This document analyzes and models single point cutting of an HSS material tool using ANSYS to optimize transient vibration parameters like temperature and pressure. It describes the tool geometry and material properties and performs a transient analysis in ANSYS applying different pressure loads over time. The results show maximum deformations, strains, and stresses remain below yield criteria, with safety factors all above 10.

![International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print),

ISSN 0976 – 6359(Online), Volume 5, Issue 6, June (2014), pp. 14-27 © IAEME

18

Bounding Box

Length X 3.0001e-002 m

Length Y 8.6052e-002 m

Length Z 3.7476e-002 m

Properties

Volume 6.9165e-005 m³

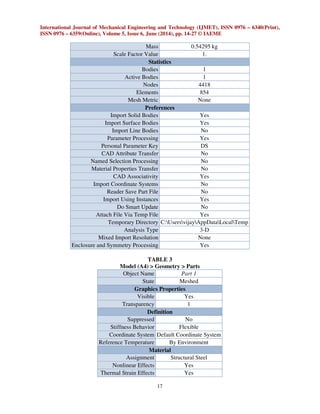

Mass 0.54295 kg

Centroid X 1.4936e-002 m

Centroid Y 2.6577e-002 m

Centroid Z 1.6318e-002 m

Moment of Inertia Ip1 3.1446e-004 kg·m²

Moment of Inertia Ip2 8.3141e-005 kg·m²

Moment of Inertia Ip3 3.1255e-004 kg·m²

Statistics

Nodes 4418

Elements 854

Mesh Metric None

Coordinate Systems

TABLE 4

Model (A4) > Coordinate Systems > Coordinate System

Object Name Global Coordinate System

State Fully Defined

Definition

Type Cartesian

Ansys System Number 0.

Origin

Origin X 0. m

Origin Y 0. m

Origin Z 0. m

Directional Vectors

X Axis Data [ 1. 0. 0. ]

Y Axis Data [ 0. 1. 0. ]

Z Axis Data [ 0. 0. 1. ]

Mesh

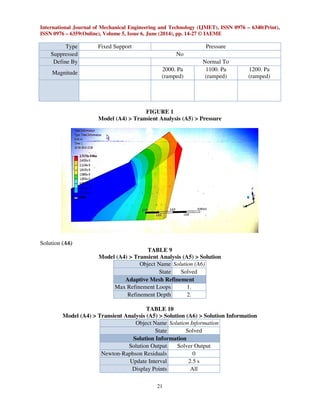

TABLE 5

Model (A4) > Mesh

Object Name Mesh

State Solved

Defaults

Physics Preference Mechanical

Relevance 0

Sizing](https://image.slidesharecdn.com/30120140506002-140627022742-phpapp02/85/30120140506002-5-320.jpg)

![International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print),

ISSN 0976 – 6359(Online), Volume 5, Issue 6, June (2014), pp. 14-27 © IAEME

26

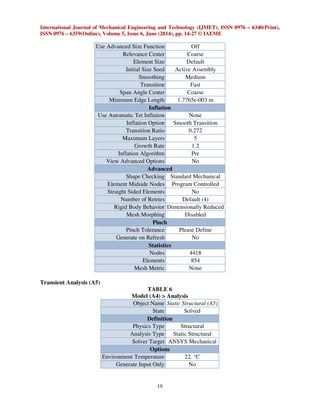

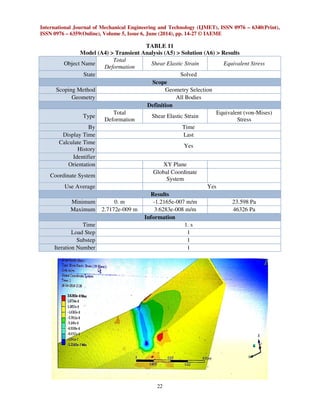

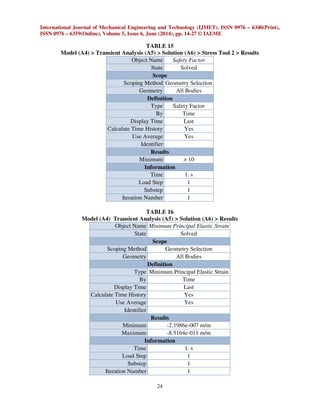

TABLE 23

High Speed Steel > Strain-Life Parameters

Strength

Coefficient Pa

Strength

Exponent

Ductility

Coefficient

Ductility

Exponent

Cyclic Strength

Coefficient Pa

Cyclic Strain

Hardening

Exponent

9.2e+008 -0.106 0.213 -0.47 1.e+009 0.2

TABLE 24

High Speed Steel > Relative Permeability

Relative Permeability

10000

TABLE 25

High Speed Steel > Isotropic Elasticity

Temperature C Young's Modulus Pa Poisson's Ratio

2.e+011 0.3

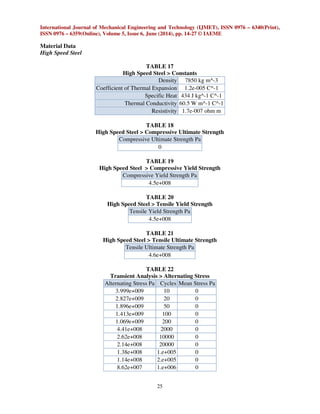

7. CONCLUSION

Thus we have seen the various aspects of machine tools vibrations and their effects. It has

been seen that the effect of vibrations can be disastrous. It may lead to undesirable results on the

work piece. Hence to minimize the vibrations in the tools a lot of research and study has been done.

This has drastically changed the machine efficiency and also minimized the harmful effects of

vibrations on the workers. With the advent of technology, software’s and highly precision

instruments have been developed to measure and analyze the vibrations caused in tools and to bring

up solutions quickly. It has become easier to evaluate the unwanted motions at different parts of a

machine and to rectify it. Hence it may be concluded that a machine tool should be designed keeping

all kinds of errors in mind.

8. REFERENCES

8.1 BOOKS

[1] Harris' Shock and Vibration Handbook 6th.Ed.(2009)

[2] James L. Taylor, The Vibration Analysis Handbook

[3] E.I. Rivin, Machine Tool Vibration

[4] MECHANICAL VIBRATION BY G.K. GROVER 8TH

EDITION

[5] Mechanical vibration by vp Singh.

8.2 JOURNALS AND TECHNICAL PAPERS

[6] Eiji Nabata, Yuji Terasaka Jig Rigidity Evaluation Technology by Vibration Analysis, VOL.

52, 2006.

[7] S. Braun Adaptronic Vibration Damping for Machine Tools.

[8] S.Y. Lin, Y.C. Fang, C.W. Huang, Improvement strategy for machine tool vibration induced

from the movement of a counterweight during machining process, February 2008.](https://image.slidesharecdn.com/30120140506002-140627022742-phpapp02/85/30120140506002-13-320.jpg)

![International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print),

ISSN 0976 – 6359(Online), Volume 5, Issue 6, June (2014), pp. 14-27 © IAEME

27

[9] Kourosh Tatar, Per Gren, Measurement of milling tool vibrations during cutting using laser

vibrometry.

[10] John G .Cherng, Mahmut Eksioglu, Kemal Kızılaslan, Vibration reduction of pneumatic

percussive rivet tools: Mechanical and ergonomic re-design approaches.

[11] Effect of cutting parameters on surface roughness and cutting forces in turning mild steel by

research journal of recents sciences vol.1(10), 19-26, October (2012) for standard design

parameters for tool design.

[12] Optimization of cutting parameters on mild steel with hss & cemented carbide tipped tools

using Ann by Proff A.V.N .L SHARMA(2006).

[13] Shaw metal cutting principle, Oxford University press (2006).

[14] Basic machining refrenance handbook, industrial press (2001).

[15] Analysis of cutting force during milling with regards to dependency on the penetration angle

(2009).

[16] Patel K. Batish and Bhattacharya A optimization of t surface roughness in an end milling

operation using nested experimental design (2009).

[17] Mile j.R-square, Adjusted R-squared, Encyclopedia of stastican Behavioral science, john

Wiley and son’s ltd (2005).

[18] Ricci L and Martinez R, Adjusted R2 –Type measure for tweedy model, computational

statics and data analysis.(2008)

[19] Sharma V.S,, Sharma S.K, and Sharma A.K, cutting wear estimation for turning, journal of

intelligent manufacturing (2007)

[20] Montgomery, D.C, Design and Analysis of experiment, John Wiley and sons (2001)

[21] Das M.N and Girl N.C, Design and analysis of experiment second New age international

p. ltd New Delhi(1999)

[22] Rodrigues L.I.R, Kantharaj B, and Murthy B.R.N Effect of cutting Parameters on surface

roughness and cutting forces in turning mild steel (2012).

[23] Prabhat Kumar Sinha, Rakesh Kumar Maurya, Rajneeshpandey and Vijay Kumar Yadav,

“Analysis of Residual Stresses and Distortions in Tig-Welded Stainless Steel Pipe”,

International Journal of Mechanical Engineering & Technology (IJMET), Volume 5, Issue 5,

2014, pp. 13 - 27, ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359.

[24] Prabhat Kumar Sinha, Rakesh Kumar Maurya, Rajneeshpandey and Vijay Kumar Yadav,

“Analysis for Free Vibration of Laminated Composite & Sandwich Plates with the Help of

Euler-Lagrange Equation Based on First Order Shear Deformation Theory, Formulations and

Solution to the Natural Frequency & Compare to Obtained Results”, International Journal of

Mechanical Engineering & Technology (IJMET), Volume 5, Issue 5, 2014, pp. 45 - 53,

ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359.

[25] Ganesan.H and Mohankumar.G, “Study on Optimization of Machining Parameters in

Turning Process using Evolutionary Algorithm with Experimental Verification”,

International Journal of Mechanical Engineering & Technology (IJMET), Volume 2, Issue 1,

2011, pp. 10 - 21, ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359.

[26] Pravin Kumar.S, Venkatakrishnan.R and Vignesh Babu.S, “Process Failure Mode and Effect

Analysis on End Milling Process- A Critical Study”, International Journal of Mechanical

Engineering & Technology (IJMET), Volume 4, Issue 5, 2013, pp. 191 - 199, ISSN Print:

0976 – 6340, ISSN Online: 0976 – 6359.

[27] R S Rajpurohit and R S Prasad, “Analysis of Mechanical Structure Under Vibration using

Vibration Measuring System”, International Journal of Mechanical Engineering &

Technology (IJMET), Volume 4, Issue 1, 2013, pp. 134 - 141, ISSN Print: 0976 – 6340,

ISSN Online: 0976 – 6359.](https://image.slidesharecdn.com/30120140506002-140627022742-phpapp02/85/30120140506002-14-320.jpg)