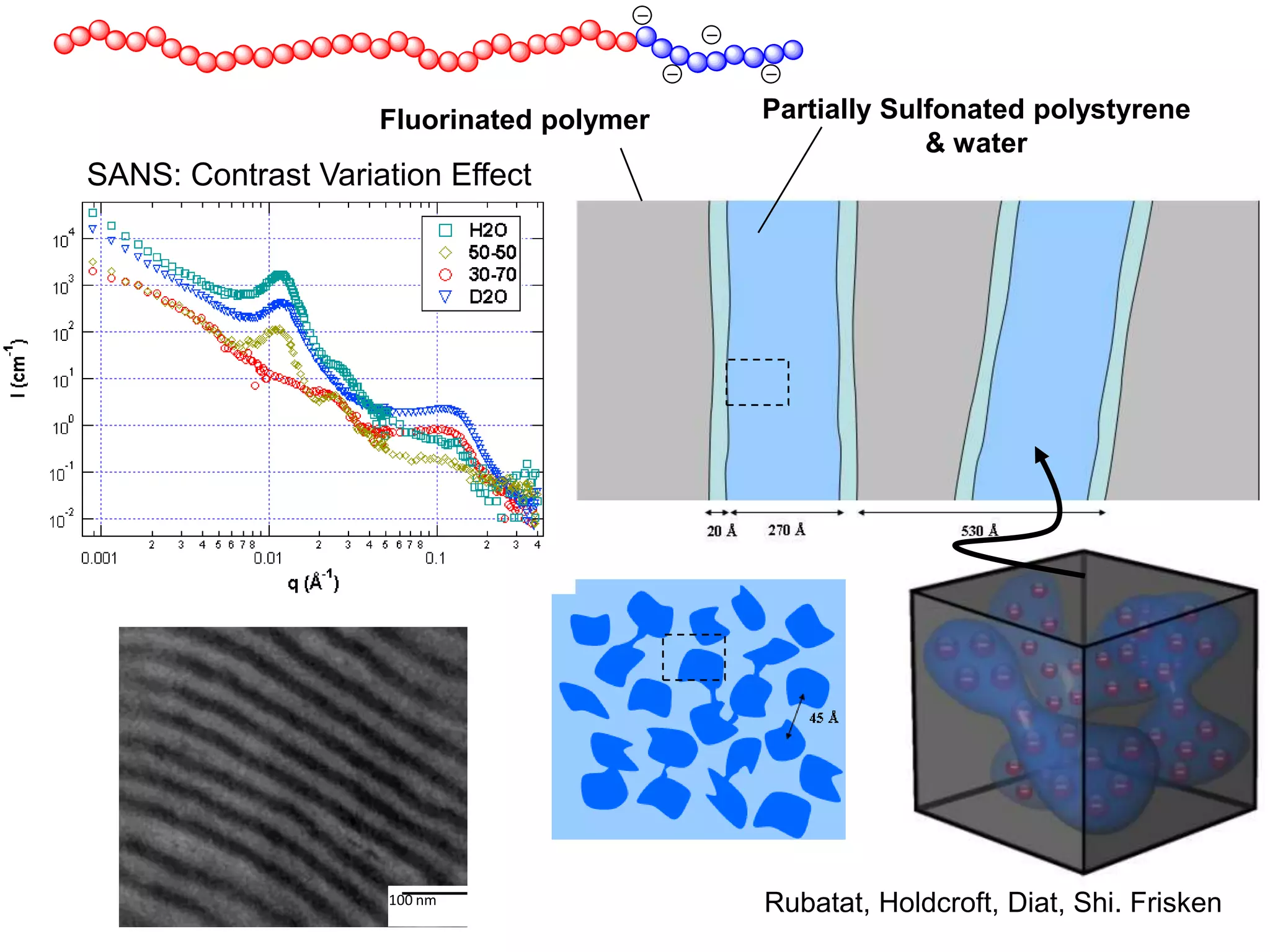

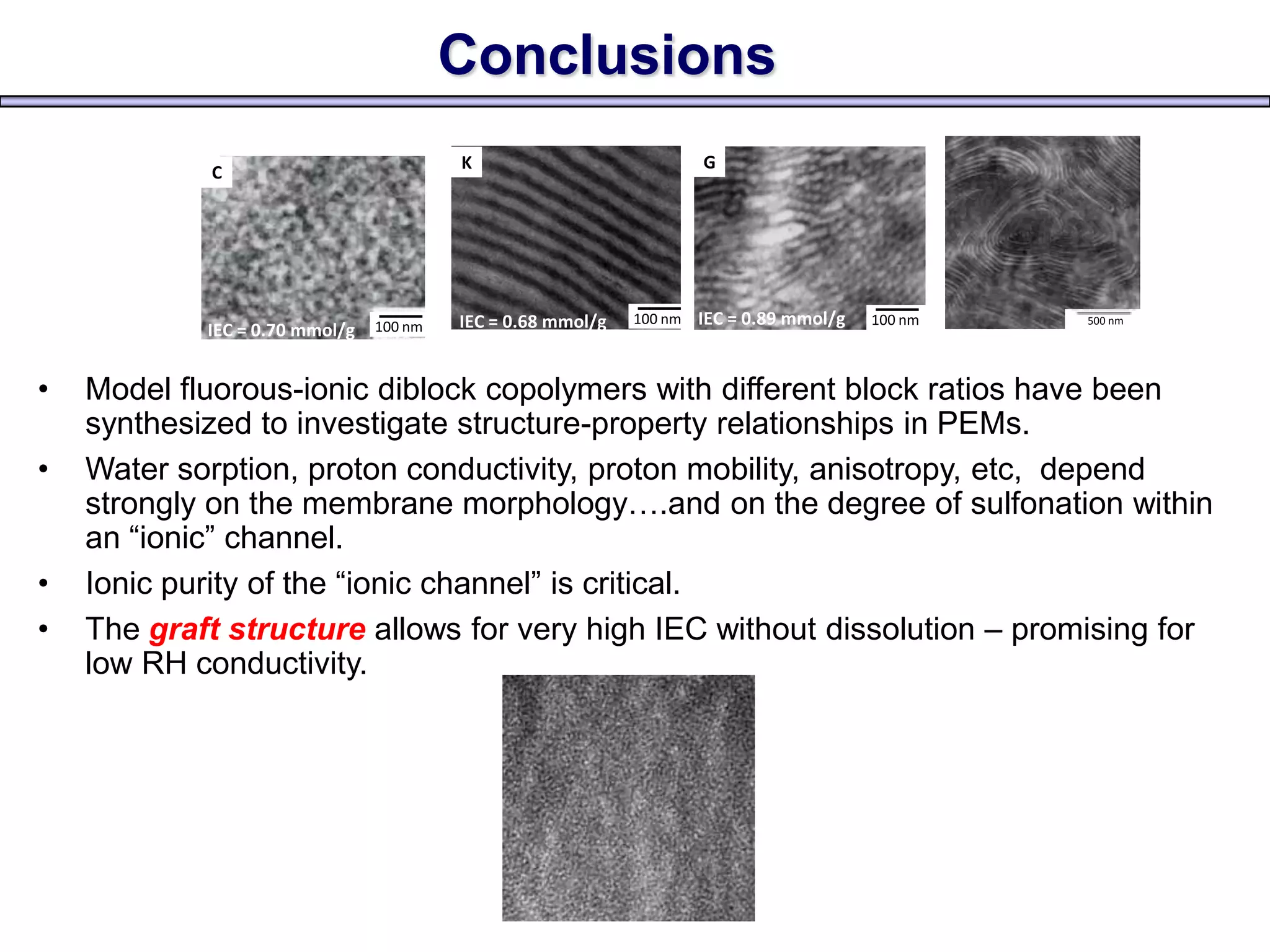

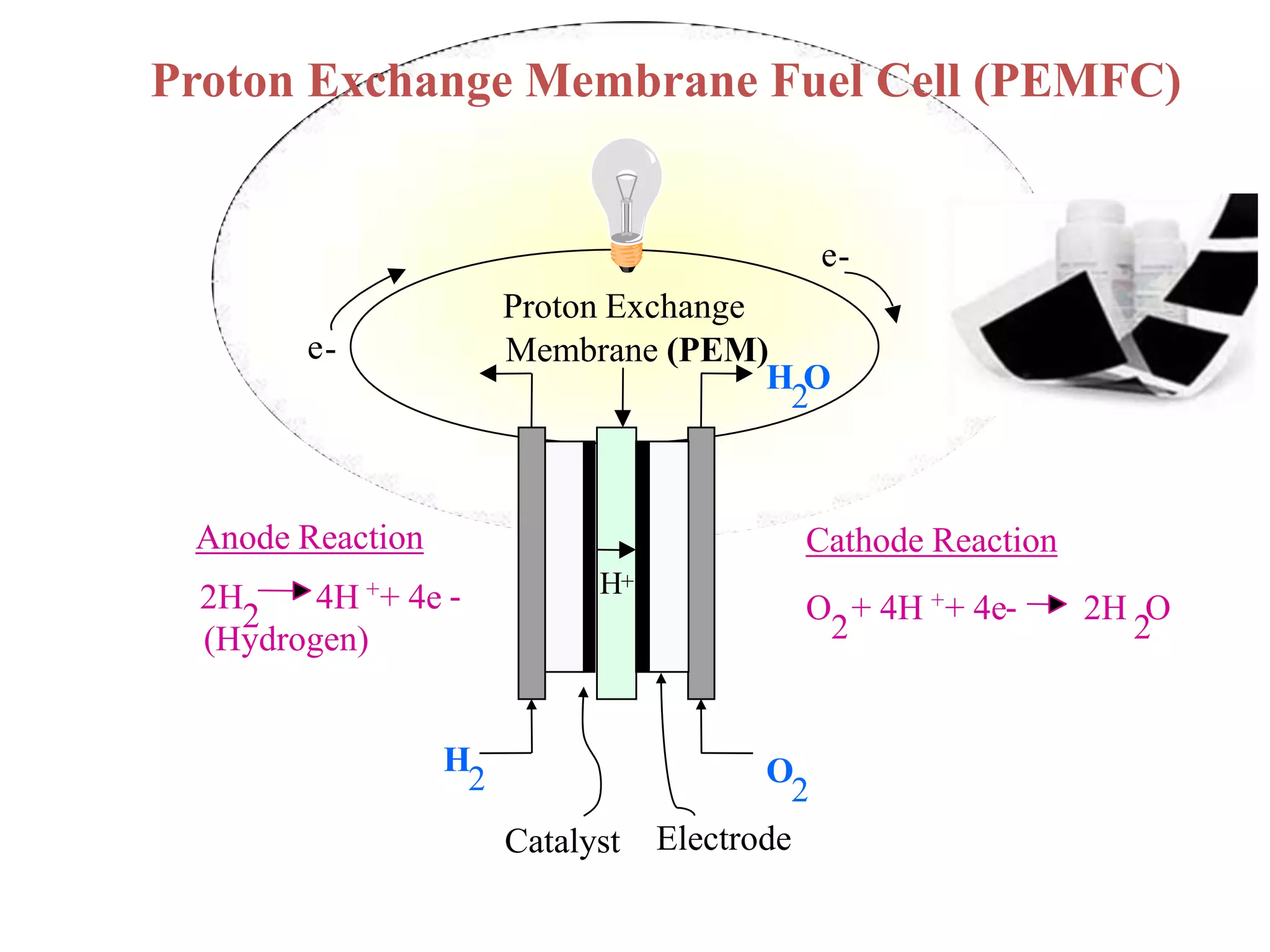

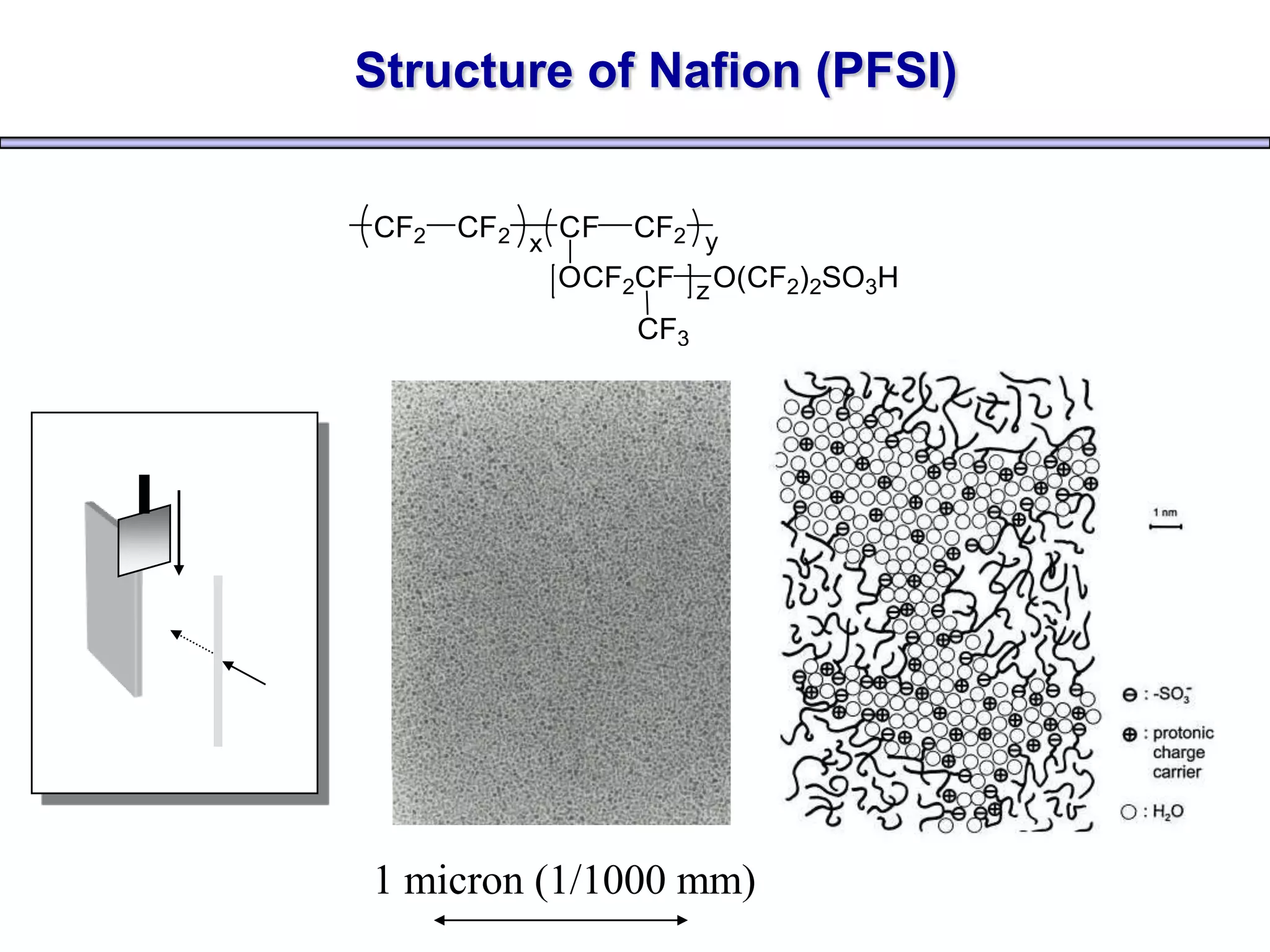

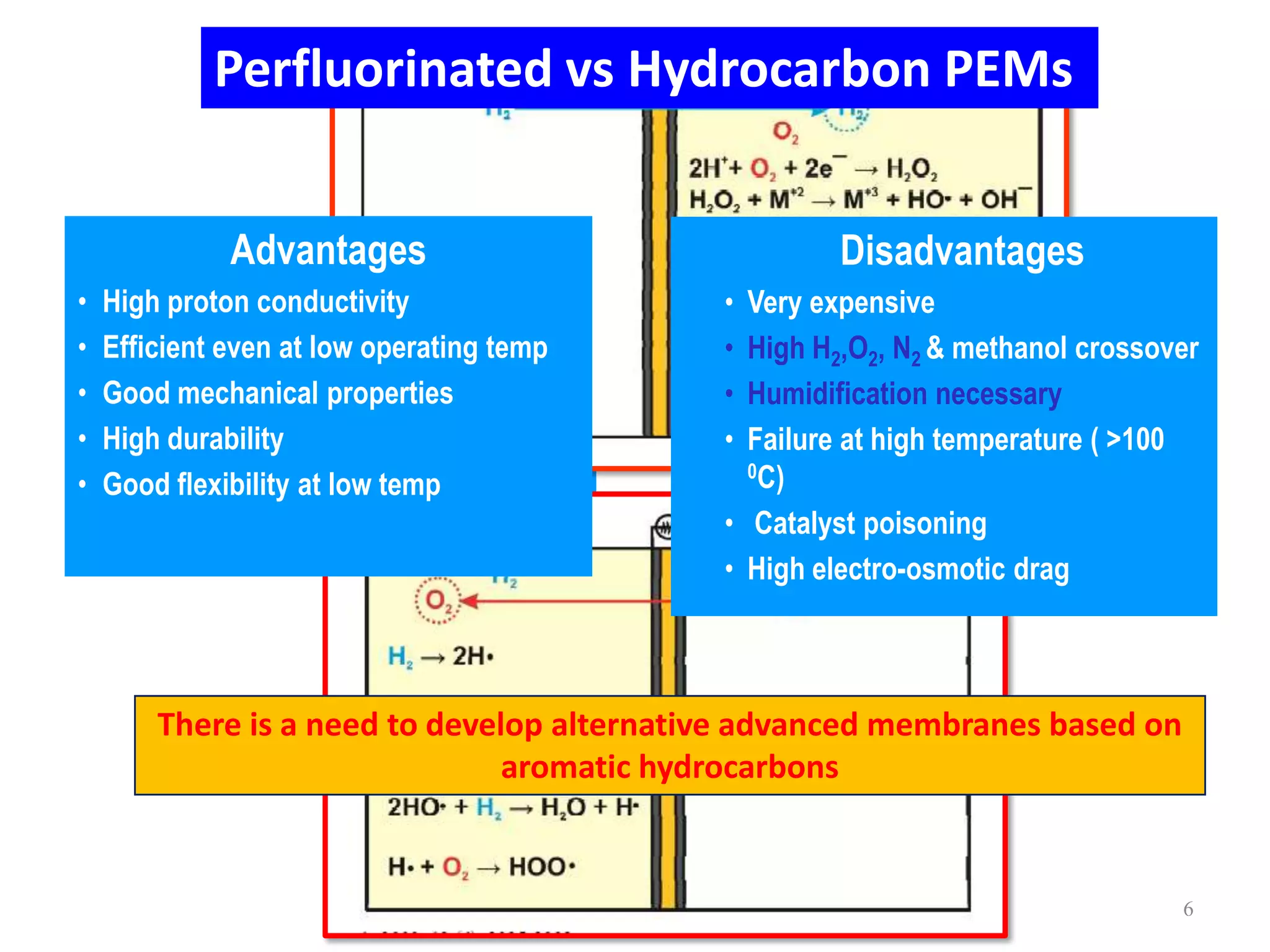

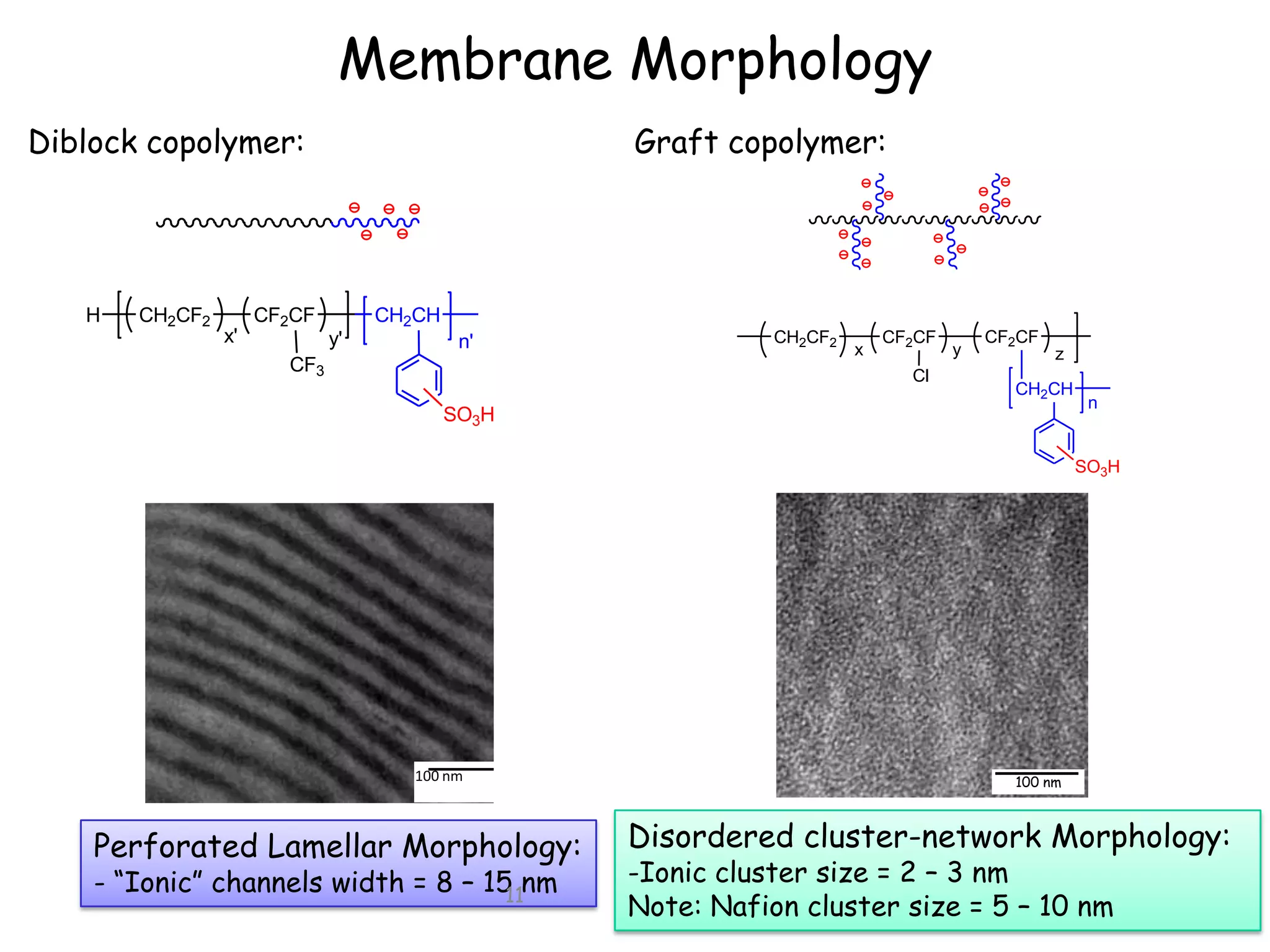

Simon Fraser University researchers developed novel polymer membranes for fuel cells. They synthesized fluoropolymer-block-ionic and fluorous-ionic graft copolymers with different architectures. The membrane morphology, including ionic channel size and continuity, depended on polymer structure and affected properties like water uptake and proton conductivity. Fully sulfonated membranes showed continuous increases in proton conductivity with ion exchange capacity, while partially sulfonated membranes peaked at moderate capacities due to conductivity drops at high capacities. The graft structure allowed high capacities without dissolution, promising for low-humidity proton conductivity needed in fuel cells.

![Diblock vs Graft Membrane

Diblock copolymer:

Graft copolymer:

100 nm

100 nm

-

120

90

60

30

0

0.08

0.06

0.04

0.02

0.00

0.0

0.5

1.0

1.5

2.0

2.5

IEC (mmol/g)

Grafts (small ionic clusters):

0.0

0.5

1.0

1.5

2.0

IEC (mmol/g)

- Less water swelling Lower proton mobility

- Maintain good mechanical property and high

proton concentrations

2.5

1.2

2.5

1.0

2.0

0.8

1.5

0.6

1.0

0.4

0.5

0.2

0.0

x 103 (cm2 s-1 V-1)

dissolves

150

3.0

eff

Proton Conductivity (S/cm)

0.10

0.0

0.0

0.5

1.0

1.5

2.0

2.5

IEC (mmol/g)

Diblocks (long-range channels):

- Greater water uptake Higher proton

conductivity and mobility

- Excessive water swelling mechanical

instability and limited attainable IEC.

[H+] (M)

H2O]/[SO3 ])

180](https://image.slidesharecdn.com/325steevn-131211235220-phpapp02/75/325-steevn-12-2048.jpg)