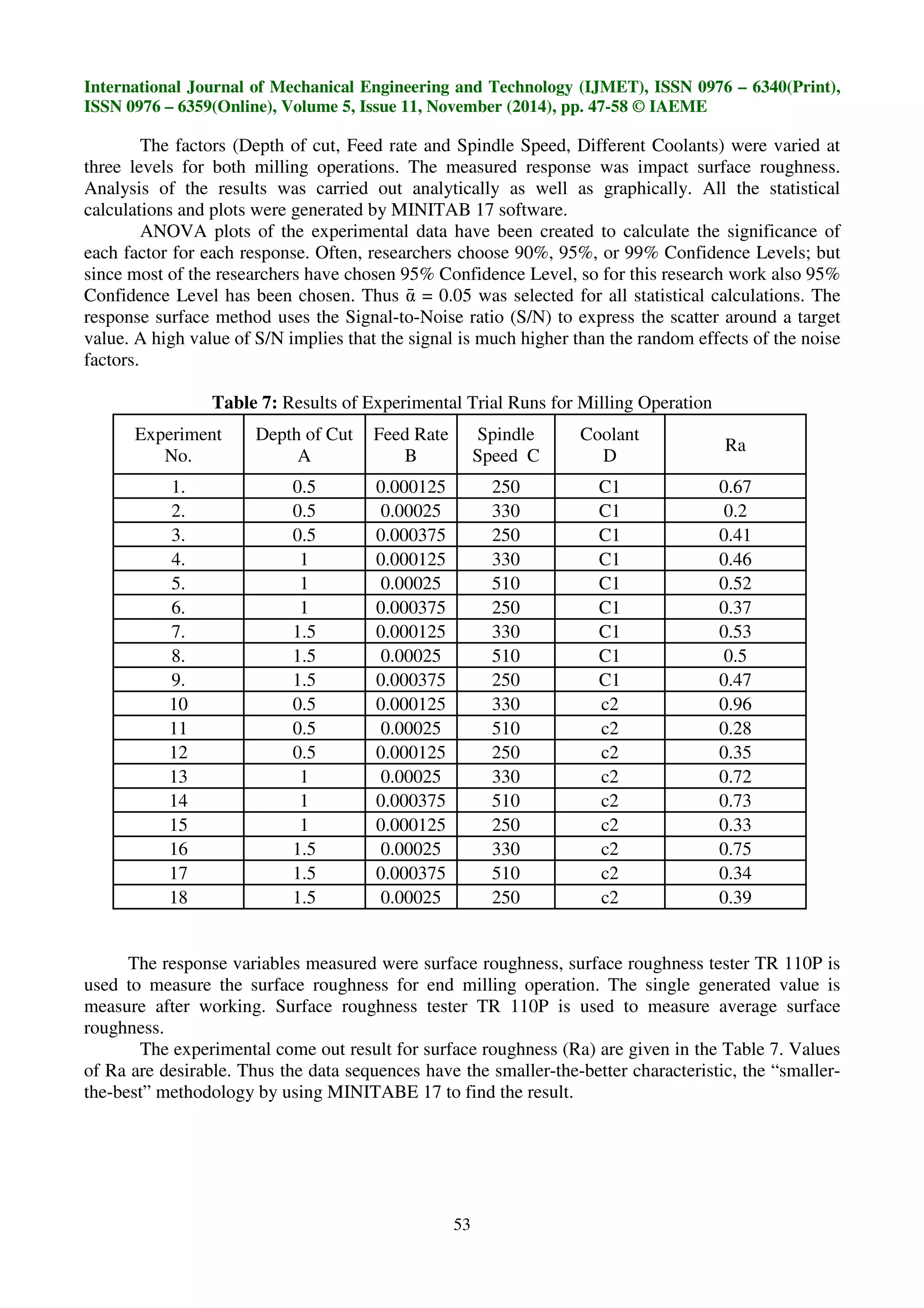

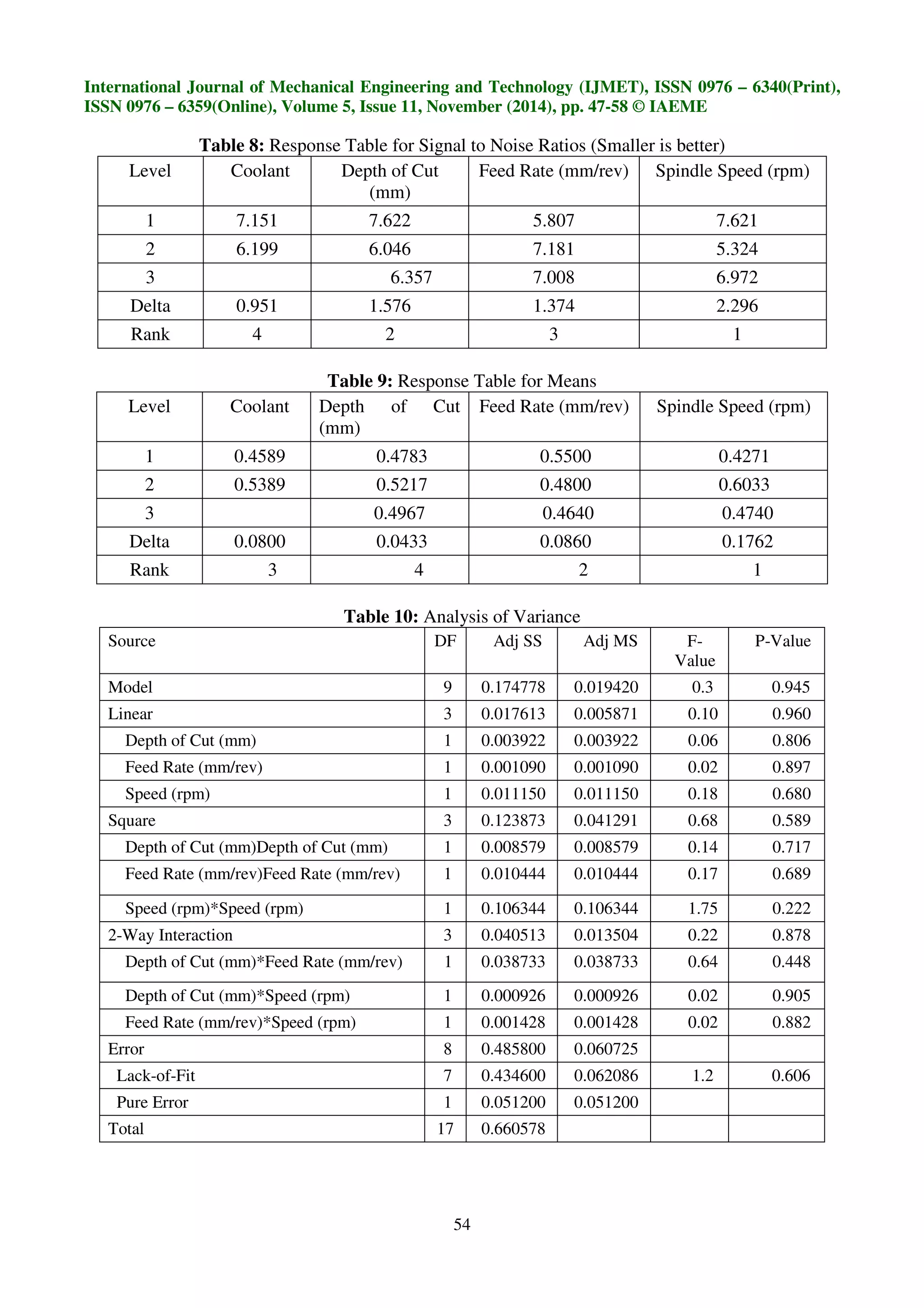

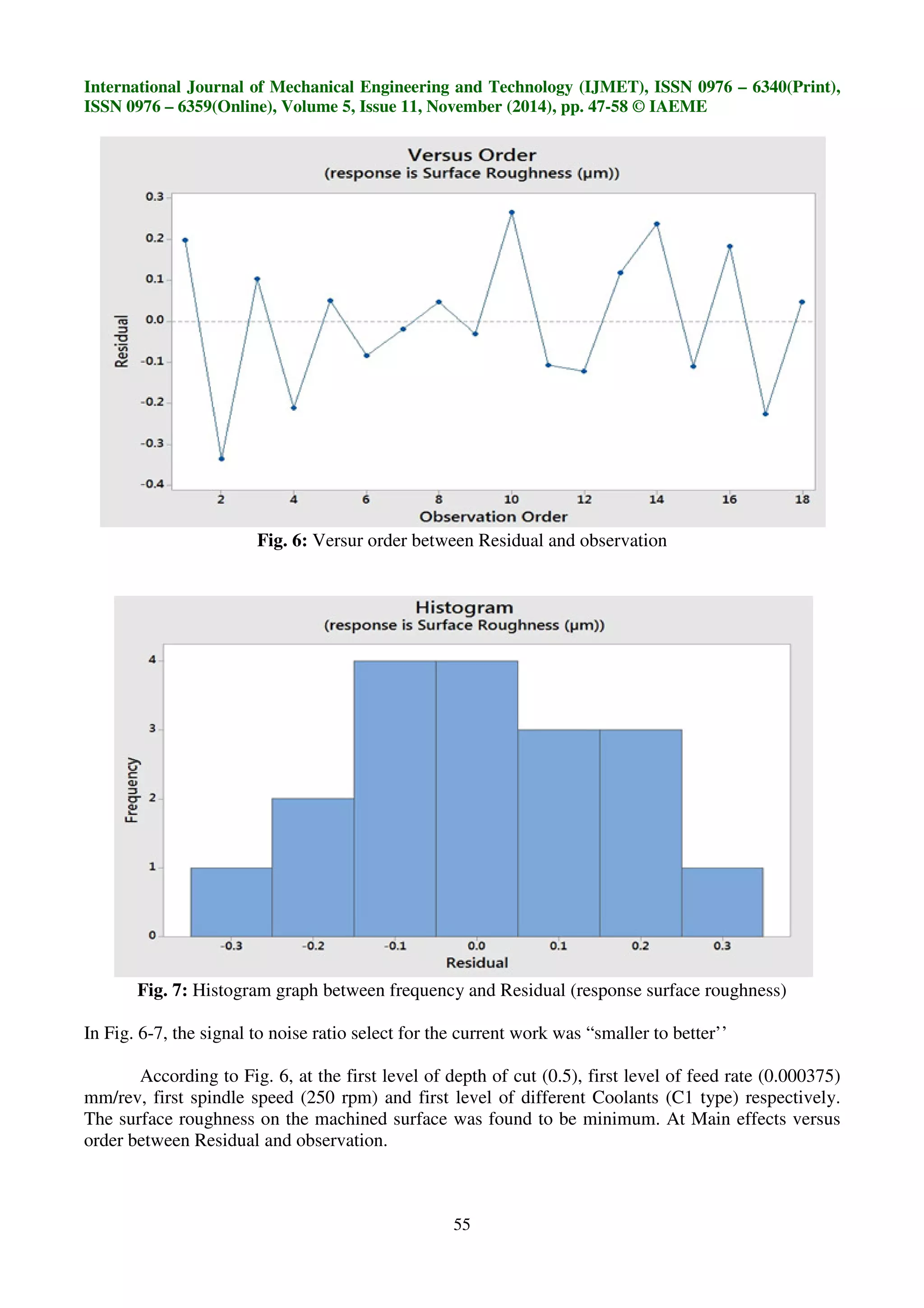

This document summarizes a study that investigated the effects of machining parameters on surface roughness in end milling of EN11 alloy steel. Experiments were conducted using an L18 orthogonal array to test combinations of depth of cut, feed rate, spindle speed, and coolant. Surface roughness was measured for each test and analyzed using response surface methodology. The results showed that machining parameters significantly affected surface roughness and statistical models could be developed to optimize the parameters to achieve a desired surface finish.

![International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print),

ISSN 0976 – 6359(Online), Volume 5, Issue 11, November (2014), pp. 47-58 © IAEME

47

A STUDY OF THE EFFECTS OF MACHINING

PARAMETERS ON SURFACE ROUGHNESS USING

RESPONSE SURFACE METHOD ON EN11 ALLOY STEEL

IN THE END-MILLING PROCESS

Vishesh Ranglani1

, Saurabh Pratap Singh2

, Shashi Kant Tripathi3

, Rahul Davis4

1, 2, 3, 4

(Department of Mechanical Engineering, Shepherd School of Engineering and Technology,

SHIATS, Allahabad, U.P, India)

ABSTRACT

A series of experiments to determine the character of surface of the alloy steel have been

conducted. The main objective of this work is to develop a holistic understanding of the effects of

feed rate, spindle speed, depth of cut and type of coolant on the surface roughness and to create a

model for the conducted study. Such an understanding can provide sapience about the shortcomings

of controlling the finish of machined surfaces when the process parameters are adjusted to obtain a

certain surface finish. The model, which includes the effect of spindle speed, cutting feed rate and

depth of cut, and any three variable interactions, predicted the surface roughness values.

Keywords: Surface Roughness, Milling, ANOVA, EN11.

1. INTRODUCTION

The evaluation of surface roughness of machined parts using a direct contact method has

limitations in handling the different geometrical parts to be measured. Surface roughness affects

many functional parameters, such as friction, wear and tear, light reflection, heat transmission,

ability of distributing and holding a lubricant, coating etc. Therefore, the desired surface finish is

usually specified and appropriate processes are required to maintain the quality. Hence, the

inspection of surface roughness of the work piece is very important to assess the quality of a

component. Alternately, optical measuring methods are applied to overcome the limitations of stylus

method, but, they are also sensitive to lighting conditions and noise. The technique proposed in this

work, requires no apriority information about the lighting conditions and source of noise. Metal

cutting is one of the most significant manufacturing processes in the area of material removal [1].

INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING AND

TECHNOLOGY (IJMET)

ISSN 0976 – 6340 (Print)

ISSN 0976 – 6359 (Online)

Volume 5, Issue 11, November (2014), pp. 47-58

© IAEME: www.iaeme.com/IJMET.asp

Journal Impact Factor (2014): 7.5377 (Calculated by GISI)

www.jifactor.com

IJMET

© I A E M E](https://image.slidesharecdn.com/a-study-of-the-effects-of-machining-parameters-on-surface-roughness-using-response-surface-method-160218115645/75/A-STUDY-OF-THE-EFFECTS-OF-MACHINING-PARAMETERS-ON-SURFACE-ROUGHNESS-USING-RESPONSE-SURFACE-METHOD-ON-EN11-ALLOY-STEEL-IN-THE-END-MILLING-PROCESS-1-2048.jpg)

![International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print),

ISSN 0976 – 6359(Online), Volume 5, Issue 11, November (2014), pp. 47-58 © IAEME

48

Black [2] defined metal cutting as the removal of metal chips from a work piece in order to obtain a

finished product with desired attributes of size, shape, and surface roughness. The imperative

objective of the science of metal cutting is the solution of practical problems associated with the

efficient and precise removal of metal from work piece. It has been recognized that the reliable

quantitative predictions of the various technological performance measures, preferably in the form of

equations, are essential to develop optimization strategies for selecting cutting conditions in process

planning [3-5].

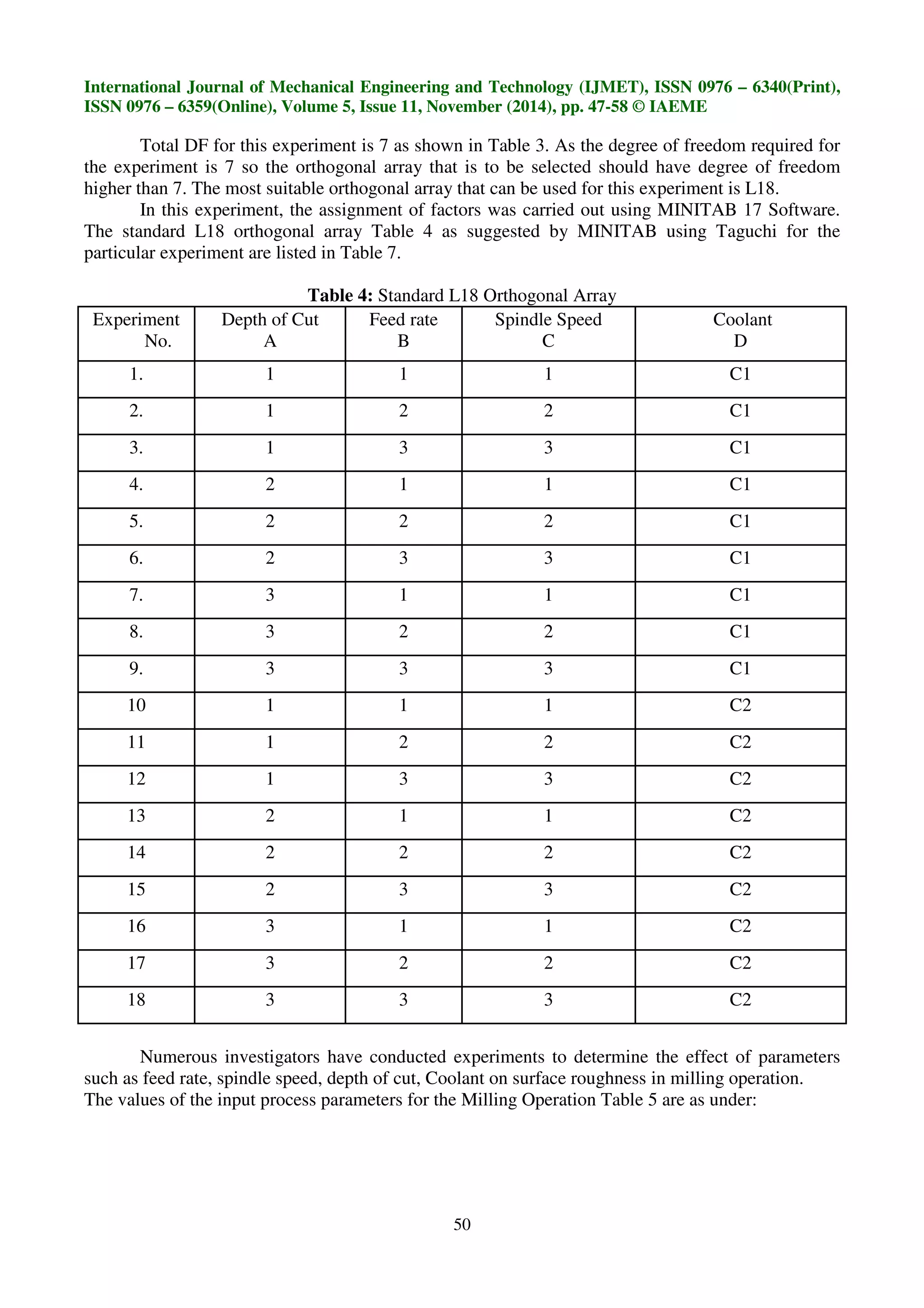

Milling is a machining process in which the removal of metal takes place due to the cutting

action of a revolving cutter when the work is fed through it. Milling refers to the process of breaking

down, separating, sizing, or classifying aggregate material. For instance rock crushing or grinding to

produce uniform aggregate size for construction purposes, or separation of rock, soil or aggregate

material for the purposes of structural fill or land reclamation activities. Aggregate milling processes

are also used to remove or separate contamination or moisture from aggregate or soil and to produce

"dry fills" prior to transport or structural filling.

2. MATERIALS AND METHODS

2.1. RESPONSE SURFACE METHODOLOGY (RSM)

It is a collection of mathematical and statistical techniques for empirical model building. By

careful design of experiments, the objective is to optimize a response (output variable) which is

influenced by several independent variables (input variables).

Originally, RSM was developed to model experimental responses (Box and Draper, 1987),

and then migrated into the modeling of numerical experiments. The difference is in the type of error

generated by the response. In physical experiments, inaccuracy can be due, for example, to

measurement errors while, in computer experiments, numerical noise is a result of incomplete

convergence of iterative processes, round-off errors or the discrete representation of continuous

physical phenomena[6]. In RSM, the errors are assumed to be random.

The application of RSM to design optimization is aimed at reducing the cost of expensive

analysis methods (e.g. finite element method or CFD analysis) and their associated numerical noise.

The problem can be approximated with smooth functions that improve the convergence of the

optimization process because they reduce the effects of noise and they allow for the use of

derivative-based algorithms. Venter et al. (1996) have discussed the advantages of using RSM for

design optimization applications.

2.2. METHODOLOGY ADOPTED FOR THE PROPOSED DESIGN

1. To design the experiment using Design of Experiment techniques.

2. To obtain a combination of the optimal levels of the parameters in order to minimize surface

roughness with the application of response surface method (RSM).

EN 11(Fig. 10) was chosen to be the specimen material in the proposed work in order to

study the effect of four different parameters (Depth of cut, feed, spindle speed & different coolants)

on the Surface Roughness of the finished specimens using L18 orthogonal design. Therefore the

milling operations and measurements of surface roughness have been done 18 times on the work

pieces for each of the following cases. The work piece were machined by HSS cutting tool wet the

cutting conditions respectively.](https://image.slidesharecdn.com/a-study-of-the-effects-of-machining-parameters-on-surface-roughness-using-response-surface-method-160218115645/75/A-STUDY-OF-THE-EFFECTS-OF-MACHINING-PARAMETERS-ON-SURFACE-ROUGHNESS-USING-RESPONSE-SURFACE-METHOD-ON-EN11-ALLOY-STEEL-IN-THE-END-MILLING-PROCESS-2-2048.jpg)

![International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 – 6340(Print),

ISSN 0976 – 6359(Online), Volume 5, Issue 11, November (2014), pp. 47-58 © IAEME

58

REFERENCES

[1] J. C Chen and R. A. Smith: Journal of Industrial Technology, vol. 13, No.3, 1997, 15-19.

[2] J. T. Black: Journal of Engineering for Industry, vol. 101, No 4, 1979, 403-415.

[3] P. L. B. Oxley: The Mechanics of Machining An Analytical Approach to Assessing

Machinability, Ellins Horwood Ltd., Chichester West Sussex, England, 1989.

[4] E. M. Trent: Metal Cutting, Butterworth-Heinemann Ltd., Oxford. England, 1991.

[5] V. P. Astakhov and M. O Osman: Journal of Materials Processing Technology, vol. 62,

No 3, 1996, 175-179.

[6] Giunta et al., 1996; van Campen et al., 1990, Toropov et al., 1996.

[7] N Tabenkin: Carbide and Tool, vol. 21, 1985. 12-15.

[8] P. Balakrishnan and M. F. De Vries: Analysis of Mathematical Model building Techniques

Adaptable to Machinability Data Base System, Proceeding of NAMRC-XI, 1983.

[9] G. Boothroyd and W. Knight: Fundamentals of Machining and Machine Tools. Second

Edition, Marcel Dekker Inc., New York. 1989.

[10] V. M. Huynh and Y. Fan: The International Journal of Advanced Manufacturing

Technology, vol. 7, 1992. 2-10.

[11] Prabhat Kumar Sinha, Rajneesh Pandey and Vijay Kumar Yadav, “Analysis and Modeling

of Single Point Cutting(HSS Material) Tool With Help of Ansys for Optimization of

(Transient) Vibration Parameters”, International Journal of Mechanical Engineering &

Technology (IJMET), Volume 5, Issue 6, 2014, pp. 14 - 27, ISSN Print: 0976 – 6340,

ISSN Online: 0976 – 6359.

[12] [14] Ganesan.H and Mohankumar.G, “Study on Optimization of Machining Parameters in

Turning Process using Evolutionary Algorithm with Experimental Verification”,

International Journal of Mechanical Engineering & Technology (IJMET), Volume 2,

Issue 1, 2011, pp. 10 - 21, ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359.

[13] Pravin Kumar.S, Venkatakrishnan.R and Vignesh Babu.S, “Process Failure Mode and

Effect Analysis on End Milling Process- A Critical Study”, International Journal of

Mechanical Engineering & Technology (IJMET), Volume 4, Issue 5, 2013, pp. 191 - 199,

ISSN Print: 0976 – 6340, ISSN Online: 0976 – 6359.](https://image.slidesharecdn.com/a-study-of-the-effects-of-machining-parameters-on-surface-roughness-using-response-surface-method-160218115645/75/A-STUDY-OF-THE-EFFECTS-OF-MACHINING-PARAMETERS-ON-SURFACE-ROUGHNESS-USING-RESPONSE-SURFACE-METHOD-ON-EN11-ALLOY-STEEL-IN-THE-END-MILLING-PROCESS-12-2048.jpg)